Almost everyone is well aware of three-phase electric motors; they are widely used in industry and allow solving a wide variety of problems. And we are accustomed to consider the principle of obtaining alternating current as a physical quantity using the example of the same three-phase asynchronous generators. But what to do in domestic conditions, where there is only one phase? Craftsmen have learned how to connect three-phase electrical machines, but this is not necessary. In practice, a single-phase asynchronous electric motor has long been used, which can perform all its functions even in a home AC network.

Operating principle and connection of a single-phase 220V electric motor

A single-phase motor operates using alternating electric current and is connected to single-phase networks. The network must have a voltage of 220 Volts and a frequency of 50 Hertz.

Electric motors of this type are used mainly in low-power devices:

Models are available with power from 5 W to 10 kW.

The values of efficiency, power and starting torque for single-phase motors are significantly lower than for three-phase devices of the same size. The overload capacity is also higher for 3-phase motors. Thus, the power of a single-phase mechanism does not exceed 70% of the power of a three-phase mechanism of the same size.

- Actually has 2 phases. but only one of them does the work, so the motor is called single-phase.

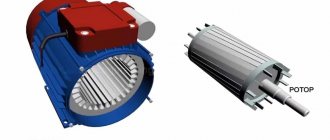

- Like all electric machines. A single-phase motor consists of 2 parts: stationary (stator) and moving (rotor).

- It is an asynchronous electric motor. on the stationary component of which there is one working winding, connected to a single-phase alternating current source.

The strengths of this type of engine include the simplicity of the design, which is a rotor with a squirrel-cage winding. The disadvantages are low starting torque and efficiency.

The main disadvantage of single-phase current is its inability to generate a magnetic field that performs rotation. Therefore, a single-phase electric motor will not start on its own when connected to the network.

In the theory of electrical machines, the rule applies: in order for a magnetic field to arise that rotates the rotor, there must be at least 2 windings (phases) on the stator. It is also required to shift one winding by a certain angle relative to the other.

During operation, alternating electric fields flow around the windings:

- According to this. The so-called starting winding is located on the stationary section of the single-phase motor. It is shifted 90 degrees relative to the working winding.

- A current shift can be obtained by including a phase-shifting link in the circuit. Active resistors, inductors and capacitors can be used for this.

- 2212 electrical steel is used as the basis for the stator and rotor.

It is incorrect to call single-phase electric motors that are 2- and 3-phase in structure, but are connected to a single-phase power source through matching circuits (capacitor electric motors). Both phases of such devices are working and are turned on all the time.

Equipment design

Even though a single-phase asynchronous electric motor has two phases, only one of them works. This is due to the technical design and other important aspects. Currently, manufacturers are paying great attention to increasing the power of all installations and reducing the size. All this happens due to internal parts. Main elements of electric motors:

- stator;

- rotor;

- frame;

- fasteners;

- wiring;

- some models are also equipped with electronic sensors and control systems.

The main advantage of single-phase models remains their simplicity of design. All parts are easy to manufacture in production conditions and quickly assembled. The main disadvantages remain the rather low efficiency.

Main types of single-phase induction motors

Household appliances and low-power devices operate on single-phase alternating current; in addition, three-phase power supply cannot be provided everywhere. Therefore, single-phase AC motors have become widespread, especially in the USA. AC motors are often preferred due to their robust design, low cost, and maintenance-free operation.

As the name suggests, a single-phase induction motor operates on the principle of induction; the same principle applies to three-phase electric motors. However, there are differences between them: single-phase electric motors, as a rule, operate at alternating current and voltage 110 -240 V, the stator field of these motors does not rotate. Instead, each time the sinusoidal voltage jumps from negative to positive, the poles change.

In single-phase electric motors, the stator field is constantly aligned in one direction, and the poles change their position once in each cycle. This means that a single-phase induction motor cannot be started on its own.

In theory, a single-phase electric motor could be started by mechanically rotating the motor and then immediately applying power. However, in practice, all electric motors start automatically.

There are four main types of electric motors:

• induction motor with capacitor start / winding operation (inductance) (CSIR),

• induction motor with capacitor start/capacitor operation (CSCR),

• rheostatic starting induction motor (RSIR) and

• permanent split capacitance (PSC) motor.

The figure below shows typical torque/speed curves for the four main types of single-phase AC motors.

What is the difference between three-phase motors

The operating principle of a three-phase motor is no different from a two-phase one, but the difference can be seen in the design. Instead of two magnetic fluxes, there are three of them, and they are shifted relative to each other in space and time, which allows you to create a magnetic flux rotating in the desired direction and at the desired speed.

It is worth noting that when rotating, the flow creates an EMF in the rotor conductors. As a result, the rotor continues to rotate even if the starting torque exceeds the braking torque. This phenomenon is called slip, which is, if not a key, then a very important parameter for an engine. Safety of operation depends on it, since reaching a critical level of slip reduces stability and the engine may suffer from rollover.

Thus, the principle of an asynchronous three-phase motor is based on the interaction of the rotor, which creates a magnetic field, and the currents that are present in this field. In this case, without a difference in the rotation frequencies of the fields, movement will not begin. In wide applications, unipolar three-phase motors are used in circular motors.

How to connect a 220V asynchronous motor

Since the supply voltages for different consumers may differ from each other, there is a need to reconnect electrical equipment. Making the connection of a 220-volt asynchronous motor safe for further operation of the equipment is quite simple if you follow the proposed instructions.

In fact, this is not an impossible task. In short, all we need is to connect the windings correctly. There are two main types of asynchronous motors: three-phase with a star-delta winding, and motors with a starting winding (single-phase). The latter are used, for example, in Soviet-designed washing machines. Their model is AVE-071-4C. Let's look at each option in turn.

- Three-phase

- Switch to desired voltage Increase voltage

- Voltage reduction

Functionality check

Breakdowns happen with any mechanism, and an electric motor is no exception. Breakdowns can most often be determined by external inspection. To carry out diagnostics and more thoroughly study defects, special equipment and instrumentation will be required. Of course, you can diagnose a breakdown by applying a starting current; if the motor does not work, then it’s time to change it. The main types of external signs indicating that repairs are needed:

- There was a burning smell.

- The paint on the body has darkened due to overheating.

- There is damage to the housing.

In some situations, you can fix the breakdown yourself. You need to connect the equipment to direct current; alternating current will not work in this situation. Next, let the engine run for about 10-15 minutes. If during this time it has warmed up, then the reason may be as follows:

- bearing defects: breakdowns, lubricant leakage and other factors.

- high capacitor capacity.

In the second situation, you can turn off the capacitor or lower its capacity, which will lead to a decrease in temperature. Currently, it is recommended to contact specialized workshops for help, since self-repair is not always effective. To make a single-phase 220 V motor low-speed, you will also need tuning on special stands.

Connection diagrams

For those who are a little unfamiliar with how asynchronous electric motors are connected to a three-phase network, I strongly recommend that you read my article Connecting a motor via a magnetic contactor. I assume that the reader knows how the electric motor turns on, why and what kind of motor protection is needed, so in this article I omit these questions.

In theory everything is simple, but in practice you have to rack your brains.

Obviously, turning on the Dahlander motor windings can be done in two ways - through a switch and through contactors.

Changing speeds using a switch

Let's first consider a simpler circuit - through a PKP-25-2 type switch. Moreover, these are the only schematic diagrams that I have come across.

The switch must have three positions, one of which (middle) corresponds to the engine being turned off. About the switch device - a little later.

Connecting a two-speed motor. Diagram on the control panel switch.

Crosses on the dotted lines of the SA1 switch position indicate the closed states of the contacts. That is, in position 1, power from L1, L2, L3 is supplied to the triangle (pins U1, V1, W1). Pins U2, V2, W2 remain unconnected. The engine rotates at the first, reduced speed.

When SA1 is switched to position 2, the pins U1, V1, W1 are connected to each other, and power is supplied to U2, V2, W2.

Switching speeds using contactors

When started using contactors, the circuit will look similar:

Scheme of switching on the motor at different speeds using contactors

Here, the motor turns on the contactor KM1 at the first speed, and KM2 at the second speed. It is obvious that physically KM2 must consist of two contactors, since it is necessary to close five power contacts at once.

Connecting a single-phase asynchronous motor

To accelerate an asynchronous motor, it is necessary to create a rotating magnetic field. This is easily handled by a three-phase power supply, where the phases are shifted relative to each other by 120 degrees. But if we are talking about how to connect a single-phase electric motor, then a problem arises: without a phase shift, the shaft will not begin to rotate.

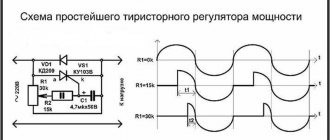

Inside a single-phase asynchronous motor there are two windings: starting and working. If a phase shift is provided in them, the magnetic field will become rotating. And this is the main condition for starting the electric motor. The phases can be shifted by adding resistance (resistor) or an inductive coil. But the most commonly used capacitors are starting and/or running capacitors.

With starting capacity

In most cases, the circuit only includes a starting capacitor. It is active only when the engine is starting. Therefore, the method is good when the launch promises to be difficult, otherwise the shaft will not be able to accelerate due to the small initial torque. After acceleration, the starting capacitor is turned off and operation continues without it.

The connection diagram for a motor with an auxiliary tank is shown in the figure above. To implement it, you will need a relay or at least one button, which you will press for 3 seconds while starting the motor. The auxiliary capacitor, together with the auxiliary winding, is included in the circuit only for a while.

This arrangement provides optimal starting torque if minor AC surges occur during startup. But there is also a drawback - when operating in nominal mode, the technical characteristics drop. This is due to the shape of the magnetic field of the working winding: it is oval, not circular.

With working capacity

If the start is easy, but the work is hard, then instead of a starting capacitor you will need a working capacitor. The connection diagram is shown below. The peculiarity is that the working capacitance, together with the working winding, is constantly connected to the circuit.

The circuit provides good performance when operating in nominal mode.

With both capacitors

A compromise solution is to use auxiliary and working tanks simultaneously. This method is ideal if the AC motor is already started with a load, and the work itself is difficult for it. Look, the diagram below is like two diagrams (with working and auxiliary capacitance) superimposed on each other. When starting, the trigger will be turned on for a few seconds, and the second drive will be active all the time: from start to shutdown.

Capacity calculation

The greatest difficulty for beginners is calculating the capacitance of capacitors. Professionals select them empirically, listening to the engine during startup and operation. This is how they determine whether the drive is suitable or whether they need to look for another one. But with a small error in most cases, the capacity can be calculated as follows:

- For a working drive: 0.7-0.8 µF per 1000 watts of electric motor power;

- For the starting capacitor: 2.5 times more.

Example: you have a 2 kW asynchronous single-phase electric motor. This is 2000 watts. This means that when connecting with a working capacitance, you need to stock up on a 1.4-1.6 µF drive. For the starting one you will need 3.5-4 uF.

Advantages and disadvantages of a two-phase motor

Among the advantages of a two-phase motor it is worth highlighting:

- simplicity of design. Due to the small number of elements, asynchronous two-phase motors reduce assembly costs. Therefore, in comparison with engines of similar power, they will be significantly cheaper. Also, the absence of complex elements increases the reliability of the design, and in the event of a breakdown, it will be much easier to repair;

- characteristics. The power and efficiency factors of all asynchronous motors, including two-phase ones, are at a very high level. Such motors will be more powerful compared to analogues in the same price category. Also, the rigid mechanical characteristic does not allow large differences in speeds during load fluctuations - they remain at the same level regardless of such jumps;

- power. Asynchronous two-phase motors have high values of permissible and starting torque on the shaft. This allows you to quickly accelerate the engine to its maximum values without wasting time;

- exploitation. As mentioned above, the design of electric motors with a two-phase connection is very simple and does not have many individual elements. Thus, maintenance of such devices is much easier, and the likelihood of breakdown is lower. With timely cleaning of dust and tightening of connection contacts, the engine will operate for 15 to 20 years without replacing bearings.

In general, two-phase devices are very popular due to their durability and reliability. They do not have separate collector groups, therefore they do not create additional friction and thereby reduce engine wear compared to analogues. Separate converters are not required to power the motor - just connect them to the industrial network and start it.

However, we should not forget about a number of disadvantages that prevent asynchronous motors from occupying a dominant niche in the market:

- their main problem is low starting torque. This somewhat limits the scope of application of asynchronous motors. For example, they are used in manipulators, cranes, conveyors, home and office tools where power is required instead of high starting torque;

- It is also worth noting the high reactive power they consume during startup. The fact is that despite the high performance, it is incommensurate with mechanical power, since it has no effect on it. It is worth taking this into account when calculating the energy consumption of equipment;

- You should be careful with the indicators in principle, since some system values may be lower than those required for consumption at the start of a two-phase asynchronous motor. Failure to meet the specifications will result in a significant reduction in operating efficiency and, in some cases, may result in equipment failure.

It is also worth considering how motors with a different number of phases - one, three and five - differ.

Connecting a single-phase synchronous electric motor

Despite the complexity of the design of synchronous motors, they have many advantages over asynchronous ones. The main thing is the low sensitivity to voltage surges leading to a sharp decrease or increase in current. No less significant is the fact that synchronous motors can operate even with overload, not to mention the optimal mode of reactive energy and shaft rotation at a constant speed. However, connecting is a labor-intensive process, and this is already a disadvantage.

Overclocking method

You cannot start a single-phase synchronous motor by simply applying power to its windings. Because at the moment of switching on, the direction of the supply current in the stator windings corresponds to figure (a). At this time, a pair of forces acts on the rotor, which is still at rest, which will try to rotate the shaft clockwise. But after half the period in the stator windings, the current will change its direction. Therefore, a pair of forces will already act in the opposite direction, turning the shaft counterclockwise, as in figure (b). Since the rotor has great inertia, it will never move.

To make the rotor rotate, it is necessary that it has time to make at least half a revolution so that a change in the direction of the current does not affect its rotation. This is possible if the shaft is accelerated with the help of outside forces. This can be done in two ways:

- Manually;

- Using a second engine.

Only low-power synchronous electric motors can be accelerated with your own hand strength. And for medium- and high-power units you will have to use a different motor.

When accelerating with an external force, the rotor begins to rotate at a speed close to synchronous. Then only the excitation winding turns on, and then the stator winding.

Asynchronous start of a synchronous motor

If metal rods are placed in the tips on the rotor poles, and they are connected to each other on the sides by rings, then the motor must be started asynchronously. These rods play the role of an auxiliary winding that an asynchronous motor has. In this case, the excitation winding is short-circuited using a discharge resistor, and the stator winding is connected to the network. This is the only way to achieve the same acceleration as an asynchronous electric motor. But after the rotation speed is as close as possible to synchronous (95% of it is enough), the excitation winding is connected to a direct current source. The speed becomes completely synchronous, which entails a decrease in the induced emf of the auxiliary winding down to zero. And it turns off automatically.

The layout and method of connecting your motor will depend on whether you have a synchronous or asynchronous motor. The power of the motor is also taken into account, as well as the starting method: with or without load. A basic understanding of mechanics and electromagnetic phenomena will help you understand the drawings.

AC brushed motor

Consider a brushed AC motor. Universal commutator motors can be powered from both AC and DC sources. They are often used in power tools, sewing and washing machines, meat grinders - where reverse is needed, adjustment of the rotor speed or its rotation at a frequency of more than 3000 rpm.

The stator and rotor windings of a commutator motor are connected in series. Current is supplied to the rotor windings through brushes in contact with the commutator plates, to which the ends of the rotor windings are connected.

Reversing a single-phase motor with a commutator is carried out by changing the polarity of the stator or rotor windings being connected to the network, and the rotation speed can be adjusted by changing the amount of current in the windings.

The main disadvantages of such an engine:

- high price;

- the complexity of the device, the practical impossibility of repairing it independently;

- significant noise level, difficult to control, creating radio interference.

This is interesting: The principle of operation of a four-stroke engine: we analyze it in detail

Basic connection diagrams

As a phase-substituting element for connecting a single-phase asynchronous motor, you can use various electromechanical elements (inductor, active resistor, etc.), but a capacitor provides the best starting effect, which is why it is used for this most often.

single phase asynchronous motor and capacitor

There are three main ways to start a single-phase asynchronous motor through:

- worker;

- launcher;

- working and starting capacitor.

In most cases, a circuit with a starting capacitor is used. This is due to the fact that it is used as a starter and only works when the engine is turned on. Further rotation of the rotor is ensured by the pulsating magnetic field of the working phase, as already described in the previous paragraph. A relay or button is often used to complete the trigger circuit.

Since the starting phase winding is used for a short time, it is not designed for heavy loads and is made of thinner wire. To prevent its failure, a thermal relay (opens the circuit after heating to the set temperature) or a centrifugal switch (turns off the starting winding after acceleration of the motor shaft) is included in the motor design.

In this way, excellent starting characteristics are achieved. However, this scheme has one significant drawback - the magnetic field inside a motor connected to a single-phase network is not circular, but elliptical. This increases losses during the conversion of electrical energy into mechanical energy and, as a result, reduces efficiency.

The circuit with a working capacitor does not provide for disconnecting the additional winding after starting and accelerating the engine. In this case, the capacitor allows you to compensate for energy losses, which leads to a natural increase in efficiency. However, in favor of efficiency, starting characteristics are sacrificed.

For the circuit to operate, it is necessary to select an element with a certain capacity, calculated taking into account the load current. An unsuitable capacitor will cause the rotating magnetic field to take on an elliptical shape.

A kind of “golden mean” is a connection diagram using both capacitors - both starting and working. When connecting the engine in this way, its starting and operating characteristics take average values relative to the circuits described above.

In practice, for devices that require the creation of a strong starting torque, the first circuit with a corresponding capacitor is used, and in the opposite situation, the second, with a working one.

Five-phase motors

Compared to the options listed above, a five-phase motor is much more similar to a two-phase one due to its design features. In most cases, a conventional one is enough for work, but a five-phase motor finds its use in cases where the system lacks resolution, acceleration and braking. In addition, it has reduced vibration and increased accuracy.

What is the difference between these motors? First of all, in the design, a 2-phase motor has eight magnetic poles, while a 5-phase motor has ten. Each of them is equipped with a winding, which leads us to the second important difference - the number of phases. As is easy to understand from the name of the motor, in a two-phase motor there are only two of them, conventionally designated as A and B. Five-phase motors have five phases at once - from A to E. Thus, while the first version of the motor operates in a strictly limited mode, the second can easily switch between different parameters, connecting phases in different combinations. This allows for wide variations in the performance, stability and intensity of the device. In fact, a five-phase motor has better characteristics in all main parameters of the device, including the driver, but in most cases they are simply not needed in the system, since standard power is sufficient for it. Thus, five-phase motors have their own strictly limited niche and are not widely used - it is worth checking the description before purchasing.

How to connect

You can connect a single-phase electric motor to a power outlet using special connectors - a plug. It is necessary to have a voltage of 220 - 240 V and a current frequency of 50 Hz. Regardless of what kind of device it is - a juicer, mixer, electric meat grinder or vacuum cleaner, the connectors of the connected electrical appliance and sockets always match!

The electric motor can be started using a capacitor of the correct capacity, connected to the starting winding, or using a resistor.

Usually all this is already provided for in the design. Just “plug the plug into the socket” and press the “start” button.

At the same time, the trigger mechanism can operate either briefly or be permanently connected to the circuit.

Thus, when choosing a purposeful “motor” for a single-phase network, it is important to start it correctly. Household appliances already have the necessary settings, just press a button

In other cases, you need to choose the right starting device so that the engine starts and performs its assigned tasks.

conclusions

Thus, asynchronous motors have carved out a strong niche in modern industry, offering many advantages at a relatively low cost of purchase and maintenance. However, it is worth noting that most systems primarily use universal three-phase motors, which can be freely converted into single-phase motors under certain system parameters.

Two-phase motors have their own niche, which they share with five-phase motors. Having different parameters and system features, they find their application in automatic devices, such as compensation or bridge systems. In addition, thanks to the ability to adjust a number of key parameters, such motors are easy to control and will heat up less. For example, it is possible to change the torque and rotation speeds through the voltage phases of the two windings. And craftsmen make such motors from a car generator.

Connection

To operate the device, 1 phase with a voltage of 220 Volts is required. This means that you can plug it into a household outlet. This is precisely the reason for the popularity of the engine among the population. All household appliances, from a juicer to a grinder, have mechanisms of this type.

connection with starting and running capacitors

There are 2 types of electric motors: with a starting winding and with a working capacitor:

- In the first type of devices. The starting winding operates via a capacitor only during start-up. Once the machine reaches normal speed, it turns off and operation continues with one winding.

- In the second case. for motors with a working capacitor, the additional winding is permanently connected through the capacitor.

An electric motor can be taken from one device and connected to another. For example, a working single-phase motor from a washing machine or vacuum cleaner can be used to operate a lawn mower, processing machine, etc.

There are 3 schemes for switching on a single-phase motor:

- In 1 scheme. The work of the starting winding is performed by means of a capacitor and only for the start-up period.

- 2 circuit also provides for a short-term connection, but it occurs through a resistance and not through a capacitor.

- Scheme 3 is the most common. In this scheme, the capacitor is constantly connected to a source of electricity, and not just during startup.

Connecting an electric motor with starting resistance:

- The auxiliary winding of such devices has increased active resistance.

- To start an electrical machine of this type, a starting resistor can be used. It should be connected in series to the starting winding. Thus, it is possible to obtain a phase shift of 30° between the winding currents, which will be quite enough to start the mechanism.

- Besides. a phase shift can be obtained by using a starting phase with a higher resistance value and a lower inductance value. This winding has fewer turns and thinner wire.

Connecting a motor with capacitor start:

- For these electric machines, the starting circuit contains a capacitor and is turned on only for the start period.

- To achieve the maximum starting torque, a circular magnetic field is required that performs the rotation. For it to occur, the winding currents must be rotated 90° relative to each other. Phase-shifting elements such as a resistor and inductor do not provide the necessary phase shift. Only the inclusion of a capacitor in the circuit allows you to obtain a phase shift of 90°, if you select the capacitance correctly.

- Calculate. Which wires belong to which winding can be determined by measuring the resistance. For the working winding, its value is always less (about 12 Ohms) than for the starting winding (usually about 30 Ohms). Accordingly, the cross-section of the working winding wire is larger than that of the starting winding.

- The capacitor is selected according to the current consumed by the motor. For example, if the current is 1.4 A, then a capacitor with a capacity of 6 μF is required.

Model overview

Among domestic suppliers and manufacturers of two-phase 220v electric motors, we can highlight the AIR series. They are great for industrial and domestic needs. Design features include the presence of flanges and special mounting feet on the body. They can be included separately or together. The price won't be much different from this. All low- or high-sided variants come with a warranty of approximately 12 months, depending on the brand. Types of cases:

- Aluminum - with a pulley rotation height of up to 90 millimeters.

- Cast iron - with a pulley rotation height of 90 millimeters.

Knowing what a single-phase 220 V motor is intended for, you can immediately choose the appropriate option. The company AACO, which is based in Italy, deserves special attention.

The company sells low-speed and other types of new generation electric motors. When purchasing, you should initially consult with the responsible managers of online stores.

Operating principle

The principle of operation of an electric motor demonstrates the simplest experiment that we were all shown at school - the rotation of a frame with current in the field of a permanent magnet.

The frame with current is an analogue of the rotor, the stationary magnet is the stator. If current is applied to the frame, it will turn perpendicular to the direction of the magnetic field and freeze in this position. If you force the magnet to spin, the frame will rotate at the same speed, that is, synchronously with the magnet. We have a synchronous electric motor. But our magnet is a stator, and by definition it is motionless. How to make the magnetic field of a stationary stator rotate?

First, let's replace the permanent magnet with a current-carrying coil. This is the winding of our stator. As is known from the same school physics, a coil with current creates a magnetic field. The latter is proportional to the magnitude of the current, and the polarity depends on the direction of the current in the coil. If we apply alternating current to the coil, we get an alternating field.

A very clear analogy with a clock will help us. What vectors constantly rotate before our eyes? These are the hour hands. Let's imagine that there is a clock hanging in the corner of the room. The second hand rotates one full revolution per minute. An arrow is a vector of unit length.

The shadow that the arrow casts on the wall varies as a sine with a period of 1 minute, and the shadow cast on the floor changes as a cosine. Or a sine phase shifted by 90 degrees. But a vector is equal to the sum of its projections. In other words, the arrow is equal to the vector sum of its shadows.

Starting current

Direct starting of the motor is characterized by a significantly higher current level than during its stable operation. The starting indicator can exceed the nominal value by 5-8 times. In this case, the rated current is always indicated by the manufacturer on the motor nameplate, while the starting current is described only in the technical documentation. In the characteristics, this parameter is indicated as the ratio of the starting current to the rated current.

How to calculate starting voltage?

There are several ways to calculate the starting current for an asynchronous motor. These options are useful if the ratio value is not indicated in the technical documentation or the accompanying papers have been lost:

- Oscilloscope. The readings are checked at the time of start-up using a resistor shunt. The effective voltage is calculated from the maximum amplitude value, after which the inrush current is determined using Ohm's law. The advantage of this method is to obtain specific data for a specific engine.

- Low voltage. In this option, a voltage reduced by 5-10 times is supplied to the engine and measurements are made. After recalculation, the starting current is obtained. Moreover, it is enough to take measurements for phase 1. On the rest, the starting indicators should be similar. This method is used in production to obtain data displayed in a table. The basis is the rated current, so in each individual case the starting indicator may be different.

- Current clamps. Simple and fast method. The most accurate readings are obtained when measuring on systems with long startup times and high inertia. For example, these could be fans or motors with massive impellers.

- Transformer. Method used in electricity metering units. Using a transformer, you do not need to measure the real current; it is enough to obtain its value reduced by a certain number of times. A significant disadvantage of the method is that the transformer is designed for a frequency range of 50-60 Hz, while starting transients can have a wider spectrum and harmonics.

It is important to remember that, due to certain factors, the starting current declared by the manufacturer will have a greater multiple than its actual value.

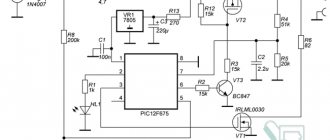

How to reduce the voltage when starting an asynchronous motor

High starting force often becomes a problem, causing power supply overloads, overheating, and accelerated engine wear. Therefore, it is necessary to be able to reduce its value to maintain the performance and durability of the systems. There are several ways:

- Smooth start. In this embodiment, a reduced voltage is first supplied to the engine with a gradual increase to the nominal value. To implement the method, soft starters (soft starters) or frequency converters are used.

- Limiters. In this design, resistors with high resistance values are used as a limiting element during startup. After the timer is triggered, the motor switches to the nominal value. To assemble such a starting device, it is enough to use a contactor and a time relay, so you can make it yourself.

- Star-triangle. A special method of connecting the windings, which allows you to immediately use the full voltage for direct starting and reverse, but gradually bring the motor’s magnetic field to rated power. This approach helps maintain the performance of the unit. A drawing of such a connection can be found on the Internet.

There are also options for starting and spinning an asynchronous reversible motor idle. The load is connected only after reaching sufficient speed. In this design, variators, clutches, and gearboxes can be used. If it is necessary to implement a quick stop, you can use dynamic braking, for which a constant voltage is applied to the stator windings.

Connection diagrams for single-phase asynchronous motors

With starting winding

To connect a motor with a starting winding, you will need a button in which one of the contacts opens after switching on. These opening contacts will need to be connected to the starting winding. In stores there is such a button - this is PNDS. Its middle contact closes for the holding time, and the two outer ones remain in a closed state.

Appearance of the PNVS button and the state of the contacts after the “start” button is released"

First, using measurements, we determine which winding is working and which is starting. Typically the output from the motor has three or four wires.

Consider the option with three wires. In this case, the two windings are already combined, that is, one of the wires is common. We take a tester and measure the resistance between all three pairs. The working one has the lowest resistance, the average value is the starting winding, and the highest is the common output (the resistance of two windings connected in series is measured).

If there are four pins, they ring in pairs. Find two pairs. The one with less resistance is the working one, the one with more resistance is the starting one. After this, we connect one wire from the starting and working windings, and bring out the common wire. A total of three wires remain (as in the first option):

- one from the working winding is working;

- from the starting winding;

- general.

We work further with these three wires - we use them to connect a single-phase motor.

With all these

- Connecting a single-phase motor with a starting winding via the PNVS button

connecting a single-phase motor

We connect all three wires to the button. It also has three contacts. Be sure to place the starting wire on the middle contact (which closes only during the start), the other two - on the outer ones (arbitrarily)

We connect a power cable (from 220 V) to the extreme input contacts of the PVNS, connect the middle contact with a jumper to the working one (note! not to the common one). That's the whole circuit for switching on a single-phase motor with a starting winding (bifilar) through a button

Condenser

When connecting a single-phase capacitor motor, there are options: there are three connection diagrams and all with capacitors. Without them, the engine hums, but does not start (if you connect it according to the diagram described above).

Connection diagrams for a single-phase capacitor motor

The first circuit - with a capacitor in the power supply circuit of the starting winding - starts well, but during operation the power it produces is far from rated, but much lower. The connection circuit with a capacitor in the connection circuit of the working winding gives the opposite effect: not very good performance at start-up, but good performance. Accordingly, the first circuit is used in devices with heavy starting (concrete mixers, for example), and with a working condenser - if good performance characteristics are needed.

Circuit with two capacitors

There is a third option for connecting a single-phase motor (asynchronous) - install both capacitors. It turns out something between the options described above. This scheme is implemented most often. It is in the picture above in the middle or in the photo below in more detail. When organizing this circuit, you also need a PNVS type button, which will connect the capacitor only during the start time, until the motor “accelerates”. Then two windings will remain connected, with the auxiliary winding through a capacitor.

Connecting a single-phase motor: circuit with two capacitors - working and starting

When implementing other circuits - with one capacitor - you will need a regular button, machine or toggle switch. Everything connects there simply.

Selection of capacitors

There is a rather complex formula by which you can calculate the required capacity accurately, but it is quite possible to get by with recommendations that are derived from many experiments:

- The working capacitor is taken at the rate of 70-80 uF per 1 kW of engine power;

- starting - 2-3 times more.

The operating voltage of these capacitors should be 1.5 times higher than the network voltage, that is, for a 220 volt network we take capacitors with an operating voltage of 330 V and higher. To make starting easier, look for a special capacitor for the starting circuit. They have the words Start or Starting in their markings, but you can also use regular ones.

Application of single-phase motors

This type of motor is used to operate devices with low power.

- Appliances.

- Fans are small in size.

- Electric pumps.

- Machines designed for processing raw materials.

Factories produce low-power single-phase 220 V electric motors of various models, with different speeds and power. It is worth noting that single-phase motors are inferior to three-phase motors in several parameters.

- These motors have lower efficiency values.

- Starting moment.

- Power.

- The ability to withstand overload of three-phase electric motors is higher than that of single-phase ones.

These parameters are smaller when three-phase motors are of the same size.