03/23/2019 Author: VT-METALL

Issues discussed in the material:

- What are the advantages of this type of metal processing such as bending?

- What are the methods of bending metal?

- What equipment exists for bending sheet steel?

- What is the sequence of operations when bending sheet steel to order

Steel products are used in all spheres of human life, from industry and construction to everyday life. In order for a steel sheet to turn, for example, into a finished part, it is processed in a special way. At first glance, cutting, drilling, grinding and other types of processing seem to be simple mechanical actions. However, in reality they are complex technological processes.

Making a metal object requires special equipment and certain skills. To create a high-quality product, it is necessary to strictly adhere to technology. In particular, bending sheet steel requires special skill and precision.

Metal bending: methods and technological features

INTRODUCTION

Bending sounds like a simple process, but in reality, it is very complex.

“Sheet” and “bending” are not very associated with high technology. However, in order to bend a “naughty” sheet, special knowledge and extensive experience are required. Explain to a technician who is not familiar with sheet metal that in our highly technical world, it is impossible to consistently achieve a 90° bending angle without changing settings. Sometimes it works, sometimes it doesn’t! Without changing the program, the angle will change if, for example, a 2 mm thick sheet is made of stainless steel or aluminum, if its length is 500 mm, 1000 mm or 2000 mm, if bending is carried out along or across the fibers, if the bending line is surrounded by punched or laser-cut holes, if the sheet has different elastic deformation, if the surface hardening due to plastic deformation is stronger or weaker, if. If.

WHICH BENDING METHOD TO CHOOSE?

There are 2 main methods: We talk about “air bending” or “free bending” if there is an air gap between the sheet and the walls of the V-shaped matrix. This is currently the most common method. If the sheet is pressed completely against the walls of the V-shaped die, we call this method "sizing". Even though this method is quite old, it is used and should even be used in certain cases, which we will look at next.

Free bending

Provides flexibility, but has some limitations in accuracy.

Main features:

- The traverse, using a punch, presses the sheet to the selected depth along the Y axis into the groove of the matrix.

- The sheet remains “in the air” and does not come into contact with the walls of the matrix.

- This means that the bending angle is determined by the position of the Y axis and not by the geometry of the bending tool.

The Y-axis adjustment accuracy on modern presses is 0.01 mm. What bending angle corresponds to a certain Y-axis position? It's hard to say because you have to find the correct Y-axis position for each angle. Differences in the position of the Y axis can be caused by the adjustment of the lowering stroke of the crosshead, material properties (thickness, tensile strength, work hardening) or the condition of the bending tool.

The table below shows the deviation of the bending angle from 90° at various Y-axis deviations.

Advantages of free bending:

- High flexibility: Without changing bending tools, you can achieve any bending angle between the V-die opening angle (e.g. 86° or 28°) and 180°.

- Lower tool costs.

- Compared to calibration, less bending force is required.

- You can “play” with force: greater opening of the matrix means less bending force. If you double the width of the groove, you only need half the force. This means you can bend thicker material at a larger opening with the same amount of force.

- Less investment as a press with less force is needed.

All this, however, is theoretical. In practice, you can spend the money saved on purchasing a lower force press that allows you to take full advantage of air bending on additional equipment, such as additional backgauge axles or manipulators.

Disadvantages of air bending:

- Less precise bending angles for thin material.

- Differences in material quality affect repeatability.

- Not applicable for specific bending operations.

Advice:

- It is advisable to use air bending for sheets with a thickness of over 1.25 mm; For sheet thickness of 1 mm or less, it is recommended to use calibration.

- The smallest internal bending radius must be greater than the sheet thickness. If the inner radius must be equal to the sheet thickness, it is recommended to use the calibration method. An internal radius less than the sheet thickness is permissible only on soft, easily deformable material, such as copper.

- A large radius can be achieved by air bending by using stepwise movement of the backgauge. If a large radius must be of high quality, only the special tool calibration method is recommended.

What effort?

Due to the different material properties and the effects of plastic deformation in the bending zone, the required force can only be determined approximately. We offer you 3 practical ways:

Table

In each catalog and on each press you can find a table showing the required force (P) in kN per 1000 mm of bending length (L) depending on:

- sheet thickness (S) in mm

- tensile strength (Rm) in N/mm2

- V - matrix opening width (V) in mm

- internal radius of the bent sheet (Ri) in mm

- minimum height of the bent shelf (B) in mm

An example of such a table is the required force to bend 1 meter of sheet in tons. Tensile strength 42-45 kg/mm2. Recommended ratio of parameters and force

Formula

1.42 is an empirical coefficient that takes into account the friction between the edges of the die and the material being processed. Another formula gives similar results:

"Rule 8"

When bending low-carbon steel, the width of the die opening should be 8 times greater than the thickness of the sheet (V=8*S), then P=8xS, where P is expressed in tons (for example: for a thickness of 2 mm, the die opening /=2x8=16 mm means that you need 16 tons/m)

Bending force and length

The length of the bend is proportional to the force, i.e. the force reaches 100% only with a bend length of 100%. For example:

Metal Bending Basics

Today sheet metal bending

carried out in various ways. The most widely used machines are the Press Brake type. The popularity of this technology is due to the following features.

- The same equipment can produce parts of different configurations from different materials and different thicknesses.

- High production flexibility - most parts are manufactured without equipment changeovers or tool changes. Moreover, often the tool does not change at all, while in production there may be a large number of parts that are different both in configuration and in material/thickness.

- High performance.

- Low equipment cost and production cost.

- Applicability of process automation.

What is metal bending and what are its advantages?

Flexible sheet steel is a type of processing in which the product is given the desired shape. The result is achieved due to the fact that the top layer of material is stretched and the inner layer is compressed.

There are different ways in which you can bend a metal sheet and change its appearance. The technology makes it possible to obtain a high-quality and durable item of the required shape in a short time. There are two types of technological process in which bending is done:

- Bending sheet steel by hand.

- Mechanical restoration.

In the first case, various plumbing tools are used (hammer, vice, pliers, etc.), in the second, industrial equipment is used.

Manual bending of sheet metal can be performed when its width is less than 0.6 mm. Otherwise, special machines will be required: press brake, rollers, roller bending machine.

Metal is modified not only by bending, but also by other methods - twisting, welding. Bending is often compared to the latter, since one product can be made in two ways: bending steel at the desired angle or connecting individual parts together using welding equipment. However, if you do bending, the process will be faster and easier. This is precisely the main advantage of the first technology over the second.

VT-metall offers services:

Other arguments in favor of using bending to process sheet steel:

- Using this method, a higher quality, stronger and more durable product is obtained. The areas of metal in the places of bending remain sealed, so the object will be more resistant to mechanical stress.

- The cost of work is lower than when welding.

- Bending is performed in a short period of time.

- If the material is bent by pressing, the risk of damage is eliminated. The technology allows you to obtain the desired shape without compromising quality. The high technical characteristics of the product, in particular, strength, are maintained.

- Bending of sheet steel is used to eliminate any changes in the physical or chemical properties of the alloy, since no significant interference with the composition occurs.

- Using technology, it is possible to produce smooth, seamless, neat parts.

The listed advantages confirm that in order to obtain a high-quality and durable metal workpiece, it is best to bend sheet steel.

Metal deformation

Bending on press brakes is based on the 3-point principle. The sheet rests on 2 matrix points. The punch presses on the sheet between 2 points of the matrix, forming a third, central point. As the punch is lowered, the center point of the sheet lowers with it, and the lower side surfaces of the sheet slide along the radii of the V-opening of the matrix. The material is somewhat compressed at the point of pressure of the punch and significantly stretched from the underside of the sheet. Also, the material is deformed at the point of sliding along the matrix - visible or invisible traces of deformation (indentation) remain there.

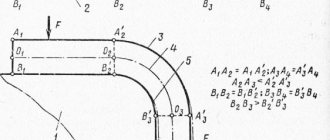

Schematic illustration of metal deformation during bending

The length of the development in the direction perpendicular to the bend line always increases. In this regard, the length of the sweep is made less than the sum of all the sides. The elongation of the workpiece at each bend depends on:

- thickness and type of material,

- bend angle,

- bending radius (width of the V-opening of the matrix and punch radius),

- rental directions.

The theoretical calculation will always be approximate. The most accurate result can be obtained experimentally. To do this, you need to take several blanks, for example, 100x100. Mark the rental direction. Bend an equal number of blanks along the rolled section and across it. Take measurements of the resulting sides. For each workpiece, sum the lengths of the sides and subtract 100. The resulting difference will be the elongation for the given bending conditions. Comparing the results obtained, the following can be assessed:

- stability of results,

- influence of rolling direction.

In most cases, the difference in elongation along the rolled section and across it can be neglected. However, if the requirements for the accuracy of the resulting dimensions are very high and/or the number of bends is large, then this difference should be taken into account when creating a development and positioning it on the sheet.

Separately, it should be noted that the more the metal needs to be deformed (reducing the minimum side, angle and bending radius), the greater the impact required. Here the impact is directly related to pressure and moment of force. Pressure is the ratio of force to the area over which it is applied. Thus, to increase impact, more force must be applied over a smaller area. The moment of force, in turn, is the product of the acting force and the length of the lever of application of the force. Reducing the minimum flange or bending radius requires the use of a die with a smaller V-opening and, as a result, less leverage. Accordingly, other things being equal, bending on a die with a smaller opening requires the application of greater force.

Schematic representation of force and leverage when bending on dies with different V-openings

ATTENTION! We have developed the StrongTonn program, which calculates bending force and other parameters. Go to the program page

There are two bending methods:

We are talking about free and air bending, when there is an air gap between the sheet and the walls of the V-shaped matrix. This is the method that is most commonly used.

The "sizing" method is an old method that is used in certain cases where the sheet is pressed completely against the walls of the V-shaped die.

Procedure for cutting metal

As a rule, before bending metal workpieces, they are given the shape specified in the drawing, which simplifies the work and obtains a more accurate bending radius.

Cutting a metal sheet is a separate technical operation, which is carried out using its own technology.

In most cases, cutting metal workpieces is carried out using sheet metal shears, which are called a guillotine.

Such machines, as a rule, are installed at enterprises and allow you to quickly complete the necessary work, taking into account the bending radius and density of the material.

At home, metal cutting is carried out using special metalwork shears.

It is worth noting that hand scissors cut metal with a minimum thickness.

For thicker metal, chair or roofing shear types should be used.

Metal cutting at home, if necessary, can be done using a hacksaw.

In this case, you will have to expend some physical effort and monitor the quality of the resulting cut.

If metal cutting is performed with a hacksaw, then the tension of the blade should be controlled while performing the work, since the evenness of the cut largely depends on this.

How to cut a metal sheet with your own hands is described in the video below.

Video:

Free bending

This direction has certain limitations.

Character traits:

- The traverse presses the sheet to a selected depth along the Y axis into the die groove using a punch;

- The sheet is “in the air” and does not come into contact with the walls of the matrix;

- This means that the bending angle is determined by the position of the Y axis and not by the geometry of the bending tool.

On a modern press, the Y-axis adjustment accuracy is 0.01 mm.

To answer the question of what should be the bending angle corresponding to a given position of the Y axis, it is necessary to find the corresponding position of the Y axis for all angles. Below is a table showing deviations of the bending angle from 90° for different deviations of the Y axis.

Free bending: advantages

- High flexibility

- Low tooling costs

- Compared to calibration, less bending force is applied

- Possibility of changing bending

- Low costs due to the need for a press with less force

All this, however, is theoretical. In practice, you can spend the money saved on purchasing a lower force press that allows you to take full advantage of air bending on additional equipment, such as additional backgauge axles or manipulators.

Air bending: disadvantages

- Having less precise bending angles

- Lack of applicability for specific bending operations

Advice:

- It is advisable to use air bending for sheets with a thickness of over 1.25 mm; For sheet thickness of 1 mm or less, it is recommended to use calibration.

- The smallest internal bending radius must be greater than the sheet thickness. If the inner radius must be equal to the sheet thickness, it is recommended to use the calibration method. An internal radius less than the sheet thickness is permissible only on soft, easily deformable material, such as copper.

- A large radius can be achieved by air bending by using stepwise movement of the backgauge. If a large radius must be of high quality, only the special tool calibration method is recommended.

Features of bending stainless steel sheets

Stainless steel gets its name due to its resistance to corrosion. This property is ensured by a combination of several elements that are alloying, that is, improving the quality of the base material. In addition to resistance to destruction from rust, impurities add other qualities to the alloy: strength, ductility, etc. There are several types of stainless steel. Therefore, before bending, you need to know the composition of the alloy.

Before bending the sheet, it is cut - laser, water-abrasive cutting, etc. are used. Using cutting, a flat roll of the future product is created.

For shaping, the sheet is bent to specified parameters. Processing of stainless steel sheets follows the same principle as in the case of other alloys. As already mentioned, bending is carried out on special automated or mechanized sheet bending machines - machines, presses, etc. Usually the metal is bent in a cold state. However, if there is a risk that the workpiece will be damaged, then sheet steel is bent with preheating.

In recent years, thanks to the automation of the steel bending process, the company has received the following advantages:

- The volume of manufactured products is increasing.

- Production costs are reduced.

- The quality of finished products increases.

- The number of defective parts is reduced.

To produce a product, it is enough to set up a special computer program, and it will autonomously perform all stages of production with virtually no participation from working personnel.

Table

In each catalog and on each press you can find a table showing the required force (P) in tons per 1000 mm bending length (L) depending on:

- sheet thickness (S) in mm

- tensile strength (Rm) in N/mm2

- V - matrix opening width (V) in mm

- internal radius of the bent sheet (Ri) in mm

- minimum height of the bent shelf (B) in mm

An example of such a table is the required force to bend 1 meter of sheet in tons.

Tensile strength 42-45 kg/mm2. Recommended ratio of parameters and force Attention! For accurate calculations, the following GOSTs must be taken into account:

- GOST 19903-74 Hot-rolled sheets (Table 3) (link to table),

- GOST 19904-90 Cold-rolled sheets (Table 2) (link to table).

When rolling, deviations in the thickness of the metal are possible, and precise measuring instruments (for example, a micrometer) are required.

"Rule 8"

When bending low-carbon steel, the width of the die opening should be 8 times greater than the thickness of the sheet (V=8*S), then P=8xS, where P is expressed in tons (for example: for a thickness of 2 mm, the die opening /=2x8=16 mm means that you need 16 tons/m)

Bending force and length

The length of the bend is proportional to the force, i.e. the force reaches 100% only with a bend length of 100%.

Advice:

If the material is rusty or not lubricated, 10-15% should be added to the bending force.

Sheet thickness (S)

DIN allows a significant deviation from the nominal sheet thickness (for example, for a sheet thickness of 5 mm, the norm ranges between 4.7 and 6.5 mm). Therefore, you only need to calculate the force for the actual thickness you measured or for the maximum specification value.

Tensile strength (Rm)

Here too, tolerances are significant and can have a major impact when calculating the required bending force. For example: St 37-2: 340-510 N/mm2 St 52-3: 510-680 N/mm2

Advice:

Don't skimp on bending force! The tensile strength is proportional to the bending force and cannot be adjusted when you need it! Actual thickness and tensile strength are important factors when selecting the right machine with the right force rating.

V—matrix expansion

According to the rule of thumb, the opening of the V-shaped matrix should be eight times the sheet thickness S up to S=6 mm: V=8xS, for greater sheet thickness it is necessary V=10xS or V=12xS

The opening of the V-shaped matrix is inversely proportional to the required force:

- a larger opening means less bending force, but a larger inner radius;

- smaller opening means more force but smaller inner radius.

Inner bending radius (Ri)

When using the air bending method, most of the material is subject to elastic deformation.

After bending, the material returns to its original state without residual deformation (“reverse springback”). In a narrow region around the point of application of the force, the material undergoes plastic deformation and remains in this state forever after bending. The greater the plastic deformation, the stronger the material becomes. We call this “strain hardening.” The so-called “natural internal bending radius” depends on the sheet thickness and die opening.

It is always greater than the sheet thickness and does not depend on the punch radius. To determine the natural inner radius we can use the following formula: Ri = 5 x V /32 In the case of V=8xS, we can say Ri=Sx1.25

The soft and easily deformable metal allows for a smaller internal radius. If the radius is too small, the material may wrinkle on the inside and crack on the outside of the bend.

Advice:

If you need a small inside radius, bend at slow speed and against the grain.

Minimum shelf (B):

To avoid the flange falling into the die groove, the following minimum flange width must be observed:

Sheet metal bending technology

Sheet metal bending is one of the most common cold and hot forming operations. It has low energy consumption.

Sheet metal bending is one of the most common cold and hot forming operations. It is characterized by low energy consumption, and with the correct development of the technical process, it can successfully produce spatial products of various shapes and sizes from flat blanks.

Classification and process features

In accordance with the assigned tasks, sheet metal bending technology is developed for the following options:

- Single-angle (sometimes called V-shaped flexible).

- Double corner or U-shaped bending.

- Multi-angle bending.

- Radial bending of sheet metal (rolling) - producing products such as hinges, galvanized clamps, etc.

The bending effort is small, so it is mainly performed in a cold state. An exception is bending steel sheets made of low-plasticity metals. These include duralumin, high-carbon steels (containing an additional significant percentage of manganese and silicon), as well as titanium and its alloys. They, as well as blanks made of thick sheet metal with a thickness of more than 12...16 mm, are bent mainly by hot bending.

Bending is combined with other sheet metal stamping operations: cutting and bending, with cutting or punching are often combined. Therefore, for the production of complex multi-dimensional parts, dies designed for multiple transitions are widely used.

How does the process of bending sheet steel work?

The technology for forming parts made of sheet steel is that an angle is formed between two sections of the sheet (the degree is strictly specified), for the calculation of which special automated programs are used. It is important to understand that when bent, the material is deformed to a certain limit, which is individual for each metal or alloy. It is important that the process of manufacturing the workpiece complies with the requirements of GOST for bending sheet steel. The degree of deformation is influenced by the following parameters:

- Metal thickness

- Bend angle.

- Plasticity and fragility of the material. Technological features of the process.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

In order to bend sheet steel without defects, industrial sheet bending machines are used. It is necessary to strictly observe the features of the technology in order for the finished products to be of high quality. Any deviations can lead to the formation of defects, which will affect the quality and strength of the finished metal structure.

Industrial equipment allows you to bend steel sheets of any thickness. In order for the deformation to be plastic, it is only sufficient to correctly calculate the stress created by the equipment.

Stages and sequence of technology

Development is carried out in the following sequence:

- The design of the part is analyzed.

- The force and work of the process are calculated.

- The standard size of production equipment is selected.

- A drawing of the initial workpiece is being developed.

- Strain transitions are calculated.

- Technological equipment is being designed.

An analysis of the compliance of the capabilities of the source material is necessary in order to determine its suitability for stamping according to the dimensions shown in the drawing of the finished part. The stage is performed according to the following positions:

- Checking the plastic ability of the metal and comparing the result with the level of stress that occurs during bending. For low-plasticity metals and alloys, the process has to be split into several transitions, and between them, interoperational annealing must be planned, which increases plasticity;

- Possibility of obtaining a bending radius at which cracking of the material will not occur;

- Determination of probable distortions in the profile or thickness of the workpiece after pressure treatment, especially with complex contours of the part;

Based on the results of the analysis, sometimes a decision is made to replace the starting material with a more ductile one, about the need for preliminary softening heat treatment, or to use heating of the workpiece before deformation.

The bending radius rmin is calculated taking into account the plasticity of the workpiece metal, the ratio of its dimensions and the speed at which deformation will be carried out (hydraulic presses, with their reduced speeds of movement of the slide, are preferable to higher-speed mechanical presses). As the rmin value decreases, all metals undergo so-called thinning—a decrease in the original thickness of the workpiece. The intensity of thinning determines the thinning coefficient λ, %, which shows how much the thickness of the final product will decrease. If this value turns out to be more critical, then the initial thickness s of the workpiece metal has to be increased.

For low-carbon sheet steels, the correspondence between the above parameters is given in the table (see Table 1).

Table 1

Thus, under certain conditions, the metal of the workpiece may even bulge somewhat.

and for large deformations, a more accurate equation of the form

table 2

The effect of probable springback can be taken into account using data on the actual springback angles β, which are given in Table 3. The data in the table correspond to the conditions of single-angle bending.

Table 3

METAL BENDING. TOOLS AND EQUIPMENT MDK FITTING AND TECHNICAL MEASUREMENTS. - presentation

METAL BENDING.

TOOLS AND EQUIPMENT MDK FITTING AND TECHNICAL MEASUREMENTS TOPIC 6. METAL BENDING 1. The essence and types of bending. 2. Tools, devices and materials used in bending. 3. Mechanization during bending. 4. Rules for performing work when manually bending metal. 5. Typical defects during bending, the reasons for their occurrence and methods of prevention. Study questions:

1. ESSENCE AND TYPES OF BENDING Bending (bending) is an operation in which the workpiece takes the required shape (configuration) and dimensions due to stretching of the outer layers of metal and compression of the inner ones. The total length of the workpieces when bending with curves is calculated using the following formula: where is the length of the straight sections of the workpiece; r 1,….,rn – radii of the corresponding roundings; a 1..., and n are bending angles. Bending can be done manually, using various bending devices and using special bending machines.

2. TOOLS, DEVICES AND MATERIALS USED IN BENDING Fig. Bending on a mandrel: a-c - sequence of operation. Steel bench tools are used as tools for bending sheet material with a thickness of 0.5 mm, strip and rod material with a thickness of up to 6.0 mm hammers with square and round strikers weighing from 500 to 1000 g, hammers with soft inserts, wooden hammers, pliers and round nose pliers.

CONTINUED QUESTIONS 2 Pliers and round nose pliers are used for bending profiles less than 0.5 mm thick and wire.

CONTINUATION OF QUESTION 2

Hot bending of pipes is carried out after preheating with high frequency currents (HFC), in fiery furnaces or forges, gas-acetylene torches or blowtorches directly at the bending site. Fillers when bending pipes are selected depending on the material of the pipe, its size and bending method. The fillers used are sand or rosin.

3. MECHANIZATION IN BENDING

CONTINUED QUESTIONS 3

4. RULES FOR PERFORMING WORK IN MANUAL METAL BENDING. 1. When bending sheet and strip material in a vice, the marking mark must be positioned accurately, without distortions, at the level of the vice jaws in the direction of bending. 2. When bending parts such as corners, brackets of different configurations, hooks, rings and other parts from strips and rods, you should first calculate the length of the elements and the total length of the part development, marking the bending points. 3. When mass producing parts such as staples, it is necessary to use mandrels whose dimensions correspond to the dimensions of the elements of the part, which eliminates the current marking of bending points.

4. When bending sheet and strip metal in fixtures, you must strictly adhere to the instructions supplied with them. 5. When bending gas or water pipes using any method, the seam must be located inside the bend.

5. TYPICAL DEFECTS IN BENDING, REASONS FOR THEIR APPEARANCE AND METHODS OF PREVENTION Defect Causes Method of prevention When bending a corner from a strip, it turned out to be skewed Incorrect fastening of the workpiece in a vice Fasten the strip so that the marking line is exactly located at the level of the jaws of the vice. Check the perpendicularity of the strip to the jaws of the vice with a square. The dimensions of the curved part do not correspond to the specified ones. Inaccurate calculation of the development, incorrectly selected mandrel. Calculate the development of the part taking into account the allowance for bending and subsequent processing. Accurately mark bending points. Use mandrels that exactly match the specified dimensions of the part. Dents (cracks) when bending a pipe with filler. The pipe is not filled tightly enough with filler. When filling the pipe with filler (dry sand), place the pipe vertically. Tap the pipe on all sides with a hammer

METAL STRAIGHTENING 1. Essence, purpose and methods of straightening. 2. Tools and devices used for editing. 3. Mechanization when editing. 4. Basic rules for performing work when editing. 5. Typical defects during editing, the reasons for their occurrence and methods of prevention. Study questions:

1. ESSENCE, PURPOSE AND METHODS OF STRAIGHTENING Straightening is an operation to straighten bent or warped metal, which can only be performed on ductile materials: aluminum, steel, copper, brass, titanium. Straightening is carried out on special straightening plates, which are made of cast iron or steel. Straightening of small parts can be done on forging anvils. Straightening of metals is carried out with hammers of various types, depending on the condition of the surface and the material of the part being straightened.

CONTINUATION OF QUESTION 1 Editing is carried out in several ways: bending, stretching and smoothing. Bend straightening is used when straightening round (rods) and profile materials that have a fairly large cross-section. In this case, hammers with steel strikers are used. Pull straightening is used to straighten sheet material that has bulges or waviness. This straightening is done using hammers with soft metal strikers or mallets. Editing by smoothing is used in cases where the workpiece has a very small thickness. Smoothing is carried out with wooden or metal bars.

2. TOOLS AND DEVICES USED WHEN STRAIGHTENING Fig. Straightening plate On such plates, profile blanks and blanks made of sheet and strip material, as well as rods of ferrous and non-ferrous metal are straightened.

CONTINUED 2 QUESTIONS Sledgehammers are hammers of large mass (2.0 ... 5.0 kg) and are used for straightening round and profile rolled products of large cross-section in cases where the impact force applied by a conventional plumbing hammer is insufficient to straighten the deformed workpiece.

CONTINUED 2 QUESTIONS Mallets are hammers, the striking part of which is made of hardwood, they are driven by sheet material made of metals of high ductility. A characteristic feature of straightening with mallets is that they leave virtually no marks on the straightened surface.

Metal or wooden smoothers (made of hard wood: beech, oak, boxwood) are designed for straightening (smoothing) sheet material of small thickness (up to 0.5 mm). During processing, this tool, as a rule, does not leave marks in the form of dents.

3. MECHANIZATION WHEN STRETCHING Fig. Manual press: a - straightening in the centers; b – straightening on prisms The simplest device for mechanizing straightening is a hand press (Fig. 2.34), which is used to straighten rolled profiles and bar material.

CONTINUED 3 QUESTIONS Fig Straightening machine: a - general view; b - editing scheme; P - straightening force Fig Straightening rollers

4. BASIC RULES FOR PERFORMING WORK WHEN STRAIGHTENING 1. When straightening strip and rod material (round, square or hexagonal cross-section), the straightened part must touch the straightening plate or anvil in at least two points (Fig. 2.37). Fig Straightening of strip and rod material

CONTINUED 4 QUESTIONS 4. Straightening of sheet material with a thickness of 0.5 ... 0.7 mm must be done using wooden hammers (Fig. 4.2). 5. When straightening strips curved along an edge (straightening), as well as sheet material with significant deformations, it is necessary to use the stretch straightening method (Fig. 4.3). Fig. Straightening sheet material with a mallet. Fig. Straightening a strip curved along an edge.

CONTINUED 4 QUESTIONS 6. Straightening of strips with a helical bend must be done in a hand vise (Fig. 4.4, b). Fig. Editing a strip with a helical bend: a - strip with a double bend; b - straightening the strip in a hand vise

CONTINUED 4 QUESTIONS 7. Quality control of straightening should be carried out depending on the configuration of the workpiece and its initial state: by “eye” (Fig. 4.5) - visually, with a ruler, by rolling on the plate; “on a pencil” (Fig. 4.6) - by rotating the straightened shaft in the centers of a manual screw press. 8. When straightening strip and rod material on a plate (anvil), it is necessary to use Fig. Control of straightening visually Fig. Control of straightening “on a pencil” with mittens; straightening should be done with a hammer or sledgehammer firmly mounted on the handle.

5. TYPICAL DEFECTS DURING STRETCHING, REASONS FOR THEIR APPEARANCE AND METHODS OF PREVENTION Defect Cause Method of prevention After straightening the processed part, there are dents in it. Straightening was done by hitting a hammer or sledgehammer directly on the part. Straightening was done through a spacer or a soft metal adapter; when straightening, the machined cylindrical parts were placed on prisms After straightening the sheet material with a mallet or hammer through a wooden adapter, the sheet is significantly deformed. Insufficiently effective straightening methods were used. Apply the straightening method by stretching the metal along the edges of the convexity, alternating this method with straightening with direct blows. After straightening, the strip is not straight along the edge. The straightening process is not completed. Finish straightening with blows along the edge. edges of the strip, turning it 180° during straightening