What is a pendulum saw

A pendulum saw is a special type of tool that is designed to quickly and accurately cut various materials. Most often wood or metal. It looks like a small machine with a cutting tool installed on it. The disc is attached to a pendulum-like device. Thanks to this, the mechanism performs pendulum movements, that is, reciprocating, which allows you to make an even cut.

This saw can be considered a type of circular saw. The difference lies in the design . In a circular saw, the motor and disk are attached to the machine in a stationary state, while in a pendulum saw they move along with the mechanism.

Such a tool is an indispensable device in any production. The saw allows you to make precise cuts in almost any material at the desired angle. The cutting element is represented by an abrasive disc. With its help you can saw various metals, wooden blanks, plastic products, porcelain, earthenware and other materials.

This is a very dangerous tool, so its use is only possible if all safety rules are followed. For protection , such machines are equipped with a protection system. Increased safety is a must for both industrial and home use.

The cost varies across a wide price range, so it is easy to choose a model to suit your own requirements. If necessary, you can assemble such a saw yourself if you have the necessary materials.

For industrial production, models with an automatic disk movement mechanism are used. For home needs, a model with a manual mechanism is suitable.

Saws with front blade feed

In saws with frontal blade feed (Spring), the blade is fed to the operator. There are options with both manual and pneumatic feeding systems. The disk tilt options are also different: manual tilt, pneumatic tilt, tilt using a servo drive.

This version of saws, due to its high structural reliability, ensures high cutting accuracy along the angle of inclination of the disk. The diameter of the cutting disc starts from 450 mm, which allows cutting two profiles at the same time. This type of head design is usually used in double-headed saws, which also indicates their high accuracy and reliability. But it should be noted that this type of saws has a fairly high price, which stops customers from choosing saws with front feed for an entry-level production workshop.

Spring 55 – single-head saw with front-feed blade with a diameter of 550 mm

Cutting tool

Abrasive discs are used as cutting tools. The diameter of such a circle depends on the model, its performance and the work requirements of the owner.

Most often, such saws are equipped with 12-diameter disks with 60 teeth. Moreover, the manufacturer of the discs does not have to be the same as the manufacturer of the tool. The main thing is that the dimensions of the circle coincide with the recommendations indicated in the technical documentation. To improve the strength and performance of the blades, the manufacturer typically applies carbide tipping to the ends of the teeth.

Saws with cantilever blade feed

This is a special type of saw, which is represented on our market by only one company - GRAULE . Like almost all German equipment, the machines of this company are designed by a designer. You can buy a machine with basic equipment and it will be a regular saw with manual feed of the disk along the console (the disk is pulled out along the guide towards the operator), or you can install all the options on it, and then it is already a complex machine with a large number of settings and very wide functionality.

Console saw GRAULE ZS 200 N

The machine is interesting because of the abundance of settings that allow you to make complex cuts, including two-plane ones. The cantilever feed of the cutting head along with the large diameter of the disc (if you choose the option with a 520 mm disc) allows you to cut profiles with a large cross-section.

But we must take into account that the cost of a saw with maximum equipment is high enough to use it in a small production: the machine will remain a single-head saw (albeit with broad functionality) and will not allow achieving high performance indicators.

The choice of a console saw is justified for a site of non-standard structures or workshops that undertake to produce structures of any complexity, but do not claim high productivity.

Single-head saws with a small blade diameter (usually bottom feed) are also used for cutting glazing beads.

Features of operation

For ease of use, it is recommended to pre-install a production table or workbench. It is desirable that such a table be height-adjustable and have sufficient area for storing workpieces and sawn parts.

Even for compact home models, the desktop area should be around 8 square meters. m. Approximate size - 2x4 meters. This allows you to cut workpieces up to 3 meters in size.

When using a pendulum saw, be sure to ensure safety, close the protective curtains and use personal protective equipment. This is very important, because when cutting wood or metal, small wood or metal shavings fly out from under the working wheel. When cutting metal workpieces, flammable liquids and materials should be removed from the workbench, as hot metal particles can cause a fire.

Roller conveyors

When talking about single-head saws, it’s worth focusing on measuring and positioning systems. When using single-head saws (it doesn’t matter what you are cutting: the main profile or bead), the main role is played by measuring systems or receiving roller conveyors ( Assomak , Quota ), which are responsible for the accuracy of the cut.

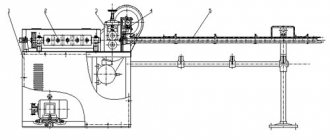

Assomak 400 VS – receiving roller conveyor

There are roller tables with a mechanical system for moving the stop and manual fixation, there are roller tables with moving the stop using a flywheel, with an electronic display and pneumatic fixation of the stop, and there are roller tables with a servo drive for moving the stop. When it comes to choice, price plays a major role.

There is no particular point in taking a roller table with a stop servo drive for a single-head saw; its cost will be higher than the cost of the saw itself, and when adding up the prices of the saw and the roller table, it will become clear that it is better to choose a two-head saw. Although there are productions where the option of a single-head saw plus a roller table with a servo drive is needed.

Production of translucent structures from aluminum profiles Double-headed saws for cutting aluminum Processing of aluminum profiles

© FIMTEC

Assembly saws

Assembly saws are a special type, they are used in construction and during repair work. They are distinguished by increased convenience and abundance.

But the construction of the mounting saw is significantly simplified. The pendulum mechanism makes cuts only at right angles, without being able to change the degree. The working disk is made of ordinary metals, without carbide coating.

For ease of use, such tools use a belt drive; it makes the work smoother, without jerking.

Working with such a tool has a number of features:

- Due to the high torque, the saw must be held firmly and launched smoothly to avoid sudden shock.

- The workpiece must be secured before sawing.

- The cutting area should be additionally cleaned, since during the work a burr will form on the workpiece.

Advantages and disadvantages

Assessing the advantages and disadvantages , it is worth noting that there are much more advantages. These include:

- Functionality. By changing the working blade and operating power, such a saw can be used for cutting workpieces made of various materials.

- Quality. Most of these tools are made for professional use. Therefore, the quality and service life of such saws is increased.

- Accuracy. The workpiece is cut very accurately at the required angle of inclination, which cannot be done using another tool.

- Speed of work. Thanks to the design of the machine, you can cut a lot of workpieces in a short period of time. At the same time, changing the angle does not require spending a lot of effort and time.

- Easy to maintain. Changing working tools is quite easy, and the necessary parts can be easily found in almost any hardware store.

The only disadvantages include the high cost of the tool. But when used professionally, it is compensated by properties and characteristics. It should also be noted the low quality of discs made by unscrupulous manufacturers. Therefore, when purchasing consumables, it is recommended to pay attention only to trusted manufacturers.

Saws with bottom feed

The simplest saws with a small cutting disc diameter can be equipped with manual lifting of the disc (such saws are often purchased for cutting glazing beads).

Saws with a blade diameter of 400 mm (Panda, Kaiman) are equipped with automatic lifting. Rotation of the disk can be either manual or automatic. When lifting manually, the main angles (45°/90°/135°) are set quite easily: these positions on the rest have a special recess and a spring-loaded lock. Intermediate angles are fixed with mechanical clamping. Machines of this type can be equipped with a digital rotation angle indicator and a laser cut indicator.

Kaiman – single-head saw with bottom feed blade with a diameter of 700 mm

Saws with bottom feed are characterized by a highly reliable design, which guarantees high accuracy in setting the angle of rotation of the blade. The saws are equipped with adjustable blade lifting speed and adjustable coolant supply. The vertical base of the machine can be shifted back (away from the operator), thereby increasing the cross-section of the cut profile.

To the advantages listed above, it is worth adding a moderate cost, compared to saws with front feed. Saws with bottom feed are often chosen for profile cutting in small production areas.

Bottom saw blade feed

Saw with your own hands

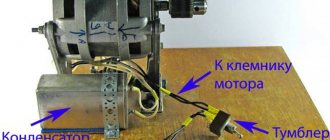

To save money, you can assemble such a tool yourself, but it is only suitable for home use. To make it, you need to have a regular circular and the necessary materials (channel and corner).

The production of the frame is carried out by installing two channels, to which the base of the pendulum mechanism is welded. The grooves for installing bearings are produced in a turning shop for a small fee. Be sure to make protective covers, which can be made from thin sheet steel.

If you are not entirely confident in your abilities, then it is better to purchase a new pendulum saw to save your nerves, money and time.

A pendulum saw for metal and a pendulum saw for wood are practically no different. The only difference is the type of wheel used.