To search for treasure in the ruins of a castle, fasteners in building structures and solve other practical problems, you can make a metal detector with metal discrimination with your own hands. This publication discusses the advantages and disadvantages of different designs. Practical recommendations will help you correctly assemble and configure a functional measuring device.

Making a simple metal detector is easy even for a novice radio amateur.

General structure of the metal detector

This device operates on the principles of changing the characteristics of the electromagnetic field when foreign objects appear in the work area. The classic scheme involves the use of the following components:

- a generator that creates oscillations in a certain frequency range;

- induction coil;

- receiver with an amplification path;

- signal decoding unit;

- visual and audio indicators;

- frame on which the working components of the installation are fixed.

Typical metal detector design

Coil

This functional element simultaneously emits and receives electromagnetic waves. To make a high-quality homemade product, you should study factory analogues. Experienced experts recommend paying attention to the following details:

- round models provide a larger coverage area;

- oval - more convenient to use;

- by installing a large coil you can increase the search efficiency (working depth) by 15-25%;

- small – provide a narrow radiation pattern, which simplifies the detection of several small objects;

- better uniformity of the cylinder-shaped working area is created by a double coil (DD);

- The ring-shaped coil has a cone-shaped radiation pattern.

Types of coils

Electronic circuit

In the simplest devices, a generator, a receiver, and a power supply are installed on one compact printed circuit board. Field changes are recorded using an audio frequency signal.

More complex metal detector circuits with discrimination provide dynamic processing of incoming information. Such devices are able to determine the difference between a steel screw and a silver coin. This selectivity greatly improves search efficiency because it automatically eliminates wasteful, time-consuming excavation work.

Discrimination

The discrimination mode of a metal detector is the ability to distinguish between metals. Thanks to it, the operator understands what is under the coil: iron debris or an interesting find of non-ferrous metal. Depending on the metal detector model, discrimination adjustment is carried out using a potentiometer, buttons or in the device menu. Through these controls, the search engine sets parameters that tell the metal detector which targets to ignore and which to voice. It is such a wonderful thing as discrimination that allows you to search in littered areas - plowed villages and tracts. Imagine if all signals rang the same way, be it a nail or a coin, what would it be like to search? However, when using metal separation, the search depth of the metal detector is “eaten up”.

Operating principle

Metal detector Terminator 3

The generator, together with the induction coil, creates a directed electromagnetic field of a certain shape. The entry of foreign objects into the work area changes the current strength in a closed circuit. This phenomenon is detected by the receiver. The greatest field disturbances are caused by objects with conductive and ferromagnetic properties.

In the processing unit, extraneous noise is eliminated and useful signals are isolated. They are then sent to display devices. The settings elements set the sensitivity and other parameters of the detector.

Which wire is better for search coils?

The wire for winding the coils does not matter. Anything from 0.3 to 0.8 will do; you still have to slightly select the capacitance to tune the circuits to resonance and at a frequency of 8.192 kHz. Of course, a thinner wire is quite suitable, it’s just that the thicker it is, the better the quality factor and, as a result, the instinct. But if you wind it 1 mm, it will be quite heavy to carry. On a sheet of paper, draw a rectangle 15 by 23 cm. From the upper and lower left corners, set aside 2.5 cm and connect them with a line. We do the same with the upper right and lower corners, but set aside 3 cm each. We put a dot in the middle of the lower part and a dot on the left and right at a distance of 1 cm.

We take plywood, apply this sketch and drive nails into all the points indicated. We take a PEV 0.3 wire and wind 80 turns of wire. But honestly, it doesn’t matter how many turns. Anyway, we will set the frequency of 8 kHz to resonance with a capacitor. As much as they reeled in, so much they reeled in. I wound 80 turns and a capacitor of 0.1 microfarads, if you wind it, say 50, you will have to put a capacitance of about 0.13 microfarads. Next, without removing it from the template, we wrap the coil with a thick thread - like how wire harnesses are wrapped. Afterwards we coat the coil with varnish. When dry, remove the spool from the template. Then the coil is wrapped with insulation - fum tape or electrical tape. Next - winding the receiving coil with foil, you can take a tape from electrolytic capacitors. The TX coil does not need to be shielded.

Remember to leave a 10mm GAP in the screen, down the middle of the reel. Next comes winding the foil with tinned wire. This wire, together with the initial contact of the coil, will be our ground. And finally, wrap the coil with electrical tape. The inductance of the coils is about 3.5 mH. The capacitance turns out to be about 0.1 microfarads. As for filling the coil with epoxy, I didn’t fill it at all. I just wrapped it tightly with electrical tape. And nothing, I spent two seasons with this metal detector without changing the settings. Pay attention to the moisture insulation of the circuit and search coils, because you will have to mow on wet grass. Everything must be sealed - otherwise moisture will get in and the setting will float. Sensitivity will worsen.

Types of metal detectors

DIY metal detector

Products in this category are divided according to their intended purpose and other important characteristics into the following groups:

- ground (standard and deep);

- underwater – with reliable sealing of electronic components;

- discriminators – detectors that provide selective search;

- highly specialized models for searching for precious metals;

- security and military;

- industrial series – designed to control individual technological operations.

Schemes of homemade MI

Factory-made metal detecting equipment is presented on the market with quite expensive professional-level electronic systems, so enthusiasts constantly exchange information on how to make a homemade metal detector at home with minimal financial costs. Step-by-step instructions for assembling and debugging the device allow you to create a fully functional metal detector from available radio components. Metal detectors, including a do-it-yourself mine detector, the circuit of which is identical to those developed for standard MIs, are made using transistors and microcircuits. The kit for DIY circuits also includes:

- capacitors of various types: ceramic, film, electrolytic;

- resistors;

- resonators;

- controllers.

Additional Information. Quite often, circuits of amateur metal detecting equipment use the NE 555 microcircuit, which is a universal timer that generates single and repeating pulses with stable timing characteristics.

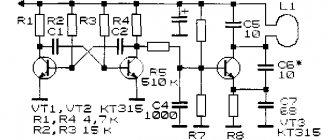

A worthy competitor to a metal detector on microcircuits is a metal detector on transistors, in which signals are generated using transistors KT-361 and KT-315 or similar radio components produced since Soviet times.

Main settings

To determine the appropriate criteria for a homemade design, it is necessary to study the basic technical parameters.

Detection depth

The principle of operation of the metal detector

This data is not always provided in the accompanying documentation. Even when the depth is indicated in the technical data sheet, this value should not be understood as a certain value. The fact is that for control measurements they use a uniform soil composition and maintain stable temperature and humidity. In a real situation, natural and other external factors will significantly worsen the results obtained under ideal conditions.

For your information. High-quality factory metal detectors are capable of detecting a product made of conductive material at a depth of 1.5-3 m. “Deep” modifications operate up to a maximum of 5-6.5 meters.

Operating frequency

You can increase the search depth by using a reduced frequency. In this case, the selectivity of the work process is significantly deteriorated. However, long waves bend around small objects, which is accompanied by a deterioration in sensitivity.

For your information. In professional metal detectors, the user can choose from more than two dozen different frequencies. With such equipment, the choice of the optimal research mode under certain conditions is simplified.

Not all metal trash is “garbage”

From all of the above, we can conclude that metal discrimination is an indispensable function for seekers. But objects that seem like trash at first glance may not always be useless. There are often cases when very valuable and ancient things are thrown into the trash. For example, a nondescript, rusty iron ax was initially discarded as trash, but after cleaning and appraising, the ax was found to date back to the 2nd century BC and was valued at several thousand dollars. Thus, it is best to take a find of value that you doubt to a specialist for evaluation, and then make a decision about its future fate.

Self-assembly of a metal detector

You won't necessarily get the perfect look when creating a product with your own hands. Nevertheless, it is not too difficult to create good functionality on a modern element base. Below is a model with a discrimination function. She is able to distinguish between the aluminum cap and foil of a cigarette pack, cheap alloy pennies and valuable gold coins.

Discrimination table

Design

The coil is made of two spiral windings (18 and 24 turns) with outer radius dimensions of 21 and 16 mm, respectively. To apply markings and create a frame, a base made of a material with non-magnetic properties is used. Sealing with epoxy resin or another compound will extend the service life.

The control unit is assembled according to this electrical diagram

Materials, parts and blanks

A standard transformer copper wire with a diameter of 0.6-0.9 mm is suitable for the coil. The control unit is assembled using standard microcircuits. The main components are the processor and the MCP3201 frequency converter. Zener diodes, transistors and other electronic components are indicated in the drawing (picture above).

Assembly procedure and design

To securely fasten the functional blocks, select a suitable strong forestay. It is recommended that the electronics unit be placed in a sealed housing to prevent short circuits in adverse weather conditions. Design is carried out taking into account personal preferences, skills and abilities.

Programming the control unit

A specialized programmer is used to flash the device. It's easy to create a printed circuit board yourself. 5 V power supply can be provided from a standard computer USB port.

Electrical circuit of the programmer

Assembly

During the assembly process, special attention is paid to the tightness and reliability of fastening of individual components. You should remember about difficult operating conditions in operating mode and possible shock impacts during transportation. The collapsible design will simplify transportation and storage.

Digital object identification

A useful thing in a metal detector that helps you identify a find without digging it up. Together with the audio response, it makes it clear the approximate metal and shape of the signal source. This function displays the electrical conductivity index of an object detected in the ground. Different metal detector manufacturers use their own conductivity scales. In Garrett devices there is one, in Minelab there is another. Moreover, on metal detectors of the X-Terra series, the VDI numbers differ from the same numbers on the Equinox. But on all devices the principle is the same - the higher the number, the more interesting the find can be. For example, silver rubles, nickels of Catherine II and other large coins sound great and show high electrical conductivity indices. But small Soviet coins, especially those made of copper-nickel, give a low electrical conductivity number.