Strong, reliable, durable and easy to install - this is the ideal set of characteristics for a fence. If it stands around a private house adjacent to other similar areas, then the spans should be “translucent” and not cast a continuous shadow. And it is desirable that the costs of paying for materials and installation are low. All these conditions are met by welded fence mesh with a polymer coating.

Welded mesh is offered in already assembled sections or rolls Source strojbum.ru

Welded mesh for fence

Unlike chain-link fencing, a fence made of welded mesh is made not only tensioned, but also in the form of sections.

The section consists of intersecting steel rods connected to each other by spot welding. The thickness of the horizontal rods is often made sufficient so that the section does not need additional supports in the form of crossbars or veins between the posts - the maximum diameter can be 10 mm. The cross-sectional diameter of vertical rods is at least 4 mm, and for suspended-strength fences they can be thicker - 5 or 6 mm.

There are different technologies for manufacturing and protective treatment of mesh.

The simplest and most inexpensive option is a mesh made of ordinary low-carbon steel without galvanizing for painting. It is rarely used as a fence for a private area due to its susceptibility to corrosion and short service life. But if you need a temporary fence at minimal cost, then this is the best choice. It is the “tension” type of fence that is made from thin rolled mesh, as a more durable option compared to chain-link.

The simplest fence made of welded mesh Source chelyabmetprom.ru

Mesh with galvanized rods is highly resistant to corrosion, and its service life depends only on the thickness of the zinc layer. If you apply any metal paint for exterior use on top, the durability will be even higher, and in any case, at least 20 years. There are two ways to manufacture a section - welding a mesh from galvanized rod and applying a coating after welding.

The next option is a galvanized fence mesh with a polymer coating (or powder coating based on film-forming polymer resins). This is the most common type of modern sectional fence made of welded mesh with high decorative properties. The metal is almost completely protected from corrosion, and the durability of the coating is determined solely by the properties of the polymer and its color. Typically, fence manufacturers offer several standard color options, but by paying a little more, you can order a different shade from the RAL palette.

Advice! When choosing a fence made of mesh with a polymer coating, you need to pay attention to whether there is a zinc layer under the polymer. There may be low quality products on the market - without this mandatory layer. You should also take into account that light shades fade less in the sun than dark colors.

Sectional fence made of welded mesh with polymer coating Source yaofuli.me

See also: Contacts of companies that build fences and enclosures.

Types of chain link

Even an ordinary chain-link can be of various types. At the same time, the difference is significant both in cost and in duration of operation. Let us note the features of some types:

- Non-galvanized. A low-cost and short-lived product that requires large expenses to maintain the fence in good condition. Immediately after installation, the material must be painted, this way you can avoid corrosion processes. Painting is done every year.

- Galvanized. More expensive in price, but does not require painting and lasts a long time.

- PVC mesh. There is a layer of plastic on the steel wire. This type of material appeared relatively recently. The price is more expensive, but the appearance is beautiful and the service life is longer. When choosing, you need to pay attention to the rigidity and cross-section of the wire located under the polymer. Good quality wire is difficult to bend by hand. If it bends, it will be difficult to attach and tighten in the future.

- Polymer. Made from polymer with additives that increase resistance to sunlight. It can be painted in different colors and is made with different cell sections. There are classic ones, reminiscent of simple chain-link cells, oblong and even round sections. Often this type of mesh is also called a plastic fence. It can be used for a neighbor's border. This product is not suitable as a fence from the street because it is fragile.

After installation

In addition to the different material, the mesh differs in the diameter of the cells, which can be 20–75 mm. The higher this size, the cheaper the material, but also the lower the strength. If you attach a chain-link fence to a corrugated pipe on the neighbor's border, use a section of 45–65 mm.

When choosing a mesh, you need to carefully look at all the rolls. Their edges must be of the correct shape. The length of the cell must have a bent part greater than 50% of the length of the link. This chain link is easier to properly attach to the post in the opening.

You should also pay attention to the cross-section of the wire, the evenness of the links, how well they fit on the corrugated pipe. Any deformation is a sign of poor quality.

Profile support

If the mesh has a polymer layer, it is necessary to clarify the warranty period. Budget ones, in addition to inappropriate quality, use cheap plastic, which crumbles after a year when exposed to sunlight. Good coating and proper installation will provide the professional pipe with a service life of up to 30 years, so you should not skimp.

Mesh weaving shape

For sectional fences made of welded mesh, the most common type is rectangular “weaving” with a vertically elongated shape.

"Square" is less common. This is a common format of welded road mesh with a wire diameter of 3 to 8 mm, which is used for the manufacture of inexpensive fences. For the fence, the smallest cell size is 50x50 mm. And these meshes can be not only “black”, but also galvanized. Manufacturers produce them in the form of rolls or cards, and fence manufacturers cut them into blanks for sections, attach them to a supporting “frame” and apply a protective coating.

Note! Weaving in the form of a “diamond” for welded mesh sectional fences does not exist - it is not economically feasible due to the large amount of production waste. This form of character is for sections made of chain-link or expanded metal mesh.

A mesh with square cells is found, but less frequently Source 911stroy.ru

Features of welded fences

- Reinforced fence. It is considered an economical option. It is made from rods of various thicknesses. The structure of rods with a diameter of up to 1 cm is not reliable and is considered a temporary structure. Her appearance is not very attractive. To strengthen the fence, thicker rods or profiled pipes are used. Instead of reinforcement, steel strips are sometimes used. They are inferior in strength to reinforcement, so they act as decorative elements.

- Welded mesh fence. Also applies to budget options. It is not considered a serious obstacle, but is indispensable in cases where it is necessary to fence off an area from small animals or birds.

- Welded sectional fence. It is being built in parts. First, a frame is assembled to which fence elements are welded - reinforcement, metal strips or mesh. Sections can be made standard (rectangular in shape with standard dimensions) or made to order. The last option will be more expensive. The finished fragment is fixed to the supports. This design has a more aesthetic appearance than a mesh without a base.

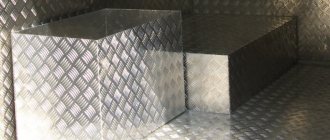

Section structure

The classic type of section has the form of a frame made of a strip, corner or profile, to which a mesh is welded.

If the welded mesh for the fence was made “individually”, then the diameters of the horizontal and vertical elements may be different. In order not to make the supporting frame of the section, the horizontal rod is installed with a larger diameter than the vertical one.

As another option for strengthening fence sections made of welded mesh, a “volumetric” mesh structure is used. It can be of two types:

- In the form of a triangular “wave”, which performs decorative functions and serves as a stiffening rib for the span structure. Such fences are called 3D.

- In the form of double horizontal rows. And if in a conventional welded mesh the rods are oriented in two planes, then in this one they are oriented in three – horizontal/vertical/horizontal.

Wave-like mesh structure Source archiexpo.com

Gitter mesh - what is it?

The basis of the grid is a sheet of galvanized steel rods, firmly welded together using the resistance welding method, which is why the mesh is called welded.

All vertical pins are equipped with additional stiffening ribs, hence the name - 3D mesh.

The steel wire mesh has a thick layer of anti-corrosion polymer, powder or galvanic coating. This type of fence reaches the consumer in the form of welded fragments, ready for installation. Along with them, you should buy all the necessary fasteners, which are usually included in the kit along with the fragments.

Example of sections for installing a Gitter fence

Yandex.RTB RA-1479455-7

The main purpose of this trend is to use it for fencing areas, but besides this, the relatively low price has made welded mesh a common material in the manufacture of structures for greenhouses, animal cages, reinforcement for pouring concrete, and special structures for strengthening brickwork. But still, the most common use of 3D mesh is a durable fence, which has a number of advantages over other types of fencing.

Poles and fittings

The sectional factory fence made of metal mesh is fully equipped for installation in different widths and span heights. Plus, some models can be equipped with additional accessories that increase protection against intrusion into the area.

In addition to the welded mesh section, the standard package includes:

- Pillars . Usually this is a square or rectangular profile pipe that has the same protective coating on the ground part as the mesh. The length of the pipe depends on the height of the pillar and the size of the underground part. There are different height options to choose from - from 1 m to 3 m. Since such a fence is of a lightweight type, and the wind load on it is minimal, the underground part is usually no more than 50% of the above-ground part. Additional stability is provided by concreting or installing a “heel”.

- Stubs . If the pipe does not have a protective strip welded on top, then the hole is closed with a polymer or rubber plug, which protects the inside of the pipe from precipitation. Some models of poles have fixed holes for fastening sections, which sometimes remain unused - they are also closed with plugs.

- Fasteners . Screw connections with clamps or clamps for fastening sections to poles.

Components for installing a fence made of welded mesh Source farpost.ru

Attaching chain-link mesh to metal posts

Before we figure out how to secure the chain-link mesh to the support posts, let’s consider what methods exist for installing this material.

Scheme of fastening to metal poles

Attaching the chain-link mesh to the corrugated pipe is carried out in 2 ways:

- Tension method.

- Fixation of sections.

Regardless of the chosen method, for installation work you will need:

- mesh material in rolls, in the volume necessary to cover the perimeter of the fence;

- steel strips and angles;

- welding machine;

- screwdriver;

- fasteners (bolts, screws, nuts, washers);

- perforator;

- wire cutters and pliers.

Option for fixing the chain-link to the corrugated pipe

Correct installation of the fencing mesh is carried out with extreme caution.

Therefore, protective gloves will also be needed. The main danger is the sharp ends of the horizontal parts of the wire. They must be bent immediately after the chain-link is fixed.

Installation procedure

The advantage of a sectional fence made of welded mesh is that welding is not required for its installation.

The installation procedure looks like this:

- Marking the perimeter, choosing a location for gates and wickets. For “frame” sections, it is advisable to calculate that a whole number of standard spans are placed between the gate supports and the corner posts. If this cannot be done, then you need to order the production of an “additional” element. For sections without a frame (for example, a 3D fence), this condition is not necessary - any section can easily be cut without losing the strength of the structure.

- Installation of pillars. The distance between the center lines should be slightly larger than the span, and the specific size depends on the method of fastening the section.

- Installation of sections using standard fasteners for this fence model.

Stage three. Installing support pillars

There are several ways to install poles, and the choice of one or another depends on the rigidity of the structure and the specific characteristics of the soil.

- By concreting into a shallow strip foundation (reinforced concrete strip on top of a “cushion” of sand and gravel 0.5 meters thick).

- Through separate concreting (a simpler and cheaper option). Make separate recesses for each pillar with a depth of 1/3 of the total length.

We will use the second method. So, having made preliminary measurements, hammer in the corner posts using a sledgehammer, reaching the required depth. After this, check them with a level to ensure they are vertical.

Mix the concrete solution (“four hundredth” cement and sand in a ratio of 1:3), you can use gravel as a filler (3/4 of the total volume). Pour the mixture into the holes, then check the verticality of the support posts again. When the mixture has hardened, stretch the twine between them to install intermediate posts. Do this using the technology described above.

By the way, you will also need a gate for such a fence. To choose the appropriate option, we recommend looking at samples of metal gates at https://sitka.com.ua/uk/vorota/. But let's get back to work.

Video description

For the procedure for installing a fence made of welded mesh, see the video:

The difference between a tension fence made of welded mesh is as follows:

- the distance between the supports can be arbitrary (at least two, but not more than three meters);

- Between the supports, veins are installed from a 40x20 mm profile pipe with a wall thickness of 2 mm;

- Rolled welded mesh is used as a fence, which is attached to posts and veins with self-tapping metal screws with a wide head or with a washer.

Methods for attaching the mesh to a pole Source pandia.ru

Properties and applications of chain-link mesh

The chain-link is used for fencing:

- agricultural crops;

- fields;

- nurseries;

- garden and summer cottage plots;

- temporary fencing of construction sites.

Profiled pipe with chain-link mesh

It is made of galvanized wire or with additional PVC coating. This construction material is resistant to external environmental factors and is easy to install independently.

Use Cases

A fence is not the only area where welded mesh can be used as a fence. With its help you can zone the internal space:

- allocate a playground or play area;

- fence off the parking lot;

- arrange an enclosure for animals;

- make a high fence for playing team sports (badminton, tennis, volleyball, mini football).

A fence made of 3D mesh with a polymer coating Source hs-zaun-halbartschlager.at

Gabions made of welded mesh can be classified as a separate category - they can also be used as a fencing for an area or for arranging fence spans around a site. And this type of fencing is increasingly gaining popularity as one of the easiest ways to install a natural stone fence.

Also no less popular is the option of using a fence made of welded mesh for arranging a hedge of climbing plants around an area.

Advantages and disadvantages

Before building this fence, it is necessary to determine in detail all the advantages and disadvantages.

A homemade fence made from reinforcement has the following advantages:

- Fast installation. If, for example, you bought an abandoned dacha and want to quickly fence it off from prying eyes, then a welded fence from reinforcement can be built in a very short time.

- Low cost. These fences, if they have a simple design and are made by hand, are much cheaper than fences made of natural stone or brick.

In the village

However, a fence made of reinforcing mesh has certain disadvantages:

- Susceptibility to corrosive processes. If a brick fence is simply “built and forgotten,” then a metal fence will require regular coating with paints and varnishes.

- Inability to hide the territory from prying eyes. Although such a disadvantage may well be an advantage for someone. Some people do not like to install monolithic fences in their dachas, since garden crops do not grow well in the shade of the fence. A reinforced fence is ideal for those people who constantly plant something in their garden. At the same time, you can create a hedge near such a fence. Taking into account the growth, it will close the territory from neighbors.

Near the house

Popular manufacturers

Domestic manufacturers of welded wire fences with a good reputation include:

- The Fensys company specializes in the production of 3D panels using European technologies, adapted to Russian conditions. Wire with a diameter of 4 mm is protected by a multilayer coating. Standard products are green, but orders are accepted for panels in white, grey, blue, yellow. The panels are available to people with low incomes.

- The Grand Line company, in addition to 3D panels made of 3.5 - 6 mm wire, offers ready-made gates and wickets of various designs. The protective coating is guaranteed for 10 years.

- The Gitter company produces lattice sections that are cheaper than their European counterparts. The products are popular among owners of summer cottages and small garden plots.

- Fenci produces reliable products with a laconic design. In a wide variety of prices and sizes, there are welded mesh for all preferences and budgets.

- At the Frunze plant you can order mesh fabric with PVC coating of non-standard size.

- At InStroySnab enterprises, customers are given a choice of protective coatings made of zinc, polymers, powder or simple paint. If necessary, specialists will make drawings of the fence taking into account the customer’s wishes.

Of the foreign manufacturers that are well-deservedly popular:

- The products of the Belgian company Bekaert are famous for their impeccable quality, high reliability, and long service life. However, not everyone can afford it.

- The French company Dirickx produces sections made of rods with a diameter of 2 - 5 mm with a two-layer coating. The zinc layer is cold applied and coated with polymer on top. Prices are lower than those of the Belgian manufacturer.

Helpful tips when choosing

To choose the right welded mesh, you need to proceed not only from your preferences, but also take into account the following recommendations:

- The larger the diameter of the wire and the smaller the size of the cells, the stronger the fence will be.

- The width of the rolled web is chosen equal to the height of the fence so that there are no horizontal joints. The minimum standard size is 0.5 m.

- The cuts of the rods should be smooth and the bends without cracks. Otherwise, rust will soon appear in the flaws.

- The shape and size of the cells must correspond to the description in the accompanying documents.

- Visible defects on the protective coating are unacceptable. It is better to choose options with two-layer protection. The increased costs will be paid off due to high reliability and long service life.

- There should be no flaws in the places where the rods are welded. High-quality rolled mesh does not form cracks when welded when unrolled.

- The seller is obliged to present a quality certificate upon request.

- The contents must match the list in the instructions.

Universal and anti-vandal fasteners

| Anti-vandal breakaway nut ART 9150 M10 (stainless) A2 (AISI 304) | Roofing screws with sealing washer, colored | ||||

| Size | Price /piece | Size | Price /piece | ||

| Anti-vandal breakaway nut M6 (stainless steel) | 12.00 rub. | Roofing self-tapping screw 5.5x19 color according to ral | 2.90 rub. | ||

| Anti-vandal breakaway nut M8 (stainless) | 17.00 rub. | Roofing self-tapping screw 5.5x25 color according to ral | 3.00 rub. | ||

Fittings and accessories must ensure ease of installation, maximum protection, stability and safety of the fence mechanism. This means that you should never save on such a purchase.

Sequence of work

Preparation of pillars

As mentioned above, a profile pipe was used for the pillars, which was purchased at a metal trade. Such a pipe is usually sold 6.0 m long, but for ease of transportation it was immediately cut into 2.0 m sections.

Of course, in some cases it makes sense to cut the pipe into two parts of 3.0 m each, but here it is necessary to proceed, firstly, from the depth of the pillar, and, secondly, from the required height of the fence. Columns 2.0 m high were enough for me.

Holes were prepared in the pipe for installing bolts to fasten the crossbars. The height of the holes must be taken depending on the immersion depth of the pipe and the desired height of the transverse runs. For these purposes, an electric drill and a metal drill ø10 mm were used.

You can make holes after installing the post in the ground, but doing this is extremely inconvenient

Before immersing in the ground, the pipe must be treated with paints and varnishes to protect against corrosion.

For these purposes, I selected the following paintwork materials:

- Soil GF-021

- Enamel PF-115

Primer GF-021 is intended for coating steel and wooden surfaces before applying enamel.

PF-115 enamel has good adhesion and is suitable for outdoor use. Operating temperature range from -50 to +60 °C.

Before applying the primer, the profile pipe must be cleaned of pockets of corrosion; for this you can use metal brushes, sandpaper and special abrasive attachments on an angle grinder.

After cleaning, the surface of the pipe must be wiped with a rag soaked in solvent or degreaser.

Next, primer is applied. For these purposes I used a brush. The drying time of the GF-021 primer is about 24 hours at an ambient temperature of 20 °C.

Then the enamel is applied. To apply the enamel, I already used a roller, since this applies the paint more evenly, which is important from an aesthetic point of view. The enamel was applied in two layers.

The drying time for PF-115 enamel is 24 hours under normal conditions - humidity up to 65% and temperature about 20 °C.

What affects the cost

If you decide to purchase fasteners for fences, you will be interested to know what the prices for such products generally consist of. The type of elements, the material used to produce them, and the manufacturer’s fame and reputation are of key importance. In order not to make a mistake, you should buy fasteners made from profiled metal pipes, the production of which was made using exclusively high-strength carbon steel with anti-corrosion characteristics.

As for the types of fasteners, there are really many of them:

- bolts and x-brackets;

- log holders;

- rivets;

- self-tapping screws;

- logs secured by screws or welding.

The cost of fasteners is influenced by the absence/presence of powder coating. Some types of elements are treated with hot zinc, for example, x-brackets made of solid metal sheets. Additional processing increases the prices of fittings and accessories. However, it also gives them additional strength, better performance and protective characteristics and beauty.

Composite clamps with plastic insert

| Composite clamp for profile posts with plastic inserts | Extreme clamp for profile posts with plastic inserts | ||||

| 40x40mm | RUB 75.00 | 40x40mm | RUB 75.00 | ||

| 50x50mm | RUB 75.00 | 50x50mm | RUB 75.00 | ||

| 60x40mm | RUB 75.00 | 60x40mm | RUB 75.00 | ||

| 60x60mm | RUB 75.00 | 60x60mm | RUB 75.00 | ||

| 80x80mm | 80.00 rub. | 80x80mm | 80.00 rub. | ||