If the main tools of a blacksmith are a hammer and an anvil, then for a carpenter there is nothing “more familiar” than his workbench. For people who work with wood, it can at the same time be a cutting platform and an assembly table, a stop and stand, a device for storing tools and even, if you want, a small carpentry machine, and sometimes a means of earning money. This article tells you how to make woodworking tables with your own hands. The instructions, photographs and drawings presented in it will help even a beginner to install this structure.

Osya member of FORUMHOUSE

First of all, after building a workshop, you need to make yourself a table. A table like a workbench, essentially. This is a table for work - fitting, assembling small things made of wood (stools, shelves, etc.). I'll call it an assembly table.

In fact, the second name for a workbench is an “assembly table.” But, as you already understand, its purpose goes far beyond assembly operations. Therefore, the design of a multifunctional workbench in a carpentry can be quite intricate (see drawing below), and its development (in the absence of experience) can be spent as much time as it takes to design the carpentry workshop itself.

Purpose

A workbench is a craftsman’s workplace used for repairing building materials.

Home workbenches are designed for carpentry, metalworking and carpentry work.

A carpenter's workbench is a small table (1×6 m), which has stops for processing workpieces.

Carpenter's workbench

Workbenches are made of wood or metal.

It is preferable for an auto mechanic to choose a workbench made of metal, and for a mechanic to choose one made of wood.

The structures are easy to assemble and disassemble, so there are practically no difficulties when transporting them.

Metal bench

The use of the design is quite common in various fields of activity. Workbenches are widely used both in utility rooms and in large-scale production enterprises.

Additional accessories that can be equipped with a workbench provide convenience when processing building materials.

A workbench for home intensifies the work process. That is why, when manufacturing it, it is important to take into account the scope of production and the layout of the room in which it will be located.

Compact workbench for small spaces

When there is not enough space to install a workbench of standard sizes, you can build a workbench consisting of one bedside table and place it on the loggia.

Universal machine height

Universal machines are an intermediate option between carpentry and metalworking. It is convenient for the garage, taking into account the minimal space for additional furniture. These tables are made of metal. They have a widened and elongated shape and can be adjusted.

Product with adjustment for standing work

Since the machine is universal, it is mainly equipped with mechanisms for changing the height of the tabletop. This is convenient, as you can adjust the height for different types of work relative to the equipment on the table.

Combining parts

The main properties of a workbench for the home:

The surface of the device is made of wood. For these purposes, dry planks with a thickness of 5–6 cm are selected. It is best to use wood that has been pre-treated with drying oil. Otherwise, the workbench tabletop will not last long.

Edged board for workbench

A vice is attached to the cover of the structure, which will fix the items being repaired.

It is preferable to make large vices from wood, and small ones from metal. If the length of the workbench exceeds 1 m, several vices of various sizes can be installed on its working surface.

Vise design

The legs of a carpentry workbench are made from boards of other wood species (maple, linden, pine). They are connected to each other by strips located longitudinally. This ensures reliability of the design.

The space under the workbench tabletop can be used rationally by installing pull-out drawers or shelves for storing work tools.

Workbench with built-in drawers

Recesses are made on the surface of the structure in which heavy items for repair will be fixed.

It is recommended to drill a hole on the back of the tabletop for repairing small parts.

Types of designs

Devices are divided into the following types:

Mobile.

It is a small table with a vice and weighs up to 30 kg.

It is better to make the lower supports of this design from metal material, as this gives the workbench additional stability.

Mobile workbench example

This device is designed for repairing small wooden pieces.

Stationary.

A fairly simple device to make. Most often used for processing large wooden products.

Scheme of a stationary workbench

Composite.

Elements of this design are connected by fastening bolts.

The convenience of this desktop lies in the interchangeability of individual elements.

Composite workbench

Making a composite workbench is fraught with some complexity.

Mechanic's workbench

This device is distinguished by its functionality and durability.

On the working surface of the bench, you can fix workpieces intended for processing, and the pull-out shelves are very practical for storing technical equipment.

Mechanic's workbench

The height of the structure is adjustable.

The main elements of a workbench of this type include the bench (its base) and the lid (working surface).

Components of a carpentry workbench

The benchtop of a bench is usually made from hardwood. However, pine is used for the underlayment.

The thickness of the cover measures approximately 60–80 mm and 500 mm in width. The parameters of the workbench depend on the main purposes of making the workbench.

The understand can be collapsible or stationary. Since the device is easy to assemble and disassemble, it is convenient to use during transportation.

Collapsible workbench

If the workbench base is made of metal, then planks are additionally attached to its base to protect it from various defects. For this purpose, the tabletop is covered with linoleum. This method will prevent small elements from falling into the cracks on the desktop.

It is recommended to install high sides on the workbench lid so that small parts being processed do not roll off the surface. A protective partition will isolate the workplace and prevent chips from flying out during metalworking.

The sides will prevent small parts from rolling off

A workbench for your home requires at least several shelves and drawers.

You can fill the space under the countertop of the device with a variety of cabinets in which it will be convenient to store building materials.

For the convenience of working at the workbench, you will need to install sockets, especially if you frequently use power tools.

In large production, it is better to use roller workbenches. This will allow you to freely move them to the desired place.

Workbench on wheels

Peculiarities

A folding workbench when folded takes up to 10 times less space than when working.

- Portable - a version whose operating principle is similar to a folding chair or a regular extendable table that is easy to carry. The disadvantage is the almost complete absence of drawers, which noticeably weigh down the structure: instead of them there are one or two shelves without back walls, the workbench itself resembles a rack.

- Universal - a structure that is attached to the wall, but unlike a regular wall-mounted table, this table has all four legs. The scheme is complicated by retractable wheels, allowing you to use the workbench as a cart. This version is reminiscent of a mobile table for preparing hot dogs, popular among fast food sellers in the 90s of the last century: there are shelves with back walls (or full-fledged drawers). It can be folded against the wall, lifted and secured, and rolled to another place. Carrying requires the help of two more people: the weight is significant - tens of kilograms.

- folding wall- mounted workbench is used in a home “office” or utility room – outside the home. It is stylized to match the general design of a home interior, and can be made as a mini-transformer, from the appearance of which guests will not immediately guess that this is a workbench. A profile pipe can be used for the underbench.

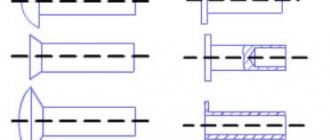

Types of vices

Before choosing a workbench, you need to find out what kind of vices exist for these devices.

The vice is designed for fastening workpieces to the structure. To ensure the efficiency of the work process, special grooves with wedges are installed on the workbench lid, thanks to which the bars are attached.

The properties of the vice depend on the specifics of the work.

The following types of fasteners are distinguished:

Chair vice.

The vice gets its name because it is attached to a chair-shaped base. They are designed to perform heavy duty work. They are used very rarely.

Chair vice

Hand vice.

They, in turn, come in three types:

– instrumental;

– rotary;

– non-rotating.

For rotary and fixed vices, the width of the jaws is approximately 80 mm.

Hand vice

Universal vice.

They are used for fastening small workpieces.

The universal vice is fixed to the workbench tabletop using mounting bolts.

Universal vice

Special vice.

They are convenient because they can be easily rotated in any plane and adjusted both vertically and horizontally. This allows you to position and fix the element for processing at your own discretion.

Special vice

Classification of metalwork benches

Locksmith workbenches can be of various types.

There are single and double designs. The type of fixture depends on the number of bedside tables it has.

Basically, the diameter of a mechanic's workbench, which has one bedside table, is 120x80 cm, and from 80 cm in height. This type of single-seat workbench is rightfully recognized as the most convenient.

Single workbench

Workbenches, consisting of several bedside tables, are usually made at large specialized enterprises.

The dimensions of the two-seater workbench are approximately 280 cm in length.

There are also pedestalless devices.

The single-pedestal workbench is made of high-quality metal, the thickness of which reaches 2 mm.

The working surface of this design is most often made of wood or galvanized material. Often these workbenches are equipped with hanging shelves for storing equipment and other devices.

Double backpack with hanging shelves

Single and double benches differ from each other only in the number of bedside tables. The more drawers and cabinets a device has, the more convenient it is to store various tools and building materials.

Today, a reinforced workbench with a metal lid reaching 5 mm in thickness is especially popular. All structural elements are connected to each other with fastening bolts.

Workbench design

The height of the device must be correlated with your own height. With an average height of a person (170 cm), it is rational to make a workbench with a height of 90 cm. It will be very convenient to work at such a table.

The configuration of a workbench for a home is selected taking into account the work that is planned to be performed on it. In the usual sense, a workbench should have stops, recesses on the working surface for various parts, and a vice.

When designing a structure, it is necessary to take into account which hand of the master is the leading one - left or right.

Simple single workbench project

The dimensions of the workbench largely depend on the size of the room. The following standard desktop dimensions are established: 2×1 m.

It is better to place the structure near the window. It is necessary to provide additional lighting sources. You need to leave space for sockets near the workbench.

If possible, place the workbench near a window

Standard options

In the process of selecting the location of the workbench tabletop level, it is necessary to determine what type of workpieces will be processed on it. If the main volume of work with wood blanks is envisaged, then in this case the workbench should have a smooth and even wooden tabletop , and if the work is more related to the processing of metal parts, then you will need a metalwork version of the table, the surface of which is covered with durable materials, for example , metal.

On a mechanic's workbench, in addition to the basic and necessary additional devices, it is recommended to equip a special mechanism for lifting heavy parts , as well as provide a system for mechanical adjustment of the height of the tabletop, which can be changed depending on the height of the worker.

There are various ways to determine the height of a carpenter's or benchtop from floor to tabletop: The worker will need to take measurements from the top of his head to his chin. Then, from the resulting figure in cm, you need to subtract the size obtained as a result of measuring the hand from the tip of the fingers to the corner of the elbow, also in cm. Next, from the result obtained, you need to additionally subtract the height of the vice, which the worker will constantly deal with, since they are the ones hold any parts during the entire processing cycle.

Use of building materials

- Planed timber is considered a universal building material for making a desktop. The size of the legs of the structure is usually 7x10 cm.

Workbench legs made of planed beams

- An old unnecessary door can serve as a workbench cover. The thickness of the boards used for the tabletop should be about 5-6 cm.

- Before making the device, you need to decide what type of workbench will be - stationary or collapsible. Based on this, the fastening is selected (bolts, screws, nuts, nails).

- It is advisable that the workbench has several vices. One can be installed on the side and the other on the front. Vices are convenient because they fix products intended for processing. The universal width of the vise jaws is 5 cm.

Attaching a vice to a workbench

How to make a DIY workbench

First of all, you need to think about the place where the structure will be located. It is also worth considering where the sockets will be installed.

The optimal size of a single-seat desktop is 80x80x150 cm.

The frame and top of a bench workbench is usually made of rigid metal. In some cases, steel profile pipes are used.

Workbench frame made of profile pipes

The main property that a structure must have is stability. The main thing is that the workbench can withstand heavy loads. The same requirements apply to the desktop tabletop. It must be reliable.

The thickness of the workbench cover is about 5 cm. The working surface is covered with linoleum or textolite to protect it from various damages during processing of workpieces. The thickness of the steel coating is approximately 0.5 cm.

The workbench top must be reliable

In its finished form, a homemade workbench will be a semi-industrial device on which, if necessary, you can install a vice.

Using welding equipment, the frame corners are connected to each other. The steel cover of the workbench is usually welded, and the wooden one is securely fixed with mounting bolts. The free space under the table top can be allocated for drawers, shelves or cabinets.

Recently, transformable workbenches have gained particular relevance. They have a sliding lid and several wooden frames connected to each other in the form of scissors.

Transforming workbench

If a finished metal workbench is impregnated with an antiseptic, it will last much longer.

The desktop frame is usually made of soft wood, and the lid is made of hard wood.

The type of workbench does not affect the choice of the place in which it will be located.

The device must be as reliable and stable as possible.

What is a circular saw?

In everyday life and in production, a circular saw is necessary for sawing various materials (wood, slate, plasterboard, soft metal, plywood, etc.). This hand-held electric tool (as standard) is designed to perform straight cuts with a depth of 40 to 140 mm (most models produced by manufacturers allow you to make right angle cuts up to 85 mm, but there is a line of more powerful equipment for construction sites). During the operation, the operator holds the device firmly in his hands and carries out sawing, moving along the workpiece. At the same time, there are no restrictions on the size of the workpieces in terms of length and width. It is possible to cut at an angle to the surface of the part.

Circular saw device

Saw models vary in power. The most budget devices have a power of up to 1.2 kW and are designed for sawing workpieces up to 4.5 cm thick. They are excellent for household needs, carrying out periodic work for short periods of time and are simple and unpretentious. If you need to make a cut up to 6.5 cm, and this needs to be done often and for a long time, you will need a semi-professional tool with a power of up to 1.8 kW . To carry out production tasks, professional equipment with a power of up to 2.2 kW , withstanding long-term loads and capable of cutting parts up to 8.5 cm thick. In addition, tools are produced intended for use in woodworking enterprises, capable of sawing workpieces up to 14 cm thick. 1 cm. Its power reaches 5.5 kW , and weight - up to 100 kg.

A circular saw

Important! For home workshops, devices with a power of about 1 kW are usually sufficient. Before purchasing a model, it is important to take this point into account, since overpaying for the saw itself and for the electricity it consumes, as a rule, is not justified by necessity.

Choosing a modification based on the purpose

When choosing disks for a tool, you need to pay attention to their technical parameters.

- Tooth sharpening angle . Soft materials are sawed with discs that have teeth inclined in the direction of rotation of the disc. To work with metal, models with a negative sharpening angle are required.

- Number of teeth . For sawing different materials, you should select discs with different numbers of teeth: for soft ones - models with a large number of teeth, for hard ones - with a small number. For example, for wood, the minimum number of teeth is 24.

The marking of the blades includes data on its diameter and the size of the seat.

To use a circular saw for a long period of time, it is important that it does not weigh too much, is ergonomic, and has well-sharpened blades. Holding the unit in your hand for a long time is not at all easy. Operator fatigue can lead to poor sawing quality. Therefore, many craftsmen who work with saws practice placing them on a table.

Circular saws are often mounted on a table

The point of such a device is to secure the saw body under the tabletop so that only one sawing disc is above the table. The workpiece moves along the tabletop and is sawed by a rotating disk. Such a stationary device greatly facilitates work and allows continuous work without loss of quality and quickly. Manufacturers offer a large number of models of saws placed on tables. The cost of structures varies from 8 (equipped with the most primitive saws) to 140 thousand rubles. Self-manufacturing of the structure allows you not only to save money, but also to have a unit at your disposal in accordance with your own requirements.

Making a table for a circular saw is easy

Homemade workbench

A do-it-yourself workbench is an excellent option for those craftsmen who are tired of using stools or other furniture attributes as a work table.

The versatile and functional design makes a great place to create and store a variety of tools.

A workbench for a home should have the following properties:

- spacious space for storing building materials;

- the workbench tabletop must have recesses for fixing workpieces;

- the structure must be stable;

- thoughtful configuration of the device;

- perfectly flat working surface.

The design of the workbench must be stable

Our idea

Most of the designs described on the Internet are stationary solutions, that is, they are mounted on some kind of large table, and transportation or the ability to fold and remove the machine is not expected. There are many options when various hand-held power tools are installed on one workbench, for example, a jigsaw, a milling cutter, a circular saw, etc. In this case, the versatility of such a comprehensive solution takes place, but mobility and transformation are also not provided for in this case.

There are solutions when the machine made from a jigsaw is not large and can be easily moved and removed. But it is not designed to be easily disassembled and folded into a compact form. An example of such a machine is described in the article “Jigsaw machine for cutting with your own hands.”

Our idea is to make a set of devices that would easily integrate with each other and complement each other, while expanding functionality. In addition to integration during operation, our tools must be able to integrate during storage. For example, to be some components of one case, which can easily find its place on a closet or mezzanine.

Thus, our developments will be most useful to those who have limited storage space and space for work. When you have a spacious workshop or a large, warm garage, there is plenty of space (although it varies), but if you want to tinker in an apartment, this option is simply necessary.

Making a workbench from plywood

To make such a homemade workbench, you will need:

- usually 2 m long;

- electric saw in the form of a disk;

- notched spatula 2x2 mm;

- “Moment” glue, intended for gluing plywood;

- plywood strip 1.22x0.3 m;

- sheet of plywood, 1.8 cm thick.

- clamps.

Tools for making a workbench

This workbench will be a structure made from several plywood sheets.

The dimensions of the tabletop should be 1.5 x 0.6 m, and the thickness of the lid should reach 7.2 cm.

Plywood is a fairly expensive building material, so one plywood sheet can cost about 1 thousand rubles, excluding delivery.

To save money, you can use only one sheet of plywood.

First of all, you need to make blanks for the desktop table top. To do this, one sheet of plywood needs to be divided into several equal parts, measuring 1.52 x 0.61 m.

Then, after checking the flatness of the sheets, you will need to fold them towards each other so that the convex side is inward.

After this, the parts must be glued together. The glue is applied with a regular brush to one surface of any plywood quickly, in a matter of minutes.

This is quite a complex process.

Instead of Moment glue, you can use PVA intended for furniture. The glue must be of high quality.

Plywood workbench

You also need to make sure in advance that you have clamps and boards on hand that can be used to press the glued parts of the plywood.

When tightening the clamps, you need to keep the plane of the plywood sheets under control. As a rule, such a tool will help with this. The workbench tabletop cannot be clamped with clamps, so it does not need to be additionally loaded.

It is better to glue several sheets of plywood together on a smooth surface. After applying the glue, the glued parts are pressed down on top with a heavy sinker.

There may not be a flat surface in the house for making this structure, but clamps will be quite enough to ensure that the sheets pressed down by the load are firmly glued together.

You need to wait for the glue to dry, remove the clamps and move on to the next step.

The working surface of the workbench should have a size of 1.5x0.6 m.

It is important that the homemade workbench has the correct geometric shape.

Assembly plan for a simple workbench

To do this, you can use a corner of the plywood to guide you. From plywood strips, about 15 cm wide, you need to make a perimeter for the workbench. The resulting strips are distributed around the perimeter of the tabletop.

The desktop supports are made of timber measuring 4x6 cm.

The legs of the workbench create the appearance of several glued parts and one block.

The height of the structure should be proportional to the height of the master, so that it is comfortable to work at the workbench.

The legs are assembled using glue.

A homemade workbench will be stable if the measurements were accurately followed during its construction.

The legs of the device are attached to the workbench tabletop using self-tapping screws, the dimensions of which should be 8x120 mm.

You will need to drill recesses on the workbench cover to secure various products during processing.

Workbench assembly plan with storage shelves

Thus, the manufacture of a homemade workbench takes place in the following stages:

- Gluing several plywood sheets measuring 1.52 x 0.61 m.

- To be effective, the glued parts of the plywood must be pressed down with a weight on top.

- You can use both Moment wood glue and PVC, but of high quality.

- To give the workbench the correct geometry, you need to take small plywood plates measuring 15 cm as a guide. They are distributed along the perimeter of the workbench cover.

- The legs of the workbench are a kind of glued structure consisting of several parts and one block. They are attached to the device cover using self-tapping screws (8x120 mm).

- Drill recesses on the workbench tabletop, which will later be needed to secure the workpieces during processing.

- Build drawers, shelves or cabinets under the cover of the workbench in which the equipment will be stored.

There are many types of workbenches for home use. Each type of design has certain characteristics and features.

To protect the device from various damages during the work process, the workbench cover is upholstered with a special material. If necessary, the workplace is equipped with a vice.

Wooden bench vice

The device significantly facilitates the work process, making it convenient and comfortable.

Making a workbench with your own hands is quite simple. You just need to follow the instructions and understand for what purpose it is being manufactured.

Recommendations

For clearer contact, the contact points between the parts are coated with wood glue. Strengthen glued joints using ready-made furniture corners or cut-off corner profiles. Strengthen corner joints where there is no contact with the drawers using triangular spacers.

It is advisable to immediately mount an extension cord with several sockets on the finished workbench - they will be needed to operate some power tools.

A folding workbench is hardly intended for heavy work such as assembling windows and doors. It makes turning operations difficult to produce massive parts weighing dozens of kilograms. For “heavy” work, it is better to assemble a stationary wooden workbench that can withstand a weight of more than one hundred kilograms.

- Regardless of how long the workbench is, it can be foldable (including a transformer). A one-room apartment or a small country house of 20-30 square meters is unlikely to allow you to place a stationary workbench that cannot be folded. Be guided primarily by the square footage of the living space. The same advice applies to an outside utility room or garage.

- Do not use plywood less than 15 mm thick or made from soft wood types for the tabletop. Such a workbench is only suitable for sewing work or activities that do not require the use of brute physical force.

- Do not work on a workbench with strong reagents, especially if there is frequent splashing. For chemically active work, special tables and stands, for example, made of glass, are used.