| Documents for enrollment | Application, photo 3x4 | ||

| Document at the end of the course | Certificate Qualification certificate "argon welder" | ||

| Program of additional professional education and advanced training | 162 | 8000 |

8 (499) 178-80-11

The training center invites everyone to take training courses for argon welders. The program includes theoretical and practical hours; based on the results, a certification exam is conducted and students are assigned the appropriate rank and issued a certificate of the established form.

Argon welding

Argon welding allows you to join parts of different sizes. With other types of welding process, when interacting with air, oxidation occurs, which significantly reduces the quality of the joint. The difference between argon welding is that the inert gas creates a shell that acts as a protection against oxygen. In addition to argon, other inert gases include others, but its advantage is its lower cost. Argon can be used to weld all kinds of metals.

Since its specific gravity exceeds that of air, argon displaces it from the weld pool, preventing the occurrence of the reaction and the formation of oxides - precursors to the appearance of rust. In this case, the inert gas argon does not come into contact with metal products.

Argon welding includes various types:

- Manual . Only tungsten electrodes are used. The process is carried out by a welder.

- Semi-automatic . In the mechanized method, the wire is fed by a machine.

- Automatic . The process is controlled remotely by the operator.

There is special equipment, the use of which makes argon-arc welding possible, the training of which expands the capabilities and improves the status of the welder.

The advantages of the argon welding method include:

- heating at a low temperature;

- ensuring protection of the welding zone;

- speed of the process;

- simple technology;

- the ability to combine metals with different properties.

To prevent argon from evaporating during the welding process, care should be taken to avoid drafts.

Features of the profession of an argon welder

Argon welding technology allows you to connect elements from different metals. During the work, no sparks are generated and an invisible weld is formed. In this regard, the popularity of argon welding is constantly growing. Qualified specialists working with this technology will always be able to find vacancies with decent wages.

There are 5 categories in the argon operator profession. Initially, a specialist is assigned rank 2, which can then be increased once a year until he reaches rank 6. The specialist level determines the list of jobs available to him.

- Level 2 – reading simple drawings, preparing products for welding, protecting the reverse side of the weld, welding and fusing simple parts (bottom, vertical seam);

- 3rd category - work with elements made of structural steels, alloys, non-ferrous metals (simple parts), carbon steel - elements of medium complexity (for example, frames, brackets, insulation elements of water-tube boilers, metal furniture, etc.);

- 4th category – welding in any weld positions of complex elements made of carbon steel, medium-complexity parts made of cast iron, structural steel (gas exhausts, mufflers, masts and other structures made of aluminum and its alloys, etc.);

- 5th category – work with elements of any complexity with any seam position; welding of structures located in difficult conditions (heat exchangers with pressure less than 4 MPa, propellers, various types of pipelines, etc.);

- 6th category – all of the above types of work, as well as welding of experimental structures (pipelines, heat exchangers, water desalination plants and other equipment operating under pressure).

IMPORTANT! Argon type welding is in great demand when working with unique and difficult to process metals and alloys, such as titanium.

The demand for the profession in question increases self-confidence and self-esteem. You will stop doubting your own future, since our state will need welders for decades - until they are replaced by robotic welding systems and other technologies. Until then, you will always find yourself a working one without any problems.

Nuances of training

In argon welding courses, training includes theoretical and practical classes. In theory lessons, basic information about welding is given and the regulatory materials governing them are indicated, as well as the rules for designation on drawings. A mandatory safety training session is required.

Practical exercises under the supervision of a teacher allow you to understand how much the material has been mastered. They learn how to ignite an arc and weld in various ways, including using special equipment. After completing the courses and successfully passing the exam, students receive a standard certificate.

What benefits will learning argon welding give you?

You get the opportunity:

- study the physical and chemical properties of metals, basic terms and concepts;

- learn how to choose the right arc power source and welding materials to produce high-quality welds;

- understand the nuances of welding work with different types of metals - cast iron, steel, aluminum.

- study safety precautions;

- gain skills in working with equipment for manual argon-arc welding in practical classes.

After completing the practical part of the training (and almost half of the time is allocated for practice as part of the argon welding course), you will be able to:

- Confidently handle the argon welding machine and use it to make high-quality welded joints.

- Start working as an argon welder. With us you can additionally obtain: A welder certification certificate and a fire safety certificate (issued additionally upon completion of welding training) and educational assistance in your employment.

Argon operator is a highly qualified profession

If anyone doesn’t already know, in order to become an argon welder, you need to understand and study several technological areas in this industry, for example, metallurgy and electrical engineering. Argon welding courses in Moscow are designed in such a way that the student can master these disciplines at a high qualification level and apply knowledge in practice to obtain a high-quality result, and for an argon welder, this means obtaining high-quality and beautiful seams of welded structures. Tig welding courses in Moscow should be considered as consisting of two stages - theory and thorough practice. At the same time, the number of hours of practical mastery of argon-arc welding skills is sufficient to become a qualified specialist, whose level will be confirmed by a welder certification certificate and a safety certificate, which will provide you with attractive conditions for employment.

Prospects for the profession of an argon welder

The peculiarity of this specialty in our country is that the need for qualified personnel exceeds the actual number of experienced specialists. Therefore, if you decide to undergo training in argon arc welding, then you can be absolutely confident in your future employment. Yes, this work requires some effort and a truly masculine character, so argon welding training is the choice of men who are ready for real, exciting and useful work. And you have to work with metal, with different brands and types, and here the opportunity opens up for a creative approach to your future profession. Depending on the location of your future work, you will have to weld not only elements of industrial facilities, but also various installations and metal sculptures, which are made using various metals.

Features of the educational process to become a welder

As a rule, there are no difficulties during training. Stainless steel argon welding training is a clear, logically complete and very practical course. This, of course, is time spent in the classroom to understand the theoretical part, but when you find yourself in training workshops, in practice, you are transformed. You truly become an argon welder, where, under the mentorship of an experienced teacher, you learn the basics of craftsmanship and the skills of an experienced industry specialist. Many students fall in love with this profession already at the training stage, and believe me, there is something to love!

Features of welding ferrous metal with argon

Ferrous metals are classically considered to be iron and its alloys. Such metals rarely act independently; more often they are taken as raw materials, produced, for example, cast iron, or used for processing for steel production.

Rarely, but sometimes situations arise when you need to deal with pure iron.

This is a very difficult task, but this gas makes it a lot easier. Like any method, argon welding has advantages and disadvantages. And if you need to get a passable result, you will have to strictly adhere to the technology.

This article talks about all this, it will also talk about how to choose a welding mode, what safety rules should be followed, and in particular fire safety. Because welding is not a simple matter and unsafe situations often arise.

Argon arc welding

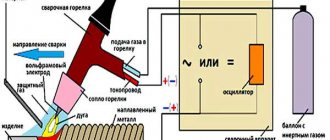

During direct current argon arc welding with a non-consumable electrode, straight polarity is used. The arc burns steadily, ensuring good seam formation. With reverse polarity, the stability of the process decreases, the tungsten electrode overheats, which leads to the need to significantly reduce the welding current. As a result, process productivity decreases.

During automatic and semi-automatic welding with a consumable electrode, a direct current of reverse polarity is used, which ensures high productivity of the process. In addition, when welding aluminum, magnesium and their alloys, a powerful bombardment of the surface of the weld pool with positive ions occurs, which, along with the process of cathode sputtering, leads to the destruction of the film of aluminum and magnesium oxides, facilitating the process of high-quality welding without the use of fluxes.

When welding with alternating current with a non-consumable electrode, it is necessary that the current source have a higher open circuit voltage, which ensures a stable arc and stabilizes the welding process. However, due to the voltage limitation for safety reasons, a permissible voltage current is used, on which a high-frequency current is superimposed, including an oscillator in the welding circuit.

When welding with alternating current, partial rectification of the current occurs due to different electron emissions from the tungsten electrode and the workpiece being welded.

During periods when the tungsten electrode is the cathode, electron emission is of greater intensity, the conductivity of the arc gap increases, and the arc voltage decreases. As a result, the welding current increases.

During periods when the product is the cathode, electron emission is less intense, resulting in a decrease in welding current. Because of this, a certain direct current component appears, which leads to a decrease in the thermal power of the arc and significantly complicates the destruction of the oxide film when welding aluminum and magnesium alloys and thereby contributes to the formation of surface and internal defects. Therefore, when welding with alternating current, measures are taken to eliminate or reduce the direct current component.

For this purpose, a capacitor battery of 100 μF per 1 A of welding current or a rechargeable battery is connected in series to the welding circuit (the positive pole of the battery is connected to the electrode). The sequential inclusion of active resistance in the welding circuit is also used, but this measure reduces the stability of the arc, and therefore, with such a welding circuit design, it is necessary to use arc power sources with an increased open circuit voltage of up to 120 V.

When manual welding with a non-consumable electrode, the arc is excited on a carbon or graphite plate and the electrode is heated for some time, and then the arc is quickly transferred to the beginning of cutting edges. When welding with alternating current, the arc is excited using an oscillator without short-circuiting the electrode to the product. In semi-automatic and automatic welding, the arc is excited by touching the lead-in bar with the electrode wire, which is installed to prevent a defect at the beginning of the weld.

Argon arc welding can be used to make seams in butt, tee and corner joints.

For sheet thicknesses up to 2.5 mm, it is recommended to weld with flanged edges.

With a small gap of the order of 0.1–0.5 mm, it is possible to weld thin-sheet material with a thickness of 0.4–4 mm without flanging or cutting edges. The smaller the thickness of the sheets being butt welded, the smaller the permissible gap. Sheets with a thickness of 4–12 mm are welded with a V-shaped groove of the edges at a cutting angle of 50–70°. The permissible gap at the joint is no more than 1.0 mm. The argon consumption should provide reliable protection of the electrode and the metal of the weld pool from exposure to air. The configuration of the product being welded should be taken into account in order to create good seam protection while using gas sparingly.

The following ratios are recommended:

Before starting welding, purge the hose and torch with a small portion of argon. The arc should be excited 3–4 s after argon is supplied to the burner. The argon jet should protect not only the weld pool, but also the reverse side of the seam. If access to the back side of the seam is difficult, then use linings or a flux pad.

Manual welding of sheets of small thickness is carried out using the left-hand method, in which the torch moves along the seam from right to left. Sheets of large thickness (more than 12 mm) are welded using the right-hand method, i.e., the torch is directed from left to right. When welding thin sheets (up to 4 mm thick), the axis of the torch mouthpiece should be 75–80° with the surface of the sheets being welded. The filler rod is inserted into the arc zone at an angle of 10–15° to the surface of the sheets being welded, i.e., almost perpendicular to the axis of the torch mouthpiece. When welding sheets of greater thickness, the axis of the torch mouthpiece is positioned almost perpendicular to the surface of the sheets being welded.

The arc length in argon-arc welding is small and amounts to 1.5–2.5 mm with the length of the protruding tungsten electrode ranging from 6–12 mm. The arc should be extinguished gradually, increasing the arc gap. The supply of argon to the arc zone should be stopped only 10–15 s after the arc is extinguished in order to protect the weld metal from exposure to air until it hardens.

Automatic and semi-automatic welding with a consumable electrode is carried out at a constant feed speed of the electrode wire, regardless of the arc voltage. The constancy of the arc length is maintained by automatic self-regulation. Electrode wire with a diameter of 0.5–2.0 mm is used. Sheets with a thickness of up to 5 mm are joined by butt welding without cutting the edges, and for sheets with a thickness of more than 5 mm, a V-shaped seam is cut with a cutting angle of 30–50°.

Read also: Correctly sharpen a feather drill

Welding current affects the nature of metal transfer into the weld. As the current increases, the droplet transfer of the electrode metal is replaced by a jet transfer and the penetration depth increases. Critical is the current value at which the electrode metal begins to flow into the weld pool in the form of a thin stream. Practice has shown that when welding aluminum alloys, the critical current is 70 A per 1 mm 2 section of electrode wire, when welding steels - 60–120 A per 1 mm 2 section of wire.

Preparation of surfaces for welding includes degreasing with solvents, aviation gasoline or technical acetone, and then removing the oxide film by mechanical cleaning or chemical means. It is recommended to carry out the treatment no more than 2–4 hours before welding. Mechanical cleaning is carried out with metal brushes made of wires with a diameter of up to 5 mm.

The chemical method includes etching for 0.5–1.0 min with a solution consisting of 45–55 g of technical sodium hydroxide and 40–50 g of technical sodium fluoride per 1 liter of water, rinsing with running water, neutralization in 25–30% aqueous solution of nitric acid for 1–2 minutes, rinsing in running water, then in hot water, drying until the moisture has completely evaporated.

Argon is a gas often used in welding. It is colorless and odorless and has excellent protective properties. The main advantage of argon is its low price. For this reason, argon is used not only in factory production conditions, but also in home welding. Argon can only be purchased in steel cylinders. Manufacturers offer different volumes; you can buy both compact 15 liters and large 40 liters.

In addition, argon does not emit toxic fumes and is not explosive. Argon is often used in arc, plasma and laser welding. For argon arc welding, consumable or non-consumable electrodes are additionally used. In this material we have collected for you all the most useful articles about argon welding. They will help you with your training.

Advantages and characteristics of welding with argon

Of course, argon welding has its advantages and characteristics, keeping up with all other types and technologies for welding metals.

This article will tell you about all the good and bad sides of argon welding, as well as some of the subtleties of working with such gas, and even about how to set up your welding machine so that the weld turns out to be of high quality.

This information is very useful to read; it will help you navigate the principles of argon and avoid mistakes. And this is important for beginners, or people who have not yet tried to work with this type of welding.

This article is very basic, it is highly recommended reading if you know nothing at all about argon cooking.

It will open the curtain for you on the processes that take place during this type of cooking and why this happens in principle. This article should be the first on your reading list, because without it you will not be able to navigate other articles.

How to weld aluminum with argon

Aluminum is one of those metals that everyone has on their tongue, even a child knows that aluminum is a metal.

This metal is used in industrial enterprises; dishes and even elements for microelectronics are made from it, and this is a very specialized niche.

BUT even such wide popularity of this metal did not ensure that everyone knew how to handle it. In most cases, a beginner will not know which way to approach a metal such as aluminum.

The reason why seams on such metal often turn out weak and not beautiful is the oxide film that covers the metal.

It is because of this that working with one of the most common metals is so painstaking and not easy. We will tell you more about the oxide film in another article, since this is a very broad and painful topic.

Another article will tell you about igniting and maintaining arc stability and the formation of a weld pool. This article will give you all the necessary information on how to cook aluminum using argon even in the wild.