A poly V-belt is a rubber product that has several wedges inside. Depending on the load of the products in question, different wedge shapes were made. Due to this characteristic, this belt is called poly-V-ribbed. The word begins with poly, which means many in Greek. And the end of the word wedge implies its technical features - longitudinal wedge-shaped strips located along the entire length of the surface. In other words, a serpentine belt is a type of drive belt that has many wedges.

Now let’s start looking at the dimensions of poly V-belts: profile, length and width. First, let's look at rubber products manufactured according to the domestic document TU 2563-040-70453527-2004.

What does a serpentine belt mean?

Polycline (from English “ribbed belt”) is the same as rivulet. Installed to transmit rotation of the drive shaft to the driven shafts of the generator and power steering pump. The poly V-belt has grooves located longitudinally.

There are several types of belts for transmitting rotational motion: crankshaft - generator - pump - power steering pump.

Classification according to the method of energy transfer:

- friction transmission;

- gear transmission.

Classification by type of belts:

- flat belts;

- wedge:

- CVT;

- ventilators;

- multi-stranded;

- poly V-belts;

- traction belts;

- toothed;

- transportation (conveyor belts);

- lingering;

- round belts (passic).

Flat drive transmission

Flat drive transmission is the oldest torque transmission scheme. The installations use:

- pulleys in the form of smooth cylinders;

- thin ribbons, the cross-section of which is a rectangle.

In ancient times, raw leather was an indispensable material for the manufacture of transmission elements. Today, flat belts are made from several layers of rubber. To increase strength, a cord of textile thread or nylon is placed inside the structure.

Flat drive transmission has several advantages. Firstly, it allows you to quite simply organize the transmission of torque not only between parallel, but also shafts intersecting at any angle. Secondly, the design of pulley wheels is extremely simple. Thirdly, a flat tape with a small thickness is highly flexible and experiences low stress during bending and deformation

But there are also significant disadvantages in using such a transfer. The main thing is the need to provide a significant tension force to generate friction force. As a result, the service life of the belt is reduced. In addition, the drive and driven shafts operate under significant load, and the bearing blocks have significant wear.

Today, to make a flat belt, rubber with reinforcement from belting fabric material, polymers, and metal cord is used. Drive systems use rubberized fabric belts. Threaded elements with layers of rubber, wrapped in layers or spirally, are used.

Characteristics of poly V-belt:

- high efficiency, about 98%;

- used in high-speed, highly loaded units;

- Poly V-belts (PR) operate with minimal noise than conventional belts;

- Wide range, can be used on shafts with small diameters, less than 20 mm.

- The wear threshold is high, long service life.

Thanks to its geometry and quality of materials, a poly V-belt or ridge belt transmits power with virtually no loss. Where such belts are installed, there must be tensioners.

Definition

Belt

is an endless belt that transfers power from the drive shaft to one or more driven shafts. The system works on the following principles:

- the belt is located on pulleys;

- power transmission and torque formation occurs due to the action of friction forces;

- For effective operation of the belt drive, tension on the working element must be ensured.

Toothed types of drive belts transmit torque not only by frictional forces, but also by engaging the protruding elements with the protrusions on the pulley wheel. Each of the currently used transmission elements has its own list of advantages and disadvantages.

Structure of a poly V-belt:

- Bearing layer. This layer is made of durable composite material threads. The threads are distributed evenly around the perimeter of the product. They are both durable and capable of slightly extending. Attached securely to the base layer. At large stretches, belts with such threads evenly distribute the load over the entire belt area, which promotes smooth energy transfer.

- Coating. This layer must be flexible and have a long service life. This coating reliably protects the supporting layer.

- The basis. The base consists of rows of parallel V-shaped grooves. Such teeth create good adhesion to the shaft pulley. The base layer is made of a durable material, such as polychloroprene elastomer, covered with transversely reinforcing fibers.

Photo gallery

Photo 1. This is what a worn strap looks like

Photo 2. V-ribbed belt with markings

Photo 3. Design of units using PR

Where is the longitudinal groove belt used?

Ribbed or multi-ribbed belts have a wide range of applications:

- in units operating under high loads;

- in designs with high gear ratios;

- in structures with high angular velocities;

- in designs with small diameter belt shafts.

PRs are in demand in the automotive industry, tractor, machine tool, metallurgical, chemical, household, and nuclear energy industries.

Such a simple element in belt drives as a belt solves many issues. Thanks to the use of a high-quality rivulet-type belt, the following indicators are improved:

- Reduced noise levels.

- Increased turnaround time.

In order not to reduce the life of the alternator belt, you should monitor the operation of the alternator overrunning clutch.

Application of belt elements in various conditions

Today, all modern belt elements for drive systems are offered in various versions to suit specific conditions. In particular, you can purchase products that allow constant contact with oils, made from synthetic elastomers. It will not be difficult to buy a belt designed for operation at low temperatures. There are products that can withstand significant loads and offer a long service life.

One thing needs to be understood correctly. In modern drive systems, only those types of belt elements of the unit that are provided by the manufacturer should be used. They must be properly tensioned in accordance with the installation instructions, checked and maintained. Without following these simple rules, it is impossible to guarantee that there will be no unexpected equipment breakdowns or increased costs for purchasing new belts to replace worn ones.

Dimensions and geometry

V-ribbed belts for a car generator come in different sizes, depending on the equipment. Ribbed belts can also be installed in the design of air conditioners, gas distribution mechanisms (GRM), etc.

Belt size table according to GOST:

GOST dimensions of ribbed belts

Worn poly V-belt

No matter how high-quality the product is, when its service life expires, it is subject to significant mechanical wear. A worn-out part in the design of a car assembly can affect the quality and safety of movement and the operation of the engine.

For those who do not yet know that you can diagnose the main components of a car with your own hands, we have prepared material: How to diagnose a car using a laptop.

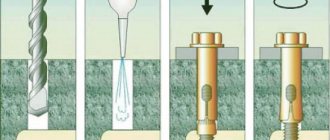

Therefore, it is recommended to periodically carry out diagnostics of belts:

- Inspection of external condition. Visual inspection is the main way to detect mechanical damage. If thread delamination or cracks appear, it must be replaced as quickly as possible.

- Inspect not only the belt, but also the pulleys. If there are chips on the pulleys, they create scuffs on the side surfaces of the belt, which leads to very rapid wear.

- Inspect the pulleys for oil. Oil and other fuel and lubricant products should not be present on the surfaces of pulleys and belts.

- In addition, it is necessary to regularly inspect the tension rollers. Make sure that the tension rollers hold the belt properly.

- Check the belt tension level.

The belt and tension rollers should be checked every 15 thousand km. When replacing the belt, it is recommended to change the tension rollers as well.

When a heavily worn belt, not only a rivulet V-belt, but also other types, extraneous noise appears.

Car repair and maintenance professionals recommend changing the alternator belt at least every 50,000 km. The belt must be tensioned so that the deflection coefficient is no more than 0.5 cm. If it is impossible to tension so that the deflection is less than 0.5 cm, then the problem is in the rollers.

Important! Inspect the belt when purchasing to ensure there are no burrs or cracks. Even expensive belts need to be inspected. All types of goods have their own percentage of defects.

V-belts: types, markings and belt selection

09/05/2018 |

Reviews: 3 | 40704 V-belts are used in belt drives, and among all belts this type is the most popular. Unlike flat belts, their cross-section is trapezoidal or wedge-shaped.

Typically belts consist of:

- Stretch layer (rubber layer);

- Elastic layer (rubber);

- Supporting layer (cord cord for belts of cord design);

- Supporting layer (fabric frame for belts of cord fabric construction);

- Compression layer (consists of rubber);

- Wrapper.

Why are V-belts capable of transmitting greater loads than flat ones?

As in other belt drives, the torque from the drive V-pulley to the belt and from it to the driven pulley is carried out due to friction forces. But in a V-belt drive, the working surfaces are the side surfaces of the belt. In this case, the contact patch is much larger than in a flat belt.

This means more friction force and, therefore, more transmitted torque. To increase the contact patch it is not necessary to increase the diameter of the pulley. It makes more sense, from the point of view of the dimensions of the structure, to choose a pulley of small diameter, but with several belts. In this case they say multi-strand pulley.

Advantages of using V-belts

- Simplicity of design.

A belt and two pulleys are simpler than a gear or chain drive, the parts of which are structurally more complex and require greater manufacturing precision. The simplicity of the design means it is cheap. - Easy to care for.

The belt drive does not require special care and lasts until the belt wears out. - Silence.

The belt is made of rubber or other similar materials that perfectly dampen any noise. In a chain one, the noise level will always be higher. - Ability to withstand excessive loads without transmission failure.

When the force on the pulley is higher than the calculated one, the V-belt or any other belt will simply slip. In a chain drive, overload will lead to breaking the chain or licking off the key; in a gear drive, it will lead to chipping of the teeth. - Ability to transmit forces over significant distances.

If you use a chain drive, the chain has significantly more weight compared to a belt drive, which will require additional drive power.

Types of belts

Standard profile V-belts:

Z/10, A/13, B/17, C/22, 25x, D/32, E40

Narrow V-belts:

SPZ, SPA, SPB, SPC, 3V/9N, 5V/15N, 8V/25N

V-belt length marking

L or La

This is the length along the outer (top) side.

Lw, Lp, Ld

The calculated (working) length of the belt (this is the length along the neutral line, that is, along the belt tension line - along the cord).

Li

Length along the inner (bottom) side.

How V-belts are marked

There are several types of V-belt markings:

- According to GOST 1284-89;

- According to the European standard DIN 2215;

- According to the international ISO standard;

- According to American RMA standard.

Designation of V-belts according to GOST 1284-89

Manufacturers in the CIS countries adhere to this marking. And also the Chinese, who supply their goods to this market. According to it, the designation of a V-belt indicates the profile and estimated length - Lp (Lw or Ld in Western catalogs)

. The estimated length is the length of the belt measured along the cord.

Designation example: Belt D(G) 2500 GOST 1284.1, where:

- D(G) – profile designation;

- 2500 – estimated belt length in mm.

In European markings, profiles are designated not by letters, but by numbers; the belt designation indicates the length along the inner edge - Li, since the length of the inner edge can be directly measured.

Designation example: Belt 25×2000, where:

- 25 – profile number;

- 2000 – internal belt length.

ISO marking is almost identical to GOST, only the profiles are designated in Latin letters. The estimated length is also indicated by the profile (cord) - Lp (Lw or Ld in Western catalogues).

Designation example: Belt SPZ 2000 Lw, where:

- SPZ – profile designation;

- 2000 – estimated belt length;

- Lw - length marking.

In the USA, letters are used to designate a profile. But the geometric dimensions of the profile are indicated in inches.

The length of the belt is measured, as in Europe - along the inner edge.

Designation example: Belt B 43, where:

- B - belt profile;

- 43 – internal belt length in inches.

Profile marking Width, mm Height, mmGOST ISO DIN RMA Wa Wp Wi TClassic beltsNarrow

| 0 | Z | 10 | — | 10 | 8,5 | 6,1 | 6 |

| A | A | 13 | A | 13 (½”) | 11 | 7,8 | 8 (5/16”) |

| B | B | 17 | B | 17 (21/32”) | 14 | 9,4 | 11 (13/32”) |

| IN | C | 22 | C | 22 (7/8″) | 19 | 12,9 | 14 (17/32”) |

| G | D | 32 | D | 32 (1 ¼”) | 27 | 19,2 | 20 (3/4”) |

| D | E | 40 | E | 40 (1 ½”) | 32 | 22,4 | 25 (29/32”) |

| У0 | SPZ | — | — | 10 | 8,5 | 4 | 8 |

| UA | SPA | — | — | 13 | 11 | 5,6 | 10 |

| UB | SPB | — | — | 17 | 14 | 7,1 | 13 |

| UV | SPC | — | — | 22 | 19 | 9,3 | 15 |

The length of a domestic and Chinese-made belt must be measured along the cord (it is clearly visible on the side edges). Another way is to measure the internal or external length, and then find the working length from the manufacturer's catalogs.

The length of a European or American V-belt must be measured along the inner edge.

Measuring the geometric dimensions of the profile does not cause any difficulties. All measurements must be carried out with the belt in a free (not tensioned) state.

How to choose a V-belt

It is highly recommended to select a belt in strict accordance with the documentation for the equipment in which it is used. Belts from different manufacturers that have the same geometric dimensions may differ in strength characteristics.

If it is not possible to supply exactly the same belt, it is necessary, in accordance with the manufacturers’ catalogs, to select the closest analogue in size. In the case of an American belt, do not forget to convert its length and profile dimensions from inches to millimeters (for this you need to multiply by 25.4).

Types of wear on V-belts

We list the factors due to which the belt drive can fail, as well as the reasons for their occurrence:

- Excessive stretching caused by:

- Inconsistency between the cross-sectional area of the belt and the resulting loads;

- Poor quality belt;

- The belt length does not correspond to the required design length.

- Increased wear caused by:

- Inconsistency between the area of the side faces and the resulting loads;

- Mismatch between the belt profile and the pulley profile;

- Pulley misalignment;

- Jamming of pulleys.

With proper selection and operation of the belt drive, it will serve for years.

Alignment and tension of V-belts

When installing a belt drive, parameters such as alignment and tension of the V-belts are very important. Deviations from the design values should not exceed tolerances according to the manufacturer’s recommendations.

Otherwise, increased wear of the belt will be observed, the service life is much shorter than that indicated in its passport.

When replacing a belt and during its operation, it is recommended to measure the tension and alignment of the pulleys using measuring tools.

V belt meters

V-belt manufacturers

There are many belt manufacturers, which can be divided into three categories:

- Premium:

Optibelt, GATES, Contitech, BANDO, SKF; - Standard:

Rubena, STOMIL, Fenner TOP DRIVE; - Economy:

China and domestic manufacturers.

As with other components, we recommend installing original premium quality belts on critical components where downtime and stoppages are unacceptable.

We offer products in various price categories from European, Japanese, American and Chinese manufacturers. If necessary, our specialists will select the required transmission in a complex in accordance with the provided initial data.

Prices

Cost of poly V-belts:

- for AUDI cars - BOSCH belt - from 251 rubles;

- for Porsche cars - Contitech 3РК600 belt - from 255 rubles;

- for Ford cars - BOSCH belt - from 253 rubles;

- for Citroen - Skf belt - from 259 rubles;

- for Alfa Romeo - Bosch belt - from 250 rubles;

- for BMW - Skf - from 250 rubles;

- for Cadillac cars - Gates belt - from 825 rubles;

- for a Hummer car - Contitech belt - from RUB 2,701;

- for Jaguar - Dayco belt - from 305 rubles;

Then the list continues, approximately in the same price range - from 250 rubles for 2022. VAZ LADA, AUDI, BMW, Mercedes, cars from Korea or China, etc., do not require large investments to replace the belt. For Rolls-Royce, Bentley, Ferrari and other top world cars, accordingly, belts cannot be bought in ordinary car stores.

Our production:

- 24.864

- 28.62

- V-belt Z 500 PRS

Retail price 31.06 rubles RUB WHOLESALE (for purchases from 50,000 rubles) 29.70 rubles VIP price (for purchases from 100,000 rubles) 27 rubles.Manufacturer:PRS

PC

31.06

Buy

- V-belt Z 530 PRS

Retail price 32.92 rubles RUB WHOLESALE (for purchases from 50,000 rubles) 31.49 rubles VIP price (for purchases from 100,000 rub.) 28.62 rub.

Manufacturer:PRS

PC

32.92

Buy

- V-belt Z 560 PRS

Retail price 28.60 RUB WHOLESALE (for purchases from 50,000 RUB) 27.35 RUB VIP price (for purchases from 100,000 rub.) 24.86 rub.

Manufacturer:PRS

PC

28.60

Buy

- V-belt Z 600 PRS

Retail price 31.30 rubles RUB WHOLESALE (for purchases from 50,000 rubles) 29.94 rubles VIP price (for purchases from 100,000 rub.) 27.22 rub.

Manufacturer:PRS

PC

31.30

Buy

- V-belt Z 630 PRS

Retail price 32.17 rubles RUB WHOLESALE (for purchases from 50,000 rubles) 30.77 rubles VIP price (for purchases from 100,000 rub.) 27.97 rub.

Manufacturer:PRS

PC

32.17

Buy

- RUB

VIEW ALL