Author of the article: Svetlana Galitsina | Updated: 01/23/2022

False eyelash bundles of the Nesura brand, 12 mm, volume 10D curve B

450 ₽ More details

False eyelash bundles of the Nesura brand, 14 mm, volume 10D curve B

280 ₽ More details

Men's slim jeans

Any gardener, amateur gardener or farmer cannot imagine how you can cultivate your plot of land without using a rake - be it ordinary garden or industrial. With this tool you can cultivate the soil, harvest crops and keep the entire area clean. What types of rakes are there, what jobs are they intended for, and how can you make a wooden rake yourself?

DIY tedder rake

Rakes are an indispensable tool in almost all types of agricultural work.

In the past, they were the main tool for hay harvesting, which was carried out in two stages. First, the grass was mowed by hand, then collected into windrows using a rake. This method of preparing feed for livestock was very labor-intensive. Nowadays, all these actions are performed by one unit - a rake-tedder. With their help, machine operators rake the mown grass, turn it to dry and collect it into windrows. If farmers and summer residents in small areas quite successfully cope with such work with the help of ordinary rakes, then in large areas they cannot do without tedders. DIY tedder rake

Features of equipment designs

According to the model type, tedder rakes can be used on tractors, mini tractors and walk-behind tractors. During operation they are operated by one person. According to their technical characteristics, they are classified according to the following parameters:

- By type of traction they are divided into tractor (for tractors) and horse-drawn (for walk-behind tractors);

- according to the method of collecting hay in windrows - transverse and lateral;

- by design (geared, wheel-finger and drum);

- according to the method of attachment to the equipment.

Due to its shape and appearance, the structure is called the “sun” due to the similarity of the rotor tubes to the sun’s rays. There are many models of tedder rakes in factory production, but the most popular are rotary and wheeled.

Rake tedder 5 wheels

Rotary rakes are designed in such a way that their basis is one wheel with rotor pipes, on which pin tubes are secured with springs. With the help of these devices, types of work such as tedding and drying grass are carried out. But they are not suitable for windrow collection. The rake is mounted on wheeled tractors and operates using the machine's hydraulic system.

Wheeled tractor tedders are a model consisting of several (4-5) “floating” wheels mounted on a suspension. This type of design makes it possible to work on fields with different terrain. Rotary and wheeled tedders can be used on all types of agricultural machines. Therefore, they often make roller rakes with their own hands.

Interesting. Replacing manual labor using simple rakes with mechanical tedders allows you to increase efficiency tenfold.

General recommendations

Farmers are choosing to assemble their own rakes to save money. However, it is worth considering that spending on homemade tedders will be less only if there is a sufficient amount of scrap metal, i.e. in the absence of the need to purchase consumables. As a result, structures assembled with your own hands last a long time, and their power is not inferior to factory-made devices.

The main recommendation is to decide which type of tool is most suitable for the area of land being cultivated. Since, for example, sun rakes and tedders with a belt structure will work effectively only on flat fields.

In addition, it is worth thinking about the choice of design device, because... rotary devices are one spinning wheel, which can be hazardous due to the large radius of rotation.

How to set up a plow on a mini tractor

Homemade cutter for t 40

Harrow for mini tractor

Hiller for mini tractor

The best mini tractors for snow removal with a bucket: how to make a snow blower yourself

How to make a PTO for a homemade mini tractor: diagram, instructions

This is interesting: Description of a manual seeder for carrots

The principle of operation of the design

The operation of the equipment is based on the transmission of the rotational motion of the tractor or walk-behind tractor engine to the rake mechanism. This allows you to use up to five pairs of wheels and carry out hay harvesting over a large area. Using special devices on wheels that resemble large hooks, you can perform several types of work: prying up armfuls of grass or shocks of straw, turning over or raking.

Everything will depend on the setting of the angle of the needle wheels. This will allow you to combine or vary the functions of the machine. You can set the rake so that it collects grass in the center or, conversely, arranges it in a row to collect hay from the front. Thanks to the simple operating principle of the unit, it will be easy to work with. Therefore, it will not be difficult for a self-taught craftsman to make a homemade rake for harvesting hay for a tractor with his own hands.

Mounted tedder rake

Operation and care

To extend the life of your garden tool, you need to take a little care of it after use. After working in the garden, the rake must be cleared of earthen lumps and grass. Metal parts must be cleaned of rust using a brush or a special product.

Do not throw the rake around to avoid the risk of injury. After work, you need to learn to immediately put garden tools away in the designated place. Wooden handles should be sanded periodically to make them smooth. To prevent the wood from drying out, it is recommended to wipe them with linseed oil. Periodically you need to re-coat them with paint or varnish.

Note! A broken stem can be temporarily repaired using duct tape and glue. Home gardening tools are stored vertically or hung on the wall. This helps protect them from dampness.

Technical capabilities of the device

The most important advantage of the unit is that its maintenance and operation are carried out by one operator. Other features include the absence of complex parts and the independent installation of component parts of the equipment, so repairs in the event of unexpected breakdowns can be carried out directly in the field. Another advantage of tedder rakes is the ability to connect windrows, tedding, shaking and airing them, which contributes to high-quality pressing into bales. The capabilities of rotary rakes allow them to carefully handle crops, as well as successfully collect wet hay.

Note! The operation of wheeled tedders is characterized by high productivity and good speed. They work especially well on straight, level areas. Such machines are good for use when harvesting hay from forage crops.

Another design that resembles the sun, a do-it-yourself tedder rake, can be made for small-sized equipment (mini tractor or MTZ walk-behind tractor).

What are boosters for?

During the drawing process, engineers can identify weak points in a structure. A master can only learn about the presence of weak points through experience.

In order not to check from your own experience how strong the product is, it is necessary to first strengthen possible weak points.

Among the places most susceptible to fracture are the following:

- middle of the racks;

- connecting the racks to the drawbar;

- spacer at the bottom of the rod.

After the strengthening work has been completed, the structure can be considered ready. All that remains is to lubricate all moving parts and attach it to the walk-behind tractor for testing.

All that remains is to attach it to the walk-behind tractor and you can go into the field

Description of the tool

Windrowing is one of the main stages of hay harvesting. Therefore, the demand for tedder rakes that effectively carry out this operation is constantly growing. To date, several types and modifications of similar equipment for tractors have been developed. The most popular types are rotary and wheeled mounted models.

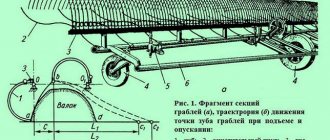

Tractor rotary tedders are a wheel-finger structure, the basis of which is thickened rotor pipes. The hay raking fingers are attached to these horizontally rotating rotors using springs with several teeth. This ensures uniform load on the device and good reproduction of the topography of the treated area.

Torque is transmitted to the rotors through cardan-type joints like car joints, which ensures equality of angular velocities. The drive is smooth and has protection against spontaneous starting during transportation. This type of tractor tedders has the ability to adjust the tedding height and angle of attack. They do not have their own power and are mounted on a wheeled tractor, working through a hydraulic system and a power take-off shaft.

Wheel rakes are a tractor-mounted structure made of floating wheels mounted on a console. They are equipped with bent wire fingers-springs for turning hay. Since outwardly such a device resembles a sun drawn by a child’s hand, this is the popular name these tractor tedders received.

The efficiency of their operation is increased due to the fact that the wheels are located at an angle relative to the direction of movement of the tractor and somewhat overlap each other’s rotation zones. The floating suspension provides excellent shock absorption, so the tedder copes well with uneven terrain, easily overcoming irrigation canals and embankments. Its wheels are interchangeable and each of them is mounted on two bearings, which increases the service life of the device and facilitates repairs. The wheels rotate independently and are carried out through a cardan, chain or belt drive. Therefore, such tedder rakes can be used as attachments for a tractor, mini tractor or walk-behind tractor.

Depending on the tractor model, devices with four and five wheels are available. The only difference between them is the working width, which determines the speed and productivity of tedding and raking the mown vegetation into windrows on a field of the same size. Also, such rake tedders are often made by hand. As a rule, these homemade devices are designed to be mounted on a small tractor or walk-behind tractor used on the farm.

What are the advantages

Both rotary and wheeled tractor tedder rakes rake the crop into windrows, making it easier for the baler to bale later. With their help, layers of hay are turned over, exposing the desired side of the windrow to drying under the sun's rays and wind blowing, thereby speeding up the process of drying the hay. Tractor rotary models have good speed and are the optimal tool for working with crops that require careful handling (for example, alfalfa). Also, a tractor with this type of tedder can easily handle wet or heavy hay.

Wheeled tractor tedder rakes are characterized by the highest productivity and work well at high speeds. Their effectiveness is maximum over a long straight distance, but deteriorates in corner areas of the cultivated area. They are easily mounted on the tractor, without requiring the connection of a power take-off shaft for operation.

The fingers on the wheels of such a tedder not only turn over the mown vegetation, but fluff it up, thereby increasing ventilation in the hay windrows. A tractor with a similar attachment processes the field with minimal loss of mown leaves when harvesting hay for forage crops. In addition, such a sun-type design for a small tractor or walk-behind tractor can be made with your own hands.

Kinds

All tedders can be divided into several types. For example, rakes differ in the rotation of the working elements when forming transverse and lateral rolls. They are also divided according to the type of working mechanisms:

- wheel-finger, allowing you to make rolls of the required size. This type can only work with dry plant mass and this is perhaps the only drawback. Thanks to the thoughtful design of the rake, tedders of this type are characterized by good performance and are considered the most practical;

- drum or rotary, characterized by structural strength and independent arrangement of raking wheels. They are considered the most expensive models on the agricultural equipment market, but this is justified by their functionality. This type of equipment can not only turn over the mown plant mass, but also form neat windrows from it;

- tooth tedders. Thanks to the design, it is possible to change the angles of inclination of the working elements.

Depending on the type of traction, the equipment can be either tractor or horse. The second type can be used together with a walk-behind tractor. Installation of factory or homemade rakes is possible in three ways:

- trailed (installed on tractors);

- semi-mounted rakes (the most affordable);

- mounted tedders (aggregated with walk-behind tractors and mini tractors).

Rotary tedders are considered the most expensive, so many people prefer to do it themselves, especially since there are no problems with spare parts. They can be purchased in specialized stores or removed from old equipment. Making your own rake is not that difficult; all you need is the desire and experience in handling a plumbing tool.

How to do it yourself

For a small tractor or walk-behind tractor, mounted rakes and tedders are not so difficult to make yourself with certain skills. On the Internet you can freely download detailed drawings that allow you to choose a frame option with two or one section and the optimal number of wheels for implementation. For those who want to make such a device with their own hands, enthusiasts have posted a large number of videos on the Internet, which show step by step how the authors created their tractor rake and tedder.

Making a cutting

In order to get a reliable and convenient handle for a rake, made by yourself, it is best to start with the choice of wood:

- pine - not afraid of moisture, quite light, but fragile;

- birch is the best option, combining sufficient strength and light weight, easy to process;

- beech – its qualities are as close as possible to birch, but requires additional processing;

- poplar - also refers to the optimal options for quality, weight and ease of processing;

- oak is the most durable material, but it is heavy and difficult to process.

To make your own cuttings, you can take a non-standard material - the trunk of a young tree (the best are considered to be: hazel, aspen or maple). Select the required length of the workpiece and check that it is free of defects (knots, cracks). Additionally, there is no need to sand or paint the finished cutting, since the very smooth surface of the cutting will turn and rub dropsy and calluses. It is very important to fit the finished cutting well and securely fasten it in the rake holder. You should also trim the cutting so that it does not extend beyond the planting nest.

Rakes and tedders for tractors: varieties, do-it-yourself production

Rakes have always been a necessary hand tool for homeowners. Virtually no land work could be done without their help. They could rake up garbage or mown grass, break clods of earth, and level beds. But their main purpose, then and now, concerns drying and harvesting hay.

With the introduction of technological progress in agriculture, even drying and harvesting hay has ceased to be hard manual labor. With the help of tractor-mounted hay rakes, these labor-intensive processes will no longer take so much time. Let's take a closer look at this type of attachment.

Types of rakes for tractors

Tractor rakes for hay have the same purpose as manual ones - turning over, raking grass, forming windrows of hay. They can be classified according to different parameters - by the type of working mechanism, by the method of fastening and traction, by the method of forming windrows, etc. But still, the main criterion by which tractor rakes differ is by design. There are 3 types of rakes:

Wheel mounted rakes for tractor

This includes the “Sun” type rake, popular among users, which is suitable for mini tractors and heavy implements.

The design allows you to quickly and efficiently turn and rake hay on both sides of the unit. The design provides from 3 to 5 or more tedder impellers.

Also, the advantages of this type of rake for a tractor include:

- ease of use and ease of repair, long service life;

- power and performance;

- The adjustment is hydraulic, the operator can easily and comfortably control the working position of the hitch.

Rotary windrow rake

They operate from the power take-off shaft.

The design is a horizontal disk with metal pipes onto which fingers made of steel rods are attached. Compared to the previous species, they have a slightly limited specialization - collecting hay and forming windrows. Although the hay also moves during the process, air circulation improves. Also, this type of tractor rake is more suitable for fragile types of hay that require careful care (for example, alfalfa).

Belt rake for tractor

More productive and technologically advanced units.

Designed for collecting and turning freshly cut grass and hay. Suitable for tractors with power from 20 HP. s., productivity – about 1.5 ha/hour.

How to make a rake for a tractor?

Making a rake for a tractor with your own hands is not that difficult. A homemade design will differ from the factory one in parameters that are ideally selected for your conditions of use. Before starting production, you should decide on the type of future equipment (wheeled or rotary rakes). First of all, the choice will depend on the type of terrain. Rotary rakes are suitable for flat terrain, as they work at a certain height. On hilly, uneven surfaces it will be easier to work with a wheeled adjustable rake.

You should also acquire drawings, tools and necessary supplies.

Drawing of a wheeled rake of the “Sun” type

To make a wheeled rake of the “Sun” type you will need:

- tools - welding, grinder, wrenches, drill, measuring tools, etc.;

- metal pipes for the frame (you can take a ready-made frame from an old motorcycle);

- wheel brackets;

- wire about 6 mm thick for making raking fingers;

- metal sheets about 4 mm thick for making working disks;

- wheel bearings;

- spare parts for the manufacture of a device for attaching to a tractor.

What to make a fan rake from for collecting dry leaves and grass

The owner of a summer cottage or personal plot cannot do without special tools. A special place is given to fan rakes, which allow you to quickly and efficiently remove leaves and small debris, as well as perform other garden work. Despite the huge selection of such equipment presented in stores, many summer residents prefer to make fan rakes with their own hands.

The teeth in a fan rake are fixed in a triangular-shaped holder. They are made from steel plates or round wire. The average number of teeth is 20-22 pieces. Some models are equipped with a special plate, by moving which you can adjust the grip width of the tool.

To make a homemade rake, you need to choose the right material. The teeth are made only from stainless steel wire with a cross section of 3-4 mm. Due to the properties of the material, the teeth will not corrode and will spring well when in contact with obstacles. Such rakes can easily withstand high mechanical loads.

At the first stage of work, the teeth are made. To do this, the wire is cut into 22 pieces 50 cm long. Then, a mark is placed on each piece at a distance of 3 cm from one of the edges and, held in a vice, bent at an angle of 90 degrees. The other edge is left flat.

To make the holder, take two metal plates with a thickness of 1-1.5 mm. The width of the plates should be 2 cm and the length 30-35 cm. Three or four holes are made in the plate into which tension bolts with a diameter of 5-6 mm are installed.

Teeth are placed between the plates. Their bent side will be used as the working part of the rake. After this, the bolt nuts are tightened by hand and the teeth are evenly distributed in the form of a fan inside the holder. The straight ends of the teeth are collected together and temporarily twisted with tape.

Now the bolt nuts are tightened thoroughly. The rake is placed on an anvil or a strong metal surface, and then the entire length of the top plate of the holder is beaten with a hammer. Thus, dents are formed in the metal, preventing the teeth from moving during operation. The steel wire from which the teeth are made does not deform.

At the final stage of work, remove the tape from the opposite edge of the teeth. Then they are slightly bent with pliers, forming a cylindrical bunch. It is inserted into a pre-prepared piece of metal pipe with a diameter of 32 mm and a length of 15 cm. One of its edges is crushed with hammer blows, tightly clamping the ends of the teeth. The other end of the pipe is used to install the cutting.