The rapid development of construction technologies contributes to the emergence of new building materials and fasteners on the market. One such innovation is the chemical anchor. Although this fastener is not currently widely used, its popularity is steadily increasing.

This type of fastening was originally developed for use in the mining industry. Using chemical anchors, structural elements were fastened to porous and loose rocks that did not have sufficient strength for fastening with metal anchors. The new fastening method turned out to be so effective that it gradually became widespread throughout the construction industry.

This article discusses the principle of operation, main types, advantages, disadvantages and scope of use of chemical anchors. In addition, a list of leading manufacturers and recommendations for independent production of this type of fasteners are provided.

What is a chemical anchor?

A chemical anchor is an innovative fastening system that provides reliable fixation of various elements of building structures in loose, hollow and porous materials. Such materials include:

- shell rock;

- limestone;

- various types of cellular concrete;

- hollow brick.

By themselves, the materials listed above do not have sufficient strength to fasten loaded structural elements, but the use of chemical anchors can solve this problem.

Depending on the material in which one or another structural element needs to be fixed, the chemical composition of the mixture can vary significantly. The exact proportions of the composition, as a rule, are not disclosed by manufacturers, but with a high degree of probability it can be said that the composition of most chemical anchors includes:

- polyurethane, acrylic or polyester resins;

- fine quartz sand;

- cement;

- hardener.

The standard packaging of a chemical anchor resembles a syringe of liquid nails or silicone sealant, but the contents of the container are an effective fastening system that ensures reliable fixation of metal rods in any building material.

What are aerated concrete anchors?

For the construction of low-rise buildings, aerated concrete, or rather foam block, is increasingly being used. The material is light and porous and needs protection from external factors. For finishing houses made of aerated concrete, a hinged ventilated facade is used, the basis of which is load-bearing profiles. Anchors are used to attach the profile to the foam block.

An anchor is a cylindrical fastening element consisting of a spacer part and an internal rod.

- Spacer part – fixes the anchor body in the porous structure of aerated concrete. The fastening method can be mechanical or chemical;

- Rod – connects the spacer part and the profile.

The diameter of the fastening element is 8-30 mm. The length depends on the type of base, the weight of the suspension system and the thickness of the wall. Usually 40-300 mm.

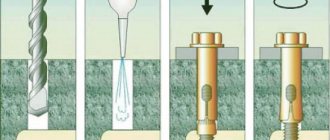

Operating principle of a chemical anchor

The principle of operation of the fastening system under consideration is that the working mixture, penetrating deeply into the pores and cavities of the material, hardens and ensures the fixation of metal rods even in cellular concrete and hollow brickwork.

Installing chemical anchors is not particularly difficult. The adhesive mixture is introduced into a pre-prepared hole, after which a threaded rod or conventional corrugated fittings are installed there. The filler tightly envelops the rod and hardens, thereby ensuring its reliable fixation. Depending on the type of chemical anchor, a special dispenser gun or a special capsule may be used to fill the hole with adhesive.

Chemical anchors are significantly superior to conventional anchor systems and dowels in their ability to withstand pull-out loads. The load-bearing capacity of chemical compounds allows the use of this method of fastening when installing balconies, canopies and even bridges, both above and below water.

It is especially advisable to use chemical anchors in cases where neither dowels nor conventional metal anchors are able to guarantee reliable fastening of structural elements to the base. Typically, this situation occurs if the base is a porous or hollow material, for example, shell rock, limestone, gas or foam concrete, cinder block, etc.

When using a fastener element, it must be remembered that the setting and complete hardening of the filler depends on its composition and can range from 5 to 24 hours.

Technology of use

Do-it-yourself installation of chemical anchors does not require special equipment or training. It is easy to do it yourself if you have a tool that every owner has.

Mark the intended location for fastening. Using a hammer drill with a diamond tip drill, drill holes that should be 2 mm larger than the diameter of the anchor pin or bolt.

Carefully remove dust from the middle.

- Insert an ampoule of glue into the hole, tighten the bolt or pin with an electric drill or hammer it in.

- If a cartridge is used, squeeze out the adhesive until the hole is completely filled, and insert the pin.

- Wait until the components specified in the attached instructions are completely dry and proceed with further installation.

Each type of anchorage is supplied with detailed instructions by the manufacturer, which explain in detail all stages of the work. The instructions must be strictly followed.

Application area

Let us consider in more detail in which cases it is advisable to use chemical anchors. According to reviews from builders and recommendations from manufacturers, chemical anchors are most often used for:

- arrangement of highways and other road works related to the installation of signs, signs, advertising brochures, etc.;

- installation of ventilation systems on loose, porous and hollow foundations;

- reliable fixation of large metal structures;

- installation of massive advertising structures characterized by increased windage;

- restoration of various types of lifts;

- erection of scaffolding and sheathing;

- restoration of monuments;

- carrying out installation work in port areas and construction of various water bodies;

- installation of funiculars used at ski resorts;

- arrangement of electrical facilities.

In domestic conditions, chemical anchors may be required to attach heavy hanging furniture and interior items to an insufficiently strong base.

Tips for use

Based on the properties of liquid dowels, let’s consider several examples where it is most advisable to use a chemical anchor for concrete:

- Installation of barriers on the finished road surface.

- For installation of floor railings and staircases.

- Fastening of utility networks, if their fastening was not provided for in advance.

- Installation of reinforcement outlets in ready-made concrete structures.

- Installation of monolithic structures, brackets on the facades of finished buildings.

A chemical anchor can be used to secure and monolith a lot of other things; all its properties and applications are countless.

Return to contents

Types of liquid anchor

As mentioned in previous sections, chemical anchors are typically two-part formulations consisting of synthetic resins and a hardener. The ingredients are mixed immediately before using the anchor. There are three types of packaging for chemical anchors:

- ampoule.

They are a capsule with two compartments, one of which contains the adhesive mixture, the other contains the hardener; - single cartridge.

Inside the cartridge there is a special partition separating the adhesive and hardener; - two-cartridge.

The kit includes two cartridges, one of which contains an adhesive, the other a hardener.

The compositions produced in cartridges work on the same principle, however, to use them you will need various dispensing guns designed to dose the mixture into a pre-prepared hole (hole).

Ampoule anchors

The main feature of such fasteners is that the diameter of the ampoule strictly corresponds to the specific diameter of the prepared hole (borehole). One ampoule is intended to fix one rod (stud, screw, etc.). It is advisable to use ampoule anchors in cases where high accuracy and cleanliness of the hole can be guaranteed.

Capsule anchors are convenient to use because there is no need to control the degree of filling of the hole. Minor differences in the diameters of the hole and capsule are fully compensated by the expansion of the adhesive composition as it hardens.

As mentioned above, the ampoule has two capsules: with an adhesive mixture and with a hardener. The connection of these components occurs by screwing in a threaded metal rod, such as a stud or screw. It should be noted that mixing of the hardener and filler occurs more evenly than when using compounds packaged in one or two cartridges.

The disadvantages of capsule chemical anchors include the inability to use them in a vertical position. This is due to the fact that the filler will flow out of the hole much faster than setting occurs.

Cartridge anchors

As mentioned above, this type of anchor can be placed in one tube, separated by a partition, and in two separate cartridges.

When using one cartridge, the filler and hardener simultaneously enter the cavity of the mixing spout, where they are mixed using a special spiral insert. To work with such anchors, you can use a regular construction dispenser gun.

The two-cartridge system works a little differently. Mixing of components also occurs in a common spout, but they go there separately. To work with such packaging, you will need a special dispenser gun that ensures simultaneous supply of filler and hardener into the mixing spout.

Types of cartridge anchors

All cartridge anchors can be divided into two types:

- universal;

- for fastening metal rods in concrete foundations.

Universal chemical anchors

The popularity of this type of anchor fastening is due, first of all, to its ease of use. During installation work, there is no need to accurately calculate the volume of material required for one fastening.

Anchors designed for attaching metal rods to concrete foundations

Chemical anchors, the main purpose of which is gluing threaded or reinforcing bars into a concrete base, most often have a thick consistency. In addition to the main components, their composition includes corrosion inhibitors and deoxidizers, which significantly increases the reliability and service life of the fastener.

Some types of chemical anchors intended for concrete are used only in combination with special chemicals designed to treat the rods and drilled holes. In addition, special devices may be required to press the rods into the holes.

A significant disadvantage of cartridge anchors is the difficulty of controlling the filling of holes with adhesive. If the amount of working mixture is insufficient, it begins to flow out of the hole if the base is porous or hollow type without waiting for setting.

You can significantly reduce the consumption of filler and achieve its uniform distribution on all sides of the hole by using special mesh bushings. These elements can have different sizes and are selected specifically for a specific mount.

Rules for installation work

Let's look at how to use a chemical anchor. Here it is important not only to follow the instructions for using dowels, but to properly prepare the work site. Thus, the arrangement of boreholes is carried out taking into account the accuracy and responsibility of installation work. In any case, the seat drilled with a hammer drill must be kept as free from debris and dust as possible. It is easier to complete the task by pre-cleaning with a metal brush and then blowing. Then the pores will be freed to form a more reliable adhesion of the chimanker to the base.

Pneumatic blow gun Source instrumentvs.ru

Another option for cleaning boreholes is washing. This method is relevant for working with a base with a closed-cell structure. Here, not just water is used, but special solutions containing surfactants (surfactants). The principle is this: the composition forms a large amount of foam, from which dirt and dust are subsequently removed. This is done by blowing.

If the work is carried out at a site with increased responsibility, the fastening is carried out on load-bearing elements, then in addition the craftsmen recommend using a special conductor during drilling. This is a small cylinder, which is fixed strictly perpendicular to the supporting platform. To form cone-shaped holes you will need a swinging jig or a special drill. This way the input diameter will remain the given shape and diameter.

Immediately after cleaning the prepared hole, you can start working with a concrete mortar. If it is a capsule, then after it is immersed, a pin is screwed in. If the base is porous or has voids, then first the mesh sleeve is inserted, then the fasteners, and finally the injection composition is introduced. To navigate relative to the volumetric part of the released mass, you can use a pistol with a dispenser.

Gun for injection anchor with dispenser Source vsmete.ru

Advantages and disadvantages

Like any other elements of building structures, chemical anchors have their advantages and disadvantages. To avoid unpleasant moments during installation and operation, it is necessary to take into account both the positive and negative features of this type of fastening.

The undeniable advantages of chemical anchors include:

- complete sealing of the hole after installing the rod;

- No tensile stresses in the concrete base.

- Versatility and wide scope of application;

- ease of installation. Installing a chemical anchor does not require experience or special skills;

- high strength characteristics of the anchor fastening after its complete polymerization. In this indicator, chemical anchors are significantly superior to metal anchors and dowels with a plastic sleeve;

- ability to withstand significant mechanical loads and tensile forces. In other words, the fastening element has a high load-bearing capacity;

- chemical anchors are not susceptible to external atmospheric influences, corrosion processes, or the effects of aggressive chemical compounds;

- special chemical anchor compounds can be used in conditions of high humidity and on waterlogged surfaces; in addition, installation of underwater structures is quite acceptable;

- the service life of such fastenings is comparable to the durability of the base itself and is usually at least 50 years;

- There are adhesives that do not contain any toxic compounds. It is advisable to use such fastenings for interior work. When purchasing chemical anchors, you need to make sure that the mixture is environmentally safe;

- The thermal expansion coefficients of fasteners and base materials are approximately equal. This eliminates the occurrence of additional internal stresses during sudden temperature changes.

Along with the above advantages, when starting to use, you should keep in mind the following disadvantages:

- Unlike metal anchors and dowels, chemical anchors require quite a long time until the installed anchor is fully ready to bear the load. The time for complete polymerization of the fastener depends on the ambient temperature:

— at a temperature of +200C, the time for complete polymerization will be from 25 to 40 minutes; will be 25÷40 minutes;

— at 50C this period will be 6 to 7 hours;

- with a further decrease in temperature, the polymerization process may stop altogether.

- Limited shelf life of unopened packaging. When packaged, the composition can be stored for no more than 1 year;

- Once the package is opened, its shelf life is significantly reduced. Based on this, it is necessary to plan installation work in such a way that the packaging is completely consumed at one time. In other words, it is not practical to print packaging for one or two mounts. In this case, ampoule anchors can come to the rescue;

- The high price sharply reduces the demand for this type of fastening.

Recommendations from experts

It is permissible to install anchors for aerated concrete blocks with a minimum distance from each other of 100 mm. Reducing the gap can lead to destruction of the porous base. This is justified by the overlap of stress, which is subsequently created by the load on the fasteners. The same applies to the edge of a separate block.

Choosing sufficiently strong fasteners is not the only condition for high-quality work. It is also important to consider the load-bearing capacity of the foundation itself. For example, blocks of class B2.5 are able to withstand a load that is half that of class B5 counterparts. But in the private sector, high-strength foam concrete is rarely used.

To ensure perpendicularity, you can use a special jig. This is a cylindrical base with a platform. If you need to form a cone-shaped hole, then in addition to a special drill, you can also use a regular one. Here, for example, a metal washer is applied to the surface of the base, and rotational movements are performed inside the hole using the nozzle.

Special jig for drilling at an angle of 90 degrees Source allegroimg.com

Types of guns for chemical anchors

The use of a cartridge chemical anchor is impossible without the use of special dispensing guns. If the material is packaged in one tube, there are no problems: you can use a regular mounting gun. If the filler and hardener are in different tubes, you cannot do without a dispenser gun of a special design, which ensures the simultaneous supply of ingredients into the mixer spout.

In order to effectively use the dual cartridge dispenser gun, some practical skills will be required. First of all, it is necessary to be able to determine with a high degree of accuracy the required volume of anchor mixture. It depends on several factors:

- diameter of the fixed rod;

- hole depth;

- the presence of a mesh sleeve;

In addition, it is necessary to take into account possible losses of the adhesive mixture during the installation process.

The cost of a dispenser gun for chemical anchors can range from 1,300 to 7,000 rubles. The most expensive and versatile models from Hilti can be used at any ambient temperature. Models are distinguished by a wide selection of dispensers; in addition, the kit may include mounting rods.

Fisher pistols are a budget modification of the tool, and are usually used when carrying out repair work on a small scale.

Models from BIT United Ltd. have gained wide popularity among ampoule automatic dispensing guns. The main advantage of this tool is its affordable price, which, depending on the configuration, can range from 700 to 1000 rubles.

How to choose a chemical anchor for aerated concrete, concrete and brick

Depending on the base material, different anchor mixtures are used. It is extremely important to ensure that the chemical composition of the anchor matches its characteristics and operating conditions. In order to accurately select a material, before purchasing it, you should carefully study the instructions included with it or located on the packaging. This document contains all the necessary information.

Most well-known manufacturers indicate in their recommendations the types of structures and materials for their manufacture, the optimal location of mounting holes and their sizes, the method of fastening, the range of humidity and temperature, as well as permissible loads for various bases. In addition, it is necessary to take into account possible limitations on operating conditions and the rate of polymerization of the mixture - this is of particular importance for chemical anchors with atmospheric polymerization.

Mounting methods

There are several main ways to install chemical anchors:

- Glass ampoule. Sold ready-made with threaded rod. The ampoule is inserted into the drilled hole. Then the pin is screwed in.

- Tuba. The chemical anchor is sold in a special plastic container for the glue gun. Inside the tube, the chemical reagents are separated. After squeezing into the hole, they mix.

The use of a chemical anchor for fastening into aerated concrete allows us to solve the main problem - tearing out the anchors. The adhesive composition completely fills the hole, securely clamping the pin.

It can be used to attach suspended structures to walls made of hollow or weakened ceramic bricks.

Similar articles

- Chemical anchor Chemical anchor

.

It is an anchor

bolt of suitable dimensions, has anti-corrosion properties and is resistant to

the chemical

components contained in the adhesive solution, forming strong adhesion with them. Its installation is carried out as follows - in the wall... Read more - Anchor pull-out test methods

Description of

the anchor

bolt.

An anchor

bolt is a durable alloy steel rod 30-200 mm long

... a chemical anchor

. In addition to the frictional force, the rod is held in the hole due to the adhesion of the cementing paste and the base material. The result is a monolithic connection with... Read more - How to decorate a house made of foam blocks from the outside: types of materials

When producing foam blocks, you need to take into account the fact that there will be open pores on their surface. What can happen to a foam block wall: 1)… Read more

- Bracket for ventilated facades: types and functions

A facade bracket is an element for fastening a substructure in a system of ventilated facades; it comes in various shapes: L or U-shaped section. Used to attach the profile to the supporting base - with... Read more

- Technology of installation of ventilated facades: device...

Description of the technology for installing ventilated curtain facades. Construction of subsystem and insulation. Types and installation schemes of ventilation facades depending on the material... Read more

- Do-it-yourself metal profile lathing for siding

The construction industry is developing along the path of simplifying and speeding up work, as well as improving the quality of building materials. Heavy and bulky buildings are being replaced by easily erected... Read more

The best manufacturers

Currently, several well-known companies occupy leading positions in the chemical anchors market. Below is a list of these companies and the technical characteristics of their products.

| (Germany) | ||

| R.M. | “Reaktionsanker” is an ampoule with an adhesive mass, inside of which there is a compartment with a hardener. The manufacturer produces ampoules of different sizes - M8 (10×80), M10 (12×90), M12 (14×110), M16 (18×125), M20 (24×170), M30 (30×280). | |

| FHP | “Hammerpatrone” is an ampoule with glue and hardener for installing metal elements into a concrete base. Produced in the following sizes – 10 (13×90), 12 (15×110), 16 (18×125), 20 (24×180). | |

| FIS V 360S | “Injections-Mortel” Double cartridge, requires a special gun to operate. Main cartridge with a volume of 360 ml and two mixers. | |

| FIS VS 150 | "Injections-Mortel" One standard size cartridge. To work, you will need a regular construction gun for standard cartridges. The kit includes a 150 ml cartridge, two mixers and an adapter. | |

| (Liechtenstein) | ||

| HVU | "Adhisitive Capsule Anchor". Ampoule with methacrylic polyurethane resin, quartz sand and hardener. Capsules have the following volume: M8 (10×80), M10 (12×90), M12 (14×110), M16 (18×125), M20 (24×170), M30 (30×280), M33 (37 ×300), M36 (40×330), M39 (42×360). | |

| HIT-HY150 | "Fast Curinq Injection System". These are two dual cartridges with acrylic resin and hardener. A special gun is required for operation. Cartridge volume 330 ml and two hardeners, HIT-HY20 has one hardener. | |

| HIT-HY20 | ||

| (Switzerland) | ||

| MSP | "Schlagpatrone". Ampoules with resin and hardener. Capsule volume: M8 (10×80), M10 (12×90), M12 (14×110), M16 (18×125), M20 (24×170). | |

| MYA | "Verbunanker". Ampoules with two components. Volume: M8 (10×80), M10 (12×90), M12 (14×110), M16 (18×125), M20 (24×170), M30 (30×280). | |

| MIT-P | One cartridge. A standard construction gun is used for the job. Cartridge volume 150 ml, two mixers. | |

| MIT-P | Double cartridge. Set: 235 ml and two mixers. | |

| MIT-SF | Double cartridge. Volume 380 ml and two mixers. | |

| (Finland) | ||

| KEM | “Kemiallinen ankkuri” – ampoules with polyester resin and hardener, volume M8 (10×80), M10 (12×90), M12 (14×110), M16 (18×125), M20 (24×170), M30 ( 30×280). | |

| KEMLA | “Kemiallinen lyontiampulli” – ampoules with polyester resin and hardener, volume M8 (10×80), M10 (12×90), M12 (14×110), M16 (18×125), M20 (24×170). | |

| ITH | "Injektointitekniika". Cartridge with injection mass based on polyester resin, volume 380 and 150 ml | |

| (Germany) | ||

| TVA | "Verbund-Anker". Ampoules with resin and hardener volume M8 (10×80), M10 (12×90), M12 (14×110), M16 (18×125), M20 (24×170), M30 (30×280). | |

| THP | "Hammerpatrone". Ampoules with resin and hardener, volume M8 (10×80), M10 (12×90), M12 (14×110), M16 (18×125), M20 (24×170). | |

| TVM-K | "Verbundmortel". Cartridge with injection mass, volume 380 and 150 ml. | |

Design and types

A chemical anchor is a fastening element containing:

- special adhesive composition;

- metal sleeve with thread inside;

- male threaded stud or regular rebar.

The adhesive composition in capsules is intended for installation of one anchor. To install many products, it is better to purchase tubes or cartridges

The metal elements of a chemical anchor can be made of galvanized or stainless steel of varying degrees of strength. The material used depends on the purpose of the fastener.

The peculiarity of using a chemical anchor is that an adhesive composition is injected into a hole in concrete, aerated concrete, brickwork or any other material, which, after polymerization, ensures exceptional reliability of the resulting connection.

Advantages of a chemical anchor compared to an expansion dowel in hollow building materials (click to enlarge)

The adhesive composition of the chemical anchor fills all free pores, providing rigid fixation even in “problematic” materials

The composition of the glue is kept a big secret by the manufacturer, but it is assumed that it includes the following components:

- artificial resin based on polyester, polyurethane and acrylic;

- fillers that provide good strength characteristics of the formed joint (such fillers are quartz sand and cement);

- a hardener that is responsible for the speed and quality of polymerization of the adhesive composition.

Chemical anchor HILTI complete with mixer and extension

As is clear from the above composition, all components of such glue are mixed immediately before installing the anchor bolt. Modern manufacturers produce adhesive compositions for chemical anchors:

- in special capsules, the diameter and height of which correspond to the dimensions of the hole for placing the bolt;

- in cartridges and tubes (the internal volume of such containers is divided into two compartments, one of which contains the adhesive composition, and the other contains the hardener).

The approximate consumption of the adhesive composition can be determined in advance

When using capsules, as stated in the detailed instructions for such elements, they are the first to be inserted into the hole. Mixing of the components of the adhesive composition and its further polymerization occurs due to the fact that a metal pin is inserted into the hole, which destroys the capsule shell and the internal partition between its compartments.

The technology for using cartridges and tubes, the internal compartments of which contain glue and hardener, looks somewhat different. To use such elements, a special gun is required, with the help of which the components of the mixture are squeezed out, while simultaneously mixing, into the cavity of a pre-made hole.

Is it possible to make a chemical anchor yourself?

Factory-made chemical anchors are quite expensive and also have a limited shelf life, especially after unpacking the cartridge. Meanwhile, it is quite possible to make a chemical anchor yourself at home.

The composition is made on the basis of epoxy resin. The physical and technical characteristics of this component fully ensure excellent adhesion to shell rock, limestone, brick, concrete and many other materials. Thanks to these properties, epoxy resin may well become the main component of a homemade chemical anchor.

To make liquid fasteners at home you will need:

- epoxy resin ED-20;

- hardener UP-583;

- Cement or plaster. A small amount of fine quartz sand can be used as a filler;

- Plasticizer DBP or DEG-1.

The preparation of the mixture consists of several stages:

- A plasticizer is added to the epoxy resin in a volume of 5 to 10% of the resin volume, after which the resulting mixture is thoroughly mixed.

- After this, filler (cement or gypsum) is added to the resulting composition. The resulting substance is mixed until a homogeneous mass without lumps is obtained. The amount of filler also ranges from 5 to 10% of the total volume of the mixture.

- The last step is to add hardener in a ratio of 1:10 or 1:8. The rate of polymerization of the composition and its strength will depend on the amount of hardener.

After thorough mixing, a ready-to-use mixture is obtained, which must be processed immediately after preparation. The setting time of the mixture is 1-2 hours, depending on the ambient temperature. Complete polymerization of the composition can last from 12 to 24 hours. The use of a plasticizer allows you to extend the life of the mixture, and the use of gypsum as a filler, on the contrary, speeds up the setting process.

Chemical anchor Tytan EV-I / Titan Evi Universal (300 ml) Titan

Return Policy

1. Return and exchange of building materials of proper quality

.

1) A potential or regular Buyer of the Stroymall online store has every reason to refuse to purchase construction or finishing materials at any time before actual receipt, as well as during the period of receipt - within 7 (seven) working days (according to the Law of the Russian Federation “On the Protection of consumer rights”, Article 26.1 on the Remote method of selling goods).

The buyer does not have the right to refuse a product that is of appropriate quality and has personal or certain physical and mechanical characteristics if the purchased product is used only by the buyer purchasing it.

If the Buyer refuses the purchased goods, the Seller returns the cost of the goods paid for by the Buyer in accordance with the signed contract for the supply of building materials, without taking into account the cost of the Seller’s expenses for delivery of the returned goods from the Buyer, within ten days from the moment the Buyer submits a mutually relevant requirement defined in Article 21 of the Rules selling goods remotely."

2) The Buyer has the right to exchange a construction product of appropriate quality for a similar construction material from the Supplier from whom this material was purchased, if the construction material is not suitable in terms of overall dimensions, color, or completeness.

The buyer has every right to exchange building material of appropriate quality within no later than 14 days, not counting the day of purchase.

The only exceptions are those goods that are indicated in the list of non-food products that cannot be returned or replaced, corresponding to Article 25 of the Law “On the Protection of Consumer Rights”.

It is permissible to return a product of appropriate quality only if the following requirements are met: the appearance is preserved, a document (check, payment) confirming the terms of payment for this product. The consumer’s lack of a payment document does not deprive him of the opportunity to provide additional evidence of the purchase of building materials from the Supplier.

2. Returning goods of inadequate quality

If defects are discovered in the product, if they were not specified by the seller, the consumer has the right to:

- demand replacement with a product of the same brand (same models or purpose);

- demand replacement with the same product of another brand (model, characteristics) with a corresponding recalculation of the purchase price;

- demand a proportionate reduction in the purchase price;

- demand immediate free elimination of defects in the goods or reimbursement of costs for their correction by the consumer or a third party;

- refuse to fulfill the supply contract and demand a refund of the amount paid for the goods (Clause 1.Article 18 of the Law “On the Protection of Consumer Rights”).

The Buyer’s absence of a cash or sales receipt, or other document certifying the fact and conditions of purchase of the goods, is not a basis for refusal to satisfy his requirements.

3. Deadline for returning goods of inadequate quality

If the goods are transferred to the Buyer in violation of the terms of the contract regarding the quantity, assortment, quality, completeness, packaging and (or) packaging of the goods, the buyer may notify the seller of these violations no later than 20 days after receiving the goods.

If defects are discovered in a product for which warranty periods or expiration dates have not been established, the buyer has the right to make claims regarding defects in the product within a reasonable time, but within 2 years from the date of its transfer to the buyer, unless longer periods are established by law or contract.

The buyer also has the right to make claims against the seller regarding defects in the goods if they are discovered during the warranty period or expiration date (Article 27 of the “Rules for the sale of goods by remote means”).

4. Return procedure Return of goods

1) If you find a defect or shortage! Notify the manager handling your order to agree on a time to replace the defective material or to deliver the missing amount of material.

2) Upon receipt of the goods, it was determined that you need another building material. Provide this information to the manager handling your order, we will pick up the unnecessary goods within the time agreed with you and deliver the necessary ones.

3) There are surplus building materials of proper quality that have not expired. Call the manager who carried out the sale to agree on the terms of returning the excess goods (The service is limited to the product group).

4) If you purchased a product of good quality, but want to return it, delivery of the product upon return is paid; check the cost of removal with the managers by phone. You can also bring the goods to the supplier’s warehouse yourself, whose address you can check with the managers.

A refund

1) Refunds are made in the same way as payment was made (cash, bank transfer).

2) If you have paid for the order in full, but will only pick up part of the goods, issue a partial refund for the goods not received.

How to use a chemical anchor

To use a chemical anchor, no special knowledge or practical skills are required. The procedure is quite simple and straightforward.

If an ampoule anchor is used, the ampoule should be placed in the hole and split with a metal rod. As a result, the components mix and harden.

When using the substance in cartridges, the required amount of adhesive mixture is squeezed into the cleaned hole, after which a metal rod is installed. After the time specified in the technical specifications, the mixture completely hardens, thereby ensuring reliable fixation of the rod.

How can I replace a chemical anchor?

Considering the high cost of chemical anchors, the question often arises: what can replace them. It is indeed possible to replace the factory chemical version, but it is necessary to take into account the base material.

For heavy concrete, a classic metal anchor is best. To be fair. It should be noted that such bases do not really need liquid fasteners at all.

When it comes to cellular concrete, a homemade epoxy resin-based anchor can be a good alternative to a factory-made chemical anchor. In addition, the use of drywall adhesive and some other gypsum-based mixtures gives good results. To achieve maximum fastening strength, holes should be drilled in the shape of a reverse cone.

Despite their high cost, chemical anchors are increasingly used to fasten building structural elements to loose, porous and hollow substrates. In terms of their strength characteristics, such fastenings are significantly superior to conventional metal anchors and dowels with plastic sleeves, especially when fastening to weak foundations.