Sheet metal bending 6 meters

The capabilities of the technology largely depend on the length of the sheet and the potential of the equipment. Bending 6 meters of sheet metal without separating it is a complex process. But if the enterprise has the necessary capacities, its own production base, and its equipment has a high technical level for the production of rolled products, processing sheets of such length is not a problem. The potential of our bending production is very wide, and if you have six meters of sheet metal, the task will be completed.

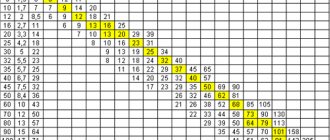

Prices

| Sheet metal thickness | Workpiece or product length | ||||

| Up to 100 mm | Up to 500 mm | Up to 1000 mm | Up to 2000 mm | Up to 3000 mm | |

| Up to 1 mm. | 5 rub. | 7 rub. | 10 rub. | 15 rub. | 20 rub. |

| Up to 2 mm. | 6 rub. | 8 rub. | 12 rub. | 18 rub. | 24 rub. |

| Up to 3 mm. | 8 rub. | 10 rub. | 16 rub. | 14 rub. | 32 rub. |

| Up to 4 mm. | 10 rub. | 15 rub. | 20 rub. | 30 rub. | 40 rub. |

| Up to 5 mm. | 15 rub. | 20 rub. | 30 rub. | 45 rub. | 60 rub. |

| Up to 6 mm. | 18 rub. | 23 rub. | 36 rub. | 54 rub. | — |

| Up to 8 mm. | 25 rub. | 35 rub. | 50 rub. | — | — |

| Up to 10 mm. | 30 rub. | 40 rub. | 60 rub. | — | — |

Sheet bending

The essence of sheet bending work is that they transform a flat product into a spatial one, “living” in three planes, and give it various shapes. Bending of a 6-meter sheet is usually performed without heating, in a cold way. Thermal exposure may be required only in cases where the rolled product has a large cross-section. Or when the raw material from which it is made has low ductility. The most difficult to process by bending are rolled titanium, duralumin and steel alloys with inclusions of manganese and silicon.

Handmade

This work is usually done with hand scissors . Marks are placed in the right places along which manual bending of the metal will be carried out. The sheet is securely fixed in a vice. The first fold is made with a massive hammer. The product is moved to a new bend location, clamped with a block of wood, and bent in the desired direction.

Upon completion of the work, you must ensure that the product meets the established standards. The check is carried out using a square and, if necessary, defects are eliminated.

Bending sheet metal with a sheet metal bending machine

In an industrial way, sheet bending 6 m long is carried out on special devices - sheet bending machines. These devices differ significantly in functionality and the way they influence the workpiece. The main components of a rotary machine are rollers. They help the workpiece acquire a rounded shape. On the simplest machines, the rollers can be driven manually; in more complex machines, this process is carried out automatically. For simple types of bending, you can use a device with a simpler mechanism. It includes two plates - static and rotary - and a pressure beam. However, it is difficult to process long sheets on these devices. A simple bend, and again for small workpieces, can be performed by a press, the operation of which is based on pneumatic or hydraulic force. The bending of the sheet is carried out by two working parts - the matrix (fixed element) and the punch (movable). This machine method can process sheets of large thickness.

Bending strips into a ring

A more complex operation is bending strips into rings. What is needed here is a small and easy-to-manufacture machine, for example, like the one shown in the video. It consists of a base plate on which three rollers are fixed - two support and one drive, on a handle 30-40 mm long. The drive roller can move along a horizontal axis and press the strip against the support. One of the support rollers must be able to move perpendicular to the direction of pressure. In this way the diameter of the resulting ring is adjusted.

The strip is placed between the rollers and pressed using a screw mechanism. When the drive roller rotates, the strip begins to move between it and the support rollers and bend towards the drive. After a complete pass of the strip, an almost perfect ring is obtained. If you make the handle telescopic so that the arm can be made longer, then you can bend strips of almost any thickness onto the ring without much physical effort.

This homemade strip bending machine is practically no different from the factory one. With the right choice of metal for the rollers and clamping device, small-scale production, for example for the manufacture of decorative fences, gates or frames of canopies and awnings, is possible even in a home garage, not to mention a metalworkshop.

Basic methods of sheet metal bending

We have already mentioned that bending 6 meters of metal is mainly performed without heating. However, in some cases, the second method is used - thermal. To prove the validity of this technique, the material is examined for:

- plasticity, that is, they determine its ability to deform;

- the ability to form an angle of the required size without cracking;

- ability to obtain a complex bending contour.

Knowing the characteristics of metals and alloys, a specialist can predict the result, relying only on theoretical calculations. However, most often the tests are carried out experimentally: in a workshop environment, using a sample for this purpose.

Basic principles

Metal bending is carried out using various methods. Welding is often used, but temperature exposure can change the shape and properties of the finished product. This reduces performance properties and manufacturing accuracy.

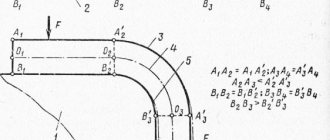

Since when bending metal, the outer layers of the metal stretch, and the inner ones begin to compress, it is necessary to bend part of the rolled metal relative to another by a given angle. The angle can be found using calculations.

The product is deformed to those values that are within the specified limits. They depend on the following parameters:

- Thickness of the metal sheet;

- How much is the bending angle?

- How durable is the material;

- Speed and time of the procedure.

The permissible deformation indicator will depend on them. The next step is to select the type of bending.

Advantages of Sheet Metal Bending

When ordering metal bending up to 6 meters or less, you get:

- still a monolithic product with no seams;

- if the work is performed correctly, it has no external or internal defects;

- a part whose appearance is not spoiled by any welds;

- as strong as before bending, and with no less service life.

It is noteworthy that most materials and alloys can be bent: steel, aluminum, copper. But not all of them can handle welding work. For the same aluminum, only a very experienced welder can make a high-quality weld without burnouts.

Bend a ring from a metal strip.

There was a need to make several rings from a metal strip 8mm thick and 55mm wide. The outer diameter of the ring is 400mm, and the inner diameter is 300mm. After bending and welding, it is finally processed on a lathe. Maybe someone has encountered a similar problem and can suggest bending technology. Perhaps there are devices for bending similar parts. I would be grateful for advice and suggestions.

Stupid question, but won't thin tape work? In general, I would contact a decent forge with this question.

eug28 wrote: There was a need to make several rings from a metal strip 8mm thick and 55mm wide. The outer diameter of the ring is 400mm, and the inner diameter is 300mm.

Something is unclear, how can this be, the outer diameter is 400 mm, the inner diameter is 300 mm, with a wall thickness of 8 mm? (400-300): 2 = 50mm, the wall thickness should be, not 8mm, if we are talking about a ring. Will scraps of pipes of the required diameter be suitable?

Suever wrote: Something is unclear, how can this be,

The strip should bend along its width, not its thickness, if I understand correctly. For such parameters it is necessary to use something like an industrial pipe bender with a powerful electric drive with appropriate mandrels.

It’s easier to cut it out of an 8 mm sheet using gas and trim it on a machine. If this is not possible, then really go to the blacksmith.

Madman wrote: For such parameters it is necessary to use something like an industrial pipe bender with a powerful electric drive with appropriate mandrels. __________________

In this case, you need to bend it on the “edge”, 8mm on the edge is something not ice, then it’s easier to draw it on an 8mm sheet, and even cut it out with a jigsaw. I understand, but it’s necessary.

In general, try to do this with a cardboard model, manually bend it on its edge, it either folds correctly or breaks, IMHO the same will happen with metal, so it’s better to cut it from a sheet.

Yann: - It’s difficult to bend. Usually cut from sheet. You go to the local boiler house or water utility, take a bottle and go to the mechanics. They are aware of these issues. I have several 400 * 10 mm nickels lying around at home, these are plugs from equipment. But how can I give them to you?

2eug28 Never bend this strip into a flat, smooth ring using any equipment. It is necessary to cut from a single sheet with gas, EMF, a jigsaw, a grinder or directly on a lathe

Vidis wrote: You need to cut from a single sheet with gas,

I think that after gas it will only end up as scrap metal.

You won't be able to bend it. If there is no solid sheet for the ring, you can weld it from a strip - in sectors (chords) with cutting and then on the machine. Something like this, if the width is 55:

Suever wrote: I think after gas he will behave like this

I assure you, it won’t lead.

You just need to make a ring X mm wide Y mm, then cut out a piece (sector) to form a sort of letter C and bend it on an anvil along the diameter until the edges meet... accordingly, do everything on a cardboard model... plus allowances for manual processing, and forward.. They usually make a cone that way.. but in general, to the pipe plant.. just order what you need..

Suever wrote: I think that after gas it will only end up as scrap metal.

Yann: - It doesn’t matter, this is usually done everywhere, and this work itself is well known to welders. You can do it yourself, find a cutter and the necessary hardware. Well, you can bend the rod, weld it and take it to the forge, where it will be heated and flattened. I see the way out as follows: - “Either to the forge, or to the welder.”

Types of metal bending techniques

The simplest bending techniques involve the formation of one or two corners on a sheet (one-corner or two-corner bending). Based on their profile shape, they are also called V-shaped and U-shaped. To obtain more angles, multi-angle bending is required. And finally, to form not corners, but rounded shapes, radial bending, or rolling, is used. According to the nature of the force that is applied to the sheet, bending of 6-meter sheet metal can be free and with a calibrating blow. It also differs in the number of transitions, that is, the efforts made to complete one fold. For ductile metals a single force is enough, for non-plastic ones two or even three are required, in especially difficult cases - with heating.

Bending strips using a vice

First, let's consider the option of bending on a bench vice at an angle of 90 0. To do this, you need a square block of steel. We clamp the strip together with the block so that the block is located on the side of the fixed jaw of the vice and protrudes 1-2 cm above the upper edge.

After such a “sandwich” is firmly clamped, take an ordinary hammer and bend the strip towards the block with light blows. If it is required that the bend surface is not damaged by impacts, then you need to use a copper or brass gasket, which we will hit with a hammer, and from it the force will be transferred to the strip.

In this way, you can bend the strip at any angle; it is only important to select a support block with the desired cutting angle. Without such solid support, achieving the desired angle will be very difficult.

Similar operations are performed in the manufacture of clamps, only in this case we use a thick-walled pipe or rod of the required diameter as a matrix. As in the case of a rectangular bend, blows with a hammer are applied towards the stationary jaw of the vice. This kind of strip bending is a slow process and requires care.

Price list for sheet metal bending

Unlike many other sites that work only at negotiated prices and do not indicate exact amounts in their price lists, we publish specific prices for this service.

However, let us clarify that these are average amounts. If you entrust us with an order of increased complexity or very urgent work, the cost of the project may increase. When completing large volumes within a comfortable time frame, we can please you with a discount. Features of sheet metal bending

The most difficult task, even for a specialist bending a 6-meter sheet, is to “feel” the balance of stress and deformation in a specific sheet of a specific thickness, made of a specific metal. In the process of bending - no matter whether manually or machine-made - two influences are alternately exerted on the sheet: first elastic, and then plastic. Thus, the inner layers are compressed in the sheet and the outer layers are stretched. The border, or neutral, layer becomes the “golden mean between them. The ability to find it is a “pass” to bending that is harmless to metal.

Methods for bending a corner along a radius

Depending on the size of the workpiece and the thickness of the metal, bending can be done cold or hot.

Cold is preferable, since any heating is an effect at the level of the metal crystal lattice. Cold bending can be carried out not only on a rolling machine: for simple workpieces, the method of free bending of a corner along a radius is no less in demand - deformation of the corner “in weight”, without the use of special equipment. However, this technology may have errors, and it is better to use it for work that does not require high precision.

Based on the direction in which the workpiece is bent, a distinction is made between bending the corner with flanges outward or inward.

Examples of work on bending workpieces

You will see that our craftsmen can easily bend 6-meter sheets if you look at samples of bent steel and products made from it in the “Examples of Work” section. Our gallery is regularly updated with new samples. After evaluating the photos and videos for the article, you will see from a live example that it is better to bend it several times than to weld it a couple of times.

Sheet metal bending in Moscow

Bending metal 6 meters is of particular importance for the capital, where all types of industry are actively developing - from heavy to light. Moscow production places higher demands on bent products: they need high-quality rolled products that completely match the proportions with the drawings. This problem can only be solved using automatic equipment. Our machines are distinguished not only by accuracy, but also by high productivity.

The result of punching and bending sheet metal

Bending metal up to 6 meters is not the only operation that can be performed for such large-sized products. In addition to it, there are punching, cutting, and cutting. And bending itself can be different: for example, combined with stretching (usually used to produce products with a large radius). The result of all these actions is no longer a blank, but an almost completed part that can be used in installation or assembly.

Laser cutting and bending of galvanized steel and powder-coated sheets

Galvanized metal, as well as powder-painted metal, has its own processing nuances. The zinc and polymer layers have sufficient impact strength and resistance to deformation of the coating, but can be damaged during mechanical cutting. Therefore, for such products they usually choose cutting with a laser beam, which is almost “painless” for coated metal.

Bending a metal strip into a ring and onto an edge

When working with metal, you often have to deal with the manufacture of products from steel strip - staples, clamps, brackets.

But not everyone knows how to bend a metal strip without losing strength and achieving the required configuration accuracy. However, this is a fairly simple operation that does not require particularly sophisticated tools. Only in the case of bending a strip on an edge, a rather complex device is needed, which is not easy to make yourself. Bending of the strip at an angle (60, 90, 120 0 ...) towards the plane is done on a regular bench vice if you need to make a single product or several pieces. In the case of small-scale production, you will need a machine for bending metal strips. If necessary, you can do it yourself.