Electrodes brand UONI-13/45 – features

The main purpose of the material is welding parts made of low- or medium-carbon steel during the installation of particularly critical structures. Thanks to these electrodes, a seam with increased ductility and impact strength is obtained. The created structures can be used for decades at low temperatures. A typical example is pipelines laid in the northern latitudes of Russia.

High ductility and impact strength of the weld metal are ensured due to the main coating of the rod:

- the coating contains calcium fluoride (CaF2);

- During the welding process, hydrogen, which is harmful to the metal, binds with fluorine into a volatile compound and evaporates from the metal surface.

Thus, the amount of hydrogen in the metal is reduced to a minimum. Thanks to this, hot cracks are eliminated, and the risk of cold cracks (due to hydrogen diffusion) is also practically reduced to zero. Thanks to these same properties, the seam does not crack in a hydrogen sulfide environment. This allows the pipes to be used not only in northern climatic zones, but also in areas where there are deposits with a high content of hydrogen sulfide (oil and gas).

UONI-13/45 (NAKS, RRR, RS) 5 mm (6 kg) Current - constant, reverse polarity

RUB 177.96 ? with VAT per 1 kg.

UONI-13/45 (NAKS, RRR, RS) 5 mm (1 kg) Current - constant reverse polarity

RUB 195.96 ? with VAT per 1 kg.

UONI-13/45 (NAKS, RRR, RS) 4 mm (6 kg) Current - constant reverse polarity

RUB 177.96 ? with VAT per 1 kg.

UONI-13/45 (NAKS, RRR, RS) 4 mm (1 kg) Current - constant, reverse polarity

RUB 195.96 ? with VAT per 1 kg.

Results and conclusions

That's all. We haven't talked about everything. For example, how the electrodes are welded and deciphered. But these are big topics that deserve separate articles.

We have provided only basic information about SSSI products to make it easier for you to select the rods you need. Don't forget to ask for all the necessary documentation when you select tools.

What do you know about UONI brand electrodes? Have you ever used them? What models have you worked with? Share these stories in the comments. Productivity at work!

UONI-13/45 – characteristics

The standard in accordance with which UONI-13/45 electrodes are produced is GOST 9467–75. The material of the rods is steel grades SV08A and SV08.

- The electrodes have a basic (calcium fluoride) coating.

- Temporary tensile strength – 460 MPa.

- Yield strength – 350 MPa.

- Deposition rate – 9.5 g/Ah.

- Surfacing productivity – 1.3 kg/h (for d 3 mm).

- Electrode consumption per 1 kg of deposited metal is 1.6 kg.

- The type of current used in welding is constant, reverse polarity.

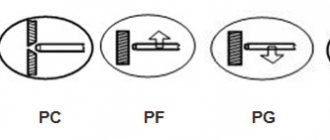

- The spatial position of welding is any except for vertical downhill.

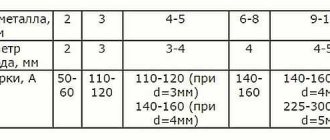

- Products are manufactured with a diameter of 2, 2.5, 3, 4, 5 mm.

Typical chemical composition of the deposited metal: C - 0.09%, Mn - 0.57%, Si - 0.25%, S - 0.014%, P - 0.017%.

ESAB OK 46.00

Some of the most popular electrodes are coated with rutile-cellulose, which are not so sensitive to metal contamination. These electrodes are convenient for welding even unprepared metal with severe rust.

These electrodes are also not afraid of moisture, since they are completely undemanding to drying and calcination. Easy separation of slag in the weld pool and excellent strength characteristics of the seam have made OK 46.00 electrodes one of the most popular among welders.

Advantages:

- Optimal combination of cost and quality;

- Possibility of welding even poorly prepared metals;

- Ease of welding thin-walled products at minimum current.

Flaws:

- Despite the strength of the weld seam obtained with these electrodes is high, for welding critical structures it is still preferable to use electrodes with a basic coating.

Both beginners and welding professionals can weld with ESAB-SVEL OK 46.00 electrodes.

Main advantages of UONI-13/45

- Easy initial and re-ignition.

- Stable burning of the electric arc.

- High penetration depth, which allows you to weld thick-walled parts.

- Small amount of spattered metal.

- Easy separation of slag crust.

- Extremely low hydrogen content in the weld metal.

- High resistance of the metal to the appearance of crystallization cracks.

- Relatively low consumption of rods.

UONI-13/45 (NAKS, RRR, RS) 3 mm (4.5 kg) Current - constant reverse polarity

RUB 182.04 ? with VAT per 1 kg.

UONI-13/45 (NAKS, RRR, RS) 3 mm (1 kg) Current - constant reverse polarity

RUB 200.04 ? with VAT per 1 kg.

UONI-13/45 (NAKS, RRR, RS) 2.5 mm (4.5 kg) Current - constant reverse polarity

RUB 216.00 ? with VAT per 1 kg.

UONI-13/45 (NAKS, RRR, RS) 2.5 mm (1 kg) Current - constant reverse polarity

RUR 234.00 ? with VAT per 1 kg.

general information

Welding electrodes of the UONI brand are an excellent choice for those who value high quality seams when manual arc welding. Any professional will tell you that to perform a truly high-quality and aesthetic seam using RDS technology, you need to practice a lot and select the right electrodes. The SSSI brand is perfect for these purposes.

What features does this brand have? Firstly, to work with such electrodes it is necessary to set reverse polarity and use direct current. It doesn’t matter at all what temperatures the welding takes place at, it doesn’t matter.

Secondly, UONI electrodes are still intended for practicing welders. If you are a beginner, you are unlikely to be able to make a high-quality seam the first (or even the fifth) time. This must be taken into account in advance and soberly assess your skills.

SSSI electrodes are available in different diameters. The most popular diameters are 3 mm and 4 mm. With the help of such electrodes you can weld most parts.

Features of use

Before welding, the electrodes must be calcined for an hour at a temperature of 350°C. Other features include:

- Welding is performed outdoors or in well-ventilated areas. This is due to the release of volatile fluoride compounds that are harmful to health.

- The surfaces of the parts to be welded must be cleaned of scale, dirt, traces of rust, and moisture must be removed.

- It is not recommended to lengthen the arc - this disrupts the stability of its combustion and can cause the formation of pores in the metal.

Using alternating current for welding is possible, but is also not recommended due to the risks of unstable arc burning.

Using Electrodes

A special feature of these electrodes is the possibility of their use in different positions. The exception is the top-down direction. This means that these rods can be used even during complex installations, when it is difficult to get to the welding site.

Due to the fact that fluorine compounds are released during welding (removing moisture and hydrogen from steel surfaces), working conditions must provide for good air ventilation. This is especially important if work is carried out indoors. The welder must have protective equipment and constant access to fresh air.

Long arc welding is not recommended as it may be unstable. In turn, this can lead to uneven seams. Craftsmen who have used these electrodes advise working carefully with the weld pool. It must be kept liquid for as long as possible, and the connection must be made with a wide seam.

Before work, the electrodes need to be calcined at about 280 - 300°C for an hour. This is necessary so that the moisture content in them decreases to 0.3%. This will be especially important if the enterprise, and therefore the warehouse with consumables, is located in a climate zone with prevailing low temperatures.

Please note that you should calcinate the number of electrodes that you need for work. The fact is that when dried again, the rods lose their properties and provide worse seam quality.

Surfaces should also be prepared before welding. The edges must be cleaned of rust, dirt, lubricants, etc.

Areas of use

In addition to pipelines used in the oil, gas, and chemical industries, electrodes of this brand are widely used for the production of:

- building structures;

- transport equipment (including for the transportation of dangerous goods);

- lifting equipment;

- equipment for metallurgy enterprises.

They are also used to manufacture boilers and boiler equipment, as well as equipment for the oil industry.

Electrodes UONI-13/45 are presented in the MEZ catalogue. These are the own products of the Magnitogorsk Electrode Plant. The high quality of products is confirmed by several documents, including a certificate from the National Welding Control Agency and a certificate of approval from the Russian River Register. The manufacturer indicates on the packaging all the necessary basic welding parameters. Delivery of goods is carried out to all regions of Russia.

general description

The products of this brand are the best option for those who strive to obtain a high-quality seam using manual arc welding. Every professional knows that in order to form a high-quality weld, you need to practice long and hard. In manual arc welding technology, special attention is paid to the correct selection of electrodes. The SSSI brand is excellent for these purposes.

What features do they have? First of all, you need to take into account that to work with these consumables you must select reverse polarity and direct current. The choice of temperature conditions for welding operations does not have any influence. Secondly, the electrodes were specifically designed to meet the needs of practitioners. A student or novice welder is unlikely to be able to immediately lay a high-quality weld. Most likely, he won’t succeed even on the fifth try. This should be taken into account so as not to be disappointed at the beginning of your journey.

UONI brand products are supplied to retail chains of various sizes. The most popular among consumers are electrodes with a diameter of 3 and 4 mm. They can be used to join most metal workpieces. Many people paid attention to the different markings of seemingly identical electrodes. Yes, indeed, their composition differs slightly. However, they are designed to join metals of different chemical compositions.

SSSI marking and explanation of the main parameters

To distinguish electrodes of even the same brand from each other, they came up with additional markings that determine their purpose. For example, what could the marking e50a or simply e55 mean? Having a special table at hand, you can easily determine what is what and how these names differ.

So, the letter “e” means that this is an electrode designed for manual arc welding. The number 50 is the limit of strength of the connection obtained when used correctly. The letter "A" is used to represent a seam. She says that the seam will be plastic and can easily withstand high impact loads.

This is followed by the name of the SSNI electrodes themselves, after which additional markings are placed, for example, 13-55 or 13-85. After this, the diameter of the steel core is indicated. It is worth noting that it is indicated with an accuracy of tenths of a millimeter. That is, if it’s a 5, then it’s 5.0, if it’s a 4, it’s 4.0, and so on.

At the very end there is a letter “U”, which indicates that this type of electrode is used for welding carbon steels.

Popular varieties

Consumables of this type are produced in a wide range of diameters (from 2 to 5 millimeters). The most popular in the model range are UONI 13 55 3mm and 4mm electrodes. At the same time, there are four types of products that have a specialized purpose and their own specific application.

- 13/45 – designed for creating highly demanding metal structures from low/medium carbon steel blanks. They are also used to repair cast and forged products and eliminate defects. The core of these electrodes contains molybdenum and nickel, which provide the weld with the necessary toughness and ductility.

- 13/55 – focused on welding structural elements made of low/high carbon steels. The coating of such models contains phosphorus, sulfur, silicon and manganese, which guarantees excellent quality of the welded joint. Used in production workshops. The products are demanding on the condition of the parts (dirt, rust and moisture on their surface).

- 13/65 - used in the same cases as analogues 13/55. These electrodes are used to produce a seam of improved quality, but the price of such SSSI per kg is noticeably higher. Therefore, such consumables are used only when creating especially critical metal structures and products.

- 13/85 - the most expensive welding electrodes from the UONI model range. They are actively used in the process of forming structures from parts made from alloy steels.