People's hobbies vary, and among various types of hobbies there is the search for treasures, ancient coins, artifacts and simply metal objects. To obtain an effective result from the actions of prospectors, a special type of equipment is used - a metal detector. Professional factory tools, with various sets of functions, are not cheap and may not pay for themselves in cases where they are purchased for the purpose of making money by selling metals. If a person has even a small supply of basic information from the field of radio mechanics, he will be able to independently assemble a useful tool, spending much less money on it.

Design and principle of operation of the device

Metal detectors on the market operate on different principles. Many believe that they use the principle of pulse echo or radar. Their difference from locators lies in the fact that the transmitted and received signals act constantly and simultaneously; in addition, they operate at the same frequencies.

The principle of operation of the metal detector

Devices operating on the “receive-transmit” principle record the signal reflected (re-emitted) from a metal object. This signal appears due to the exposure of a metal object to an alternating magnetic field generated by the metal detector coils. That is, the design of devices of this type provides for the presence of two coils, the first is transmitting, the second is receiving.

Metal detector circuit

Devices of this class have the following advantages:

- simplicity of design;

- Great potential for detecting metallic materials.

At the same time, metal detectors of this class have certain disadvantages:

- metal detectors can be sensitive to the composition of the soil in which they search for metal objects.

- technological difficulties in the production of the product.

In other words, devices of this type must be configured with your own hands before work.

Other devices are sometimes called beat metal detectors. This name comes from the distant past, more precisely from the times when superheterodyne receivers were widely used. Beating is a phenomenon that becomes noticeable when two signals with similar frequencies and equal amplitudes are summed. The beat consists of pulsating the amplitude of the summed signal.

The signal pulsation frequency is equal to the difference in the frequencies of the summed signals. By passing such a signal through a rectifier, it is also called a detector, and the so-called difference frequency is isolated.

This scheme has been used for a long time, but nowadays it is not used. They were replaced by synchronous detectors, but the term remained in use.

A beat metal detector works using the following principle - it registers the difference in frequencies from two generator coils. One frequency is stable, the second contains an inductor.

The device is configured with your own hands so that the generated frequencies match or at least are close. As soon as metal enters the action zone, the set parameters change and the frequency changes. The frequency difference can be recorded in a variety of ways, from headphones to digital methods.

Devices of this class are characterized by a simple sensor design and low sensitivity to the mineral composition of the soil.

But besides this, when using them, it is necessary to take into account the fact that they have high energy consumption.

Typical design

The metal detector includes the following components:

- The coil is a box-type structure that houses the signal receiver and transmitter. Most often, the coil has an elliptical shape and polymers are used for its manufacture. A wire is connected to it connecting it to the control unit. This wire transmits the signal from the receiver to the control unit. The transmitter generates a signal when metal is detected, which is transmitted to the receiver. The coil is installed on the lower rod.

- The metal part on which the reel is fixed and its angle of inclination is adjusted is called the lower rod. Thanks to this solution, a more thorough examination of the surface occurs. There are models in which the lower part can adjust the height of the metal detector and provides a telescopic connection to the rod, which is called the middle one.

- The middle rod is the unit located between the lower and upper rods. Devices are attached to it that allow you to adjust the size of the device. On the market you can find models that consist of two rods.

- The top rod usually has a curved appearance. It resembles the letter S. This shape is considered optimal for attaching it to the hand. An armrest, a control unit and a handle are installed on it. The armrest and handle are made of polymer materials.

- The metal detector control unit is necessary to process the data received from the coil. After the signal is converted, it is sent to headphones or other display devices. In addition, the control unit is designed to regulate the operating mode of the device. The wire from the coil is connected using a quick release device.

Metal detector design

All devices included in the metal detector are waterproof.

It is this relative simplicity of design that allows you to make metal detectors with your own hands.

Types of metal detectors

There is a wide range of metal detectors on the market, used in many areas. Below is a list that shows some of the varieties of these devices:

Ground model Deep metal detector Underwater vehicle Security device Industrial metal detector

- Ground. These devices are designed for searching with your own hands for scrap metal, jewelry, coins, etc.

- Deep. These devices are used to search for the above-mentioned metal products at great depths.

- Underwater. Devices of this type are designed to operate underwater. They can work at different depths.

- Metal detectors for searching for gold. These devices allow you to find gold and gold jewelry in any environment.

- Security devices. These devices are used to detect metal products on the human body and in luggage. Such devices are made in the form of arches and are installed at the entrance to places with large crowds of people, for example, at train stations, shopping centers, etc.

- Industrial. This equipment is part of conveyor lines. Their main task is to detect metal in other substances. For example, in a mined sand-soil mixture.

- Army. The military uses such devices to detect mines, unexploded shells, bombs, etc. with their own hands. The military calls such devices mine detectors.

- Do-it-yourself devices are most often assembled by novice “treasure hunters”.

The use of modern materials allows us to design and manufacture devices with high accuracy in detecting metals in different environments. The use of microelectronics has made it possible to minimize their overall weight parameters. In addition, the simplicity of the electrical circuit allows you to make a metal detector with your own hands at minimal cost.

Video

To be honest, it was not possible to find information in Russian anywhere, so everything you read above was collected from English-language sources, and translation is extremely difficult due to the inconsistency of the data. But since these AKS metal detectors are sold by a dozen sellers, it seems to be a popular thing. It’s still difficult to say how true this description is to reality, so if you have something to report on this device, go to the forum.

Discuss the article AKS DETECTOR-METAL DETECTOR OF GOLD AND DIAMOND

A device that allows you to search for metal objects located in a neutral environment, such as soil, due to their conductivity is called a metal detector (metal detector). This device allows you to find metal objects in various environments, including in the human body.

Largely thanks to the development of microelectronics, metal detectors, which are produced by many enterprises around the world, are highly reliable and have small overall and weight characteristics.

Sapper working with a metal detector

Not so long ago, such devices could most often be seen among sappers, but now they are used by rescuers, treasure hunters, and utility workers when searching for pipes, cables, etc. Moreover, many “treasure hunters” use metal detectors, which they assemble with their own hands .

Main settings

Like any technical device, a metal detector has certain parameters that characterize its functional properties.

Detection depth

In the first place is the depth of metal detection. By the way, many companies producing such devices do not indicate the maximum depth at which their products can detect metal products. And if such a figure is indicated, then most likely this is data obtained during laboratory tests. That is, real field conditions differ significantly from laboratory (test) conditions.

This means that when doing real work with your own hands, the detection depth will be slightly less than indicated in the passport. Why is this happening? The fact is that the composition of the soil has a significant impact on the capabilities of the metal detector. In fact, it is one thing to search in river sand, and another in soil with a high iron content. Metal products, especially those that remain at depth for a long time, oxidize and change their properties, and this affects the ability to detect an object.

Metal detector detection depth

Most modern metal detectors can find metal objects at a depth of up to 2.5 m; special deep products can detect a product at a depth of up to 6 meters.

Operating frequency

The second parameter is the operating frequency. The thing is that low frequencies allow the metal detector to see to a fairly large depth, but they are not able to see small details. High frequencies allow you to notice small objects, but do not allow you to view the ground to great depths.

The simplest (budget) models operate at one frequency; models that fall into the middle price range use 2 or more frequencies. There are models that use 28 frequencies when searching.

Parameters of metal detectors depending on purpose and technical device

Metal detectors for amateurs are the simplest dynamic type devices. The search head of the device must constantly move; this is the only way the desired signal can appear. If you stop moving, the signal will disappear. Such simple detectors are convenient because they do not require complex settings and allow you to exclude medium soils. Disadvantages include its low sensitivity and frequent false alarms in difficult areas.

The scanning speed of the device is about 30 centimeters per second.

Mid-range devices have better sensitivity. In the factory configuration, this device comes with several search heads of different sizes. Setting up the detector will require certain skills. Mid-range metal detectors are capable of recognizing metals.

Computerized devices are already professional instruments with a liquid crystal screen and pointer indication. The memory of its processor is loaded with programs capable of recognizing and distinguishing a signal and classifying each detected object. Professionals independently program devices for search conditions, eliminating unwanted triggers.

Gold detecting tools work not only on coins and jewelry in the ground, but also on native metal. It is not suitable for searching for small particles such as sand. It does not recognize them, especially if the soil is highly mineralized.

Otherwise, these metal detectors are very sensitive and work great, for example, when searching for gold jewelry in the sand of the beach

Depth detectors are designed to search for objects located at impressive depths. They can detect metal at a depth of up to 6 meters, while other models “pierce” only up to 3. Such devices recognize voids and other internal soil anomalies. Depth detectors operate on two coils, one is parallel to the ground surface, the other is perpendicular.

Stationary detectors are frames installed at particularly important protected sites. They detect any metal objects in people's bags and pockets that pass through the circuit.

Metal detector with metal discrimination

Modern metal detectors are equipped with a function such as metal discrimination. It allows you to distinguish the type of material located at depth. In this case, when ferrous metal is detected, one sound will sound in the search engine’s headphones, and when non-ferrous metal is detected, another sound will sound.

Such devices are classified as pulse-balanced. They use frequencies from 8 to 15 kHz in their work. Batteries of 9 - 12 V are used as a source.

Devices of this class are capable of detecting a gold object at a depth of several tens of centimeters, and ferrous metal products at a depth of about 1 meter or more.

Metal detector with metal discrimination

But, of course, these parameters depend on the device model.

Features of AKS2016

- Can be configured to detect the following elements: gold – silver – gemstone (ruby-sapphire-emerald) – diamond

- Detects objects at a depth of up to 30 meters

- AKS has a digital detector

- The device has a self-diagnosis system,

- Antenna at the top of the device in accordance with the free movement system

- Powered by 12 V 1600 mAh battery

- Trigger frequency: 5.6 – 6 kHz

- Signal frequency: 360 – 440 Hz

- Average price $200

How to assemble a homemade metal detector with your own hands

There are many models of devices on the market for detecting metal in the ground, walls, etc. Despite its external complexity, making a metal detector with your own hands is not that difficult and almost anyone can do it. As noted above, any metal detector consists of the following key components - a coil, a decoder and a power supply signaling device.

To assemble such a metal detector with your own hands, you need the following set of elements:

- controller;

- resonator;

- capacitors of various types, including film ones;

- resistors;

- sound emitter;

- Voltage regulator.

Do-it-yourself simple metal detector

The metal detector circuit is not complicated, and you can find it either on the vast world wide web or in specialized literature. Above is a list of radio elements that are useful for assembling a metal detector with your own hands at home. You can assemble a simple metal detector with your own hands using a soldering iron or other available method. The main thing is that the parts should not touch the body of the device. To ensure the operation of the assembled metal detector, power supplies of 9 - 12 volts are used.

To wind the coil, use a wire with a cross-sectional diameter within 0.3 mm; of course, this will depend on the chosen circuit. By the way, the wound coil must be protected from exposure to extraneous radiation. To do this, shield it with your own hands using ordinary food foil.

The simplest metal detector at home

To flash the controller firmware, special programs are used, which can also be found on the Internet.

Possible problems during assembly

The same Do It Yourself website warns of possible difficulties that may befall a homemade treasure hunter when assembling and setting up a metal detector. They mainly relate to incorrect geometry or winding of the coil, the use of defective or unusable used radio components.

Metal detector without chips

If a novice “treasure hunter” has no desire to get involved with microcircuits, there are circuits without them.

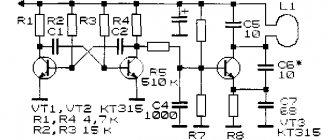

A simple circuit using transistor oscillators

There are simpler circuits based on the use of traditional transistors. Such a device can find metal at a depth of several tens of centimeters.

How to Use AKS to Detect Gold

Place the device parallel to the soil and turn it on by pressing the button for selecting the desired target for search (for example, gold). Then start searching according to the size of the area - in this case, the device sends signals in the vertical and horizontal planes, and then you will need to go around this area in search of the exact vector to the target. Here's a clearer picture:

Diagram of a deep metal detector

Deep metal detectors are used to search for metals at great depths. But it is worth noting that they are not cheap and therefore it is quite possible to assemble it yourself. But before you start making it, you need to understand how a typical circuit works.

Diagram of a deep metal detector

The circuit of a deep metal detector is not the simplest and there are several options for its implementation. Before assembling it, you need to prepare the following set of parts and elements:

- capacitors of various types - film, ceramic, etc.;

- resistors of different values;

- semiconductors - transistors and diodes.

Nominal parameters and quantity depend on the selected circuit diagram of the device. To assemble the above elements, you will need a soldering iron, a set of tools (screwdriver, pliers, wire cutters, etc.), and material for making the board.

Assembly process of a deep metal detector

The process of assembling a deep metal detector looks something like this. First, a control unit is assembled, the basis of which is a printed circuit board. It is made from textolite. Then the assembly diagram is transferred directly to the surface of the finished board. After the drawing is transferred, the board must be etched. To do this, use a solution that includes hydrogen peroxide, salt, and electrolyte.

After the board is etched, it is necessary to make holes in it to install the circuit components. After tinning the board. The most important stage is coming. Do-it-yourself installation and soldering of parts onto a prepared board.

To wind the coil with your own hands, use PEV brand wire with a diameter of 0.5 mm. The number of turns and the diameter of the coil depend on the selected circuit of the deep metal detector.