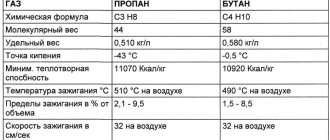

When choosing technical gas, enterprises, first of all, are guided by the fact that the organization of various technological processes requires flammable gases with different characteristics. The main ones are flame power and temperature, oxygen consumption and areas of gas use.

For metal cutting, welding and other similar processes, an indicator such as flame power plays an important role. Also of great importance is the ability of the flame to transfer energy to the exposed material. In this regard, technical acetylene is better than propane, since its use allows you to create a flame that will quickly heat the metal surface to the required temperature.

The time it takes to complete the work depends on the temperature that the flame produced using technical gas can reach. Therefore, it is very important for the surface heating process. In this regard, again good results can be achieved using acetylene. While propane flame temperatures can reach 2,800 degrees Celsius, acetylene heats up to 3,100 degrees Celsius. However, acetylene is significantly inferior to propane in terms of energy reserve: 55 versus 95 MJ/m3.

To use technical gases, different amounts of oxygen are required. For acetylene, 1.1 cubic meters is enough to form a flame normal for the work, and for propane, almost four cubic meters of oxygen are required.

Another positive feature of acetylene is that its composition can be changed to result in a reducing or neutral fire. All other gases, including propane, at the temperatures required for industrial purposes, can only form an oxidizing type flame. Therefore, welding cannot be done with propane.

But if it is necessary to carry out general heating of a metal surface, then you cannot do without propane. This thermal process requires gas with a significant energy reserve per cubic meter. Propane gas has these properties.

To summarize, we note that acetylene is good because it can be used in oxidative, neutral and reduction processes when hardening, cutting and welding metals. It is highly effective in carrying out processes that need to be interrupted. It can also be used on contaminated surfaces.

Hydrogen

Below is only background information about hydrogen; for more detailed information, read the article density, formula, mass, production and other characteristics of hydrogen

Hydrogen H2 under normal conditions is a flammable gas, colorless and odorless. This is one of the lightest gases, it is 14.5 times lighter than air. Hydrogen is capable of forming explosive mixtures with air and oxygen in certain proportions. Therefore, when welding work, it is necessary to strictly observe labor safety rules. Hydrogen is produced by decomposing water with electric current. Hydrogen is delivered to the welding site in steel cylinders in a gaseous state under a pressure of 15 MPa. Hydrogen cylinders are painted green. Hydrogen used for welding must meet the requirements of GOST 3022-80. The hydrogen-oxygen flame is blue in color and does not have clear outlines of the flame zones, which makes it difficult to regulate.

Every year at the end of summer, propane prices skyrocket. This year was no exception. The situation was also complicated by the fact that the end of quotas for propane supplies to the domestic market of the Russian Federation coincided with the next round of crisis in relations between Russia, Ukraine and Europe, which prompted nimble European merchants to actively participate in the purchase of liquid “blue fuel” in the Russian Federation. And so the question arises: “Isn’t it more profitable now to use acetylene where it is replaced with propane precisely for the purpose of saving?”

The combustion temperature of propane in a cutter is 2000-2500 degrees Celsius, for acetylene it is 3260. The time it takes to heat the metal to the melting point during oxygen cutting with propane is much longer. Cutting lightly alloyed and thick steels is possible only with acetylene. An acetylene cylinder, despite its higher cost, has much greater survivability compared to a propane one. The use of valve cutters that cut off the heating mixture during the actual cutting will add further savings on gas. The table below shows the characteristics from the data sheet of the P1 type cutter. From this table it can be seen that not only propane, but also oxygen is consumed in a propane cutter by 30% more than in an acetylene cutter. And this despite the fact that the difference in the price of refilling an acetylene and propane cylinder already differs by only the same 30%.

Maybe it makes sense to look into the far corners of the warehouse, pull out the dusty acetylene cylinders, change the mouthpiece in the cutter from propane to acetylene and give it a try? And if we also remember that you can also cook with acetylene? And that an acetylene torch costs much less than a semiautomatic welding machine. And as a welding wire in an emergency situation, when every minute counts, you can use a regular electrode, which you can simply “tap off the coating”, rather than buying a 5 kg reel. And there is no need to rush for carbon dioxide or a mixture. Maybe it's time to start saving?

| Technical specifications | ||||

| Thickness of cut steel, mm | up to 15 | 15-50 | 50-100 | |

| Mouthpiece internal | 1A/1P | 3A/3P | 4A/4P | |

| Outer mouthpiece | 1A/1P | |||

| Inlet pressure kgf/cm2 | Oxygen (nominal) | 3,0-3,5 | 4,0-4,2 | 4,5-5,0 |

| flammable gas, A/P | 0,03 — 1,2/0,01 — 1,5 | |||

| Consumption m3/hour | oxygen when working on A | 2,6 — 2,8 | 5,4 — 5,8 | 8,6 — 10,2 |

| oxygen when working on P | 3,2 — 3,5 | 7,7 — 8,5 | 11,1 — 13,1 | |

| flammable gas, A/P, no more | 0,26/0,4 | 0,33/0,48 | 0,36/0,56 | |

| Weight of cutter, kg, no more | 0, 75 | |||

| Cutter length, mm, no more | 500 | |||

| The internal diameter of the attached sleeves is 6 or 9 mm | ||||

Coke gas

Coke oven gas is a colorless flammable gas with the odor of hydrogen sulfide. Coke oven gas is produced by producing coke from coal; it consists of a mixture of gaseous combustible products of hydrogen, methane and other unsaturated hydrocarbons. Mainly used for cutting steels, welding and soldering low-melting non-ferrous metals. For welding and cutting, coke oven gas is used, purified from sulfur compounds and resinous substances. For complete combustion of 1 m3, 0.9 m3 of oxygen is required. Coke gas is supplied to the welding and cutting site through pipelines at a pressure of 1.3-1.5 kPa.

Differences

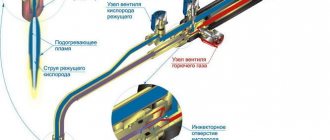

The main difference between a propane burner and an acetylene burner is based on the different calorific values of the gases and different proportions when creating the working mixture . The proportions of oxygen and acetylene are 1:1, oxygen and propane are 3.5:1. In an acetylene burner, the combustion rate of the mixture is significantly higher.

Accordingly, the cross-section and shape of the injection channels, working chamber and nozzle differ.

When propane is supplied to an acetylene burner, unstable combustion is observed, the torch power decreases, and backfire is possible. This type of use is unacceptable and may result in a serious accident.

City gas

City gas is a compound flammable gas. Typically, the main component of city gas is natural gas, to which coke oven and generator gases are added. The composition of city gas is not constant; Moscow type gas has the following composition: methane (70-95%), hydrogen (up to 25%), heavy hydrocarbons (up to 1%), nitrogen (up to 3%), carbon monoxide (up to 3%), carbon dioxide (up to 1%), oxygen (up to 0.5%). City gas is delivered to the welding site through pipelines. As a substitute for acetylene, it is used for cutting steels, welding and soldering low-melting non-ferrous metals.

In-nozzle mixing

In devices with intra-nozzle mixing, the mixture is formed in slotted channels between the outer sleeve and the inner mouthpiece. The supply of cutting oxygen is carried out by a lever valve, and the heating and combustible gas is supplied by regulators installed on the handle.

This equipment is available in 3 versions: for working with acetylene, propane and natural gas. Since the gas is mixed not at the handle, as in injection devices, but at the head, such devices have an increased level of safety. At the same time, this principle of operation requires a more complex design, which leads to an increase in the cost of the device. Also, for stable operation, an increased pressure of combustible gas is required - from 20 kPa.

Devices with intra-nozzle mixing

Propane

Technical propane is a colorless flammable gas with a pungent odor, consisting of propane C3H8 or propane and propylene C3H8, the total content of which must be at least 93%. Propane is obtained by processing petroleum products. Under normal conditions, propane is in a gaseous state, and when the temperature decreases or pressure increases, it turns into a liquid state. Thus, at a temperature of 293 K, propane transforms into a liquid state at a pressure of 0.85 MPa. Evaporation of 1 kg of liquid propane produces 0.53 m3 of vapor.

Propane-butane mixture is a colorless flammable gas with a pungent odor and is a by-product of oil refining.

The mixture easily turns into a liquid state, for example, at a temperature of 233 K, a propane-butane mixture liquefies at atmospheric pressure. Liquefied gases are stored only in closed containers, since liquid evaporation occurs even at 273 K.

The density of propane-butane is greater than the density of air, so it is necessary to carefully monitor the tightness of equipment and communications to avoid the formation of an explosive mixture of gas and air below the room. Filling containers with propane and a propane-butane mixture, transporting them, as well as draining the gas must be carried out in accordance with the “Rules for the design and safe operation of pressure vessels” approved by Gosgortekhnadzor.

Propane-butane mixtures are widely used in cutting steel, welding and soldering low-melting non-ferrous metals, hardening, and gas welding of plastics. The mixture is delivered to the welding site in steel cylinders under a pressure of 1.6 MPa or through gas pipelines through a bypass ramp. When 1 kg of propane evaporates, 500 dm3 of gas is formed.

Injector and non-injector burners

In devices with an injector, oxygen enters the mixing chamber by forcefully drawing it in from the atmosphere through a special valve.

The flammable gas is supplied through an injector to the mixer from a cylinder under higher pressure and combines with oxygen. The formed composition is fed through the tip pipe into the mouthpiece. In this case, the pressure of the gas emanating from the mouthpiece channel becomes significantly less than atmospheric. In injection-free burners, both working gases are directed into the chamber under equal pressure (about 100 kPa). Instead of an injector, in devices of this type, an ordinary nozzle is installed, which is screwed into the tip.

A serious drawback of injection devices, despite their widespread use and demand, is the instability of the composition of the gas mixture, due to which it is not always possible to ensure consistently high-quality combustion.

Kerosene

Kerosene is also a product of petroleum refining and is a colorless yellowish liquid that evaporates easily. Kerosene used for welding and cutting metals must meet the requirements of TU 38.71-58-10-90. Kerosene is also used for welding and soldering low-melting non-ferrous metals.

So, we have learned that acetylene is the main combustible gas for gas welding, but other, less expensive gases are used for gas cutting, which allow the cutting process to be carried out without a significant loss in productivity and quality.

Classification of gas-flame welding torches

Gas burners are classified according to the method of supplying gases to the mixing chamber - injection and non-injector .

By power or combustible gas consumption - micropower with combustible gas consumption from 10 l/hour; low power, with a fuel gas consumption of 25-400 l/hour; medium power, with a flow rate of 400-2800 l/hour or high power, with a flow rate of 2800-7000 l/hour.

By type of combustible mixture - gas burners (flammable gas), liquid burners (flammable liquid vapor).

According to their purpose, torches are divided into universal (gas welding, soldering, heating, metal cleaning) and specialized .

Depending on the number of flows and method of application, burners can be single-flame - hand-held burners and multi-flame - along with single-flame ones, they are used in mechanized installations.

Acetylene welding torches

Burners for acetylene welding according to GOST 1077 are divided into four types according to power: G1 (micro-power), G2 (low power), G3 (medium power), G4 (high power). All burners are equipped with tips of different sizes and different diameters of the outlet channel. Replaceable tips are made of heat-resistant and heat-conducting materials - M3 copper, BrKh0.5 chromium bronze.

Before moving on to choosing a gas burner, you need to decide on its purpose and scope of application. In domestic conditions and in the garage workshop, low- and medium-power burners are most widespread. For example, single-flame universal low-power acetylene torches G2 are used for welding metal with edge thicknesses from 0.2 to 0.7 mm. G2 burners are equipped with four replaceable tips of different sizes.

Using medium-power G3 , products made of non-ferrous metals and alloys based on them, as well as cast iron, are welded. G3 torches can be used not only for welding, but also for surfacing, soldering or heating metal. The set of such burners already includes seven different nozzles. The thickness of the edges of the metal being welded is from 0.5 to 30 mm.

Injector and non-injector welding torches

The difference between injection and non-injector burners is in the method of gas supply. Injection systems are more common; the design of the injector, which is a hollow cylinder with a small diameter hole in the center for oxygen and radial holes for combustible gas, allows oxygen to pump (suck) the combustible mixture into the mixing chamber. In this case, oxygen is supplied under pressure, and the combustible mixture is freely pumped by the oxygen flow. The power of the welding flame in injection torches is adjusted using replaceable tips. The disadvantage of injection models is the relatively unstable flame due to the fact that the mixture of combustible gas with oxygen is not constant, the composition of the gas changes. Due to the low pressure of the combustible gas, the nozzle with the mouthpiece of the injection burner is prone to overheating.

In injection-free burners, oxygen and the combustible mixture are supplied at the same pressure (within 0.05-0.1 MPa) and mixed in a mixing nozzle. Non-injector burners, as a rule, have low power (acetylene torch G1 ). The amount of gas supplied to the combustion zone is regulated by valves, the flywheels of which are colored accordingly: the oxygen valve is blue, the valve for combustible gas is red.

Types of portable burners

Gas burners are devices that differ in design and purpose, but they are united by a common feature - they operate using gas.

Portable devices designed to operate from a small tube filled with propane-butane or other gas should not be confused with ovens or powerful welding units that operate from natural gas or a large cylinder.

We offer a brief overview of the main design elements of an inexpensive gas cartridge burner, which serves as an excellent example of a home device. It may be useful for repairs in the country or for a barbecue.

Using a compact device, you can quickly light a barbecue, heat bolts or nuts in the cold, melt plastic parts, and process heat shrinks. The flame temperature (up to +1300°C) is enough for soldering metal pipes.

This is an example of a burner type that is popular among users, but the range of devices is much wider. Let's look at the most popular types.

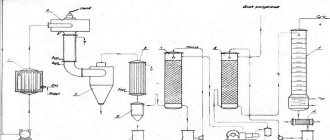

Production of acetylene by pyrolysis method

Pyrolysis acetylene is produced by burning methane mixed with oxygen in reactors at a temperature of 1300-1500°C. The result is a mixture that contains:

- acetylene - up to 8%;

- hydrogen - 54%;

- carbon monoxide - 25%;

- impurities – up to 13%.

Using a solvent (dimethylformamide), acetylene with a concentration of 99.0-99.2% is extracted from it. The remainder of the pyrolysis gases is used to produce ammonia and other products.

Acetylene is also produced by decomposing liquid fuels (oil, kerosene) using an electric arc discharge, which is called electropyrolysis.

Pyrolysis and electropyrolysis of acetylene in its properties is identical to acetylene obtained from calcium carbide, but is 30-40% cheaper.

Basic methods of maintaining the torch and filler material

Specialists use two ways of holding the instrument: “pull” and “pull”.

When driven from yourself, a wire is located in front of the burner. This method is used when welding structures of large thickness. In this case, the molten metal of the parts and additives simultaneously fills the weld pool.

This method requires the welder to ensure uniform mixing of the base and filler metal. If there is insufficient amount of wire melt, the seam becomes weakened.

With the “pull” acetylene welding method, the torch comes first, and when the base metal is melted, metal from the wire is added to the bath. Here you need to position the burner correctly.

It should go at an acute angle in relation to the parts. This method is the simplest. You need to heat the metal, remove a drop from the wire and stretch it along the seam. According to this principle, the seam leg is formed.

For greater convenience and to prevent the formation of burns, the burner is moved either in a crescent or in a circular motion.

A major role in the quality of the connection is played by the correct joining of parts and the absence of large gaps when welding thin sheets or pipes. It should be remembered that before acetylene welding, the parts must be grabbed in several places. On small diameter pipes, tacks are made after about 1200.

The performance of welding work is also influenced by the characteristics of the metal being welded.