In the auto body repair business, fixing dents is an everyday activity.

From the moment it became clear that such a defect was easier to eliminate by pulling the metal outward, a special device appeared, called a spotter.

Its use reduces the time it takes to restore the shape of sheet metal, and therefore the usefulness and efficiency of such equipment in a body shop remains at the highest level.

It is interesting that this name refers to any resistance welding machine, but only in the CIS countries spot welding machines designed specifically for restoring a car body are called spotters.

Purpose of the spotter

A spotter is a resistance spot welding machine that is used in the restoration of vehicle body panels.

In general, the principle of operation, like many other welders, is the release of thermal energy at the point of contact of the materials being welded due to the passage of current.

Body repair is the main purpose of the spotter.

This is especially true for volumetric parts that are difficult or impossible to get to from the reverse side.

In this case, the device allows you to straighten the material without the need to dismantle the entire part from the car, that is, right on the spot.

Here, the so-called pulling method is used, when a fastening element is welded to the damaged plane, using which the dent is pulled out.

Body panels, as a rule, are made up to 1.5 mm thick, so straightening them by stretching does not cause problems.

Some spotters are used to heat sheet metal, which allows the damage to be repaired very quickly without resorting to pulling, when the material settles on its own without any mechanical force.

Device and characteristics

The spotter consists of a welder module for resistance welding, and this can be an option for both direct and alternating current.

Adjacent to this block is a ground wire and a cable ending with a special welding gun.

At the end of the latter, depending on the specifics of the work, various attachments are attached.

On the front panel of the welder there are controls for setting various welding modes, power, current, and advanced units also have a display that displays real operating parameters, allowing you to fine-tune the equipment and monitor the progress of the process.

The work of the spotter looks like this:

- The battery is removed from the car.

- The ground wire is fixed to the body.

- The gun with the nozzle is brought to the repair area.

- The electrical circuit is completed by pressing the trigger, which results in the flow of current.

- At the point of contact of the nozzle with the body, the temperature rises until the electrode is welded to the metal, but this prevents overheating of the part and its through burning.

- The next step is to pull out the dent.

Material

The contents of modern spotters are hidden in a body made of sheet metal or aluminum; sometimes individual elements made entirely of impact-resistant plastic are used, such as the back cover and carrying handle.

The front panel is metal; adjustment knobs can also be made of metal or plastic.

Legs with rubber pads are attached to the bottom of the welder, which increases its stability.

Visually, the device strongly resembles a welding inverter.

NOTE:

For ease of movement around the workshop, some models are assembled on the basis of a vertical metal cart with wheels.

Dimensions and weight

Depending on the design, the weight of the spotter can vary widely.

Portable options weigh on average 14 - 25 kg, and models assembled on a trolley can weigh up to 90 - 100 kg.

As a rule, the dimensions of the spotter are within the following limits:

- for portable options (mm) – 210 – 390x 260 – 360 x 155 – 240

- for models with a trolley (mm) – 1000 – 1800 x 500 – 600 x 700 – 950

Operating modes and power

Modern spotters are equipped with electronic control, which allows you to simply select from the available operating modes and set the required contact time, after which the device will automatically stop supplying voltage to the gun.

The operating modes of the device are numbered and additionally indicated by corresponding icons.

The following main operating modes are distinguished:

- Welding is performed with a reverse hammer or puller, and the mode itself is designed to remove dents of small diameter and shallow depth.

Considering that such damage occurs extremely often, it is in this mode that a greater amount of work is performed, especially since modern materials from which car bodies are made easily return to their original shape due to elasticity. - Using special electrodes, any pulling element is welded to the metal. Due to this, it is possible to correct significant defects, for example, restore jammed ribs and thresholds.

- A short-length copper-plated electrode is used, which is used to deposit convexities formed, for example, by a ground terminal.

- Used to heat a decent surface area using a carbon electrode. If you pull out a large damaged surface, a so-called “pop” is formed, which in this mode is eliminated due to the deposition of metal.

- During the repair process, it is often necessary to remove fastenings, for example, moldings. Upon completion of the work, they must be welded, for which copper-plated electrodes are used.

- The mode is suitable for pulling out metal with hooks and rings using a reverse type hammer weighing 2.5 kg, but its main purpose is welding the washer for securing the ground terminal.

- A copper-plated electrode with a magnet is used, through which the welded bolt is held. It is used for welding bolts, installing ground terminals, and brake pipes.

One of the main characteristics of a spotter is its power.

We are talking about the output current, the maximum value of which should ideally not be lower than 3 thousand amperes.

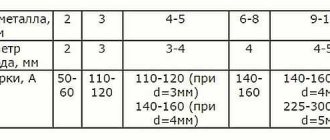

Different tasks require their own current strength:

- Welding rings and triangles – 800 – 1000 A.

- Welding corrugated wire – 1 – 1.2 thousand A.

- Work with a copper electrode - 1.4 thousand A.

- Working with a graphite electrode to heat the surface - 2.2 thousand A.

Spotter attachments

The spotter works using the following main accessories:

- The return hammer is a removable part of the gun, for the operation of which various tips are used.

- Puller - designed for express extraction, that is, it allows you to correct minor damage by smoothly leveling the surface. Structurally, it consists of a lever mechanism.

Dents can be pulled out using a needle or star attachment, which is inserted into a reverse hammer and directly welded to the part.

A hook is also often used, but it is not welded directly, but hooked onto previously welded washers.

Types of equipment

There are two main types of devices: transformer and inverter. Based on the scope and method of use, two more groups are distinguished: for straightening and welding of the body using the contact method. Straightening spotters are small devices for manual work.

They are always equipped with a reverse hammer and additional parts for repairs. The design contains special pliers. Most devices are low power. Due to the low accuracy of welding work and rapid overheating, the spotter is not able to provide high-quality welding.

Spotters are also classified according to the required power supply voltage. Standard devices are designed for 220 V, and powerful ones 380 V.

Types of spotters and their prices

By design, a spot welding machine can only belong to one of two groups:

Inverter

Thanks to the converter, which allows you to receive energy from any voltage, these models are used to perform multitasking work.

They have compact dimensions and provide high quality welding, since there is no drop in current during operation.

Price – from 25 thousand rubles.

Transformer

Powered by AC power, designed to perform simple operations.

The most extensive capabilities here are provided by models operating from three phases of power supply, due to their increased power.

Among the disadvantages, it should be noted that such models are not able to work with galvanized surfaces.

Price – about 15 thousand rubles.

Some craftsmen use the so-called battery spotter, which consists directly of a battery and a retractor relay.

This homemade device will cost much less than the factory versions of any plan; it does not require a network connection when operating, but naturally has serious disadvantages:

- Short operating time, need to charge the battery.

- No time relay.

- Lack of ability to adjust basic operating parameters, such as current.

Devices for resistance spot welding can be divided into 2 more groups, depending on the type of material they can work with:

For steel

Designed for straightening conventional steel bodies.

For aluminum

They are used for straightening aluminum parts, since aluminum has completely different properties.

Multifunctional

In terms of the number of types of work performed, there are truly multifunctional spotters capable of not only leveling surfaces, but also performing spot welding, as well as soldering metal with carbon electrodes.

By the way, a welding spotter, based on the method of forming a welding point, can be:

- For single-sided spot welding using a special electrode.

- For double-sided spot welding with special pliers with manual or pneumatic drive.

Mini spotter

In addition to full-fledged welding installations weighing more than 10 kg, you can find on sale a mini-spotter for one-sided welding and leveling surfaces with a maximum welding current of about 1.5 thousand amperes and weighing only 4 - 5 kg.

Such portable options are supplied in convenient cases, comparable in size to a pistol-type soldering iron, and their average cost is 20 - 40 thousand rubles.

Functionality of serial model spotters

Spotters manufactured in production conditions are multifunctional. Among the useful features:

- create conditions for the use of repair washers;

- maintain connection with a metal electrode for subsequent pulling;

- combined with graphite electrodes: they are useful due to the precipitation of iron (both heating and cooling);

- ease of maintenance and comfort of use;

- support two operating modes: long-term and short-term. When operating in a constantly active mode, a carbon type of electrode is installed. Short-term operation is useful for installing a metal electrode or repair washers. The duration of operation is set by a toggle switch on the case;

- cooling system. The design has a built-in thermostat that controls the temperature of the spotter and performs an emergency shutdown of the device in case of overheating. When cooled, the structure turns on again.

Fastening washers can be used several times, since they do not melt during welding

Which spotter should you choose?

When choosing a device for body repair, you need to focus on the following tips:

- For professional activities, it is better to immediately buy a spotter with maximum functionality and a wide selection of operating modes. Such equipment will allow you to perform most of the straightening work using one model.

- To work with metal whose thickness exceeds 1.5 mm, you will need a model capable of welding on both sides. If the thickness of the body elements is less than 1.5 mm, a one-sided spotter will cope with the task.

- When choosing a model for home, there is no point in buying professional equipment with a full set of straightening devices. At first, a medium-power device will be suitable, with which you can perform simple work, such as leveling dents on flat surfaces.

- Transformer models have higher efficiency and power, however, they also consume much more energy than converter options. The former are suitable for systematic work, and the latter for periodic work.

When choosing a spotter, it is better to give preference to digital models, the design of which includes electronics that can independently control welding modes and automatically dose the welding pulse.

Rating of the best spotters for home and professional use

TELWIN DIGITAL MODULAR 400

Excellent spot welding pliers that will be a great addition to any service center. The spotter type is transformer, so the maximum current can reach 6300A, while the power is 13000 W. The maximum thickness of the metal being welded should not exceed 4 mm, then the device will reveal its capabilities by 100%. Two sides are used for welding, the duration is adjusted automatically.

The peculiarity of the device is the manual compression drive. With dimensions: 440x100x185 mm and a weight of 10 kg, the device can be transported to any place without any problems. Number of phases – 3. Suitable for welding sheet metal and steel. The protection class is IP20, so large particles of dirt and dust will not get into important elements and will not cause a negative reaction, but it is better to refrain from getting water, as this will damage the device.

Sold in many online stores at a price of 45,000 rubles.

TELWIN DIGITAL MODULAR 400

Advantages:

- Good protection against dust penetration;

- Power;

- Quality;

- The assembly is made to last for many years;

- Functions with 4mm metal.

Flaws:

- Not detected.

Fubag TS 3800T

Another great device for repairing minor damage that will impress the user with its impressive appearance and efficiency. The maximum current is 3800A, while the power is 7400 W. One side is used for welding, but it ensures the reliability and quality of the operations performed.

A manual compression drive is used, there is the possibility of unhindered transportation, but it is worth knowing that the weight of the tool is 26 kg, with dimensions of 360x225x235 mm. Normal frequency is 50 Hz. The control is carried out manually, so it is necessary not to be distracted while working. The manufacturer provides a two-year warranty on the product, which shows the quality and reliability of the device.

The average cost is 32,000 rubles.

Fubag TS 3800Ti

Advantages:

- Three phases;

- The set includes a reverse hammer;

- Durability;

- Good protection against dirt;

- Suitable for steel and sheet metal;

- Good technical characteristics;

- Possibility of transportation.

Flaws:

- Weight – 26 kg.

WIEDERKRAFT WDK-5000

An excellent professional product that is intended for everyday use. Perform operations of any complexity with speed but accuracy. The maximum electric current is 3800 A. The power is standard for such equipment and is equal to 10,000 W. One side is used for welding; this is important to consider when purchasing. The duration is adjusted manually, but the transition to cooling mode occurs automatically.

The spotter can be transported indoors; for this, the manufacturer has equipped the tool with special legs that make this task easier. Dimensions - 600x500x950 mm, weight - 63 kg. For convenience, the device is equipped with an informative display that indicates the current status and allows you to adjust the power and current. It is used for sheet metal and shows high efficiency. Used in large service centers.

The average cost is 35,000 rubles.

WIEDERKRAFT WDK-5000

Advantages:

- Availability of display;

- Convenient control;

- Easy to transport;

- Air cooling system;

- Nice build.

Flaws:

- Not detected.

ELITECH ATS 5

Spot welding for home use will help remove household dents. Power source type – transformer. The possible current value is 15 A, which is less than professional ones, but given the scope of application, this is enough. Spotter power – 3500 W. One side is used for welding. The operation time depends on the user.

The device can be transported without problems, since its dimensions are 340x105x240 mm and its weight is 4 kg. Suitable only for welding steel; the tool cannot cope with complex materials. Acceptable operating frequency is 50 Hz. The manufacturer also paid attention to the configuration and added elements that will make welding better.

Sold at a price of 5,500 rubles.

ELITECH ATS 5

Advantages:

- Convenient manual model;

- Good power indicators;

- Design;

- Efficiency;

- Equipment;

- Suitable for welding steel;

- Weight only 4 kg.

Flaws:

- Not found.

FoxWeld KTR-8

A model from a top manufacturer that will immediately recoup the investment and get the job done without wasting time. Tool power – 6500 W. The thickness of the welded product is 3 mm, which is suitable for repairing cars. Double-sided welding is used, with manual control.

The design has standard dimensions and the weight is 14 kg. Intended for professional and frequent use only. The manufacturer has selected a reliable element base that will allow the tool to serve beyond the established period and without failures at the wrong time.

The average cost is 12,200 rubles.

FoxWeld KTR-8

Advantages:

- Low price;

- Efficiency;

- Ergonomics;

- Designed for professional use;

- Welds sheet metal.

Flaws:

- Not found.

Nordberg WS4

A branded element that will perform welding at the highest level. The current value is 3500 A, while the equipment power reaches 12300 W. The spotter can easily work with material whose thickness does not exceed 2 mm. One side is used for welding. It is adjusted automatically, which increases the service life by 2-4 times.

When overheating is reached, the device automatically turns off and cools down thanks to the air system. Dimensions - 350x250x220 mm, weight - 20 kg.

The average cost is 28,000 rubles.

Nordberg WS4

Advantages:

- Performance;

- The work is carried out efficiently;

- Durability;

- Transportation will not take time;

- Single phase.

Flaws:

- Not detected.

Redhotdot HAMMER T-26

A reliable spotter designed for high-speed body repairs of any complexity. The maximum current is 3800 A, while the power is only 5200 W. One side is used for welding operations. To ensure greater safety and preserve the tool for as long as possible, the manufacturer has equipped it with automatic adjustment of the welding duration. Input voltage – 220-230 V. Dimensions – 360x225x235 mm, weight – 23 kg.

Sold at a price of 38,000 rubles.

Redhotdot HAMMER T-26

Advantages:

- The spotter is designed for body work of any complexity;

- High reliability indicator;

- Build quality;

- Convenient operation;

- An excellent option for service centers.

Flaws:

- Not detected.

What you need to know about spotters?

The quality of work as a spotter directly depends on the experience of the operator. Following several rules will protect the master from troubles:

- Work comfort can be ensured by clearing the cleaned area of the body from dust, as otherwise a large number of sparks may form. As a result, tip consumption increases.

- The ground terminal should be installed at the minimum possible distance from the welding point.

Attention!

Do not fix the ground terminal to an adjacent part.

- During work, it is necessary to monitor the quality of contact of the mass and at the point of attachment of the tool. If the contact is poor, this will certainly lead to breakage of the tool attachment point, as well as breakdown.

- It is necessary to pull the material on the damaged area in a spiral, moving from the periphery to the center. This method will save time, as it will eliminate excessive stretching of the material and the appearance of dips around the center of the dent.

Important!

The device should be connected to the outlet using wiring with a cross-section of at least 2.5 sq. mm.

If you plan to use an extension cord, then the cable cross-section should be higher based on the length.

Spotter manufacturers

Among the companies engaged in the production of spotters, the leading ones are:

- Garwin GS series – popular among body repair specialists, they are equipped with a set of additional tools and have an affordable price.

- Hammer TT series are French devices with microprocessor control and increased safety. Cheaper than the previous ones, but also have less power.

- Karcher – devices on Kraft trolleys with pullers. Due to their high cost, their operation is justified only in workshop services.

Models from Aurora, Telwin, Nordberg, Holex, and Russian Master also deserve attention.