What can be made from metal

The most popular products that are created using welding are practical household structures, furniture and decorative elements.

Household products include elements of fences, gates, as well as small products such as boxes, containers for food and other things. The artistic welding method allows not only to give the desired shape to the product, but also to create an original pattern or texture on the surface.

Metal specialists can make decorative tables, coffee tables, chairs, hangers, shoe racks and other items that serve a practical function and are used indoors or outdoors.

Such artistic furniture has an original appearance, is not afraid of moisture when properly processed, can withstand heavy mechanical loads, and has a long service life.

The cost of artistic welding cannot be called low due to the material used in the work. These are mainly titanium and stainless steel. Zirconium is used to obtain color shades.

Artistic welding allows you to create a variety of objects used for decoration. These can be animal figures, ornamental details for decorating walls, ceilings, columns or arches, details in the shape of flowers and plants.

The number of options to choose from depends solely on the wishes of the client and his budget, as well as the style features of the interior. Most often, decorative items created by welding are ordered by people living in luxury cottages and who want to demonstrate a sense of taste and originality of design. But everyone can afford a small stainless steel craft.

Artistic welding - a new way of metal processing - Blacksmiths and forges

Modern technologies allow craftsmen to create real miracles with such a durable and seemingly unyielding material as metal. Lacy ligatures of forged fence bars and real works of art, for example, forged furniture and accessories, have become a familiar element of many stylish interiors. However, progress does not stand still, and today such a method of artistic metal processing as artistic welding has become relevant. It opens up completely new opportunities for designers and craftsmen, because with the help of artistic welding you can create original, unlike anything else products.

The authors of this method of metal processing are employees of the Kyiv Institute of Welding named after. E. O. Paton. They began experimenting with titanium sheets - seams were welded onto them, and flat shapes were created from them. Later, with the help of welding, they began to create three-dimensional figures, real sculptures from metal.

If a master is faced with the task of creating a small sculpture, then titanium is most often used as the starting material, less often with an admixture of zirconium for an additional decorative effect. If you need to weld, for example, a gate or a section of a fence, then cheaper stainless steel is used as the main material, and small decorative elements are made of titanium.

Additional attractiveness is given to the product using an effect that is considered an unacceptable defect during technical welding. This effect is called “tarnish color” and is a whole rainbow of colors playing on the surface of the metal. It arises as a result of complex physical processes, and looks simply beautiful on the product.

By choosing artistic welding as a method of working with metal, the customer can be completely confident in the originality and uniqueness of his product. After all, mass production with this processing method has not yet been developed - each creation is made exclusively by hand and its quality depends only on the skills of the craftsman.

Artistic welding allows you to create almost any object - from the smallest sculptures to large fence sections and gates, as well as real sculptural compositions that can become a real garden decoration.

See also:

kuznecy.kovka-svarka.ru

Advantages of welded products

One of the main advantages of things created using artistic welding is their beautiful and original appearance.

This method makes it possible to produce hundreds and thousands of options for finished products and parts that can perform a practical function or serve solely as decoration. Welding allows you to create elegant and attractive objects that cannot be replicated exactly.

Although it is a relatively new art form, unlike forging, it is gaining more and more attention. One of the centers of artistic welding is the Paton Institute.

Another advantage of iron products made using artistic welding is their high strength and reliability. Such items, be it ornaments for decorating a fence or furniture for the street, are not afraid of increased mechanical loads, have a long service life, do not require specific or complex care, maintaining not only their physical qualities, but also their appearance. For additional protection of artistic products, you can use special compounds to repel dust, dirt and moisture.

Metal crafts combine well with other objects and various materials, including brick, block, stone and wood.

If, for example, welded decorative elements are intended to decorate a fence or gate, they look great in combination with corrugated sheets, red and facing bricks, concrete and other materials.

Furniture created by artistic welding looks beautiful in a classic, Baroque, Romanesque, Greek style interior, and small items can decorate a room decorated in the High-Tech direction.

Artistic welding: from experiment to new art

Our readers are well aware of all the main areas of artistic metal processing - hot and cold forging, casting. But today another, fundamentally new and promising direction has emerged for creating easel and applied works of art from such a durable but malleable material. This is art welding, which was started by specialists from the Kyiv Institute of Welding named after. E.O. Paton. It gives new opportunities to artists who translate their ideas into metal. We bring to your attention an interview with one of the leading masters of this direction, an employee of the Institute named after. E.O. Paton by Dmitry Kushniruk.

Dmitry, artistic welding is a relatively new area of metal processing. How did it arise and develop? What is the role of your teacher Grigory Grigorievich Dochkin here?

Grigory Grigorievich is a pioneer in this field of welding. Dochkin worked at a military plant in Omsk, where at that time they were welding titanium. It was there that he had the idea to experiment with a metal like titanium, doing something new with it, significantly different from traditional, technical welding. At first, he made planar works on titanium sheets - he put seams on the sheet and welded silhouettes with the seams. And subsequently, voluminous works appeared.

How did you get into artistic welding yourself, and why did you choose it?

After joining the Paton Institute, I began to study technical welding. During this period, I saw for the first time artistic products that were created using welding. I liked it, they interested me, and I decided to try myself in this direction, and considering that I am a creative person by nature, then I succeeded. I became seriously interested in this business and fell in love with working with this type of technology. You can also say that the impetus for taking up artistic welding was the fact that I saw what could be achieved by welding with metal, in this case titanium. Although it is possible to use other materials.

Dmitry Kushniruk. Snake table

Dmitry Kushniruk. Frog on a leaf. Size: 20×15x15 cm

What are the fundamental technical differences between artistic welding technologies and conventional welding techniques?

In technical welding, such a phenomenon as discoloration is unacceptable; this is considered a serious defect and is classified as a defect. But what is called defect in technical welding is specifically used in artistic welding as a decorative technique.

Tarnish colors are rainbow stains (straw, gold, purple, violet and other colors) on the clean surface of heated metal, resulting from the appearance of a thin layer of oxides. This thin oxide film, a few molecules thick, forms on the surface of a pure metal under the influence of a local heat source, its color depends on the thickness, since oxides of different thicknesses reflect light differently. The thickness differing in different areas causes the appearance of multi-colored stains. Metal processing by welding creates temperatures high enough for the formation of tarnished colors, but in technical welding this must be avoided, since tarnished colors worsen the appearance of products and are considered defective.

Artistic welding of titanium today is an argon-arc torch, two eyes and two hands of a welder, plus material.

This is completely manual work, not an assembly line. But if a person appears who can put this on a conveyor belt, then artistic welding will cease to be an art...

What is the application of these products? How widespread are items made in this way among design solutions?

Products made using artistic welding technologies are widely used. Art welding masters are able to produce products for a wide variety of purposes; they can vary widely in size. With the help of artistic welding, you can make anything, from small products - miniature figures (flies, ants, candlesticks, etc.) to architectural details (for example, gates) and sculptural compositions that decorate houses, parks, gardens. Readers can see examples of our work in the photographs.

Dmitry Kushniruk. Bird

What materials are used in artistic welding - is it only titanium, or are other metals used?

Indeed, we are talking mainly about titanium. Zirconium is used as an auxiliary metal, allowing additional shades of colors to be obtained. Relatively large architectural details, such as gates, are mainly made of stainless steel, but titanium is used in their decorative elements. They, like park sculptures, can be made only from titanium, but this requires considerable time and is quite expensive.

Institute of Welding named after. E.O. Paton, a recognized center for research in its field, also became one of those places where the art of artistic welding was born and developed. Where else is this trend actively cultivated and which famous masters could you name? Where can you see their work?

Dmitry Kushniruk. Vase with dragon

Dmitry Kushniruk. Dinosaur

As far as I know, this direction is quite new, and, according to my information, today no one else, except me and my teacher Grigory Dochkin, specializes in this type of art. The leading master, of course, remains Grigory Grigorievich, who began conducting master classes in the direction he founded. You can get acquainted with the works made using this technique at our institute, where there is a permanent exhibition. In addition, we regularly organize exhibitions outside the institute.

Is there a high level of interest in this direction among craftsmen and customers and what are the prospects for its development?

Previously, artistic welding aroused great interest only among foreign customers. What was the reason for this? Most likely, financial difficulties and lack of information. Today, on the contrary, the interest of domestic customers is great. I think that the prospects for the development of such a direction of artistic metal processing as art welding are quite good, since, from my point of view, such use of welding and the creation of works of art with its help is of undoubted interest both for metal artists and for spectators .

ostmetal.info

Tools and drawings

To practice artistic welding using rolled metal, you need the following devices and equipment:

- a machine for manual argon arc welding (they use it to weld non-ferrous metals and stainless steel), a torch for it, filler wire and an argon cylinder;

- paper. Without it, it is impossible to draw drawings with determination of dimensions and small nuances that are difficult to take into account when visualizing without a plan. However, in the modern world you can also use computer programs;

- stationery for marking (pencil, ruler, protractor);

- working surface, which must be made of materials resistant to high temperatures and flames.

Before starting work on artistic welding, it is necessary to make a drawing and think about what size the product will be, what it is intended for, and what style it should be combined with.

The finished image is only part of such a drawing. In addition to the sketch, it is necessary to draw individual details, indicate connection points and their number, and examine the object in several planes.

Correct deposition

The proper approach to work will make the task easier. Draw up a plan in which diagrams, sketches and quantities of material are indicated. Step by step deposition:

- Come up with an image or find it on the Internet or in a book. It all depends on the preferences of the master.

- The original photo of artistic welding is transferred to a cardboard sheet. In order not to draw by hand, there is a way to help you cope with the matter. A thin landscape sheet of paper is applied to the monitor with a picture and the lines are traced with a pencil using light touches.

- The blank is placed on cardboard and fixed with glue. Use scissors or a utility knife to cut out unnecessary parts to make a stencil.

- The canvas is attached with tape to the door in the center. In the installed stencil, the internal spaces are outlined with chalk. The thicker the line, the better, since you will have to view the outline through darkened glasses.

- The steel is wiped free of dust. Filler wire is fused along the boundaries and throughout the entire area of the print. They make a three-dimensional sculpture. Metal is deposited on top of the primary layers where needed. If it is a dragon, then the head, body, and tail are thickened.

- The work is brought to a finished state. The rough surface of the product is cleaned to a smooth state with a grinder and files. The last tool is suitable for hard-to-reach areas.

Additional detailing will enhance the aesthetics of the iron sculpture. At the end they are painted in various colors - black, brown, and treated with silver.

Main job

At this stage, the master selects the material. Thus, for small and elegant figures or sculptures, titanium can be used in its pure form or with small additions of zirconium, which gives the products a special shine.

When artistic welding is used to create a fence, gate, furniture or other large objects, steel is usually used as the base material. The stainless steel construction is not susceptible to the negative influence of moisture and is resistant to accidental and targeted impacts.

After determining the materials, shape and dimensions, the master, using a welding machine, produces the desired item.

Depending on the complexity and size, artistic welding can take from 1 day to several weeks.

The surface can be polished or engraved; in some cases, individual fragments are decorated with tarnish colors. This is an effect in which the steel surface becomes iridescent and iridescent, and is achieved through exposure to high temperatures. After the product is ready, it must cool.

What is forge welding

Forge welding is commonly called the technological process of creating a strong connection between metal parts during thermal heating under the influence of external pressure. That is, parts of iron blanks at the site of future welding are heated to high temperatures, achieving a dough-like surface state. Then they create pressure by hammer blows on the workpiece lying on the anvil, thereby achieving the creation of a strong permanent connection.

Technologically, forge welding includes the following individual operations:

- mandatory preparation of the welded surface,

- thermal heating to a strictly defined temperature,

- joining the ends of workpieces by forging,

- final forging to give the workpiece the required shape.

One of the most important conditions for successful forge welding is temperature. It must be detected by the color tone of the glowing surface. So, for iron, a temperature of 1300⁰ C has a bright yellow surface color, and when it reaches 1400⁰ C, the metal begins to glow with a bright white hue. Immediately upon reaching the required temperature, it is necessary to perform forging welding, since overexposure will lead to burning of the metal and the formation of a larger layer of scale.

Safety precautions and processing nuances

Like any other welding work, artistic welding requires strict adherence to safety rules.

If you use the equipment incorrectly, you can get an electric shock, become partially or completely blind when exposed to ultraviolet radiation or scale, get poisoned by fumes arising from metal processing, get burned as a result of the melting of the material or an accidental explosion of the cylinder.

Such consequences are dangerous to health and life, so you need to use a mask and protective clothing . It is best to choose a product with chameleon glass, which changes the degree of darkness depending on the amount of ultraviolet light hitting the surface

Before you start welding steel, you need to clear the work area of foreign objects. It is better to start experiments in artistic welding with products of simple shape.

It is also necessary to study welding techniques well in order to firmly connect structural parts and spend a minimum of time on this.

Forge welding methods

There are several simple, not requiring special preparatory measures, methods for making joints using forge welding, namely:

- end-to-end;

- overlap;

- in girth.

The only mandatory condition for such welding methods is the need to make the ends of the workpieces in the form of a convex shape and with significant thickenings at the ends. This is due to the fact that during forge welding (namely, during thermal heating), a slag film is actively formed on the welded surface and in order for the slag particles to be squeezed out during the forging of the workpieces, a convex surface is required. But the thickened welded ends of the workpieces are, first of all, needed for the process technology itself and allow, after forging the welding area, to bring the cross-sectional shape of the workpiece to the specified dimensions.

More technologically complex methods are:

- split welding, for example, for joining steel strips in the manufacture of steel tires for village carts;

- welding with checkers, which was mainly used to create strong connections of large-sized parts.

In the first case, the ends of the strips are specially prepared by pulling and cutting so that they can be connected to the ceiling before welding, and then, after heating to the required temperature, they are welded on both sides using forging.

In the second case, during the preparation of the future welding site, they are made in the form of angles of 30 or 40 degrees, and additional parts for inserts, which are called checkers, are made of the same angular shape. Next, the entire structure is brought to welding temperature and, using a hammer and anvil, the joint is given strength and the desired shape.

Equipment and consumables

In order to independently engage in forge welding and hot artistic forging, you will not need much equipment and tools to organize a small forge.

So, to operate a full-fledged blacksmith’s workshop you will have to purchase:

- portable and stationary forge, i.e. a special device for heating metal to the required temperature (in extreme cases, a simple gasoline autogen will do);

- several types of anvils: large and small, one-horned and two-horned, which must be placed in the workshop with special strength;

- blacksmith pliers of different sizes;

- various types of hammers, ranging in size from a good sledgehammer to a plumber's hammer;

- two containers for cooling: one for water, the other for oil.

Additionally, you may need various scrapers, molds, stands, tools for bending workpieces, and much more.

You should definitely take care of fire safety and personal protective equipment, such as glasses, a leather apron and canvas gloves.

Areas of application

Forge welding is an ancient craft and is still widely used by artists and blacksmiths today.

So, along with hot or artistic forging, they also use artistic welding to create various decorative and design products from metals. This welding method is also used in forges to produce various kinds of composite tools, for example, axes, plows and other agricultural implements.

The industrial use of forge welding is gradually losing its position. This comes with a number of significant disadvantages. Such as:

- slow heating,

- relatively weak strength,

- low productivity,

- heterogeneity of precipitation processes,

- demand for qualified craftsmen.

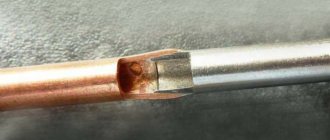

Although there are still areas of industry where forge welding remains in demand. For example, for the production of steel water pipes with a small diameter of up to 100 mm. To do this, strip steel is heated in thermal furnaces and rolled through coils, and at the end of the process it is pulled through special drawing mandrels at high speed, due to which pressure welding of the longitudinal seam of the pipe occurs.

They use industrial forge welding technology to obtain a multilayer steel structure and to produce bimetallic plates by jointly rolling heated workpieces through rollers or pressing in vacuum thermal chambers.