The most popular method of cutting metal nowadays is gas cutting. This is caused by a number of reasons. The main ones are:

- simplicity of the technological process. To carry out cutting, only two gases are needed: a gas heater for the material being processed (propane, acetylene, etc.);

- oxygen directly, which carries out the process of metal separation;

To perform this operation, you need a gas cutting machine - equipment for cutting metal with gas. This article will be devoted to getting to know this equipment.

By the way: other articles on our site are devoted to gas metal cutting technologies - you can easily find them if you use the “Site Search” service.

Gas welding, gas cutting and heating equipment Messer Cutting Systems

Thermal cutting of metals is the most cost-effective method both in domestic conditions and in industry.

Gas (autogenous) cutting methods provide good speed, acceptable quality at not too high operating costs. Any metalworking production begins with the preparation of metal and its cutting, followed by the operations of machining, assembly and welding, gouging, heating, etc. But not only metalworking industries use autogenous gas welding, gas cutting and heating equipment. It finds its application in radio electronics, the manufacture of refrigeration systems and air conditioners, jewelry, the glass industry, and auto repair. Gas-flame equipment provides soldering, melting, welding, cutting, heating, heat treatment, straightening, and descaling. Working with flammable gases, high pressure and open flames is a source of increased danger, therefore compliance with safety requirements and the use of special safety devices is mandatory. The ITS-Engineering company is the official distributor in Russia of the world-recognized leader in the production of autogenous equipment for gas welding, cutting and heating - Messer Cutting Systems (Germany). You can buy the entire range of Messer products from us from stock in Moscow or on order with delivery in the shortest possible time. The most popular models of equipment are always available: safety devices, gearboxes, manual gas torches and cutters, portable automatic gas cutting machines, nozzles, hoses, spare parts. In addition to standard gas welding and metal cutting equipment packages, we can work together to create a personalized solution for soldering, welding, cutting and heating. The Messer modular system allows you to create an individual tool, a torch for gas welding and cutting, by selecting the handle, the necessary insert or nozzle depending on the task. We can prepare a proposal for equipping your production with a Messer CNC gantry thermal cutting machine. For us, the task of ensuring human safety is always in first place, quality and reliability are in second place, and simplicity and ease of use are in third place.

Equipment for cutting metal with gas: machines

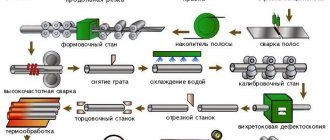

In cases where for some reason it is difficult to move the workpiece being processed (it is large in size and, as a result, mass, complex cut shape, etc.), the kinematic diagram of the equipment changes. It is built in such a way as to move the assembly with the cutting tool (the heavy workpiece remains stationary). This type of equipment is called a gas cutting machine.

Gas cutting machines, like machines, are divided into two large classes:

- mobile . These are small mobile units that are moved using transport carts;

- stationary _ According to their design, they are divided into the following types: P - portal. They are located on support posts located directly above the workpiece. The number of cutters may vary, pcs: 1…12;

- P-K – portal-console. Installed on a console mounted on a stand. The suspension mechanism is located directly above the workpiece being processed. The number of cutters may vary, pcs: 1…4;

- Ш – hinged. The cutters are mounted on articulated frames. This type of equipment is intended for vertical cutting only. The number of cutters may vary, pcs: 1…3.

Based on the type of cutting technology, such machines are divided into types of processing:

- Kf – oxygen-flux cutting;

- K – oxygen cutting;

- Gl – gas laser cutting;

- PL – plasma arc cutting.

According to the trajectory of movement of the contour with the working tool, machines are distinguished:

- L – linear. They perform straight-line cutting;

- M – magnetic. Perform figure cutting on a steel copier;

- F – photocopying. Carry out figure cutting according to design drawings. The process is carried out through photoelectronic copying followed by microprocessor control;

- C – digital. Machine tools with numerical control (CNC). They are designed for figured cutting of blanks.

Currently, the following models and brands are in great demand:

- CNC gas cutting machine model “Start-2” brand “Teploventmash”;

- small-sized machine for gas-plasma cutting of metal with CNC model “Crystal 1.5x1” brand “PKF “Crystal”.

The cutting process on the Start-2 gas cutting machine. East. https://stanki-tvm.ru/produkciya/stanki-gazovoy-rezki-s-chpu.

Main types of equipment

- balloon and ramp reducers

; - safety devices

; - modular torch systems for heating, soldering and welding

; - hand cutters for cutting, gouging, heating

; - machine cutters

; - various accessories and consumables

; - portable automated cutting machines

; - Gantry CNC Thermal Cutting Machines

;

Areas of application of gas cutters

These units are used for the following purposes:

- for the purpose of cutting scrap metal before melting during sorting;

- for sampling seam defects that appeared during welding;

- to eliminate the consequences of accidents;

- to remove surface defects on ingots during foundry production;

- for the purpose of cutting metal sheets and rolled metal before installing metal structures;

- for the purpose of preliminary cutting of edges before welding;

- for the purpose of dismantling steel structures.

Basic services

- selection of autogenous equipment

; - non-standard solutions for heating systems

; - modernization of thermal cutting machines

; - Autogenous cutting robotization

; - supply of original spare and consumable parts

;

Preparing a place and conditions for safe and comfortable work

To ensure safe work using a cutting torch, you must follow the following rules and recommendations:

- To perform the work, choose only a place in a perfectly ventilated room or in the open air.

- You can cut away from flammable substances and materials.

- The floor in the room should be concrete or earthen.

- The surface of the earth or concrete must be cleared of any foreign objects and materials within a radius of at least 5 m, since sparks from the metal being cut scatter over several meters and can set fire to dry rags, shavings, paper, dried plants or leaves.

- The metal to be cut is placed on a suitable support so that the cutter can be used at a comfortable working height. For these purposes, it is best to use a steel table.

- Do not allow the flame to touch the concrete (especially if it is fresh) - this will cause its expansion and subsequent intense cracking with small fragments of concrete flying out of it.

- It is strictly forbidden to use flammable surfaces as workers, or on which flammable or explosive materials are spilled.

- The location of the metal cut is marked as shown in the video.

Application area

- soldering;

- cutting;

- welding;

- planing;

- heat;

- descaling;

- heat treatment;

- automated heating solutions;

Properly selected autogenous equipment allows you to effectively solve many production problems in various industries and in the domestic sphere. Correct operation and routine maintenance in accordance with safety standards and manufacturer's recommendations will allow you to enjoy the work and get a quality result. The use of original spare and consumable parts will ensure reliability and long service life of the equipment. We guarantee an individual approach and attention to each Customer; for us, it is important both for an individual entrepreneur who wants to buy autogenous equipment and needs a good quality cutter or burner for crafts or a workshop, and for a large enterprise with its own special tasks and wishes. We have something to offer every potential Customer.

Gas cutting machine: conclusions

Gas is an explosive substance. To avoid injuries and casualties, the requirements must be strictly observed and the “Safety Rules” must be followed. Therefore, persons at least 18 years of age are allowed to maintain and operate gas equipment. They must go through the following stages of preparation:

- undergo introductory safety training when working with gas;

- on-the-job training;

- training course on safe work practices.

Upon completion of training, they must pass an exam on the theory and practice of safe working practices, which must be confirmed by receiving the appropriate “Certificate”.

Only competent, experienced welders with relevant work experience should always be involved in the selection, testing and training of working on gas welding equipment.

Cutting Features

The cutter must be moved smoothly along the cutting line and monitor the angle of inclination, which deviates 5-6 degrees against the movement of the tool. When the metal thickness is more than 0.95 m, the deflection is increased by cutting through the metal to a depth of about 20 mm, and the deflection angle decreases again. We have already explained in detail how to cut with a cutter so that the cut is even in the previous section.

How much gas is consumed?

Gas consumption when cutting metal with a propane-oxygen cutter depends on the thickness of the structure and the configuration of the cut. For clarity, we present the table below:

| Workpiece size (thickness), mm | Hole time, sec | Cut size (width), mm | Consumption, per m 3 cuts | |

| propane | oxygen | |||

| 4,0 | 5—8 | 2,5 | 0,035 | 0,289 |

| 10,0 | 8—13 | 3,0 | 0,041 | 0,415 |

| 20,0 | 13—18 | 4,0 | 0,051 | 0,623 |

| 40,0 | 22—28 | 4,5 | 0,071 | 1,037 |

| 60,0 | 25—30 | 5,0 | 0,087 | 1,461 |

Gas consumption is significantly reduced when surfacing or soldering is performed.

Nuances

The main task of the performer is to maintain the speed correctly:

- normal mode - sparks fly at right angles relative to the surface of the workpiece;

- low speed - flying away from the performer and an angle of less than 85 degrees.

After the process is completed, the oxygen supply is turned off first, and the propane is turned off last.

Negative deformation

Beginning welders are concerned with the question of how to properly use a propane-oxygen cutter so that warping of the surface of the part does not occur. First you need to figure out what factors contribute to the occurrence of these defects:

- with uneven heating of the surface;

- a high cutting speed was selected;

- there was a sharp cooling of the heating area.

To eliminate the occurrence of the listed factors on the workpieces, they are first securely fixed and heated, and the speed is increased gradually. If warping does occur, then the original shape can be returned by firing or tempering, and the sheets can be straightened on rollers.

Kickback hazard

If the jet burns in an incorrect mode, a bang occurs and the flame is drawn inside the product, which leads to an explosion, as the fire spreads through the hoses and reaches containers with gases. To prevent a dangerous situation, the cutter is equipped with a non-return valve, which cuts off the flame and prevents it from spreading.

Terms of use

They are similar to safety precautions when welding, but have specific additions:

- It is not recommended to neglect protective equipment, as this leads to injury in the form of skin burns or damage to the cornea of the eyes from flying sparks, so goggles and gloves with long bells up to the elbow are required.

- The performer's clothing and shoes are made of non-flammable material.

- Gas cylinders are located no closer than five meters from the cutting site.

- The flame of the cutter is directed only in the direction opposite to the hoses.

- Cutting is carried out in rooms equipped with strong ventilation or in open areas.

If the equipment is idle for a long time, it is necessary to carry out preventive maintenance before using the cutter for its intended purpose.

Ignition of the torch and heating of the metal

Before igniting the torch, you must:

- make sure that all connections (valves, pressure gauges, hoses, other fittings) are tight - any gas leak can instantly cause a fire;

- check the place of work again for the absence of flammable materials, strangers (especially children), and animals;

- make sure you are ready to work;

- Wear safety glasses and gloves.

Then the acetylene valve on the cutter is opened, allowing the oxygen in the mixing chamber to escape. A few seconds are enough for this. Then they tighten the valve until you can hear that acetylene is barely coming out. A special lighter for it is placed in front of the cutter, as shown in the video, so that its inner part touches the mouthpiece. Then press the lighter lever. When the sparks produced ignite the acetylene, a small yellow flame should form in front of the mouthpiece.

By tightening the gas supply valve, the flame length is increased to approximately 25 cm. The torch should start at the very mouthpiece of the cutter. The flame will come off or jump when too much acetylene is supplied.

Slowly open the front oxygen valve. In this case, the flame should change color from yellow to blue - at this moment, the supply of such an amount of oxygen will be provided, which is sufficient for the complete combustion of acetylene. The oxygen supply should be increased until the inner tongue of blue flame decreases and contracts towards the mouthpiece.

The oxygen valve is opened even further - the size of the torch is increased until the length of the internal flame becomes barely greater than the thickness of the steel being cut (for cold-rolled sheets with a thickness of 9.5 mm, it is enough to exceed the flame length by 1.3 mm). When you hear a "snuffing sound" or the blue flame appears feathery and unstable, there is too much oxygen being supplied. It is reduced until the entire flame stabilizes and the internal one takes the shape of a clear cone.

The very tip of the internal flame is brought to the surface of the steel being processed. It is heated until a pool of molten glowing metal forms at the point of contact. The tip of the flame must be kept motionless at a distance of approximately 10 mm from the surface of the steel as shown in the video, so that all the heat is concentrated in one area.