How to make rivets from nails

Making rivets with a knife lock is not that difficult. This will not take much time, and the only materials you will need are a couple of nails.

Such rivets will not need to be flattened; I will form a hat. They themselves will rivet from small blows, firmly holding the side pads of the knife.

We take nails

So, the steel nails themselves. You can buy them in any hardware store in all sizes; there is definitely no shortage of them now.

It is advisable to take one thicker and the other thinner, but you can also take the same type. But in this case, processing them will take a little longer - you will have to grind off one nail.

Making rivets from nails

First of all, let's form a beautiful hat. To do this, clamp the nail in the screwdriver chuck and process it with a metal file.

- First from the side.

- Then from above.

- The view is decent.

- It’s okay if the thickness of the cap is different - after the rivet nothing will be visible.

- Then we take the knife for which the rivets are made and measure their length. It should be more than half.

- Cut with a hacksaw for metal.

- We sharpen one, the thinnest rivet, to a cone at the end.

- The second, thick one, with a core at the end.

- We drill a blind hole with a drill whose diameter is approximately 0.1 mm smaller than the thin rivet.

- It turned out to be a couple.

- We check the depth so that the rivet that will go in does not rest and reliably compresses the knife pads.

- Prepare the knife. Drill a hole the same size as the large rivet.

- We rivet with a hammer.

- Holds up great! The lock clicked inside. We rub the cracks with wood glue, use sandpaper to form a single surface of the handle and then rub it with impregnation.

- It turned out very beautiful.

Such a connection will not fall apart, will not fly out and will serve for many years.

How to install buttons on jeans and outerwear

The easiest way to install buttons is from four parts (pictured No. 2), which are slammed shut using a ring located at the top of the button. Using the same tool as for the blocks, it is easy to “flare” the button leg into petals, both the upper part and the lower part. However, for this type of buttons, special punches are often included with them. But from practice we know that using them is ineffective. It is much more convenient and easier to use a punch that “splits” the stem into petals. By the way, if you often have to install accessories on clothes, various types of buttons, especially tendril ones (pictured No. 1), then be sure to buy several types of dowels at a hardware store. This is a construction nail with a wide head that is impossible to bend. Ask your husband to “blunt” several dowels of different thicknesses. Surely he has something in his garage to do this with (emery). Next you will understand why you need such dowels.

Instructions for making metal rivets

1. Several strips measuring about 30-50 centimeters are cut out of thick metal, at least one centimeter thick. On the wide side, the cut strips of metal are connected by welding with a hinge so that they can subsequently be folded together.

On the other hand, a piece of 6 mm metal wire (wire rod) is welded to the plates along the entire length. The wire is needed as a lever that could be used to clamp the device in a vice when making rivets.

2. After the wire is welded to the plates, you should clamp them in a vice and make a small hole at the junction of the strips using an electric drill. The depth of the finished hole should be no more than 15 mm and the diameter 4 millimeters.

Then a drill with a diameter of 7 mm is taken, and with the help of it, the resulting hole is countersunk to a depth of no more than 2 millimeters. This will create a conical hole in the metal strip to form the head of the aluminum rivet.

In order to make a rivet with your own hands using this homemade device, just take a small piece of aluminum wire and lower one end of it to the very bottom of the drilled hole.

Then, using wire cutters, the wire is bitten off above the edge of the metal strip with a margin of at least 3-4 millimeters. Using a hammer, a piece of wire inserted into the hole is carefully tapped until the wire finally sits in the hole.

At this point, the production of a homemade aluminum rivet is almost ready. All that remains is to release the vice and remove the finished rivet.

As you can see, making a rivet with your own hands is not so difficult, and you will need few materials for this. However, knowing the home process for making rivets, you don’t have to worry about not having a rivet at hand in an urgent need.

Metal riveting

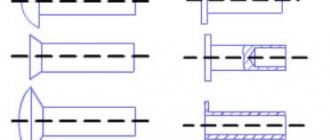

The process of riveting metals consists of two stages: preparatory and the actual installation of hardware. Preparation - drilling holes, if necessary, countersinking for countersunk heads

Please note that countersunk heads can be on one (either) side or on both

The riveting process itself is as follows:

- insert the rivet;

- tighten the parts to be connected;

- form a closing head using a tool;

- check and clean the connection.

This is how blind rivets are installed

With a good tool, work goes quickly. For private use and one-time work, manual riveters are usually used. And even with them, the process itself (without drilling holes) takes a matter of seconds. If we talk about installing corrugated sheets or metal tiles, it is recommended to coat each hole made with paint to prevent corrosion. It is these processes - drilling and painting - that take a lot of time.

In general, there are two ways to install rivets: cold and hot. When hot, the joint is preheated to a certain temperature (determined by the metal and the thickness of the parts). In practice, it is used when installing rivets of large diameter - 12 mm or more.

The rivets are placed in rows. The minimum distance between adjacent ones is 4 diameters; from the edge of the sheet to the center of the hardware is no less than 1.5 times the diameter of the rivet. When attaching a profiled sheet, place it in a recess, not in a wave.

Device for making rivets

A simple machine for making rivets with your own hands will greatly speed up this difficult process. I suggest making a small device, like in the photo, which will be clamped in a vice.

It needs to be made from a piece of thick metal, the thickness of which would be equal to the length of the rivets being made.

- For these purposes, you need to drill 5-10 through holes in the center of a metal rectangle, and then cut the metal exactly in the middle of the resulting holes. Then, from one edge, you need to weld the metal plates, using for these purposes a piece of thin-bodied pipe cut lengthwise. Thus, to create something like a canopy.

- It will help the plates not to diverge too much to the sides and hold the wire for making rivets. After the wire is installed in the hole, the plates are clamped in a vice, and then the work of making rivets is carried out as in the previous time. Use a hammer to hit the end of the wire and cut it to the desired length. There are also factory-made devices for making rivets at home. They all have holes of different diameters.

- If you don’t have time to bother making rivets from wire, and you don’t need a large quantity of them, then you can simply drill a hole in the parts to be joined, then cut off a small piece of aluminum wire, insert the wire into the hole, and then flatten it on both sides with a hammer . In the same way, holes in dishes, for example, in aluminum cylinders, are sealed.

Types of hand tools

To date, several types of rivets have been produced that are used in the home workshop. Threading and drawing tools fall into this category. To understand which of these tools is better, you need to study their characteristics and functionality in detail.

A manual pull riveter fastens the rivet by creating a certain traction force. A small through hole is drilled in those workpieces that need to be connected to each other, and after that a rivet is fixed in a certain way in the device itself. After this, the rivet is carefully inserted into the prepared hole and carefully expanded. It is worth considering that reliable fixation occurs due to squeezing and unclenching the handle of the device.

For domestic needs, you can purchase a threaded riveter, the operating mode of which is almost similar to an exhaust unit. The only difference is that in the working body the ball is pulled into the rivet due to the rotation of the thread. This joining method is considered optimal for workpieces with small thickness. This is due to the fact that thread cutting is much more problematic on thick metal. The great advantage of using this hand tool is that a bolt or screw can be driven into the rivet itself if necessary.

How to make rivets from a tin can

Such a rivet can be made not only from a tin can, but also from any thin metal. It can be made “in a hurry” and practically “on the knee”.

- To demonstrate the making of a rivet, the master took a tree branch. I drilled a hole in it and split it into two halves.

- A strip of metal is cut from the lid of a tin can.

- Using pliers, wrap the strip around the sewing needle. It turns out to be a metal tube. Cuts it off from the rest of the sheet.

- Connects the two halves of the branch and inserts a tube into the hole.

- Rivets the rivet on both sides.

- This is how you can quickly fasten two parts together.

DIY rivets

How to make rivets from wire with your own hands

Very often you need to assemble something and rivets are used for these purposes. They can be purchased or made from a nail or soft metals such as aluminum and copper. The easiest rivets to make are made from wire, aluminum or copper, it doesn’t matter.

To make rivets, you will need a vice, but you can make a special device for these purposes. In this case, you will be able to make a lot of rivets, which will definitely be useful in the household of every craftsman.

Tools and materials

If a person needs a large amount of such fasteners, then it is more profitable to manufacture it yourself from aluminum or copper wire. Rivets are also made from brass wire, but it is rarely on hand.

For a large volume of fasteners, it is better to make a special device, which at a stretch can be called a machine for making rivets.

The tool is a thick steel bar in which holes of different diameters and depths are drilled (according to the size of the required fasteners). If a suitable metal bar of the required thickness is not available, then it can be made into composites - by fastening together several plates from steel blanks with a smaller thickness (2-5 mm).

The plates must have the same dimensions in length and width. They can be fastened by welding or bolts.

If you need several rivets, then you don’t need to make any equipment - it will be enough to have a hammer, a vice, a flat file and a chisel to chop the required number of wire blanks. Sometimes you may need an electric drill with a set of drills of different sizes and a center punch.

The wire is taken with such a cross-section as to reliably serve as fasteners as rivets. Most often, a section from 6 to 20 mm is used, but this parameter depends on the size of the structure that will need to be riveted. Electrical cable cores are best suited for rivets.

A good option is homemade rivets of thinner diameters made from construction nails.

Overview of species

Products with a semicircular head have become widespread. This item meets the requirements of GOST 10299-80. The cross-section of the rod ranges from 0.1 to 3.6 cm. A steel rivet for a hammer with a countersunk head must comply with GOST 10300-80. For products with a flat head, standard 10303-80 is used. Finally, for semi-hollow samples GOST 12641-80 is used.

For the manufacture of such devices, the following types of steel are used:

- 10kp;

- 15kp;

- St2;

- St3.

Solid shank rivets have superior load carrying capacity. However, they are quite difficult to install. The semi-hollow type is formed in such a way that the section of the rod near the embedded head is partially empty. Finally, a hollow product will not be difficult to rivet. The downside of this advantage is the insufficient reliability of the connection. Semicircular heads can have different heights. Their use is considered the optimal solution in terms of reliability and stability of the seam being formed.

In aggressive environments, rivets with a cylindrical or cone-shaped head are used. Concealed as well as semi-concealed types are needed if it is necessary to prevent the formation of a protrusion above the surface. Such designs are used only in cases where there is no worthy alternative to them. The universal type of fastener for a riveter is shaped like the contours of a mushroom. A separate category includes embedded, pull-out, traction and tear-off products. Such hardware consists of two main parts. There is no need to hold them on the other side of the seam. This circumstance is very attractive when creating fences and forming roofing.

Sometimes there are so-called threaded rivets. They are used when it is necessary to connect parts with particularly thin walls (no more than 0.03 cm). Inside there is a special thread, and outside there is a vertical notch that blocks rotation around its axis. As for driving rivets, they are usually made from:

- brass;

- aluminum;

- copper (and all such products are designed for hammering and do not require a riveter).

Zinc coating is sometimes used to improve corrosion resistance. Both “cold” and “hot” galvanizing perform well. After such treatment, not only performance qualities are improved, but also the visual perception of the products.

Important: it is necessary to take into account the formation of galvanic pairs and electrochemical reactions between them. The copper-steel bond results in accelerated destruction of the product

Manufacturing

You should begin preparing workpieces after determining the true dimensions necessary for a high-quality result of subsequent riveting work. You should know exactly the thickness of the connection of the parts that need to be riveted in order to calculate the correct length of the workpiece, taking into account its processing for the embedded head and lock.

If the connection is complex and different lengths of rivet material are required, then it is better to make a drawing on which to mark all the places indicating the thickness of the finished connection, and then base the calculations on the length of the workpieces on this basis.

- The diagram will make it clear how many blanks are required for each length. Next, using a chisel and a hammer, cut wire blanks with a reserve quantity.

- The production of rivets consists of a number of operations. First, let’s talk about how to make a wire rivet using a machine.

- We select a hole on the machine that is suitable in diameter and length for the workpiece we need. The workpiece must have a sufficient length of protruding part from which the embedding head is to be formed.

- By tapping with a hammer on the protruding part of the wire, we form the head. First, we flatten the end of the wire with blows from above to form a head, like a nail, and then we process this head by tapping from the sides, giving it a spherical appearance.

- After forming the head, we will correct the result with a file, if this matters for the appearance of the structure being connected.

- We remove the workpiece from the hole and process the end opposite the head (straighten with a file or sharpener).

- When making a rivet without a machine, exactly the same actions are performed as with it, only the workpiece is clamped in any other device, for example, in a vice. All other operations are performed in the same order as on the machine.

- Sometimes it is necessary to make rivets with flat or countersunk heads. In the latter case, you can also use the device mentioned above.

To do this, you need to drill as many more holes in the bar as required - they are made deeper than the length of the countersunk rivets. These holes should then be widened from above to a cone using a drill with a diameter slightly larger than the holes themselves (for the head).

It is into these newly prepared holes that the blanks are inserted, the length of which is selected to match the depth of the hole plus a small protrusion on the head. All that remains is to tap the end of the wire with a hammer, filling the prepared bed for the head with flattening so that it does not protrude above the surface of the machine.

Rivets with flat heads can be made using the same technology as the previous version, but only the bed to form this part of the product is drilled cylindrical, not conical.

A homemade rivet of small diameter, consisting of two parts - a mortgage and a lock - can be conveniently made from a pair of nails. To do this, take one of the nails with a larger diameter - a hole is drilled in its rod 0.1 mm smaller than the diameter of the second nail.

It will serve as a lock for the future rivet.

The second nail, the shaft of which should have a shorter length than the depth of the lock hole, is sharpened at the end to a cone. The nail heads are ready-made heads; they just need to be sanded a little for appearance. The hole in the connection for which such a rivet was prepared is drilled to the size of the diameter of the locking part of the fastener.

How can you make steel rivets yourself?

But first, let's figure out how to install the simplest denim button in design.

Punch a hole in the waistband of your jeans with an awl and insert the leg into it. Place the button on an anvil (preferably on a metal surface) and hammer into the stem. It's a leg, not a button. When buying a denim button, choose a set with a threaded leg, as in this photo. This leg will be securely held inside the button. The smooth leg may “pop out” over time or under load. Now let's try installing a jeans button with a more secure design, one whose leg moves freely. This is where you will need a dowel cut down on sandpaper. The fact is that the leg of such a button needs to be flared inside the button itself. You won’t be able to “get close” to it without a special tool. But with the help of a sawn dowel this is easy to do. And since the dowel does not bend, it can be used to reliably flare the leg. But first, insert the leg into the belt, place a button on top of it and see how far the leg comes out of it. You may need to “bite off” the edge with pliers. Otherwise, your leg will simply bend and you won’t be able to flare it later.

The antenna button (No. 1) is installed in approximately the same way, only this operation needs to be performed only for the upper part of the button. The lower part is much easier to install. To install the second part, you can buy a special tool with a recess inside in the store. But if you don’t have one, then you can use a metal plate with a hole exactly the size of the “bump.” Insert this little bump into the hole in the metal plate, and “slam” the leg with a hammer on the back of the clothing. The antenna button is very difficult to install without special tools, so buy more of these buttons than you need.

The latter type of button, which is sometimes used in knitted clothing, is not particularly difficult to install. However, some advice can also be given. First, make sure that the tabs on the bottom of the button fit exactly where they should. Sometimes they are bent, so you have to bend them or straighten them with pliers so that during installation all the petals “go” into the upper part. If for some reason the button is not installed correctly, remove it and install another, new one. It is better not to use a damaged button again, since it will no longer hold securely. They are inexpensive, so buy them with a reserve.

How to open a mini-atelier At home, a press for installing buttons is not required, but in a studio, such a tool is definitely needed, especially if your studio repairs leather clothes, bags and other accessories, where various accessories are often used.

Technology of sewing and cutting of natural fur Sewing of fur or leather can only be done with high quality by a professional who has special equipment, tools and experience, including tools for installing clothing accessories. However, in some cases it is possible to install buttons or blocks without special tools and devices.

Recommendations for working with leather Almost any leather clothing and accessories use various accessories. To “punch” a neat hole in the leather to install a button or block, you must use a special punch.

How to sew curtains yourself - small tips For curtains, special fittings are often used - eyelets. The eyelets look like blocks, but it is impossible to install metal eyelets yourself, since without a special press you will not be able to accurately flare their edges. Use plastic eyelets. Their halves snap together and installation therefore will not cause any difficulties.

Padding and adhesive materials When installing accessories on clothes made of loose, knitted fabrics, be sure to use adhesive fabrics. The glued sections of clothing will be securely held between the parts of the block.

Recommendations

For better and more efficient production of homemade rivets, you need to listen to some recommendations.

- Spherical heads of finished products are always easy to convert into heads of the desired shape by grinding or mechanical action.

- Before drilling a hole in the shank of the locking part of the rivet, it is necessary to mark the center with a core for precise installation of the drill.

- To grind the heads and ends of products, you can use a drill, inserting the workpieces into the tool chuck, and when rotating, resting them on the sharpening device.

- If you plan to do a large amount of work on making rivets, the best decision would be to make a device for this and even buy a ready-made machine. Otherwise, the work will take a long time.

How to remove old rivets using a plumbing tool

The principle and procedure are completely similar to the previous method, but there are some advantages:

- A high-quality chisel can easily cope with hardware, regardless of what materials were used in their production.

- The chisel is considered a profile tool. With its help, it is possible to knock down rivets with almost one blow, provided that it is placed correctly.

- It takes less than a minute to dismantle one rivet, thereby increasing productivity, which is beneficial for large volumes of work.

Of course, experience will be required when using a chisel, especially when the material is thin. This method is most often used when it is not possible to drill out the hardware. Or if the safety of the parts from which the rivets are removed is not a priority.

How to remove steel rivets: an effective method

It is quite difficult to remove steel rivets using a screwdriver or chisel, especially if they are made of carbon steel. In this case, it would be correct to use a drill. The work is performed in the following sequence:

- The drill should be a few millimeters smaller than the rivet. Its choice must be taken responsibly, especially if it is important not to damage the surface of the material.

- We reduce the tool speed to a minimum: in this case, the quality of work will be as high as possible. You need to drill strictly perpendicular to the working surface. It is important to ensure that the drill does not come off the center of the rivet head.

- After removing the head, the second part of the hardware falls out of the hole. In rare cases, it becomes necessary to push it out.

Before you begin, you should study the recommendations, which explain how to remove a rivet from metal using a drill, so as not to damage the material that it connects.

What to rivet from

Perhaps we shouldn’t talk separately and in detail about the fact that the quality of the wire will directly determine the quality of the rivets themselves. This fact is obvious.

It is most advisable to choose wire options from:

- Copper.

- Brass.

- Aluminum.

The diameter is preferably 20-30 mm, although there are sizes that are slightly smaller. Here it depends on the required dimensions of the product.

Note. An excellent option are wires made from electrical cables.

The process itself involves the formation of a rivet head, which is tapped with a hammer. To do this, they use clamping the wire in a vice, but there may be other options, it is not so important where exactly to clamp the wire, the more significant question is how to properly tap the cap and get the desired shape.

However, in essence, the process is incredibly simple:

- we fix the wire;

- we begin to tap the edges;

- we form a cap around the perimeter;

- we try to create a spherical shape;

- cut to the required length.

As you can see, there is absolutely nothing difficult. The remaining options are more delights and, as they say, rationalization proposals.

For example, it is possible to make a small machine from metal plates and insert blanks into it, which are then tapped on the protruding part, creating the desired shape.

In order to make the required batch for your home, no additional machines are required. If you need a larger scale, make a machine from scrap materials.

We will not give specific diagrams, since the materials at hand are different for everyone, but the principle here is clear.

Fluffy (chenille) wire for crafts

I continue to talk about interesting materials for children's creativity. Today we will talk about fluffy wire for crafts. This wire is also called chenille, shaggy, plush, and is sometimes called fuzzy sticks.

Chenille - (from the French chenille - caterpillar) - a fluffy cord with velvety pile, twisted from several threads, between which are caught a number of short ends of the threads sticking out in all directions (pile). Chenille is often called any fabric with short pile - velvet, corduroy.

Actually, this flexible fluffy wire is a pipe cleaner for cleaning smoking pipes. It has never been produced in our country, so until a few years ago many people had never heard of it. And foreigners quickly realized that this was a very useful thing for children's creativity. You can make cute fluffy crafts from it. In addition, these crafts can be disassembled and the next time you can make different ones (however, over time, the wire loses fluff and in some places ceases to be fluffy).

Foreigners liked this idea so much that many authors of pedagogical methods recommend fluffy wire among other mandatory aids for the development of fine motor skills in preschoolers. Therefore, in the USA, for example, children make crafts from chenille wire both in kindergartens and in schools during creativity lessons.

Fluffy wire comes in different lengths, different colors, including striped and shiny, has the same thickness along the entire length or its thin parts alternate with wide ones (“Feathers” shape). Shiny fluffy wire is tougher than regular plush wire, but it makes very beautiful crafts for the New Year and Christmas.

Crafts made from fluffy wire

You can make various crafts from fluffy wire: flat,

and voluminous.

Figures made of fluffy wire can be used to decorate various works, for example, this is how flowers made of fluffy wire look like (see this link for several more options).

When making crafts, it is very convenient to make paws for various animals from fluffy wire. For example,

In my other blog, I once showed a couple of crafts my daughter made from fluffy wire: turkeys and a sunflower.

Here is another video master class on how to make a butterfly from fluffy (chenille) wire.

Where to buy fluffy wire

Where to buy fluffy wire? In the creativity departments or order online.

For example, you can buy fluffy (chenille) wire at Ozone:

- ordinary one-color fluffy wire in Ozone,

- striped fluffy wire and fluffy wire “feathers” in “Ozone”.

I ordered fluffy wire from Aliexpress several times for my daughter and for gifts (the cost of goods and delivery is much lower than orders from Ozone or Labyrinth):

- ordinary fluffy wire (I ordered the color “Multicolor” or “Mix” - they received sets of one hundred wires 3 cm long, 10 different colors, 10 wires of each color).

- shiny fluffy wire (I ordered the color “Many” - a set of one hundred multi-colored wires also came).

Yulia Valerievna Sherstyuk, https://site

All the best! If the article was useful to you, please help the development of the site by sharing a link to it on social networks.

Posting site materials (images and text) on other resources without the written permission of the author is prohibited and punishable by law.

Many unusual materials are used in needlework. Sometimes they initially had some very primitive use, but over time they became materials for creativity. For example, chenille wire was originally invented as a means for cleaning smoking pipes, and its “great-grandfather” was an ordinary chimney sweep.

Hidden hats

An interesting option is to create rivets with hidden heads; they have a concave shape and are sometimes used for special purposes when you need to leave a flat surface without a protruding part of the rivet.

It is absolutely clear that the matter cannot be solved by a simple method of tapping, but there are no difficulties observed here either. You just need to make a small machine.

- It is made from simple metal plates, in which you will need to drill a hole to the diameter of the wire and, accordingly, the rivet and select the desired length.

- Further from above, where the hole itself is located in front of the cavity, it is slightly countersunk with a drill of a slightly larger diameter to fit the size of the head. In this way, a small depression is made, which will allow the formation of a hidden cap.

- All that remains is to install the workpiece of the required length (a little longer with a margin for the head) and tap.

- To do this, it is possible to use, for example, a core of the required diameter or another rod, after which the workpiece is simply knocked out of the machine.

To install the fittings you must first “punch” a hole

In our practice, in an atelier, to install fittings, we use a press and numerous attachments suitable for one or another type of button or block. With the help of such attachments, the edges of a button or block are carefully flared, acquiring a “factory” appearance. But since buying a press with attachments and other additional tools for home use is unjustified, we suggest that you use “improvised” tools. In your arsenal you should definitely have a small hammer and an anvil (you can use another hammer), an awl and several additional tools that you will have to buy at a sewing supply store. One of these tools should be a punch.

It is imperative to use a punch to ensure that the hole is perfectly straight and the edges of the fabric do not fray. You can have only one punch, the smallest size, or, in extreme cases, two (the second one is slightly larger). But it is best to buy a set of punches with removable attachments. It is not advisable to cut a hole with scissors, since from time to time the block or button will definitely “fall out” of it. The hole for the block or button should be minimal; it is advisable to even slightly stretch the fabric over the leg of the block, since the tighter the fabric is pressed against the leg, the more securely it will be fixed.

You need to punch a hole in fabric or leather on an anvil, not a metal one, but a wooden one. The tree should be very dense (not loose), for example the area where the knot is located. You can use other materials that are dense, but do not damage the tip of the punch. Tip: Areas where holes will be punched on knitted fabrics and other bulk materials can be glued with adhesive fabric.

Instructions for making rivets from metal strips

- Several strips measuring about 30-50 centimeters are cut out of thick metal, at least one centimeter thick. On the wide side, the cut strips of metal are connected by welding with a hinge so that they can subsequently be folded together.

- On the other hand, a piece of 6 mm metal wire (wire rod) is welded to the plates along the entire length. The wire is needed as a lever that could be used to clamp the device in a vice when making rivets.

- After the wire is welded to the plates, you should clamp them in a vice and make a small hole at the junction of the strips using an electric drill. The depth of the finished hole should be no more than 15 mm and the diameter 4 millimeters.

- Then a drill with a diameter of 7 mm is taken, and with the help of it, the resulting hole is countersunk to a depth of no more than 2 millimeters. This will create a conical hole in the metal strip to form the head of the aluminum rivet.

- In order to make a rivet with your own hands using this homemade device, just take a small piece of aluminum wire and lower one end of it to the very bottom of the drilled hole.

- Then, using wire cutters, the wire is bitten off above the edge of the metal strip with a margin of at least 3-4 millimeters. Using a hammer, a piece of wire inserted into the hole is carefully tapped until the wire finally sits in the hole.

- At this point, the production of a homemade aluminum rivet is almost ready. All that remains is to release the vice and remove the finished rivet.

As you can see, making a rivet with your own hands is not so difficult, and you will need few materials for this. However, knowing the home process for making rivets, you don’t have to worry about not having a rivet at hand in an urgent need.

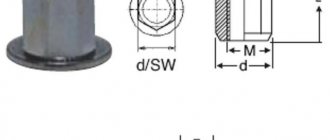

Selection of rivet sizes

Rivets are selected based on the thickness of the metals being connected. The following are important: the parameters of the embedded head and the diameter of the rod. The diameter of the rod determines the diameter of the drill, which is used to prepare a hole in the parts to be joined. You can approximately determine the diameter of the rivet by doubling the thickness of the parts being connected. The length of the rod is at least 2 times the diameter of the rivet, and the protruding part must be at least 1.25-1.5 times the diameter.

| Rivet diameter | 2.0 mm | 2.3 mm | 2.6 mm | 3.0 mm | 3.5 mm | 4.0 mm | 5.0 mm | 6.0 mm | 7.0 mm | 8.0 mm |

| Hole diameter for precision assembly | 2.1 mm | 2.4 mm | 2.7 mm | 3.1 mm | 3.6 mm | 4.1 mm | 5.2 mm | 6.2 mm | 7.2 mm | 8.2 mm |

| Rough hole diameter | 2.3 mm | 2.6 mm | 3.1 mm | 3.5 mm | 4.0 mm | 4.5 mm | 5.7 mm | 6.7 mm | 7.7 mm | 8.7 mm |

In general, the diameter of the rivet rod can be from 1 mm to 36 mm, and its length can be from 2 mm to 180 mm. Moreover, a larger diameter does not equate to greater joint strength. Here, both the material from which it is made and its type (hollow or solid) play a role. How to choose? According to the characteristics of the rivets. After all, you choose them to connect certain materials of a certain thickness. You know approximately the load that will be applied to the connection

Therefore, when selecting, pay attention to what the manufacturer recommends

How to select a rivet according to the thickness of the material being fastened? According to the manufacturer's instructions, but in general, the diameter of the rod should be at least twice the thickness of the materials

Must be indicated:

Recommended diameter for connection. All you have to do is select a drill and make a smooth hole without burrs. Minimum and maximum thickness of the connected package

It is important that your connection is within the specified range. Shear force. This is the load applied perpendicular to the connection that the rivet can withstand without destruction. Breaking force

Under what load along the rivet will it fail?

It is the tensile and shear forces that determine the strength of the future seam. The higher these values, the greater the load it will withstand.

Types of forged rivets: decorative, square and others

There are several types of forged staves. Familiarization with the assortment will allow you to choose the element you like and make it yourself:

The hat most often has a geometric shape: round, square, pentagonal and hexagonal. Often there are elements with caps, the texture and configuration of which imitate flowers, leaves and other plant-themed items. Non-standard configurations may include figurines of animals, birds and insects.

- Forged rivet with round head

- The size directly depends on the diameter of the element’s cap, which varies widely.

- Forged hex rivet, large, diameter 40 mm.

- Parts with and without legs.

What products are used to decorate?

Forged parts of different sizes are used to complement:

- small products: door handles, mailboxes, flowers and so on;

- medium-sized items : barbecues, fireplace accessories, paintings, mirrors and others;

- large structures: doors, gates, gates, benches, stairs and others.

Examples of using rivets and contact pins.

Small rivets may be needed when assembling amateur designs.

And contact pins for connecting cables to the printed circuit board.

Also, based on the contact pins, you can make a very convenient breadboard for reusable prototyping of radio circuits.

How to flare a contact pin in a breadboard or printed circuit board?

The finished contact pins are riveted into the printed circuit board using a lower mandrel, which is a steel pin with a hole slightly larger than the diameter of the contact pin. This mandrel is fixed in a vice or screwed into some kind of massive base. Please note that one side of this mandrel is ground off so that pins located close to each other can be riveted.

Flaring of a contact pin in a printed circuit board can be done either with a regular hammer or with a hemispherical mandrel of the appropriate diameter.

The video shows how to use the die and how to flare the contact pins in the PCB.

July 4, 2014 (11:39) in Technology