A hydraulic cylinder is a volumetric hydraulic engine in which a plunger, rod or sleeve (cylinder body) performs reciprocating movements due to the pressure of the working fluid in the piston cavity.

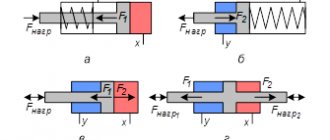

Hydraulic cylinders come in the following types:

- unilateral action (due to fluid pressure, the moving link moves in one direction, and in the opposite direction it moves under the action of the return mechanism);

- double-acting (under the influence of working fluid pressure, the working stroke is carried out in both directions);

- piston hydraulic cylinders with single-sided and double-sided rods;

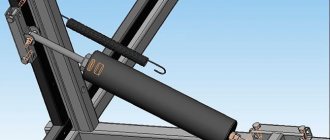

Hydraulic cylinders are used in such areas as road construction, hoisting and transport machines, earth-moving, drilling equipment, and technological equipment (machine tools, presses, etc.)

Hydraulic cylinder design - operation and principle of operation

A hydraulic cylinder is the simplest example of an engine.

The output (moving) link, which can be a rod, a plunger, or the cylinder body itself, carries out a reciprocating movement. The main parameters that characterize all hydraulic cylinders are the internal diameter, piston stroke, rod diameter and nominal pressure of the working fluid. Hydraulic cylinders come in several types: piston, telescopic, plunger, double-acting and single-acting. Based on the type of fastening, hydraulic cylinders are divided into models with hinged and rigid mounting.

A single-acting hydraulic cylinder exerts a force on the moving link, which is directed only in one direction (the working stroke of the cylinder). In the opposite direction, the moving link simply moves back under the influence of gravity or a return mechanism such as a spring. These cylinders have only one working plane.

Double-acting hydraulic cylinders have slightly more capabilities. They have two working planes, that is, they can create working forces on the output link in two directions. To ensure reciprocating motion, the liquid is alternately supplied under pressure into the cylinder cavity. When one of the cavities is filled with liquid, the other is connected to the drain. The hydraulic cylinder has two cavities: the rod cavity, in which the rod is located, and the piston cavity.

Now let's take a closer look at the design of a hydraulic cylinder using the example of a double-acting cylinder. The main parts that make up the cylinder are the hydraulic cylinder body, consisting of a sleeve (19) and a rear cover screwed to the sleeve, a front cover (9), which has a hole for the rod and is screwed onto the sleeve, a rod (18) with an eye (2 ), piston (15).

The figure shows the structure of a hydraulic cylinder. It consists of a spherical bearing (1), rod eye (2), wiper (3), sealing rings (4, 5, 8 and 13), cuff (6 and 14), cuff holder (7 and 12), front cover (9 ), locknut (10), damper (11), piston (15), nut (16), cotter pin (17), rod (18), cylinder liner with back cover (19), bushing (20) and wiper nut (21 ).

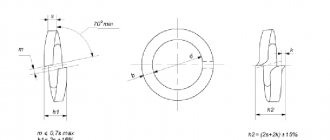

Using a piston with cuffs (14) and an o-ring (13), the piston and rod cavities are hermetically separated, and the force created by the pressure in the working cavity is transmitted to the rod. The piston is attached to the inner end of the rod using a nut (16), which is secured with a cotter pin (17). Cuff holders (12) keep the cuffs from moving along the piston axis. The front cover (9) is secured to the cylinder liner threads using a locknut (10). A bushing (20) is inserted into the cover (9), which serves as a guide for the rod. To avoid leakage of working fluid from the rod cavity, rings (8) are installed in the groove of the cover (9); cuffs (6), sealing rings (4) and (5) in the bushing are also used for this purpose. To avoid axial displacement when the rod moves, the cuff is restrained by a cuff holder (7). At the outer end of the cover there is a wiper (3), held in place by a nut (21), which is screwed into the internal thread of the cover. If the mechanism that is driven by the cylinder is deprived of stops that limit its stroke, which would fix it in extreme positions, then hard collisions between the piston and the hydraulic cylinder cover are possible. To soften these shocks, by damping or braking the piston as it approaches the cover, different types of damping devices are used. In the cylinder design, which is shown in the figure above, this function is performed by a damper (11) installed next to the piston (15) on the rod. The damper (11) softens the impact of the piston and the front cylinder cover at the end of the full stroke. The gap at the end of the rod stroke, located between the conical surface of the damper and the edge of the cover (9), through which the piston squeezes the working fluid from the rod cavity into hole “A”, decreases. During this process, due to the throttling of the liquid through the gap, the movement of the piston is inhibited.

Even if you know the structure of a hydraulic cylinder very well, repairing it at home or assembling your own cylinder is quite a difficult task. This requires special equipment and skills. Therefore, it is better to turn to experienced professionals with such questions. We specialize in the repair of hydraulic cylinders, as well as the manufacture of hydraulic cylinders according to your orders. Our company deals with the full range of work related to hydraulic cylinders. Our workers repair hydraulic cylinder rods, repair hydraulic cylinders for special equipment such as loaders, asphalt pavers, excavators, concrete pumps, truck cranes and manipulator cranes. We can also manufacture a hydraulic cylinder according to the drawings or samples you provide. We guarantee high quality and short terms of work.

TESTS

Acceptance of hydraulic cylinders is carried out in accordance with GOST 22976-78, 18464-80, taking into account the requirements of the industry standard OST 22-1417-79 and is aimed at determining consistency with the drawings and specifications. For mass-produced hydraulic cylinders, acceptance, periodic, and standard tests are assigned. The list of tested indicators is given in table. 3.

Table 3 Test indicators

Hydraulic diagrams of stands for acceptance and periodic testing are shown in Fig. 6 and 7.

Before testing, you should make sure that the hydraulic cylinder meets the manufacturing requirements, inspect the condition of the mounting surfaces and connecting holes and run it in at idle speed.

Figure 6 — Test bench for testing GC for strength under static load, external tightness and internal leaks, break-out pressure and idle speed:

1 — tested hydraulic cylinder; 2 - pressure gauge; 3 - valve; 4—measuring container; 5 - hydraulic distributor; 6 - filtering installation; 7 — thermometer; 8 — hydraulic tank; 9 - pump; 10 - heat exchanger; 11 - safety valve; 12 - filter

Figure 7 — Test bench for testing the GC for pushing and pulling force of the rod, total and mechanical efficiency, service life and braking;

1 - test hydraulic cylinder; 2 - dynamometer; 3 - limit switch; 4 — load hydraulic cylinder; 5 - pressure gauge; 6 — damper; 7 - check valve; 8 — throttle; 9 - pumping station; 10 - hydraulic valve

Operating principles of a hydraulic cylinder

A hydraulic cylinder is a volumetric, cylindrical engine that supplies working fluid under pressure, driving any component of the hydraulic system. This mechanism is widely used in such types of special equipment as excavators, rollers, earth-moving, quarry machines, drilling rigs, machine tools, presses, cranes, etc.

Principle of operation:

In the standard case, the basis of the design is a liner - a pipe with a carefully processed inner surface, inside which a piston moves, which has rubber lip seals that prevent the flow of working fluid from the cylinder cavities separated by the piston. When the working fluid is supplied into the cavity, the liquid under pressure begins to move.

Where are they used?

Hydraulic cylinder for turning the bucket of the 702EM backhoe loader

In devices that have hydraulic motors in their design, operate under heavy loads and require increased functionality. These are, for example, construction and repair, road and earth-moving equipment, cleaning units. Modern cranes and dump trucks, bulldozers and heavy-duty vehicles cannot be imagined without hydraulic cylinders. In addition, they are used in production: they are equipped with machines that cut metal, forging units, and presses.

Types and characteristics of hydraulic cylinders

When purchasing a hydraulic cylinder, you should take into account a number of parameters and purpose. The main characteristics of these devices are:

- P —nominal pressure of the working fluid:

- D —diameter of the cylinder (piston);

- d —rod diameter;

- L —rod stroke.

Nominal pressure is the main indicator. The technical resource is determined by the operating mode of the engine at maximum pressure, therefore this indicator is also important. The maximum value of the rod speed should not exceed 0.5 m/s. If higher speed is required, special seals are used.

Depending on the purpose or scope of application, there are hydraulic cylinders for turning, lifting the boom, arm, bucket, blade, support, etc.

Depending on the principle of operation, hydraulic cylinders are single-acting and double-acting, telescopic and piston with a single-sided and double-sided rod.

Single acting hydraulic cylinders

— the extension of the rod is carried out due to the pressure in the piston cavity, and the return is made by the force of the spring. If the return is carried out due to the action of the drive of another hydraulic cylinder or the gravity of the lifted load, there is no need for a return spring, that is, the principle of operation in this case is similar to jacks.

Double-acting hydraulic cylinders

— during forward and reverse stroke of the piston, the force on the rod is created by creating pressure of the working fluid in the piston and rod cavities. In this case, the force during the forward stroke is slightly greater, and the speed of the rod movement is less than during the reverse stroke due to the difference in areas - the effective cross-sectional area.

Telescopic hydraulic cylinders

– have a structural similarity to a telescope. They are several cylinders inserted into each other in such a way that the body of one cylinder is the rod of another. They are available for both single- and double-acting.

Piston hydraulic cylinders

with a one-way rod are used most often in self-propelled machines. Double-sided - for turning the working equipment of mounted excavators. The working fluid is supplied into the cavity, both through the body and through the rod itself.

carries out repairs and restoration of hydraulic cylinders of all types and manufacturers on favorable terms in Moscow. We can also provide advice on the effective use of various models of hydraulic motors.

Hydraulic cylinder - device, operating principle, force calculation

The performance of many types of power equipment, both industrial and domestic, is ensured by a device such as a hydraulic cylinder. Acting as a reciprocating drive motor, such a mechanism, with minimal energy consumption, ensures a full cycle of operation of power equipment used in construction, in various industries, in agricultural enterprises and in everyday life. Hydraulic cylinders are most widely used as the main element of equipment for pressing equipment, which is actively used to solve various problems.

A hydraulic cylinder is a volumetric hydraulic motor that converts the energy of fluid flow into mechanical energy

Areas of application

If we talk about the most common area of application of hydraulic cylinders, then it is equipping presses for various purposes. Presses, the driving element of which is a hydraulic cylinder, are actively used in enterprises involved in the processing of agricultural products, in metallurgical and machine-building enterprises, as well as in many other areas.

Presses equipped with hydraulic cylinders of various capacities are successfully used to solve the following problems:

- pressing and pressing out bearings and various shafts;

- metal bending and cutting;

- gluing products from various materials, performed under pressure;

- extracting oil and juice from vegetable raw materials.

The working element of this manual crimping of tips is a hydraulic cylinder

Presses equipped with hydraulic cylinders are actively used not only in manufacturing enterprises, but also in everyday life (in particular, for squeezing juices from fruit and berry raw materials, as well as for solving problems of repairing automobiles and any other equipment). Many home craftsmen make such presses with their own hands, using a car jack as the main working body, which, in fact, is a typical hydraulic cylinder capable of developing quite serious forces - up to 50 tons or more.

Depending on the purpose of the press, hydraulic cylinders with the appropriate technical characteristics are selected to equip it. The main characteristics are the operating pressure and the speed at which the plunger moves.

The hydraulic cylinder of this tabletop press is driven by a manual pump station

Design features and principle of operation

The design of any hydraulic cylinder includes the following elements:

Plunger hydraulic cylinders are somewhat different in design, in which the plunger simultaneously performs the functions of a piston and a rod.

Hydraulic cylinder diagram

The operating principle of any type of hydraulic cylinder is based on the pressure of the working fluid on the piston. As a result of the impact on the hydraulic cylinder piston, the rod begins to perform cyclic work, transmitting force to the working unit of the equipment served by the device. Such a working unit, the functioning of which is ensured by a hydraulic cylinder, depending on the type and purpose of the equipment, can be a compacting platform, a bending or pressing mechanism, as well as a device of any other type that ensures the transmission of the force of the hydraulic cylinder to the final recipient of power energy.

Sliding hydraulic cylinder device

Since the force created by a hydraulic cylinder, as mentioned above, is formed due to the pressure exerted by the working fluid on the piston, the properties of this fluid have a significant impact on the efficiency of use, technical and operational characteristics of the cylinder itself. As a working fluid for piston or plunger type hydraulic cylinders, as a rule, a special oil is used, which must meet certain requirements for a number of parameters:

- chemical composition and density;

- temperature values at which the working fluid retains its original characteristics;

- the tendency of the working fluid to develop oxidative processes.

To operate hydraulic cylinders of various types and models, working fluid is pumped into their internal chamber using a manual or electric pump.

Recommendations for use

The efficiency and correct functioning of hydraulic cylinders, which are the main elements of hydraulic systems, depend on the quality and technical condition of the latter. That is why the issues of operation and maintenance of hydraulic cylinders should also be approached systematically, assessing all factors that may influence the efficiency of their use. Thus, it is necessary to check pumps, oil lines, valve devices and filters.

When using presses equipped with hydraulic cylinders capable of developing forces that can amount to tens of tons, one must remember not only the rules for operating such equipment, but also compliance with safety measures.

Main varieties

Different types of hydraulic cylinders are distinguished according to a number of parameters. So, depending on the number of positions that the device’s rod can occupy, it can be:

Depending on the nature of the stroke of the piston and rod, the following types of hydraulic cylinders are distinguished:

- single-stage devices;

- telescopic hydraulic cylinders.

Operating principle of various types of hydraulic cylinders

A single-acting telescopic device or a double-acting telescopic hydraulic cylinder is used in cases where it is necessary for the rod overhang to exceed the length of the hydraulic cylinder body. A telescopic hydraulic cylinder consists of several cylinders that are nested one inside the other, and the body of each subsequent cylinder is the rod of the previous one.

According to the method of fastening the rod and sleeve, hydraulic cylinders can be divided into the following groups:

- 1. On lugs with articulated bearings

- 2. On the eye with a spherical bearing and a journal on the body

- 3. On the eye with a hinged bearing and with the preparation of the rear cylinder cover for welding with the mating structural element

- 4. With the outer end of the rod prepared for welding with a mating part and on the eye with a hinged bearing

- 5. With the preparation of the outer end of the rod for welding with the required part and with fastening

- 6. With preparation for welding of the outer end of the rod and the rear cover of the hydraulic cylinder with the required parts

Depending on the manufacturer, the layout of the elements of this circuit may vary.

Here are examples of hydraulic cylinder designations:

TsG-125×80×1000.11 manufactured by JSC "ELETSGIDROAGREGAT" where 125 piston diameter, 80 rod diameter, 1000 working stroke, 11 design: lugs with articulated bearing on the body and rod

G-150.125.56.400G manufactured by JSC "SDM" Orel where piston diameter is 125, rod diameter is 56, stroke is 400

Moreover, the plant that produces the machine often uses its own separate product markings, for example: the G-150.125.400G engine also has the designation TO-30.44.10.000, which is used directly by the plant that produces the TO-30 loader.

All features of markings and symbols must be reflected in the corresponding accompanying documentation of a particular hydraulic cylinder manufacturer.

Main characteristics

When selecting a hydraulic cylinder, you should focus on its parameters, which can be divided into two main groups:

- characterizing the power potential of a hydraulic cylinder;

- related to the design features of the device.

From the point of view of power potential, the most important parameter of a hydraulic cylinder is the force it creates. Various models of hydraulic cylinders offered on the modern market are capable of creating pressure, the value of which varies in the range from 2 to 50 tons, while the minimum forces (up to 10 tons) are created by single-sided hydraulic cylinders, and the maximum by double-sided ones.

Hydraulic cylinders are available with gravity, hydraulic or spring return, as well as with a locking nut

Knowing the dimensions of the hydraulic cylinders, as well as the pressure that the working fluid exerts on their piston, it is possible to calculate the force created on the rod. In order to calculate a hydraulic cylinder in order to determine the force created by the rod, it is enough to multiply the values of the pressure of the working fluid and the area of the piston on which it acts. When performing such calculations, it is important to take into account friction losses, for which a special coefficient is used, which is substituted into the formula used.

Calculation of the main parameters of a hydraulic cylinder

To determine the geometric parameters of the selected device, it is not necessary to study the drawings of the hydraulic cylinder; to do this, it is enough to understand its markings. Thus, the marking of hydraulic cylinders, the requirements for which are specified by the provisions of the relevant GOST, contains information about the following geometric parameters:

- diameter of the piston working surface;

- diameter and stroke of the pump rod.

In addition, the marking of hydraulic cylinders contains information about:

- design of the pump;

- type of device (single- or double-acting).

Based on the designations of hydraulic cylinders, you can also determine for what climatic conditions a particular model is intended.

Marking of piston hydraulic cylinders according to OST 22-1417-79

The efficiency of a hydraulic cylinder is ensured not only by its design and technical parameters, but also by the characteristics of the elements of the hydraulic system working in conjunction with such a device. A hydraulic cylinder, consisting of a working chamber, piston and rod, requires a supply of working fluid in the required volume and under a certain pressure, the degree of purity and other characteristics of which must meet certain requirements.

Compliance with such requirements is ensured by elements of hydraulic systems, the selection and maintenance of which, as well as the selection of the hydraulic cylinder itself, should be given special attention.

What is a hydraulic cylinder?

A hydraulic cylinder is a mechanism of the hydraulic system, which is an integral working element of equipment for various purposes, the main principle of which is the transformation of hydraulic force into mechanical force - the output link. The process of converting force is carried out using reciprocating or rotary-rectilinear movements.

What does a hydraulic cylinder look like?

The hydraulic cylinder is used in the manufacture of construction, road and agricultural equipment that has drives for raising and lowering mounted structures - manipulator cranes, buckets, shovels, seeders, hydraulic hammers, plows, buckets, etc. Hydraulic cylinders are also often used for wood splitters.

Types of hydraulic cylinders

Product variants require different configurations and application options. And for convenience, they are usually divided into specific types.

By type of direction of action of the liquid:

- Single acting;

- Double acting;

- Telescopic models;

- Differential;

- number of rod positions: two positions and many positions;

- by type of travel: telescopic or single-stage;

- in the direction of fluid pressure: single- or double-acting;

- by the presence of braking: with or without braking.

Classification of hydraulic cylinders depending on the working unit used:

- piston with one- or two-sided rod;

- bellows - with a working link in the form of a bellows;

- plunger - in which a plunger is used as a piston;

- membrane - have a link in the form of a membrane.

Based on the type of fixation in the system, units are divided into options with fastenings on hinges or more rigid fasteners.

Single acting

Such hydraulic motors are characterized by a certain direction of movement of the rod in it when the fluid pressure increases. A spring returns it to its normal position, creating certain forces for this.

Drawing of a single-acting hydraulic cylinder

It resists the standard elastic force of the spring during the smooth movement of the cylindrical rod. The functions of a return type mechanism in such a mechanism are performed by a spring. A slightly different method of operation is observed in jacks that do not have a return spring. When the mechanism is activated, the rod is returned by engaging the functions of another hydraulic motor or the force of gravity of the load being lifted or lowered.

Double acting

During normal piston movement, the force on the rod is achieved by providing increased pressure of the available fluid in the cavities of the rod and piston type cylinder.

Drawing of a double-acting hydraulic cylinder

The forward stroke, compared to the reverse stroke, is characterized by increased reinforcement on the rod and low speed of movement. This is due to the difference in areas to which the pressure force of the available fluid is applied. This type of hydraulic motor is used to lift and lower blades in many brands of bulldozers.

Telescopic

They are named so due to the structural features of the structure, visually reminiscent of a small telescope and due to the characteristic operating principle.

Drawing of a telescopic hydraulic cylinder

Structurally, the mechanism looks like several cylinders of different diameters inserted into one another. It is relevant to use such mechanisms in situations in which a large stroke of the cylindrical rod is required, but the size of the product itself must be small. This type of mechanism can be found in the form of single- or double-acting. Actively used in dump trucks.

Differential

This type of mechanism is characterized by a complex design, where pressure is applied to the piston pushing the liquid from both sides at once. The areas of pressure on the cylindrical rod are different from different sides. The speed of movement in relation to the forces in strokes of different directions is commensurate with the ratio of the areas of the piston. Accordingly, there is a relationship between effort and speed: the higher the speed, the lower the effort and the lower the speed, the higher the effort.

Drawing of differential hydraulic cylinder

When operating a hydraulic motor, the dimensions of the pistons, which have a ratio of 2 to 1 (differential), provide identical speed and rod stroke options in two directions. Similar functions are not found for hydraulic cylinders with a one-way piston without auxiliary elements or special adjustments.

Technical characteristics of hydraulic cylinders

The scope of application of the mechanism, as well as the period of its trouble-free operation, depend on the characteristics and parameters of the unit. It is important to know what it consists of so that, if necessary, you can easily purchase a replacement for the faulty part.

Main operating parameters:

- The diameter of the rod is a fairly important parameter that determines the scope of operation of the product. When choosing, it is important to focus on the type of equipment in which it will function. When designing a hydraulic system for a specific vehicle, it is imperative to take into account the dynamics of the load on the mechanism, as well as its load-carrying capacity. This eliminates bending of the rod during operation of the hydraulic cylinder.

- The diameter of a cylindrical rod, the main function of which is to determine the value of pulling and pushing forces;

- characteristics of the stroke of the cylindrical rod - a parameter that determines the movement of the piston and the dimensions of the mechanism in working condition.

- design features that allow you to determine how to attach the hydraulic cylinder.

- pulling force (kg).

- non-operating distance on centers that provide an effective assessment of the connecting dimensions of the unit.

- nominal pressure, calculated in MPa.

- pushing force (kg).

- the mass of the product itself.