Bending is one of the metalworking methods. The process involves plastic deformation of the surfaces and internal layers of the metal, changing the shape of the workpiece. This method is suitable for almost all ductile metals, alloys and other materials.

Bending:

- Allows you to obtain parts of complex configurations.

- Does not leave seams susceptible to corrosion.

- Allows you to obtain monolithic products with uniform mechanical characteristics.

Bending is a waste-free method of metal processing. Manufacturing products using this method in some cases is much cheaper than welding, soldering, melting and casting.

Design and scope of application of sheet metal bending machine

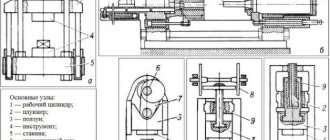

Machines for bending sheet metal are used in home workshops and factories. The devices have the same operating principle. Only the drive type changes. Bending machine design:

- The base that holds the desktop, movable mechanisms. This applies to models that are not fixed to workbenches.

- Pressing flywheels that hold the part during operation. Usually they are a metal plate.

- A wooden beam that acts as a cushion that acts as a support for the workpiece.

- Protractor for setting the desired angle.

- Stops limiting the sheet at the front and back.

Sheet benders are equipped with a special knife for cutting metal sheets. It is a separate tool that is mounted on the machine. The craftsman needs to make an effort to move it across the entire width of the workpiece. Sharp discs will cut thin sheet material to the specified size.

Sheet bending machines are used in various areas of industry:

- Manufacturing of roofing components.

- Mechanical engineering - creation of parts for housings.

- Manufacturing of window sills for plastic windows.

Basic methods of metal bending

There are 2 main bending methods - manual and mechanized. In the first case, the shape of the workpiece is given by blows of mallets or hammers. This method is used in piece production; for mass production, manual bending is low-productive.

Mechanized bending is carried out using machines and presses. There are 2 methods of metalworking – rolling and punching. The working tool of rolling machines is one or several pairs of rollers made of high-speed or tool steel. A metal sheet or roll is rolled between rollers, which give the workpiece a given shape.

In presses and punch machines, bending is carried out as follows: the workpiece is placed between the working tool and the matrix. The punch is pressed into the metal, giving it the appropriate shape. The force that creates the pressure is developed manually, by electric motor or hydraulics.

During free bending, the working tool does not press the workpiece against the walls of the die. Bending by embossing is carried out by tightly pressing the metal into the matrix and holding the tool in a pressed state. The choice of bending method depends on the elasticity and other properties of the metal being processed.

Types of sheet benders

Bending machines are divided according to various factors. Depending on the type of drive, the following types of equipment can be distinguished:

- Manual - models installed in private workshops and enterprises. They consist of a pressure plate, a work table, and a bending mechanism that works after transmitting human force through special handles. To work with the equipment you do not need to have additional skills.

- Mechanical - structures that consist of a flywheel, a moving shaft, and pressure plates. To bend the workpiece, you need to spin the flywheel.

- Hydraulic - a system that operates using fluid. Under pressure, it begins to act on a hydraulic cylinder, which bends the sheet.

- Electromechanical - consists of an electric motor, which, using belts and a set of gears, transmits force to a clamping bar, a moving mechanism. Allows you to bend workpieces of large thickness.

- Pneumatic - mechanisms operating using pneumatic cylinders.

- Electromagnetic - modern equipment on which high-power electromagnets are installed. After turning on the machine, they begin to move the bending bar to the specified angle.

Compact models of sheet benders should be included in a separate group. They can be used on a construction site. The downside is the insufficient size and power, which does not allow bending sheets of large sizes and thickness.

Manual sheet bending machine

Profile bending, pipe bending and reinforcement bending machines

Information about domestic pipe bending machines of the ASV-Tekhnika industrial group is given in table. 6; profile bending - in table. 7; cutting and bending of reinforcement - in table. 8; equipment for the manufacture of air ducts - in table. 9.

Table 6. Pipe bending machines

| Model | type of drive | Dimensions, mm | Weight, kg |

| UGS-5 | Electromechanical | 720x700x900 | 330 |

| IV 3428 | Same | 3485x1370x1355 | 1100 |

| IV 3429 | Electromechanical | 3485x1370x1355 | 1250 |

| IV 3430 | Same | 3730x1930x1160 | 2100 |

| RGU-1 | Hydraulic | 450x105x405 | 15 |

| RGU-2 | Same | 735x215x305 | 50 |

| RGU-42 | —»— | 530x170x260 | 30 |

| RGU-80 | —»— | 705x325x300 | 80 |

| RGU-90 | —»— | 705x325x300 | 90 |

Table 7. Roll forming machines

| Profile | Model | |||||||

| LNG-1 | LNG-2 | LNG-3 | LNG-4 | |||||

| Size, mm | Bending diameter, mm | Size, mm | Bending diameter, mm | Size, mm | Bending diameter, mm | Size, mm | Bending diameter, mm | |

| 50×10 | 800 | 60 10 50 12 | 800 800 | 60×10 20×10 | 800 300 | 60×10 40×10 | 900 600 | |

| 80×15 | 700 | 120 15 | 750 | 80×15 | 600 | 120×25 | 600 | |

| 30×30 | 700 | 35 35 20 20 | 1200 400 | 32×32 | 700 | 50×50 | 708 | |

| ∅30 | 700 | ∅35 | 800 | ∅35 | 700 | ∅50 | 700 | |

| ∅60×2 | 1200 | 70 2 | 1200 | ∅60×2 ∅15×1 | 1000 350 | ∅100×2 ∅3×2 | 1800 1500 | |

| 11/2″ | 900 | 33,7 2,65 | 320 | 60×2,9 (2″) 3/8″ | 1000 300 | 88,9×3,2 33,7×2,6 | 1500 500 | |

| 50x30x3 | — | 50x40x3 | — | 60x30x3 | — | 80x40x3 | — | |

| 40x40x3 | — | 60x60x3 | — | 45x56x3 | — | 70x70x3.2 | — | |

| 40×5 | 400 | 50 5 | 850 | 50×5 25×3 | 600 350 | 70×6 40×5 | 1000 500 | |

| 40×5 | 500 | 50 5 | 1200 | 45×5 25×3 | 600 400 | 70×6 40×5 | 1400 500 | |

| 50 | 800 | 50 | 650 | 50 | 600 | 100 | 1000 | |

| 50 | 850 | 50 | 900 | 50 | 600 | 70 | 900 | |

| 50 | 800 | 50 | 750 | 50 | 600 | 80 | 800 | |

| 50 | 400 | 50 | 550 | 80 | 800 | 120 | 600 | |

| 50 | 500 | 50 | 700 | 80 | 1200 | 120 | 1200 | |

| — | — | — | — | — | — | 100 5 | 700 | |

| Weight, kg | 185 | 363 | 480 | 1100 | ||||

| Overall dimensions, mm | 665x550x1350 | 725x900x1350 | 705x900x1460 | 875x1250x1735 | ||||

Table 8. Machines for cutting and bending reinforcement

| Model | Machine type | Workpiece (diameter), mm | Dimensions (L W H), mm | Weight, kg |

| SMZh-172A | Electromechanical | 40 | 1100x430x790 | 435 |

| SMZh-322 | Same | 40 | 1500x585x850 | 1060 |

| SMZh-133B | Hydraulic | 40 | 1360x410x980 | 490 |

| SMZh-160 | Same | 60 | 980x670x960 | 630 |

| H1226 | Electromechanical | 40 | 1370x450x850 | 585 |

| SGA-1 (bending) | Same | 40 | 760x790x790 | 380 |

Table 9. Equipment for the manufacture of air ducts

| Model | Purpose | Characteristics, mm |

| STD94 | Flange bending machine | Corner 25 25 3, 36 36 4 strip 25 5 |

| LED865 | Mechanism for making bends | V = 0.8 |

| STD518 | Mechanism for rolling shells | B = 1, L = 2000 |

| VMS76V | Mechanism for the production of shaped parts of air ducts | B = 2 |

| L578 | Manual stitching machine | B = 1.2 |

| STD11019 | Roll rolling machine | B = 0.5—1.0 |

Note. B is the thickness of the air duct, L is the length.

Advantages and disadvantages of bending machines

Industrial equipment and compact machines have strengths and weaknesses. Advantages of sheet bending machines:

- Creating the required components without welding workpieces.

- The product does not lose strength indicators, the structure does not change as when heated.

- Rust does not form at the bend site.

- The part remains intact.

Flaws:

- To work on manual machines, you need to make a lot of effort.

- It is important to accurately align the sheet in front of the clamp to avoid misalignment.

Often, after cutting products, a person handles them with bare hands, which can cause injury.

Advantages of metal bending on CNC machines

More and more, the use of computer-controlled equipment is becoming the norm rather than the exception. Such machines can be seen in almost any production, regardless of its scale. The use of specialized software allows not only to increase the processing speed of parts, but also leads to noticeable savings in metal and increased accuracy of workpiece processing.

The work of processing workpieces on bending machines under CNC control is as follows:

The use of control systems allows you to achieve certain advantages over other metal processing methods:

In addition to the mentioned parameters, it is impossible not to mention the fact that the work on manufacturing products can be carried out 7/24 without the involvement of additional human resources.

Principles of selection and operation of a sheet bending machine

When choosing a metal bending machine, you need to consider a number of factors:

- For one-time work, a manual model is suitable.

- It is necessary to take into account the dimensions of the working part so that you can bend sheets of the desired size.

- Take into account the maximum permissible thickness of the bending product.

- A model equipped with legs and a work table with stops is much more convenient and reliable than a mechanism mounted on a workbench.

When bending metal, you need to take into account the operating features of the equipment:

- Wear protective gloves, as the thin sheet metal has sharp edges and can cause cuts.

- Do not attempt to bend thick sheets on manual models.

- Do not start lifting the handles until the workpiece is positioned. When bending, you need to put both hands on the handles.

Masters recommend using mechanisms equipped with a pedal for control. It allows you to protect yourself in the process.

Tips for choosing a bending machine

Let's consider which bending machines are suitable for a workshop, workshop or factory. Equipment chosen:

- By appointment. For single production or the production of a small batch of similar products, a manual or segmental machine is sufficient. For serial and mass production, processing of 3-5 mm rolled products, you need an electric or hydraulic machine.

- By thickness and parameters of parts. The working length, feed and bending force of the machines must correspond to the characteristics of the rolled product and the manufactured products.

When choosing, they also pay attention to the presence of an automatic control unit, error, the possibility of installing a roller knife and other characteristics. Before purchasing, it is better to consult with employees of the manufacturer or trading company. A specialist will help you select equipment that meets production conditions.

Do-it-yourself sheet bender

In order not to spend money on a purchased model, you can assemble a sheet metal bending machine with your own hands. Initially, you need to calculate the dimensions, draw a drawing, prepare consumables and tools.

Do-it-yourself sheet bender

Preparation and equipment

To make a design with your own hands, you need to prepare:

- metal channels;

- corners, depending on the length of the working part;

- door hinges;

- fittings or small diameter pipes for making handles;

- metal sheet, rods to create a frame;

- wooden beam.

Tools you need are a grinder, a welding machine, and a metal brush.

Assembly steps

When making a homemade machine for bending sheet metal with your own hands, you need:

- Draw a design drawing. Indicate dimensions and moving elements.

- Make a frame with stable legs from channels and metal rods. Fasten a sheet of metal to the workbench. Everything is held together with a welding machine. The seams are cleaned with a brush and coated with an anti-corrosion compound.

- Fasten the corners parallel to each other. Connect them with loops. This is a movable element that needs to be fixed to the desktop.

- On one of the corners you need to weld tubes that will act as handles.

Bending machines are used to bend metal sheets at different angles. In order not to buy expensive equipment, you can assemble it yourself. To do this, you need to calculate the dimensions of the sheet bending machine, prepare materials, and carry out assembly.

Purpose, principle of operation and manufacturers of straightening machines

The principle of operation of straightening machines is based on the creation of plastic deformation in order to eliminate the curvature of products; bending machines are based on plastic transverse bending of various materials in order to obtain residual plastic deformation.

The main technological processes of bending and straightening are carried out in rollers and rolls, as well as in dies. In addition, free bending according to a template, bending and straightening using tensile deformation are carried out. Some processes use a combination of different processes: bending with stretching, stretching with compression, etc.

Due to the use of welding in mechanical engineering and metalworking, rotary straightening and bending machines for straightening and bending sheet materials are becoming increasingly widespread. Models of equipment for bending sheet materials on the Russian market are presented in Table. 1—16.5.

OJSC Donpressmash (Azov) supplies fashion presses. I142.01—I1428.01, I1428A.01, K10.4.30.01, I143AF2, K10.4.34.06 with table length 1350...6000 mm, table width 100...320 mm.

Various designs of hydraulic press brakes are manufactured in the I13, I14, IB14 and other series with the characteristic “nominal force table width” from 400 kN 1000 mm to 2500 kN 5000 mm.

The same enterprise produces three-roll bending machines for sheets with a thickness of 2.5...16 mm and a table width of 1250...2000 mm and mechanical creasing machines mod. IV14 and IV16 for sheets with a thickness of 2.5 and 4 mm. JSC Nelidovo Hydraulic Press Plant produces hydraulic press brakes of the IB14 series with a nominal force of 630...1000 kN and a table length of 2000...4000 mm, as well as hydraulic press brakes with a rotary beam of the IV21, IB14 series with a nominal force of 400 and 300 kN (with a width table 2000 mm).

SE "Kuzlitmash" (Belarus) manufactures mechanical (crank) sheet-bending presses mod. IG1330, IG1230V, IG1332, IG1334, IG1334A with a rated force of 1000...2500 kN, table length 2500...5050 mm; pneumatic sheet bending press with a nominal force of 100 kN, table length 780 mm; hydraulic sheet bending presses mod. IG1330, IG1230V, IVG1332, IG1334, IG1334A with a rated force of 100...630 kN, table length 1050...3150 mm.

Table 1. Three-roll sheet bending machines

| Model | Sheet length, mm | Sheet thickness, mm | Dimensions (L W H), mm | Weight, kg |

| IB2213V | 1250 | 2 | 2500x745x1310 | 950 |

| IB2216V | 2000 | 4 | 3600x1040x1450 | 2550 |

| IB2219V | 3150 | 8 | 5000x1350x1510 | 6140 |

| IB2220V | 2000 | 10 | 3940x1350x1510 | 4800 |

| IB2222V | 2000 | 16 | 4040x1590x2095 | 7200 |

| VEPP 10/20 | 1020 | 2,0 | 1700x1700x1150 | 370 |

| VEPP 15/20 | 1520 | 2,0 | 2200x700x1150 | 480 |

| VEPP 20/20 | 2520 | 2,0 | 2700x700x1150 | 880 |

| VEPP 25/20 | 2520 | 2,0 | 3200x700x1150 | 1100 |

| VEPP 20/50 | 2000 | 5,0 | 1320x950x1450 | 2950 |

| VEPP 25/40 | 2500 | 4,0 | 3720x950x1450 | 3300 |

| VEPP 20/30 | 2020 | 3,0 | 3150x600x1150 | 1100 |

| VEPP 25/30 | 2520 | 3,0 | 3200x700x1150 | 1600 |

Table 2. Manual rollers

| Standard size | Sheet length, mm | Sheet thickness, mm | Minimum bending diameter, mm | Dimensions (L W H), mm | Weight, kg |

| 1m | 1000 | 2,0 | 90 | 1700x1000x1100 | 300 |

| 1.5 m | 1500 | 2,0 | 90 | 2200x1000x1100 | 340 |

| 2.0 m | 2000 | 1,5 | 90 | 2700x1000x1100 | 380 |

| 2.5 m | 2500 | 1,2 | 90 | 3200x1000x1100 | 420 |

| ZS-8/1000 | 1000 | 0,8 | 90 | 1400x310x500 | 86 |

| ZS-15/1300 | 1300 | 1,5 | 90 | 1800x500x500 | 200 |

Table 3. Manual sheet bending machines

| Sheet width, mm | Sheet thickness, mm | Weight, kg |

| 1000 | 1,5 | 335 |

| 1500 | 1,5 | 430 |

| 2000 | 1,2 | 530 |

| 2500 | 1,0 | 630 |

Table 4. Press brakes

| Model | Force, kN | Table length, mm | Dimensions (L W H), mm | Weight, kg |

| IT1330 (mechanical) | 1000 | 2500 | 3000x1820x2945 | 9570 |

| IT1330V (mechanical) | 1000 | 3150 | 3660x1820x2945 | 10 300 |

| IR1332 (mech.) | 1600 | 4050 | 4330x2230x3620 | 18 000 |

| I1420 (hydr.) | 100 | 1050 | 1190x780x1730 | 1025 |

| I1422 (hydr.) | 160 | 1450 | 1620x890x1690 | 1780 |

| IP 1424 (hydr.) | 250 | 2020 | 2200x955x1820 | 2450 |

| IR1426 (hydr.) | 400 | 2500 | 2765x1050x1915 | 3500 |

| IG1428 (hydr.) | 630 | 3150 | 3390x1115x2300 | 5300 |

| IB14306-02 (hydr.) | 1000 | 2400 | 2640x1650x2830 | 6800 |

| IB1430B-01 (hydr.) | 1000 | 3200 | 3440x2650x2830 | 7500 |

| IB1430B (hydr.) | 1000 | 4000 | 4240x1650x2830 | 8300 |

| APHS 2004 60 (hydr.) | 60 | 2600 | 2800x955x1740 | 5500 |

| APHS 3705 120 | 120 | 3700 | 3800x1630x2550 | 11 500 |

| APHS6108 300 | 300 | 6100 | 6300x2060x3300 | 26 500 |

| APHS 2103 40 | 40 | 2100 | 2300x1200x2000 | 3000 |

| APHS 3104 90 | 90 | 3100 | 3300x1300x2330 | 6500 |

| APHS 4112 300 | 300 | 4110 | 4400x1870x2900 | 18 500 |

Table 5. Sheet bending machines with a rotary bending beam

| Model | Sheet length, mm | Sheet thickness, mm | Dimensions (L W H), mm | Weight, kg |

| IV2142 | 1600 | 6,0 | 2950x2400x2420 | 5230 |

| IV2143 | 2000 | 5,0 | 3300x2400x2420 | 5580 |

| IV2144 | 2500 | 4,5 | 3790x2400x2420 | 6380 |

| IV2145 | 3200 | 4,0 | 4500x2400x2420 | 7800 |

| IV2146 | 4000 | 3,5 | 5300x2400x2420 | 9280 |

| MGL-2000 | 2000 | 2,0 | 2680x425x1148 | 1100 |

| MGL-2500 | 2500 | 2,0 | 3280x425x1148 | 1300 |

| LGM3 2000 | 2000 | 3,0 | 3300x820x1320 | 2420 |

| LGM4 2500 | 2500 | 4,0 | 3350x960x1516 | 3230 |

| LGM5 2000 | 2000 | 5,0 | 2850x960x1516 | 2890 |

Roller knife

To cut the resulting part, you can use several types of knives, for example, saber or roller. Most often they are used to work with thin sheet material. When assembling a homemade sheet bender, it is advisable to purchase a roller blade from a company that supplies such equipment.

Roller knife of a homemade sheet bender

The thing is that for the manufacture of roller shears, as well as others, tool steels are used. To obtain working parts, it is necessary to use heat treatment, and this is unlikely to be done at home.

Machine base

To manufacture the frame, you will need a certain amount of profiled metal. This can be a channel or an I-beam.

Bed - base for the machine

When assembling it, you must remember that the structure must be rigid. The quality of metal processing depends on this parameter.

Why do you need a homemade sheet bender?

Bending sheet metal with your own hands is a completely feasible operation that can be performed at home. But many home craftsmen are stopped by the rather high price of sheet metal bending machines. For the needs of small-scale production or for work around the house, there is no need to install complex machines with hydraulic wires, but a manual machine will suffice.

In order to manufacture a machine of this kind, it is necessary to have at least draft documentation. It can always be found on the Internet, where you can either simply download or buy it. But it is best to study the operation of a working manual machine and implement the acquired knowledge in metal.

Homemade sheet bender

In fact, to build such a machine, you will need a certain amount of rolled metal, sheet material, a welding machine and metalworking tools.

Why do we need bending machines?

There is sheet metal.

And there are various profiles - bent sheet metal of the most varied shapes and purposes such as gutters, ridges, cornices and other roofing profiles. The difference in cost of sheet material and finished bent parts varies several times. Therefore, bending sheets yourself is a profitable business from an economic and professional point of view. When it is profitable not to buy, but to do it yourself - a rather rare situation in the modern technical world with the narrow specialization of any production.

Bending profiles on a machine.

Simplicity of execution, high productivity and cost-effectiveness are an excellent combination of advantages that homemade bending equipment of various types has.

Let's understand and put in order information on metal “bending” issues and ways to solve them.