The welding consumables market is replete with many brands of coated electrodes . On the one hand, this makes it possible for experienced welders to choose the best option for welding work, on the other hand, it is difficult for beginners to understand this large number of different items. To help a novice welder, there is advice to immediately decide on the coating of the consumable. Essentially, retail outlets offer consumables with basic and rutile coatings.

If you have to weld a critical structure, where increased demands are placed on the ductility and strength of the seam, then the UONI brand with a base coating will be the best option to choose. Here we will not talk about the technical characteristics of brands. For more information about the characteristics, see the reference book on the pages of these brands, links to which are presented in the text.

UONI or rutile (MP3, ANO-21, OK 46 ESAB, OZS) - what is the difference

All brands of the listed electrodes are the same in application - they are used for welding carbon and low-alloy steels, widely used in industry and everyday life. The difference between SSSI and their rutile counterparts is the manufacturability of the welding process and the technical parameters of the connection .

If there is a need to repair or install by welding the frames of homemade equipment (circular saw, pipe bender and other similar devices), the horizontal bar on which you are going to spin the “sun,” then it is better to use electrodes with a basic coating. Welding seams made with these consumables guarantee more reliable and safe operation of these devices than using technology with rutile consumables.

If you do not have the skill to work with consumables with a basic coating, there are many welding jobs using rutile electrodes. The ease of initial and re-ignition of the arc, the absence of the need to control its length, gives beginners the opportunity to experience belonging to a contingent of people who know welding. At the same time, unlike consumables with a basic coating, there is no need to clean the welded edges from rust, coating residues and other contaminants. In a private house, it is sometimes necessary to repair leaking pipelines - the presence of moisture is not an obstacle to repair welding work using rutile consumables. It is better for beginners to weld thin-walled workpieces such as, for example, profile pipes with rutile electrodes.

Protective covering

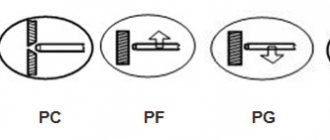

Electrodes differ in the type of coating used. There are four types of coatings:

- main or SSSI;

- cellulose;

- rutile;

- sour.

Rods with cellulose and base coating create elastic, reliable, impact-resistant seams when carrying out welding work with direct current. Rutile with acid coating are universal. Coatings are used for welding with both direct and alternating current.

Electrodes coated with acidic coating are toxic. Work with them is carried out in closed spaces only when the rooms are equipped with good forced exhaust. Rods coated with rutile, which has a bluish or greenish tint, are easy to ignite. This parameter remains unchanged when operating the inverter at low open circuit voltage.

Advantages of UONI 13/55 over rutile

Main advantages of SSSI.

The amount of slag produced is small , it is as fragile as glass and is easy to knock down. With rutile electrodes, the slag is plastic, making it more difficult to remove.

The weld seam made by UONI 13/55, due to its good fluidity, is clearly visible to the welder , which facilitates its high-quality formation - the seam is smooth and beautiful. Rutile electrodes form a fairly large amount of slag, which makes it difficult to control the quality of the weld, which creates conditions for the formation of welding defects (lack of penetration and others).

The strength characteristics of a weld made by UONI 13/55 exceed the corresponding parameters of a joint made with rutile electrodes.

UONI 13/55 is recommended for use when welding long-length seams without separation. (There is an opinion with which we do not entirely agree.) Such welding joints using this technology can be difficult to make with rutile electrodes, and frequent interruptions for re-ignition affect work productivity.

Electrode diameter

With increasing wall thickness of the metal surface, the required time for welding work increases. The thicker the surface, the larger the diameter of the electrodes used. Rods with a thin diameter burn out very quickly and are most often used on tacks. Working with them requires a certain skill in welding.

“Troika” (rods with a diameter of 3 mm) is suitable for welding structures and elements with a thickness of 3-4 mm, “four” - for elements with a thickness of 4 to 9 mm, “five” - for elements with a thickness of 9-10 mm. For areas where major sealing is not required, rods with a diameter of 0.5-2 mm can be used. Profile structures for support and assembly can be welded using electrodes up to 2 mm.

Advantages of rutile over SSSI 13/55

The main advantages of rutile electrodes (MP3, ANO-21, OK 46 ESAB, OZS) .

Rutile electrodes are easy to ignite both at the beginning of work and if re-ignition is necessary to continue work. Easy ignition makes it possible to work at low current , which allows you to cook thin-walled workpieces without burning (this method is in the arsenal of beginners). The use of tack welding technology with rutile electrodes is based on problem-free re-ignition.

Changing the arc length when working with rutile electrodes is not critical for the stability of the technological process . UONI 13/55 operate only on a short arc, which can only be maintained by experienced welders.

Rutile electrodes do not require careful adjustment of the welded edges to each other; there is no need to clean them from rust, remnants of previous coatings and other contaminants. UONI 13/55 on a dirty and poorly mated surface to be welded will fade and stick to it.

Rutile electrodes are less demanding on the power source than consumables with a basic coating. Welding is performed by them both on direct current and alternating current. UONI 13/55 produces a high-quality weld only with direct current of reverse polarity.

Electrodes for inverter

They are electrically conductive metal rods (cores) with a special protective coating - coating. The arc temperature during welding causes the core to melt. This process is accompanied by burning and melting of the coating. The combustible coating turns into a gas cloud, blocking the access of oxygen. The melting part of the coating becomes liquid, covers the molten metal with a thin layer, and protects it from interaction with oxygen.

The presence of chips on the protective coating is unacceptable. Violation of the coating does not allow achieving uniform heating and high-quality execution of the seam. In order for the arc to be in the center, you need to choose electrodes whose tips have a coating thickness that is uniform on all sides. The coating must be dry. Electrodes with wet coating do not ignite easily. You can dry them, but this will reduce their performance characteristics.

UONI 13/55 and LB – 52U

Consumables UONI 13/55 and LB-52U are essentially, in the context of our article, not absolutely complete, but analogues, since in addition to their general applicability for welding carbon and low-alloy steels, they have similar welding characteristics due to the similarity of the coating material related to the main coating. Some differences occur due to differences in production technology between Russian and Japanese manufacturers.

Core

Consumable type metal rods used when working with an inverter are selected in accordance with the type of metal of the parts and structures being welded. The welding wire from which the electrode core is made must comply with state standards.

There are three types of electrodes for inverter devices: alloyed, highly alloyed and carbon. Each of them is made from a corresponding type of welding wire. When working with high-alloy and stainless steel, experts recommend using rods TsL-11, carbon steel - ANO-21, UONI-13/45, MR-3S, cast iron - OZCH-2, low-carbon steel - ANO-4 and ANO-6.

Advantages of LB – 52U over SSSI 13/55

Japanese consumables LB-52U perform welding on both direct and alternating current, unlike UONI 13/55, which operates only on direct current.

Deeper penetration of the seam with the LB-52U electrode makes it possible to increase the strength of the reverse side of the seam.

The ability to perform high-quality hermetic one-sided welding is a distinctive feature of the LB-52U brand in comparison with analogues, including UONI 13/55. Important: there are many fakes on the market under the LB-52U brand that do not match the quality of the original. Here you should find a reliable seller and use his products.

What types of electrodes are there?

Conventionally, rods for working with an inverter-type welding machine are divided into two categories. The former are intended for complex and critical work, while the latter can be used when welding in less demanding and simple areas. The first group consists of UONI melting-type electrodes, and the second group consists of ANO, MP-3.

ANO brand electrodes are chosen for performing simple welding for domestic needs. They are suitable for working with almost all types of inverter welding machines. They are most widespread among home and novice craftsmen. Electrodes of the MP-3 brand are considered unpretentious and universal. They can weld wet, rusty, poorly cleaned metal surfaces.

The SSSI brand is more “capricious”, it requires certain skills, but it allows you to weld surfaces of any complexity together and obtain the most dense seams. Electrodes in this category are often chosen by professionals. A novice welder with no actual experience will find it difficult to work with them.

Usage

ANO-21 welding electrodes are suitable for types of steel: from “St3kp” to “St20k”. They are used both when working with structural and carbon steel. The thickness of the metal that can be worked with is no more than 5 millimeters.

The type of connection (corner, butt, lap) does not matter for ANO-21 rods. It is possible to work with them in any spatial position, even vertically when forming a seam from top to bottom.

These rods will cope with both simple home or training manipulations and industrial needs. As a result of the work, the resulting seams will meet all quality requirements, despite the spatial position during the welding process.

General recommendations for choosing electrodes

You need to purchase rods only in specialized stores that guarantee the quality of the products offered. This is due not only to the characteristics of the proposed electrodes, but also to compliance with the rules for their transportation and storage, and the availability of all necessary documents and certificates. Damp elements can be dried, damaged ones cannot be used.

All necessary information about the electrodes is indicated on the packaging. It is recommended to choose welding rods with the lowest slag rate. Electrode consumption is no less important. The parameter indicator is also written in the labeling. Please note that the value may change upward. It depends on the purpose and quality of the surfaces being welded.

Welding rods are purchased according to their purpose. If the electrodes used are intended for another type of welding, the result of the work done will be of poor quality, and its safety indicators will sharply decrease. It is also necessary to take into account the area of application of the welding machine.

If the inverter is used for domestic needs, electrodes for them are selected with a diameter of 2 to 4 mm. To “grab” metal structures, electrodes of the MR and ANO brands are suitable. The quality will not cause any complaints. To weld utility forks, for example, water supply or heating pipes, it is necessary to use SSNI rods that ensure the reliability of the resulting seam.