What is a miter saw?

A crosscut saw is a mechanism with a cutting disc designed for sawing wood and composite materials at right or other required angles.

Designed to work on a flat surface. Allowed to be moved and installed in a temporarily equipped workplace. Their appearance resembles machines for cutting pipes, fittings, and stone. There are several types of miter saws:

Pendulum - a horizontal frame with a turning circle. A lever (pendulum) is attached to the reverse side of the circle, which is where it got its name. The saw blade is mounted on this lever. The workpieces are fed along the guide bar. To make a cut, a lever with a rotating disk is recessed into the board.

Combined - everything is the same. Thanks to the hinges, the ability to rotate the lever relative to the horizontal plane has been added.

With horizontal stroke. It resembles a pendulum saw, but allows you to cut wider parts by moving the mechanism with a rotating disk along the runners back and forth.

As an addition to all trims included:

- dust bag;

- laser illumination;

- pipe for connecting a vacuum cleaner.

Engine Installation

To make a homemade circular saw, you need to think in advance about what device will be used to transfer the force from the motor to the cutting disc. Small equipment can be placed directly on the engine axis. However, this will not have the best effect on the power of the circular machine

made with your own hands.

An ordinary bicycle spindle can act as such a transmission mechanism, without which the operation of any circular saw is impossible. This is often called the housing in which the shaft with bearings is located. To cut it off the bike, you can use a hacksaw. In this case, you will not need the sprocket, since in this case it is best to take it from the D6 or D8 engine. In order for this sprocket to fit securely on the new shaft, you will need to make an adapter sleeve. Before you install the circular saw on your bicycle spindle, you need to make sure that it has the size of the mounting hole you need. Now, taking this information into account, it is necessary to establish the outer diameter of the bushing intended for the transition mechanism. The bushing should be attached to the spindle in several places at once. Next, a plate with a thickness of at least 5 mm should be secured to the spindle assembly body.

Now take an asterisk, approximately 2-2.5 times larger in size than the one that was previously installed on the spindle, and install it on a homemade circular saw. And at the end of making a saw with your own hands, when all its parts are well secured, put on the chain and you can use it for its intended purpose.

READ How to Use a Makita Screwdriver

Additional functions

Modern power tools are equipped with additional functions that have become available thanks to the development of electronics. Also, different models may have additional capabilities that are made using mechanical devices.

When choosing, you should pay attention to the presence of these functions and know what they give the user. Let's look at the main ones in more detail.

Rotation speed stabilization system

This is an electronic system that, when under load, increases the current supplied to the electric motor. And, conversely, it decreases when working with a light load or without it. As a result, the disk rotates at the same speed under any load.

Under excessive loads, the speed will still drop or the engine will be switched off by the protective system, if any. However, the system allows for smooth operation of the saw in different modes, which makes work easier.

Soft start system

When starting, most electric motors consume 3 times the rated power. For example, a 2.2 kW motor can consume up to 6.6 kW at startup, putting an excessive load on the network.

Sometimes networks that are not designed for this and are loaded with other consumers cannot handle it. And in any case, during startup, the light “goes down” for a while, which can be seen from the fading light of the incandescent light. The soft start system avoids this.

In addition, it improves safety. If, during startup, the disk accidentally ends up “in the wrong place,” it will not cause harm, since at first it will rotate slowly and there will be time to correct the situation.

This is a useful function, but there is a drawback - the saw does not immediately start working, it takes from 3 to 5 seconds to reach full speed.

Overload protection system

Performs the function indicated in the name itself. If the engine overheats, the disk or gearbox jams, or there is overload, the system will turn off the engine. Its only drawback is that it can be set too “vigilant” and turn off the engine too often due to minor overloads.

Electrodynamic brake

Without such a system, when the saw is turned off, the disk continues to rotate for some time by inertia. The electrodynamic brake, after turning off the rotation, creates a magnetic field in the engine that slows down the rotation almost immediately. This increases safety and convenience when working.

Slip clutch

The function protects the engine mechanically. If the disk jams, when clamped with a certain force, the engine will not burn out, because the drive from the engine to the disk will slip due to the clutch.

Protection against accidental activation

Made in the form of a switch with two buttons. The first button unlocks the main power button. The system increases safety, but creates some inconvenience when turned on.

Pay attention to our selection tips, they will help you make the right choice

Spindle stop

In order to unscrew the disk clamping washer (remove the disk), you need to fix the spindle (the shaft on which the disk is located). Otherwise, the disk fastening bolt will spin along with the shaft and it will not be possible to unscrew it. On different models, this fixation is performed in two ways:

- The spindle has edges for a wrench.

- A stopper lever is built inside the mechanism, by pushing it in you can lock the spindle.

Rip fence and guide rail

The rip fence is available with almost all models. It allows you to cut the workpiece into thin slats, but only if at least one side of the workpiece is smooth. The stop is inserted into the saw body, and its platform moves along the flat side of the workpiece, ensuring an accurate cut.

The guide bar is a platform that is placed and secured to the workpiece. The saw moves relative to the guide bar, so it is not necessary to have a straight edge to the workpiece.

Both devices can be useful in certain operations.

The guide allows you to make a very even cut; it is considered especially useful when sawing laminated chipboard.

Spring loaded housing

All models of circular saws are equipped with this function, as it ensures safety. The casing opens slightly as sawing, freeing the passage of the rotating disk through the workpiece. When removing the saw from the workpiece, the spring automatically closes the blade with a protective cover.

Large homemade circular saw

When making a frame for the top of the saw, it is best to use a metal corner 25 mm wide. In this case, the rectangle, which will represent the frame of the upper part of the homemade circular, should have dimensions of 600x400 mm. Next, four pipes are welded in the corners of this quadrangle, the diameter of which should be 17 mm and the height should be approximately 2.2 m.

After this, it is necessary to strengthen two corners on the frame, on which the bearings will later be fixed. The distance between these corners directly depends on the length of the shaft. To fix bearings, as a rule, clamps are used. It is best if the bearings installed on a homemade circular are closed. This way you won’t have to worry about wood chips getting into the space between the balls, rings and separator. Don't forget to also cut a thread at the very end of the shaft so that you can install a cutting blade on it later.

Circular saw device.

The lower part of the circular saw should be made much more massive, which will provide it with the necessary stability and reliability. Therefore, when making the lower frame, you need to take a corner with a width of at least 40 mm. Next, across the frame it is necessary to secure two additional corners, which will later support the motor of the homemade circular saw. The most suitable motor for a DIY circular saw is an asynchronous three-phase motor with a power of at least 1.5 kW and 1500 rpm. The pulley groove should be quite large, approximately 80 mm, and it should be mounted directly on the shaft itself. In addition, you will need to weld a fairly small metal platform to the frame on which the starting device will be placed. Large pipes 2.2 m long, which you previously welded in the corners of the frame, are necessary for high-quality tension of the belt so that the metal wings press the thin pipes.

Electric motor for circular saw 220V 4kW 3000rpm.

Measuring with a mechanical tachometer requires direct contact with the surface of the object.

Now you need to insert both the lower and upper parts of the homemade saw into the finished supports made of pipes, and then tighten and tighten the belt with metal wings. You can start the motor in this model of circular machine yourself using starting capacitors. In order to additionally load the motor and increase its torque, you can use a 220/36,400 W transformer.

Pendulum circular saw with electric motor

Scheme for testing the functionality of a circular saw.

You can make a homemade circular saw quite easily to cut logs and pieces of wood, the thickness of which corresponds to the strength of the electric drive installed on it. If you intend to work with large and very thick pieces of wood, then you should equip your homemade saw with a truly powerful electric motor, as well as install a shaft and belt drive on it. The best solution in this case would be to install a special pendulum frame.

When making a pendulum circular with your own hands, only very strong steel corners should be used as the material for the frame. Next, on the finished steel frame you will need to place all the mechanisms necessary for the normal operation of a homemade circular saw. With this design, you can personally set the flight altitude of the cutting blade without any special effort, while avoiding excessive design difficulties.

What is a circular saw for?

Before starting work, it is necessary to determine the main tasks of the sawing machine. If you just need to cut firewood for the winter, or do basic carpentry work like making a fence, a strong table with a slot for a saw blade is enough. These options are popular in rural areas.

Circular for working with logs

Some of these “models” have a shaft for securing the knives of a plane or jointer. As a rule, a frame is welded from a corner or channel, an electric motor from discarded factory ventilation is mounted on it, and with the help of a pulley the torque is transmitted to the disk. It makes no sense to describe in detail the manufacturing technology of such a machine.

It's another matter if you want to do carpentry work. In this case, you need a coordinate table with guides that are fixed at different angles.

Since such a stationary saw can work with small-sized workpieces, it is necessary to take care of the operator’s safety. It is advisable to provide adjustment of the rotation speed and the ability to easily change disks with different diameters.

Circular on the motor from the washing machine

You won't miss in an accident

El Dorado

Eldorado needs no introduction, as it has an established reputation as a major Russian retailer. Among the appliances that you can purchase in Eldorado are 4K TVs, electric shavers, washing machines, vacuum cleaners and capsule coffee machines from all well-known manufacturers.

The seller provides users with a huge selection of products at discounted prices. Whirlpool, Tefal, Rowenta, Braun and Dyson are just some of the reputable brands you can buy in Eldorado. The company cares about the safety of its customers, so all payments and personal data on the site are protected from hacking.

On the shelves of an online store there are all types of goods that can be found in a retail network. In the household appliances segment, Eldorado always has a large selection of devices (audio and video equipment, gadgets, laptops, photographic equipment). You can often find special offers and products of the day on the site.

Assembly instructions

Using the washing machine engine, you can assemble a circular machine not just “for beauty”. Such a device will be useful for installation, sawing or construction work. For example, using a circular saw you can easily unravel a 10*10 block. Isn't this an indicator?

How to connect the motor?

Connecting the motor is the main stage in building a circular saw.

If you fail to connect the motor from the washing machine correctly, the device simply will not work.

The difficulty is not in connecting the engine, but in ensuring stable speed control.

As already written above, without this the saw will simply tear the material. To ensure regulation, you can use a voltage regulator instead of a tachometer, which is equipped with washing machine motors.

When connecting, some masters get confused, since the commutator motors that are installed on automatic machines have several outputs at once. Therefore, it is not clear how to make the connection.

The connection occurs as follows:

- First, the motor must be cranked several times in order to find the excitation coil or shoes. There should be 2 or more wires coming from them.

- Using an ohmmeter set to minimum resistance, we ring each output in turn. Here you need to find two with the highest resistance out of all the available outputs. This is the case if there are more than two wires.

- After this, you need to find the motor commutator and brushes, from which there should also be two wires.

- After this, you need to find the tachometer outputs. Often these wires can be found directly on the housing. If they are not there, then they are hidden in the housing, then you will have to disassemble the engine a little.

- Now you need to take one wire from the collector and connect the wire from the coil to it.

- The other collector wire must be connected to a 220 V network.

If necessary, you can change the direction of rotation by simply swapping the wires. We do a test run, having previously marked the wires of the coil and tachometer.

If the engine starts without problems, then everything was done correctly. Separately, you can consider the process of connecting the engine using a speed controller:

- We connect one of the coil wires to one of the armature wires.

- We connect the other one to the network.

- We connect the second armature wire to the dimmer.

- We connect the other output of the dimmer to the network.

- Let's try to start the engine.

Moving parts

After the motor is connected, you can proceed to creating the circular. The next step is the assembly of the moving elements, since it is they that bear the load, namely:

- Motor shaft.

- Saw shaft.

- Drive belt.

- Motor pulley from the washing machine.

- Circular saw pulley.

What voltage to use: 220 or 380

Voltage of 220 V is ubiquitous in household electrical networks, but devices with 380 V are considered more stable and powerful. In principle, both parameters can satisfy the conditions for connecting an asynchronous motor for a circular saw.

It is better to use a voltage of 380V, because... it allows the use of a more powerful engine, and with more torque.

If the house does not have 380V voltage, then you will have to use 220V.

There are situations when there is a 380V motor, but the voltage in the house is 220V. How to connect such a motor?

How to connect 380 V to 220 V voltage

All possible connection diagrams for converting 220 V to 380 V are indicated on the nameplate of the electric motor. Therefore, we first look at it and, first of all, are guided by what is written there.

In practice, when connecting a conventional asynchronous motor, 2 methods are used:

- a frequency converter . Its purpose is to convert 1 phase at a voltage of 220 V into 3 phases 380 V with exactly the same voltage parameter. Frequency converters are expensive, so they are rarely used for conversion at home;

- using a capacitor . An AC unit will be required. But the capacitor should be connected to one of the motor windings - in this case, a phase shift will occur, and a torque will arise due to the formation of an EMF in the magnetic field.

You cannot use capacitors for direct current in an alternating current network, as during operation the device may overheat and explode.

After watching the video, you can see two practical ways to connect a 380V electric motor to a household AC network.

Designs of homemade machines

There are three main elements at the heart of any circular, two of which cannot be made by yourself:

- engine.

- shaft, with jointing knives or the simplest, without them.

Third, the bed (table) is easy to make on your own.

You can make such a stand with your own hands without any problems.

Additional elements are also required:

- starter, switch for the electric motor;

- electrical wire;

- drive belt;

- pulleys on the shaft and motor.

Main types of structures:

- The disk is mounted directly on the engine, without a belt or gear drive.

- The disk is mounted on a shaft with a belt drive.

- The shaft is the simplest, only for the disk.

- Shaft with jointing knives.

The first option is the simplest, but with a big drawback. The height of the engine “eats up” most of the working diameter of the disk. If the engine has a diameter of, for example, 200 mm, then a disk with a diameter of 200 mm will protrude above it by only 100 mm. Another part of this distance is reduced due to the motor mounts, connection box, and the thickness of the desktop.

As a result, only the outermost part of the disk diameter, where the greatest “lever” of resistance to engine rotation will actually work, will work. Even with a large blade, the cutting depth remains small, since the blade protrudes little.

If you install the motor with the blade on the side of the table, with the motor elevated relative to the table, the width of the cut will be limited. The wide piece will rest against the engine housing. It is impossible to extend the motor shaft with attachments, since the disk must be located as close as possible to the bearing. In another case, decentration of the shaft, beating and wobbling of the disk are possible.

The second option, the simplest shaft, also inevitably “eats” the working height of the disk, but much less. Only to the height of the bearing carriage from the center of the shaft. Therefore, when choosing a finished shaft, the height of the carriage matters. For powerful shafts this is 80-120 mm (40-60 mm from the center of the shaft). For thin shafts with small bearings 60-80 mm (30-40 mm).

The option with a shaft and belt allows you to select the number of revolutions of the saw blade due to the size of the pulleys on the motor and shaft. The belt can also act as mechanical engine protection. If it is not tightened, when the disk gets stuck in the workpiece, the belt slips along the pulleys, but the engine does not jam.

The simplest option is also possible, without an adjustment platform. In this case, the planing depth is set by the position of the knives in the shaft itself. This option is suitable for rough processing. For example, on jointing knives with a planing depth of 3-5 mm, you can plan one surface lightly. Then, having one flat plane to move along the table, cut the workpiece on the remaining sides with a saw blade.

How to install a 220 V engine preheater

A pre-heater is an indispensable device for most drivers in the cold season. Thanks to a simple but effective device, starting the engine at sub-zero temperatures will occur in a matter of minutes. But you won’t have to warm it up at idle for a long time.

Many will probably think that this is impossible. After all, warming up the engine in the cold season is simply necessary, and to do this you need to start the unit and stand for some time with the engine running. Only after this can you move away, and then without accelerating to high speed.

This process usually requires a significant investment of time and gasoline. And the lower the ambient temperature, the longer it will take to warm up the engine. Of course, this factor does not have a very favorable effect on the environment. A reasonable alternative is to install a pre-heater for the motor. Next, we will tell you how this mechanism works and how you can install it on your car. And at the same time - about the peculiarities of operating the pre-launch mechanism. We will also provide a video on installing a 220V pre-heater on a car.

What characteristics you need to pay attention to: power, speed

The main characteristic of an electric motor is power. The following power ranges are selected for circular saws:

- up to 800 W - low-power saws for cutting small wooden workpieces;

- from 800 W to 1200 W—saws with engines in this power range are mounted in small carpentry and furniture shops with continuous production;

- over 1200 W - very powerful circular saws that ensure uninterrupted production in large woodworking shops.

The rotation speed of the circular saw blade directly depends on the number of revolutions of the engine shaft. As a rule, electric motors are selected in the range from 3000 to 6000 rpm. In this case, the optimal value is considered to be 5000 rpm, which allows:

- Easily cuts through hardwood.

- produce a more even cut line when using discs of different thicknesses.

- Avoid jamming the saw blade in the wood.

It should be noted that the temperature of the working surface during prolonged contact with the saw also depends on the rotation speed. The higher the speed, the stronger the heating.

Introduction

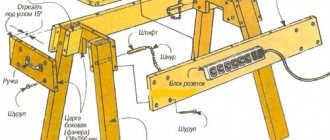

The machine consists of three main structural elements:

- base;

- sawing table;

- parallel stop.

The base and the sawing table itself are not very complex structural elements. Their design is obvious and not so complicated. Therefore, in this article we will consider the most complex element - the parallel stop.

So, the rip fence is a moving part of the machine, which is a guide for the workpiece and it is along it that the workpiece moves. Accordingly, the quality of the cut depends on the parallel stop because if the stop is not parallel, then either the workpiece or the saw blade may become jammed.

In addition, the parallel stop of a circular saw must be of a rather rigid structure, since the master makes efforts to press the workpiece against the stop, and if the stop is displaced, this will lead to non-parallelism with the consequences indicated above.

There are various designs of parallel stops depending on the methods of attaching it to the circular table. Here is a table with the characteristics of these options.

| Rip fence design | Advantages and disadvantages |

| Two-point mounting (front and rear) | Advantages: · Quite rigid design, · Allows you to place the stop anywhere on the circular table (to the left or right of the saw blade); · Does not require the massiveness of the guide itself. Disadvantage: · For fastening, the master needs to clamp one end in front of the machine, and also go around the machine and secure the opposite end of the stop. This is very inconvenient when selecting the required position of the stop and with frequent readjustment it is a significant drawback. |

| Single point mounting (front) | Advantages: · Less rigid design than when attaching the stop at two points, · Allows you to place the stop anywhere on the circular table (to the left or right of the saw blade); · To change the position of the stop, it is enough to fix it on one side of the machine, where the master is located during the sawing process. Disadvantage: · The design of the stop must be massive in order to ensure the necessary rigidity of the structure. |

| Fastening in the groove of a circular table | Advantages: · Quick changeover. Disadvantages: · Complexity of design, · Weakening of the circular table structure, · Fixed position from the line of the saw blade, · Quite a complex design for self-production, especially from wood (made only from metal). |

In this article we will examine the option of creating a parallel stop design for a circular saw with one attachment point.

Mini circular saw: manufacturing instructions

Mini-circular base

To make such homemade products you will need:

- two metal plates;

- wooden beam;

- spindle from a bicycle;

- star;

- chain.

Circular saw device with a separate motor.

The mini-circular saw should be placed on a strong and stable table, since any rocking can pose a danger to human health and also interfere with normal operation of the saw. Before you start making a machine from a hand-held circular saw, you need to make a special table. In this case, you can use metal sawhorses and a regular old kitchen table as a bed. To begin, you will need to connect the trestles to each other with a wide wooden board at least 50 mm thick, and then secure the kitchen table to this base.

Read also: Miracle jigsaw cutting out drawings with a jigsaw

You can make the tabletop itself from two metal (preferably steel) plates with a cross-section of about 4 mm. In addition, you can use thick wooden blocks for this purpose.

It is important not to forget to leave a small gap between the metal sheets, the size of which is usually 10-12 mm. In this case, you need to ensure that the edges of the metal plates are perfectly parallel to each other

Now that the table is completely ready, you can begin attaching the circular saw itself to it. It is important to note that it should be fixed from below, and in such a way that its cutting disc is directly in the gap between the two sheets of the tabletop

In this case, you need to make sure that the edges of the metal plates are perfectly parallel to each other. Now that the table is completely ready, you can begin attaching the circular saw itself to it

It is important to note that it should be fixed from below, and in such a way that its cutting disc is directly in the gap between the two sheets of the tabletop

Engine Installation

To make a homemade circular saw, you need to think in advance about what device will be used to transfer the force from the motor to the cutting disc. Small equipment can be placed directly on the engine axis. However, this will not have the best effect on the power of a handmade circular saw.

An ordinary bicycle spindle can act as such a transmission mechanism, without which the operation of any circular saw is impossible. This is often called the housing in which the shaft with bearings is located. To cut it off the bike, you can use a hacksaw. In this case, you will not need the sprocket, since in this case it is best to take it from the D6 or D8 engine. In order for this sprocket to fit securely on the new shaft, you will need to make an adapter sleeve. Before you install the circular saw on your bicycle spindle, you need to make sure that it has the size of the mounting hole you need. Now, taking this information into account, it is necessary to establish the outer diameter of the bushing intended for the transition mechanism. The bushing should be attached to the spindle in several places at once. Next, a plate with a thickness of at least 5 mm should be secured to the spindle assembly body.

Now take an asterisk, approximately 2-2.5 times larger in size than the one that was previously installed on the spindle, and install it on a homemade circular saw. And at the end of making a saw with your own hands, when all its parts are well secured, put on the chain and you can use it for its intended purpose.

Isolux

Isolux is a well-known online store that has been selling quality tools for many years. We have hand tools, durable building materials, insulation, heating and a reliable roof. The customer can filter the product by brand, price, power, cartridge, cable length and battery type.

Popular among buyers are construction tools under 3,000 rubles, equipment from DWT, Bosch brands and goods made in Germany. Each item in the store has a detailed description indicating characteristics (weight, country of production, type and size), customer reviews of the product and reliable photographs.

OBI

OBI closes the ranking of the best Russian companies that sell construction tools in Moscow. Among the advantages, we can note a wide network of hypermarkets in Krasnodar, Saratov, Volgograd and Ryazan. The variety of assortment starts with garden swings and ends with professional equipment for private craftsmen and large companies.

This technique will allow you not only to hang cabinets in the kitchen, but also to break down a concrete wall, install a toilet, windows, doors and replace old wooden floors. Another option would be to buy used instruments (used) for 1-2 thousand cheaper than new analogues. As a nice bonus, there will be free delivery over 3,000 rubles.

OBI is available for online orders not only to residents of large cities. Courier and postal services deliver your order to your home as quickly as possible. In addition to equipment, you can buy building materials, garden furniture, kitchen sets, shower cabins and sinks. OBI is the best retailer of goods for the home, garden and renovation in the 2022 ranking.

Which engine to choose to make a circular machine

Every owner would like to have a device for working with lumber in a garage, in a country house, in a private house or when renovating a city apartment. But even a hand-held circular saw costs from 10,000 rubles. In this article we will talk about how a circular machine is made from an engine from a washing machine that has served its life. This homemade electric saw, assembled with your own hands at home, is capable of unraveling boards five centimeters thick. At the same time, it weighs just over 20 kilograms and is easily transported in the trunk of a car.

https://www.youtube.com/watch?v=5sBGdbhsLps

A circular saw is always useful on the farm: at the dacha or in a private house. But not everyone can afford a good expensive tool, and a cheap analogue quickly breaks down. The way out of the situation is to make a circular saw with your own hands. For example, you can make it from an engine from an old automatic washing machine, which is a shame to throw away and takes up space.

The working motor from an automatic washing machine should not gather dust in the garage. Even a home craftsman can find a use for it. We will tell you how to make a homemade circular from a washing machine engine.

This tool will help you cut wood and master carpentry.

However, be careful: careless use of a homemade machine can lead to unpleasant consequences. Therefore, before you take on a job, you must be completely confident in your abilities.

A 350 mm disk will require 1 kW of energy to start. A disk with a diameter of 170 mm will require about 500 W. Therefore, you can install a motor from an old washing machine.

In the washing machine, the speed is controlled by a tachometer, which is controlled by a control module. But it is impossible to connect a module to the circular, so install a voltage regulator. Use the wiring diagram to correctly install the motor.

You have figured out which motor is needed and how to connect it. Now consider the design diagram of a circular saw.

The main load will be on the moving elements. This:

- saw and electric motor shaft;

- motor pulley and saw shaft;

- drive belt.

Let's look at the features of each of them:

- The drive belt does not have to be taken from the washing machine; other belts can be used. The main thing is that they have serrations, like a V-belt.

- Flow grooves need to be made on the small pulley. The belt will cling to them during operation, which will prevent slipping.

- A larger disc is welded onto the large pulley, which will prevent the belt from slipping off.

- To fasten the circular saw, use a shaft into which it is mounted, as well as a washer and nut, which are used to secure it. It is recommended to select or take this kit from the factory to ensure the drive is secured as securely as possible.

When creating a design, you need to take into account that it is designed for a three-hundredth disk. Of course, a self-made circular machine is only suitable for household use. Therefore, try not to overload the engine.

Often such machines are stored in the yard, on the street, so protect the electrical part from moisture.

The frame is made of metal sheet 3 mm thick. Before making the frame, prepare a 30 mm metal corner.

As shown in the photo above, the craftsman installed the frame into homemade pipe racks. Now it is possible to adjust the height of the device. However, it is recommended to make a solid frame by welding pieces of corner together. Strong vibration over time loosens the fastenings of bolts and other elements.

We suggest you read: Zanussi washing machine does not turn on reasons

Please note that the mini circular saw varies in size. It is much smaller than usual and can fit into a pantry when stored.

A washing machine is a useful thing in the household. However, over time the device breaks down. There is an element in the washing machine that should not just be lying around in the garage - this is the motor. It makes an excellent circular saw.

Refrigerator

This is a great place to look for new home appliances. Products available in store categories: refrigerators, washing machines, electric stoves, microwave ovens and electric kettles. Buyers receive a factory warranty on all equipment, and a promotional code on the website will help you save up to 30% when ordering.

A user-friendly user interface allows you to quickly find the things you need for your kitchen and bathroom. Large, clear images and detailed characteristics will help you make the right decision before purchasing. Subscribe to the newsletter so you don't miss promotions and save your family budget.

How to make a circular saw drive

What engine does it need? It depends on what kind of automatic washing machine you have gathering dust in your storage room. It is better to take an engine, of course, with more power.

Although for a mini-circular, which is assembled in a similar way, a less strong one will do. Its difference is its light weight and the installation of the mechanism not on a stationary base, but on a wooden box. It serves as both a bed and a chip storage.

Preparing the motor

The collector motors of washing machines have several outputs. How to determine and connect the ones you need? We use an ohmmeter to test the second coil, selecting the one with the highest resistance.

We check other connections at the commutator and brush outputs.

We also find, measure and mark the speed sensor wires. They may be located inside the case, then disassemble it.

We connect the first output of the collector and one from the coil. The second one, with the remaining coil contact, is connected to the network. We are doing a test run.

To enable reverse rotation, the contacts are swapped.

Adjusting the speed

In order for a circular saw to process materials of different sizes, a device is needed to add or reduce the number of revolutions.

In the device from which we removed the motor, this function is performed by a tachometer operating through an electronic module. The latter will not work with our device.

The simplest thing is to use a dimmer or trigger from a hand-held electrical appliance to control the voltage supply and, accordingly, the shaft rotation speed. The connection goes like this:

- one coil terminal is terminated with the armature terminal;

- the second - for mains power;

- the remaining armature output through the dimmer is the same;

- Having checked the connection, we test it.

A more complicated option is using a tachometer. It will allow you not to lose electric drive power during operation. It must be connected through a microcircuit, which will equalize the power as the load on the shaft increases. If it is impossible to buy a ready-made one, using the TDA 1085 board diagram and the list of necessary parts, you can assemble it yourself.

Motion module

It consists of:

- Shaft for attaching the cutting disc.

- Motor shaft.

- Transmission belt.

- Motor pulley.

- Saw pulley.

To simplify things, you can assemble the device without bearings.

Through a drive belt placed on a pressed-in smaller pulley, the shaft transmits rotation to the saw blade. The pulley must have notches so that the serpentine belt does not slip on it.

A small protrusion is welded onto the edge of the larger pulley to prevent the drive loop from slipping.

The disk must be securely fastened to the shaft, otherwise it will come off and cause injury.

Bore the holes for fixing the engine to adjust the belt tension.

Starting device

You can choose a switch for a household electrical appliance for it. It’s better to install a push-button one from a Soviet washing machine.

Its connection diagram is as follows:

- At the input it is powered by two contacts, and inside one wire bifurcates.

- Of the three outputs, one will be phase, the second zero.

- The third, through a capacitor, will give a shifted phase.

This connection will provide better launch. But after it it is necessary to disconnect the capacitor.

bed

For a welded frame, a rectangular twenty-millimeter profile is suitable.

The drive and motion module are securely attached at the bottom. This design leaves the upper platform free.

According to the testimony of the craftsmen who made such machines, they spent about six months on it. But we are quite satisfied with the equipment. So go for it too!

Video:

Bad 6

Interesting 15

Super

Options for making a woodworking machine

Today, there are a large number of ways to make a stationary circular saw. Angle grinders, hand drills, screwdrivers, and many other tools are used as drives for them.

The most common drive options are:

- drive from a hand-held circular saw;

- machine with a motor from a washing machine.

How to make a stationary sawing machine - step by step guide

When manufacturing, you will need a small amount of material and hand tools, which, as a rule, are in everyday use of every owner. This includes:

- wooden blocks;

- OSB or plywood sheet;

- fastening hardware;

- drill with a set of drills;

- hand-held circular saw.

A sheet of plywood or OSB with a thickness of at least 20 mm and dimensions of 1100 x 880 mm will be used as a desktop. To make a stationary machine for cutting wood, you must perform the following steps:

- Place the hand-held circular saw in the intended installation location and trace the outline. After this, make a recess of about 12 mm.

- Drill holes along the contour of the recess for the M8 mounting bolts and use them to fix the hand-held circular saw on the back base of the table.

- Install a socket next to the saw and connect the saw to it, make a groove in which the saw blade will be located.

- Make a frame for the perimeter of the table and legs of the required length from a wooden block. Install a folding box at the place where the saw is attached, constructing it from thin plywood. Install a power button at the end of the table, having previously connected it to a socket.

- Make a hole in one of the corners of the box to connect a vacuum cleaner. To fix the hose, you can use a plastic fitting with a diameter of 50 mm.

- The box is fixed to the table using metal corners and screws.

- Then, across the table it is necessary to cut 2 longitudinal grooves to install a 150x100x10 mm channel. Since the work table will be covered with 4 mm thick PVC sheets, the depth of the grooves under the channel should be 6 mm.

- After this, you can begin making pushers. Hardwood slats are used as guides. The pusher frame can be made of laminated chipboard with a thickness of 16 mm.

After watching the video, you can familiarize yourself with detailed step-by-step instructions for making a stationary circular saw from a hand-held circular saw.

Homemade cutting machine driven by a washing machine

Another common option is to use an asynchronous motor from a washing machine as a saw blade drive. For domestic use, a low-power electric motor is suitable, for example the engine from an old Malyutka washing machine or any modern automatic machine.

Sawing machine from a drill at home

You can also make a good circular saw using a hand drill. The costs for materials are minimal, and almost everyone in the house has a drill. You will find more details about all the nuances and a step-by-step algorithm for making it yourself in our article on how to make a circular saw from a drill.

Petrovich

User selection

The Petrovich construction tools store was founded in 2003. They are known as a trading house for building materials, plumbing, workwear, doors and electrical equipment. The cost of delivery within the country starts from 150 rubles to the point of delivery of orders. A competent support service will help you with any questions you may have.

Petrovich sells construction tools from popular world brands: Bosch, DeWalt, Black & Decker, Hitachi and Karcher. There is a wide selection of tools for beginners and professionals on store shelves. Drills, grinders, spray guns, circular saws and planes - low prices with the ability to order online with home delivery.

Petrovich guarantees the quality of the goods and provides the necessary certificates. If the purchase is not suitable, you can return the product to the online store within 180 days. With the arrival of summer, garden tools become relevant: lawn mowers, trimmers, chainsaws, welding equipment and generators for work in the country house or garden.

Leroy Merlin

Leroy Merlin offers excellent prices on construction tools from a large catalog of electrical goods. Popular sections include angle grinders (grinders), circular saws, welding machines, high-pressure washers and construction vacuum cleaners. The cost of carpentry tools starts from 150 rubles, and the price of high-quality tools reaches 15,000 rubles.

The Leroy Merlin catalog presents equipment options for painting, tile laying, metal scissors and wood saws. Personal protective equipment is well suited in combination with any manual or electrical appliance. You can personally add your order to the cart on the website and order delivery from the nearest store to your apartment.

Building blocks, plasters, drywall, thermal insulation and metal tiles are just a small part of the available finishing material options. We recommend purchasing construction tools from the Leroy Merlin online store so that they serve reliably for many years.