It is well known that the repair of welding machines in the vast majority of cases can be organized and carried out independently. The only exception is the restoration of the electronic inverter, the complexity of the circuitry of which does not allow for a full repair at home.

Just trying to disable the inverter protection can baffle even an electrical specialist. So in this case, it is best to seek help from a specialized workshop.

Frequent malfunctions

The main manifestations of problems with electric arc welding machines are:

- the device does not turn on when connected to the mains and started;

- sticking of the electrode with a simultaneous hum in the area of the converter;

- spontaneous shutdown of the welding machine in case of overheating.

Repairs always begin with an inspection of the welding machine and checking the supply voltage. Repairing transformer welding machines is not difficult, and they are not picky about maintenance. With inverter devices, it is more difficult to determine a breakdown, and repairs at home are often impossible.

However, if handled properly, inverters last a long time and do not break down. It is necessary to protect from dust, high humidity, frost, and store in a dry place. There are the most typical malfunctions of welding machines that you can fix yourself.

The device does not start

In this case, first of all, you need to make sure that there is voltage in the network and the integrity of the fuses installed in the transformer windings. If they are in good condition, you should use a tester to ring the current windings and each of the rectifier diodes, thereby checking their performance.

If one of the current windings breaks, it will need to be rewinded, and if both are faulty, it is easier to replace the entire transformer. The damaged or “suspicious” diode is replaced with a new one. After repair, the welding machine is turned on again and checked for serviceability.

Sometimes the filter capacitor fails. In this case, the repair will consist of checking it and replacing it with a new part.

If all elements of the circuit are in working order, it is necessary to deal with the mains voltage, which can be greatly underestimated and is simply not enough for the normal functioning of the welding machine.

General procedure for diagnosing welding inverters

Before repairing the device, you should check the functionality of the cooling system. Cooling radiators clogged with dust remove heat from the power elements much worse, which means the fins should be completely cleaned of dust and other debris.

Repair of inverter welding machines should begin with diagnosing the input rectifier.

To fully check this node you should:

- disassemble the module;

- remove the radiator;

- remove the diode bridge;

- ring the contacts of the diode bridge.

If no problems with the diode bridge are identified, you should move on to the next module - the output rectifier.

Typical inverter faults.

The functionality of the output rectifier is checked using the following algorithm:

- disassemble the module;

- unsolder the diode assemblies;

- ring the diodes.

In addition to diodes, the output rectifier circuit contains radiators that should be installed back after repairing the module.

After examining the output rectifier, you should proceed to diagnosing the key module.

This inverter module consists of:

- four groups of transistors;

- key control boards;

- smoothing rectifiers.

The procedure for examining the key module is as follows:

- Checking transistors. As a rule, a faulty element is clearly visible to the naked eye. If this is not the case, then you should check the sequence of all available transistors with a tester.

- If measurements with a tester do not produce results, you need to diagnose the transistor assemblies using an avometer, measuring the resistance.

- If all components appear to be in good working order, all transistors should be unsoldered one by one. This diagnostic method is suitable if there is a short circuit on the board.

If the transistor converters of the control unit are fully operational, you need to inspect the key control board. To carry out such diagnostics, you should prepare an oscilloscope.

Most inverter problems can be diagnosed by carefully inspecting the electronic components. If defective parts are identified, you should immediately remove them and replace them with similar characteristics.

Electrode sticking (arc interruption)

The cause of electrode sticking and arc interruption may be a decrease in voltage due to a short circuit in the transformer windings, faulty diodes or loose connecting contacts. A breakdown of the capacitor filter or short circuit of individual parts to the body of the welding machine is also possible.

Organizational reasons due to which the machine does not weld as it should include the excessive length of welding wires (more than 30 meters).

If sticking is accompanied by a strong hum from the transformer, this also indicates an overload in the load circuits of the device or a short circuit in the welding wires.

One of the repair options to eliminate these effects could be restoring the insulation of connecting cables, as well as tightening loose contacts and terminal blocks.

Prices for argon arc welding repairs:

| Services | Term | Price |

| Diagnostics | 2-3 hours | 0 rub. |

| Pickup of equipment in Moscow and within a radius of 30 km from the Moscow Ring Road | 1 day | 0 rub. |

| Power section repair | 1-2 days | from 1500 rub. |

| Oscillator repair | 1-2 days | from 3500 rub. |

| Power supply repair | 1-2 days | from 4100 rub. |

| Control board repair | 1-2 days | from 1100 rub. |

| Replacing transistors | 1-2 days | from 880 rub. |

Spontaneous shutdown

In some cases, repairs can be carried out independently if the device begins to turn off spontaneously. Most models of welding machines are equipped with a protective circuit (automatic) that is triggered in a critical situation, accompanied by a deviation from normal operation. One of the options for such protection involves blocking the operation of the device when the ventilation module is turned off.

After spontaneous shutdown of the welding machine, first of all, you should check the state of the protection and try to return this element to working condition.

If the protective unit is triggered again, it is necessary to proceed to troubleshooting using one of the methods described above related to short circuits or malfunctions of individual parts.

In this situation, first of all, you should make sure that the cooling unit of the unit is working normally and that overheating of the internal spaces is excluded.

It also happens that the cooling unit does not cope with its functions due to the fact that the welding machine was under a load for a long time that exceeded the permissible norm. The only correct solution in this case is to let it “rest” for about 30-40 minutes, and then try to turn it on again.

In the absence of internal protection, a circuit breaker can be installed in the electrical panel. To maintain normal functioning of the welding unit, its settings must correspond to the selected modes.

Thus, some models of such devices (welding inverter, in particular), in accordance with the instructions, must work according to a schedule that requires a break of 3-4 minutes after 7-8 minutes of continuous welding.

Why us?

Just contact us by phone.

Examples of completed repairs of argon arc welding machines:

Go to YouTube video channel

Malfunctions of inverter devices

Before repairing an inverter welding machine with your own hands, it is advisable to familiarize yourself with the principle of operation, as well as its electronic circuit. Knowing them will allow you to quickly identify the causes of breakdowns and try to eliminate them in a timely manner.

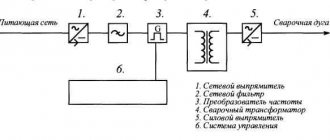

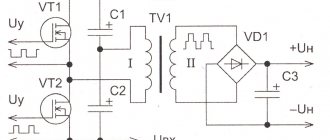

Electrical diagram

The operation of this device is based on the principle of double conversion of the input voltage and obtaining a direct welding current at the output by rectifying the high-frequency signal.

The use of an intermediate high-frequency signal makes it possible to obtain a compact pulse device that has the ability to effectively regulate the output current.

Failures of all welding inverters can be divided into the following types:

- malfunctions associated with errors in choosing the welding mode;

- operational failures caused by failure of the electronic (converter) module or other parts of the device.

The method for identifying inverter malfunctions associated with disturbances in the operation of the circuit involves sequential execution of operations carried out according to the principle “from simple damage to more complex damage.” The nature and cause of breakdowns, as well as repair methods, can be found in more detail in the summary table.

It also provides data on the main welding parameters, ensuring trouble-free (without turning off the inverter) operation of the device.

Features of operation

Maintenance and repair of inverter-type welding machines differs in a number of features related to the complexity of the circuitry of these electronic units. Repairing them will require certain knowledge, as well as the ability to handle measuring instruments such as a digital multimeter, oscilloscope and the like.

In the process of repairing an electronic circuit, a visual inspection of the circuit boards is first carried out in order to identify burnt or “suspicious” elements within individual functional modules.

If during the inspection no violations can be detected, the troubleshooting continues by identifying violations in the operation of the electronic circuit (checking voltage levels and the presence of a signal at its control points).

To do this, you will need an oscilloscope and a multimeter, which you should start working with only if you have complete confidence in your abilities. If you have any doubts about your qualifications, the only right decision is to take (take) the device to a specialized workshop.

Specialists in the repair of complex pulse devices will quickly find and eliminate the malfunction, and at the same time carry out maintenance of this unit.

Repair of argon welding machines of any brand on-site and in an Authorized Service!

inverter and transformer

TIG machines

Contact the Welding-Zone service center at the first sign of device malfunction. Tig welding service and repair is our specialty. The material base includes its own warehouse of spare parts, equipment for diagnostics and restoration of devices, documentation, and software. The staff consists of engineers with extensive experience and thorough knowledge of power electronics brands EWM, BlueWeld, Lorch, Cebora, Kemppi, Svorog, Kedr, Start, etc. After diagnostics, we agree on an estimate and, in some cases, notify the client that repairs are impractical. Urgent orders are processed.