The idea of replacing labor-intensive forging with rolled metal arose at the beginning of the 16th century, and at the same time the first rolling mills appeared, giving metal its shape by compressing it between rotating rolls. The power of the water wheels that drove the rolling mills was only enough to process soft metals - tin, lead, copper. The advent of the steam engine made it possible to roll hard steel. The development of railways increased the demand for rolled products - steel rails. The first mill to roll steel rails opened in 1828 in Bedlington, England.

1. Gold wire jewelry. Northern Europe. II - I millennium BC e. 2. Russian filigree: gold bracelet of the 13th century. and a silver button from the 16th century.

Purpose

Metal rolling machines are mechanical installations designed to create metal products by deforming raw materials in roll devices. The equipment allows us to produce various types of products:

- Long products. These include rods and strips of various geometric shapes, as well as shaped parts, spring and rhombic.

- Special purpose profile. Metal products in the form of angles, channels, I-beams, as well as combined blanks with a variable cross-section.

- Rolled products in the form of thin sheets up to 4 mm, as well as thick sheets more than 4 mm.

- Pipe profile with connection using welding and seamless joints.

This is interesting: Lathe 1M63 - technical characteristics and design

Design and principle of operation

The rolling press consists of three main parts:

- The cage is working. The design of these elements includes rolling rolls, installation plates, a base frame, and wiring.

- Electric motors for transmitting movement to working elements.

- Mechanisms of distribution and transformation of motion. Consists of a spindle, couplings and gears.

The units differ in the number of stands and work roll sizes:

- Machines for thick metal have up to two working compartments with rollers ranging from 3 m to 5.5 m in length. In addition, vertical rollers can be installed, which are used for processing side edges.

- Broadband equipment contains up to 15 stands, rolls have a length of up to 2.5 m.

- Universal rolling presses consist of 5 compartments, and the length of the shafts is up to 1.5 m.

In industry, there are three methods for processing metal raw materials until they acquire the required geometric shape:

- In the first case, a rolling device is installed on the casting unit, and the initial contour of the part is obtained until complete crystallization. The disadvantage of this method is the need to maintain a high temperature until the end of processing, as well as additional precise running-in.

- As a result of rolling through furnaces with temperatures inside the chamber up to 1350 C, the edges are independently welded. At the exit of the equipment, a finished pipe profile is obtained.

- The third method involves manufacturing parts at a workpiece temperature corresponding to the environment. To prevent defects, the units use a large number of rollers that rotate in the opposite direction.

Specifications

Rolling machines have characteristics that distinguish them from analogues:

- the type of profile produced in a particular installation can be pipe, section, as well as thin and thick sheet;

- the range of metal thickness intended for rolling is from 0.4 mm to 200 mm;

- necessary raw materials for rolling;

- performance indicator, the choice of machine before purchase, as well as the preparation of raw materials, depends on this factor;

- number of working cells with rolls for the required profile;

- the diameter of the working shafts for rolling, as well as their useful length;

- rated voltage - 220 V / 380 V;

- the power indicator of the electric motor used is from 2.2 kW and above;

- assembled installation dimensions;

- total weight of all equipment in the complex;

- presence of reversal in the rolling mill.

Rolling machine

Jewelry thought

Wire jewelry in the 2nd millennium BC. e. confirm that even then the ancient craftsmen, in addition to forging - the simplest method of processing metals by pressure - used drawing - pulling cast rods of soft metals through the narrow holes of drawing boards, to thin them and turn them into wire .

In Byzantium and Russia , laying out wire patterns - filigree - was especially popular. Wire for filigree was often flattened, and perhaps as early as the 15th century. , flattening rollers began to be used . Later, having made streams in the rollers - notches of different widths and shapes, they found a new way of drawing wire: the stream compressed the workpiece, giving it the desired thickness and profile . Jewelry flattening rollers could become the prototype of a sheet rolling mill (for rolling flat metal sheets), and wire drawing rollers suggested the idea of a forming rolling mill (for rolling beams of different profiles).

Leonardo da Vinci's rolling mill: drawing from 1495 and modern layout. The handle (1) rotated the upper roller (2), and through a gear train (3) consisting of several gears (to facilitate rotation), movement was also transmitted to the lower roller (4). A cast tin plate was rolled between the rollers; the rollers compressed and thinned it, turning it into a sheet.

Features of the operation of rolling machines

Purpose

The equipment allows us to produce various types of products:

- Long products. These include rods and strips of various geometric shapes, as well as shaped parts, spring and rhombic.

- Special purpose profile. Metal products in the form of angles, channels, I-beams, as well as combined blanks with a variable cross-section.

- Rolled products in the form of thin sheets up to 4 mm, as well as thick sheets more than 4 mm.

- Pipe profile with connection using welding and seamless joints.

Design and principle of operation

The rolling press consists of three main parts:

- The cage is working. The design of these elements includes rolling rolls, installation plates, a base frame, and wiring.

- Electric motors for transmitting movement to working elements.

- Mechanisms of distribution and transformation of motion. Consists of a spindle, couplings and gears.

The units differ in the number of stands and work roll sizes:

- Machines for thick metal have up to two working compartments with rollers ranging from 3 m to 5.5 m in length. In addition, vertical rollers can be installed, which are used for processing side edges.

- Broadband equipment contains up to 15 stands, rolls have a length of up to 2.5 m.

- Universal rolling presses consist of 5 compartments, and the length of the shafts is up to 1.5 m.

In industry, there are three methods for processing metal raw materials until they acquire the required geometric shape:

- In the first case, a rolling device is installed on the casting unit, and the initial contour of the part is obtained until complete crystallization. The disadvantage of this method is the need to maintain a high temperature until the end of processing, as well as additional precise running-in.

- As a result of rolling through furnaces with temperatures inside the chamber up to 1350 C, the edges are independently welded. At the exit of the equipment, a finished pipe profile is obtained.

- The third method involves manufacturing parts at a workpiece temperature corresponding to the environment. To prevent defects, the units use a large number of rollers that rotate in the opposite direction.

Specifications

Rolling machines have characteristics that distinguish them from analogues:

- the type of profile produced in a particular installation can be pipe, section, as well as thin and thick sheet;

- the range of metal thickness intended for rolling is from 0.4 mm to 200 mm;

- necessary raw materials for rolling;

- performance indicator, the choice of machine before purchase, as well as the preparation of raw materials, depends on this factor;

- number of working cells with rolls for the required profile;

- the diameter of the working shafts for rolling, as well as their useful length;

- rated voltage - 220 V / 380 V;

- the power indicator of the electric motor used is from 2.2 kW and above;

- assembled installation dimensions;

- total weight of all equipment in the complex;

- presence of reversal in the rolling mill.

Varieties

Based on the number of rolls located in the working stand and their placement, rolling machines are divided into the following types:

- double-roll - the design has paired mechanisms for pressing, which can rotate in different directions;

- three-roll - contain three shafts in each stand;

- four-roll - consist of two pairs of working parts;

- multi-roll - have a design of 4 or more rolls, and in universal ones they are used in a vertical position, sometimes they are installed in the spaces between horizontal ones;

- rolls mounted at an angle to the surface of the metal workpiece.

Rolling presses are distinguished by the location of the stands:

- equipment with working mechanisms arranged in one line is called linear;

- in stepped installations, the stands are installed in several lines parallel to the main flow;

- equipment for continuous and semi-continuous rolling; with the help of such machines, industry achieves high productivity.

Depending on the type of product produced during the process of pressing blanks, installations are divided into the following types:

- Crimping equipment. Allows the production of steel ingots weighing up to 25 tons. A piece of square or rectangular cross-section comes out of the working stands.

- Continuous pressing machines for blank material. As a result of the operation of such mechanisms, steel plates are modified into a special profile and sheets.

- Rail and beam machines roll blooms into rails, channels and large beams. In industry, step and sequential mills are used.

- Sectional machines are used to produce metal parts of different grades.

- In the process of manufacturing wire, wire mills are installed in the workshop; they are divided into stepped, semi-continuous and continuous.

- Slabs are processed using a sheet rolling machine. Thick-sheet, wide-strip, and also with winders are used.

- Pipe rolling equipment produces seamless and welded pipes. During the rolling process, two levels of processing are used. Initially, a hollow sleeve is made from a round bar, then a pipe of the required diameter is made from it.

Selection principle

When purchasing equipment, pay attention to the following:

- Productivity of finished products, process automation, reliability and profile quality.

- The use of additional installations to ensure automatic rental.

Advantages and disadvantages

The advantages of the rental method include:

- increased productivity;

- wide range of finished products;

- use of software control to automate the process.

Among the negative indicators it is worth noting:

- Using rolling machines requires costs for raw materials and electricity, as well as equipment maintenance.

- After rolling, additional processing is required.

- To press the workpieces should be heated.

Manufacturers and price

Metallurgical enterprises use equipment from foreign and domestic manufacturers. Russian companies are trying not to give in to foreign competitors.

The price of rolling mills depends on the manufacturer. The cost starts from several thousand and reaches 5–6 million rubles. The price is also influenced by productivity, type of finished profile, as well as the number of stands and rolls.

Exploitation

To ensure safe operation of the equipment it is necessary:

- install an automatic control system for the rental process;

- Before starting, check that the installation is working properly;

- moving parts and mechanisms should be protected;

- carry out maintenance of bearing connections and rollers;

- Provide areas exposed to high temperatures with additional ventilation.

Compliance with safety requirements when operating equipment will prevent possible injuries and accidents. As a result of rolling on serviceable machines, the consumer receives high quality material.

Rolling is one of the most important inventions made by man during his centuries-long acquaintance with metals. It has long been noted that products that have the same cross-section along their entire length (for example, rails, angles, beams, sheets, rods) are much easier to produce by passing them between two rolls than by traditional forging. One might even say that this method is not only the most convenient, but also the best overall. Without it, there could be no talk of building cheap railways, iron bridges, iron ships and much, much more. After all, it was thanks to rolling that it became possible to give iron and steel blanks complete uniformity. It is not difficult to imagine how much effort it would require from a blacksmith, for example, to forge each rail or wheel of a railway car. Meanwhile, it is not difficult to obtain such products using rental, moreover, in large quantities and of high quality. Therefore, already at the end of the 18th century, rolling became one of the main links in the production cycle of metallurgical plants, gradually replacing forging. And it originated in the Middle Ages in the manufacture of thin sheets of soft metal (for example, lead), which could be rolled by hand without preheating. The oldest image of such a simple rolling machine can be seen in an engraving from 1615.

Hot rolling became known only at the beginning of the 18th century, and at first more or less thin iron sheets were prepared using this method, but already in 1769 they began to roll wire in this way. The first rolling mill for iron bars was proposed by the English inventor Cort while he was working on his method of puddling. Kort was the first to realize that in the manufacture of some products it is more rational to entrust the hammer only with squeezing out the slag, and give the final shape by rolling. In 1783, he received a patent for the method he invented for rolling shaped iron using special rollers. From the puddling furnace, the dough went under the hammer, here it was forged and received its original shape, and then passed through rollers. This method later became widespread. But it was only in the 19th century that rolling technology was brought to its proper height, which was largely due to the intensive construction of railways. Then rolling mills were invented for the production of rails and carriage wheels, and then for many other operations.

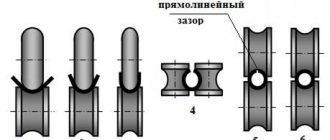

A rolling mill is a machine for processing metals by pressure between rotating rolls. The design of a rolling mill in the 19th century was simple. The rollers rotating in opposite directions grabbed a white-hot metal strip and, compressing with greater or lesser force, passed it between their surfaces. During the passage of the workpiece, two closely related processes occurred. Firstly, the metal of the product was subjected to strong compression at high temperatures, and secondly, the workpiece acquired the required shape. In this case, for example, iron received properties that it did not have by nature. Individual grains of the metal, which before rolling were located in disorder in its mass, during the process of strong compression were stretched out and formed long fibers. After this, soft and brittle iron became elastic and durable.

The rolls were placed between powerful frames. The roll journals were placed in bearings. Usually the lower bearing m was stationary. The upper bearing could be moved up and down using bolts h. Screw e, with which the liner was installed, took on all the pressure exerted on it. A safety cap i was usually inserted between it and the liner, which burst as soon as the pressure on the shaft reached a dangerous limit. This cheap cap, which was easy to replace, acted as a preventative against failure of other, more important parts of the mechanism (breakage could easily occur if the rolls gripped the workpiece too thick and could not withstand the pressure). During rolling, the upper roll lay with pins on a clamp d, equipped with an insert e and suspended on two bolts. To connect two such frames to each other, four thick bolts were used, passing through the holes n of the crossbar and placed behind the recess b. A coupling was used to engage the rollers with the engine. The lower roller was driven directly by the steam engine, and its axis coincided with the main axis of its shaft. The movement was transmitted to the upper roll using a gear drive.

The shape of the product depended on the shape of the rolls. Rolls with a smooth surface were used to make flat iron such as sheets. For rolling figured varieties, they were equipped with recesses corresponding to the purpose - they were calibrated. Passing between them, the workpiece received the desired shape, that is, it turned into a strip of round, square, oblong, quadrangular or other cross-section. The desired profile was not given to the product immediately, but gradually. The blank passed successively through a number of rolls, of which only the last had the form of finished bar iron. Shown in black is a profile that gradually acquired raw metal as it was rolled in different rolls.

By the end of the century, rolling technology had improved so much that not only solid, but also hollow products began to be produced this way. In 1885, the Mennesmann brothers invented a method for rolling seamless iron pipes. Before this, pipes had to be made from iron sheets - they were bent and welded. It was both long and expensive. At the Mennesman mill, a round blank was passed between two rolls placed obliquely to each other, which acted on it in two ways. Firstly, due to the frictional forces between the rolls and the workpiece, the latter began to rotate. Secondly, due to the shape of the rolls, the points on their middle surface rotated faster than the outer ones. Therefore, due to the oblique arrangement of the rolls, the workpiece seemed to be screwed into the space between them. If the blank were hard, it would not be able to pass. But since it was previously heated strongly to white heat, the metal of the workpiece began to twist and stretch, and in the axial zone it was loosened - a cavity appeared, which gradually spread along the entire length of the workpiece. Having passed through the rolls, the workpiece was mounted on a special rod (mandrel), due to which the internal cavity was given the correct circular cross-section. The result was a thick-walled pipe.

To reduce the wall thickness, the pipe was passed through a second so-called pilgrim rolling mill. It had two variable profile rolls. When rolling the pipe, the distance between the rolls was first gradually reduced and then made larger than the diameter of the pipe. The rolling cycle consisted of two periods - working and idle. During the working period, the pipe into which the spiral mandrel was inserted was gripped by the rollers and compressed to the diameter of the finished pipe. At the same time, its walls were made thinner, and it itself was stretched (the rollers seemed to remove a layer of ring metal and roll it out to a given thickness). Then the idle period began, when the diameter of the caliber exceeded the diameter of the pipe. At this time, the workpiece left contact with the rolls and processing of this area ended. The workpiece moved forward and rotated 90 degrees around its axis (for a more uniform finish). The cycle was thus repeated in subsequent sections of the pipe.

Selection principle

When purchasing equipment, pay attention to the following:

- Productivity of finished products, process automation, reliability and profile quality.

- The use of additional installations to ensure automatic rental.

Advantages and disadvantages

The advantages of the rental method include:

- increased productivity;

- wide range of finished products;

- use of software control to automate the process.

Among the negative indicators it is worth noting:

- Using rolling machines requires costs for raw materials and electricity, as well as equipment maintenance.

- After rolling, additional processing is required.

- To press the workpieces should be heated.

Improved performance

Manufacturers and price

Metallurgical enterprises use equipment from foreign and domestic manufacturers. Russian companies are trying not to give in to foreign competitors. The price of rolling mills depends on the manufacturer. The cost starts from several thousand and reaches 5–6 million rubles. The price is also influenced by productivity, type of finished profile, as well as the number of stands and rolls.

This is interesting: Surface grinding machines - design and methods of metal grinding

Development of the idea

G. Bessemer, who in 1856 discovered a cheap method for producing high-quality steel - the Bessemer process , which replaced puddling, made a revolution in rolled metal, in 1857 he patented casting and rolling mills. The Bessemer mill did not require a workpiece - the smelted steel was immediately poured between rolling rollers, the metal quickly solidified on the rollers, but, being very soft, was easily deformed - this was how it was possible to obtain very strong steel sheets with a thickness of 2 cm to 1 mm.

The production of thin-sheet steel immediately revolutionized shipbuilding . By this time, the military fleet had already turned from a sailing fleet to a steam one. But if a small hole in the side of a sailing ship did not prevent it from continuing the battle, the steamer was completely immobilized by any damage to the steam engine, and only the wooden lining of the side protected the engine from shells. Sheathing made of light and durable sheet steel turned out to be excellent armor for the engine. This is how a new class of ships appeared - battleships . Soon civilian ships began to be built from metal.

Share link

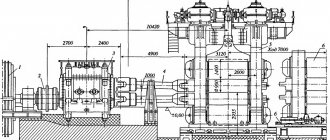

Basic equipment for rolling production

The main equipment of rolling production is rolling mills and rolls. A rolling mill is a technological complex of sequentially located machines and units designed for plastic deformation of metal in rolls (rolling itself), its further processing, finishing (straightening, trimming edges, cutting into dimensional products, etc.) and transportation.

Rice. 5. Rolling scheme with two rolls

Rolling rolls (Fig. 5) are the main part of the rolling mill: they compress metal 1 and give it the required shape. The rolling roll consists of a barrel 4 (smooth or with grooves), necks 3 located on both sides of the barrel and resting on the roll bearing, clubs 2 intended to connect the roll to the spindle. Roll ends can be flat or cylindrical (splined or keyed)

The rolls are made of bleached cast iron or alloy steel (chrome-nickel and chrome-molybdenum) and carefully ground; steel rollers are heating up. The rolls have a hardness from 150 to 800 HB Brinell. Steel rolls are either cast or forged. Forged rolls are stronger than cast ones. Prestressed composite rolls are used. Currently, small-sized carbide rolls have appeared (for example, from alloys VK6, VK8, etc.). Rolls come in diameters from 3 to 1500 mm and barrel lengths up to 5000 mm.

The necks of the rolling rolls rotate in liners made of textolite, plasticized wood, sliding bearings or roller bearings installed in the stand pads. Textolite liners are lubricated and cooled with water.

Devices that ensure metal deformation in rolls are called main equipment, and equipment for other technological operations is called auxiliary equipment.

Main equipment includes:

- the working cage and its components and parts (rolls, bearings, pressure and balancing devices, axial roll installation devices, roll reinforcement, etc.). The defining characteristics of the working stand are the diameter and length of the roll barrel;

- rolling mill electric motor;

- transmission mechanisms that ensure the transmission of rotation from the engine to the work rolls (spindles, main and main clutches, gearboxes, flywheels, gear cage)

The kinematic diagram of the rolling mill is shown in Fig. 6. In the working stand, a workpiece 2 is rolled between rollers 1 located in pads with bearings. The rotational motion of the rollers is transmitted from the main electric motor 8 through a gearbox 7 with flywheels 6, couplings 5, a gear stand 4 and spindles 3

Rice. 6. Kinematic diagram of a three-roll rolling mill

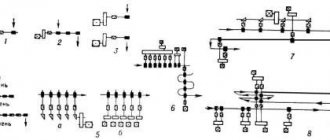

Rice. 7. Classification of working stands of rolling mills : a - duo; b - trio varietals; c - leaf trio; g - quarto leaf; d - quarto for rolling rolls; e - multi-roll (six-roll); g - multi-roll (twenty-roll); z - universal; and - special

Depending on the design and arrangement of the rolls, the working stands of rolling mills are divided into six groups: duo, trio, quarto, multi-roll, universal and special design. Duo (two-roll) stands are reversible (rolling is carried out in both directions) and non-reversible (in one direction) (Fig. 7).

Trio (three-roll) stands are most often non-reversible. Rolling in such mills is carried out forward between the lower and middle rolls and backwards between the upper and middle.

Quarto (four-roll) stands have four rolls (Fig. 8), located one above the other, of which two work rolls are of smaller diameter and two support rolls are of larger diameter.

Multi-roll stands have five or more rolls.

Rice. 8. Quarto mill for cold rolling of strip : 1 - feed winder drive; 2 — rolled tape; 3 — electric motor for driving the rolls; 4 - gearbox; 5 - spindles; 6 - support rollers; 7 - work rolls; 8 — drum of the receiving winder

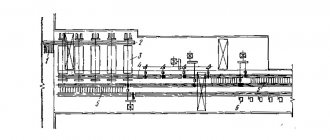

Rice. 9. Continuous rail and beam mill (PRC)

Depending on the location of the working stands, rolling mills are divided into single-stand, linear, sequential, semi-continuous and continuous (Fig. 9). Continuous mills are the most advanced. Thanks to automation, rolling speed can reach 60 m/s.

The working stand is the main unit of the rolling mill. Metal is rolled in a stand. It consists (Fig. 10) of two frames 5 with bosses (feet) 2, plates 1 on which the frames rest, installation pipes 9 connecting the frames, covers 3, rolling rolls 10, cushions of the lower 7, middle 6 and upper 4 rolls and bearings for them, a mechanism 8 for installing the rolls in the vertical plane and in the axial direction, and a device 11 for balancing the lower roll. In addition, there are roller fittings (rulers, wires, passes, etc.), devices for lubricating, cooling or heating the rolls.

The supports (cushions) contain sliding liners or rolling bearings for the roll journals. The frames are made in two types - closed and open (with a lid). Closed beds better ensure the accuracy of the rolled profile, but in such a mill it is difficult to replace rolls. But there are designs of open beds with a wedge fastening of the lid (Fig. 1 61), which have high reliability and in terms of rigidity bring the open bed closer to the closed type beds.

Rice. 10. General view of the trio stand of the large-section mill 500

Rice. 11. Wedge fastening of the bed cover

In addition to rolling stands with horizontally located rolls, stands that simultaneously have horizontal and vertical rolls for compressing rolled products from all sides without turning are widely used.

For rolling mills, DC or AC motors (asynchronous and synchronous) are used. Since the speed of high-speed motors usually does not correspond to the number of revolutions of the rolls in rolling stands, gearboxes are installed between the motors and the stands. In rolling stands, the motor torque must be distributed among several rolls. For this purpose, gear stands are used. Torque from the engine to the rolls is transmitted using spindles and couplings.

MMK's rolling production celebrates its anniversary

280 3 min.

On July 28, 1933, a crimping and billet mill, Blooming No. 2, came into operation at Magnitka, on which the first steel ingot was crimped. This event marked the beginning of the rolling redistribution of MMK. The design and manufacture of blooming equipment was carried out by the German company Demag. The importance of this unit for the economy of the young Soviet republic of the 30s can be judged by the fact that the People's Commissar of Heavy Industry of the USSR G.K. came to its launch. Ordzhonikidze. Blooming in combination with successively located continuous billet mills 630 and 450 was only the first step in the development of MMK's rolling production, which today occupies a leading position in the Russian metallurgical industry.

A year later, in August 1934, Magnitka's first medium-sheet rolling mill 500 with a capacity of 320 thousand tons went into operation, with the launch of which MMK turned into an enterprise with a complete metallurgical cycle. In July 1936, the first million Magnitogorsk rolled products were issued. Before the war, five more section mills were built and put into operation at the plant, as well as the second blooming mill produced by Uralmash, which became the first domestic rolling unit at MMK.

Magnitogorsk rental companies made a significant contribution to the cause of the Great Victory during the Great Patriotic War. It was at MMK that for the first time in the world metallurgy, armor plate was rolled on blooming. This happened on July 28, 1941, exactly eight years after the launch of blooming. This bold experiment made it possible to organize the production of much-needed products for the front before the launch of the 4500 and 2350 mills that arrived in Magnitogorsk from Mariupol and Zaporozhye. Every second Soviet tank during the war was made of Magnitogorsk armor, and this is a huge merit of the Magnitogorsk distributors.

In the post-war period, MMK's rolling production also actively developed. The emphasis was placed on the production of sheet metal, in the production of which the plant quickly became a leader. In 1951, sheet-rolling shops No. 1 and 2 were built and put into operation. In 1956, sheet-rolling shop No. 3 began operating, where the production of canned tinned tin and galvanized tin was later mastered. In 1960, the existing LPM No. 4 with a hot rolling mill of 2500 steel sheets was put into operation, and in May 1969, LPM No. 5 with a cold rolling mill of 2500 was put into operation. In 1973, a workshop for the production of electrotin-plated sheets was put into operation, and a year later, LPC No. 7, a workshop for bent profiles, was put into operation with four roll forming mills capable of producing dozens of economical and diverse profiles. In December 1982, an act of the state commission was signed on the commissioning of the carbon strip shop - Rolling Plant No. 8. On October 8, 1994, sheet rolling shop No. 10 with a 2000 hot rolling mill for steel sheets was put into operation - a unit of a new technological generation, which is by far the most productive at MMK. After reconstruction carried out in the mid-2000s, it is capable of producing 6 million tons of rolled steel per year. And in total, throughout their 85-year history, Magnitka’s rolling mills have produced about 670 million tons of hot rolled products - an astronomical result, a record for the domestic metallurgy.

Over the past 15-20 years, production at the Magnitogorsk Iron and Steel Works has undergone major changes. A large-scale investment program was implemented in the technical re-equipment and modernization of equipment, and the lion's share of these investments fell on rolling production. Among the key projects for the modernization of the rolling process during this period, one can highlight the complete reconstruction of the long-rolling production (2005-2006) with the replacement of outdated mills with new Danieli units, the creation of modern capacities for the production of coated rolled products, as well as MMK’s two largest investment projects of the last decade - construction complex for the production of plates (mill 5000, continuous caster-6 and out-of-furnace processing complex - 2009-2010) and the creation of a modern cold rolling complex for the production of high-quality automotive sheets. (mill 2000 – 2011-2012). Currently, the reconstruction of mill 2500 in LPC-4 is ongoing, where the heating furnaces have been replaced, the roughing mill is being reconstructed, and it is planned to replace the finishing group of stands. MMK's efforts to create a modern high-tech rolling production are bearing fruit - the plant has been repeatedly recognized as the best producer of sheet metal in the ratings of the Metal Supply and Sales magazine.

Department of Information and Public Relations of PJSC MMK