Bonding of metal (and other) parts is carried out using a variety of methods. Using a welding machine is not always possible (for example, in situations with plastics) or impractical, as is cutting threads for screws or bolts with preliminary drilling of the material.

Special threaded rivets have virtually no restrictions in their use and provide reliable fixation at the joint. What kind of products these are and what is their feature is the topic of this article.

In fact, it is a hybrid of a traditional rivet (“hammer”) and a threaded fastener. Do not confuse such products with exhaust hoods!

Advantages of threaded rivets

- Simple installation technology. Possibility of reliable fastening of parts made of materials of increased fragility or low thickness (for example, sheet metal). The threaded rivet practically does not cause their deformation. If the total thickness of the connected samples exceeds the length of the fastening element, then the so-called one-sided fixation is performed, without a through passage. At the same time, the quality of bonding does not deteriorate.

Types of threaded rivets

The assortment is so large that listing it in full is both impossible and makes no sense. Knowing what types of threaded rivets there are, it is easy to determine what exactly is needed for specific purposes.

According to the material of manufacture

- Copper.

- Aluminum.

Products made of non-ferrous metals are used in cases where the aesthetic component comes to the fore. Therefore, such rivets are used mainly for decoration.

These samples provide greater joint strength and increased corrosion resistance.

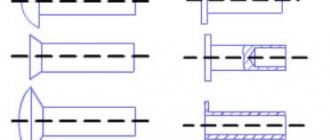

By head type

- Flat.

- Secret.

By type of thread

- Nut (M4 – permanent connection. It is advisable to use when it is impossible to access the back side of the part or in conditions of limited movement.

- Screw (M3 – 16) – collapsible type.

According to the profile of the leg

- Round.

- Hexagonal (to prevent rotation in the seat).

By type of pile

- Open or closed.

- Secret.

- Small or large.

By purpose

- Electrically conductive.

- With increased force (or pressing, or stretching).

- For highly leak-tight connections.

- With an enlarged head.

- With inch thread.

- With tags (allow for visual identification).

- With vibration isolation.

This list of varieties according to the specific application can be continued, but it is already clear that the industry produces threaded rivets for literally all occasions.

How do threaded rivets work?

In principle, it is not much different from installing conventional rivets “under a hammer”.

Algorithm of actions for a rivet nut:

- Drilling a hole in the material. Installing a threaded rivet into a special tool. Placement in place (in the hole). Squeezing (compression) of the fastener.

Application

Basically, anywhere. As already stated, there are no restrictions. The main thing is to choose the right type and size. It is especially convenient to use threaded rivets to connect products, after installing them in place, access to the reverse side will be difficult or impossible.

Almost every person encounters rivets, even those who have nothing to do with construction. Some of their types are present on clothing, which makes it easier to use. In construction, rivets are most often used to secure two parts together. But there are also rivets that perform a different role. They are called threaded. Why are these elements needed and how are they installed. This will be discussed in the article.

Overview of species

Nut or screw rivets are available on the market in a wide range.

Each type of this product has its own characteristics and advantages, as well as scope of application. Therefore, first you need to understand the characteristics in order to make the right choice. Rivets are distinguished by their design, namely the internal thread, since it forms a closure belt during compression. These products are distinguished by the type of head and type of thread. The M4 - 8 nut rivet has a permanent connection, so it is only suitable for conditions where movement is limited, if it is impossible to access the back of the part. The screw sample belongs to the category of collapsible rivets. The profile of the leg also differs between products - hexagonal and round. The type of collar can be open, closed, hidden, small or large, which should also be taken into account when choosing a fastener.

The hexagonal rivet is intended for fastening sheet profiles to each other. This nut looks like a sleeve with an internal thread. This element is an excellent alternative to welded joints, so you can fasten products with thin-walled material. Often used in the manufacture of furniture, electrical devices, air conditioning systems and the manufacture of metal cabinets. A blind nut is designed to create threads when using screws, studs and bolts. If tight fastening is required, it is better to choose this option. Thanks to standard sides, deformation of the base material is prevented, since the contact area is large. To install such a rivet, you need to drill a hole.

Cage nuts are used when there is no fastening element. If there is a hole, but no thread, this product will help out. However, this will require a special tool that is designed to work with blind nuts. The most common form of riveting nuts is cylindrical. This is a strong item that is easy to work with.

Varieties

The difference between rivets of this type lies not only in their diameter, but also in other parameters, one of which is the metal of manufacture. The following can be used as a basis:

Each of these metals has its own advantages over others. Regular steel rivets are most often coated with zinc to prevent rust during use. In this regard, stainless steel products benefit, but their cost is slightly higher. They also have greater strength. Copper and aluminum are used in cases where interaction with a similar metal is required, and the rivet will not hold a module that is too heavy. Each element has a head that guarantees fixation on the front side. It can be flat or hidden. The second option will require widening the outer diameter of the hole to hide the sides. Blind rivets are used most often in case of one-sided installation. The latter is carried out in a situation where the thickness of the metal of the workpiece is greater than the rivet and the latter does not have the opportunity to fully compress it. In this embodiment, fixation occurs due to the expansion of the element body inside the hole.

Read also: DIY living water scheme

Mounted modules have different pitches and thread diameters, so products are required to match them. That is why companies producing such fasteners are most often ready to provide their customers with rivets that have a diameter from M4 to M8. This applies to nut structures when there is no access to the reverse side of the metal. There is also a collapsible screw type, which is available in sizes from M3 to M16. The cut profile of the product may also be different. Most often, round is used, but hexagonal can also be used. In the second case, making a hole for such a unit requires some effort, but turning it is much more difficult, and in some cases impossible, when compared with the round version.

Threaded rivets can be specialized, so depending on the application, they may have reduced resistance to electrical current. Other elements have increased strength, because they are designed to work under heavy loads. Depending on the shape, the clamps are able to provide a tight connection. The heads of some elements have special marks that allow them to be identified among other products. Vibration-isolating rivets are often used in automobiles. Especially when it comes to mounting on body parts.

Rivets

The most commonly used in construction are blind rivets. They are available (can be purchased at any hardware store and market), are easy to use and completely provide a reliable permanent connection of materials.

Blind rivets are differentiated by size and type of material used to make the rivets.

The material of the rivet is an extremely important factor. The choice of rivets based on material directly depends on the type of material of the parts being fastened and the environment in which the fastener will be located.

The materials for making rivets can be the following:

- Cink Steel.

- Aluminum. There is pure aluminum and its options: anodized, varnished.

- Stainless steel. A2 - resistant to rust, A4 - resistant to corrosion and acidic environments (used in the chemical industry). Or imported analogues, for example, DIN 7337. Stainless steel is one of the most common and durable materials.

- Copper - Copper rivets are used to fasten copper materials.

- Copper-nickel alloy (Monel). Contains 70% nickel, 30% copper.

A pop rivet is a tube with a cap. Inside the structure there is a steel rod, one of the ends of which is slightly expanded. The riveter pulls the rod, causing the tube to gradually expand. When the force becomes maximum, the rod is bitten off.

In blind rivets, the process of deformation of the sleeve is carried out using a rod with a thickening at the end, pressed inside the body of the fastening sleeve. In order to seat the body of the rivet, its end is pressed against the supporting surface of the rivet maker; after alignment, the central rod is pulled out with force by several millimeters. As a result, the walls of the sleeve are deformed, forming a fairly strong permanent connection. The shank of the rod most often breaks off or is cut off at the level of the sleeve cut.

Main types of rivet hardware

All rivets are of two types - threaded and blind, both types of rivets are installed due to deformation that occurs from the pulling force of a special tool - a riveter.

Blind rivets

Blind rivets

consist of a rivet body with a side (flange) and a pull rod, which, when pulled out, deforms the tail part of the rivet body, forming a reverse head that tightens the connected elements. After reaching the maximum traction force, the rod breaks off in a special separation zone, forming a reliable, permanent connection.

Threaded rivets

Threaded rivets

are one-component, and are used to create a strong collapsible connection, while threaded rivets are placed on only one sheet (surface), and the second sheet or material is attracted to the first by screwing a bolt, screw, etc. into the thread.

Threaded rivets are much more commonly used to hold multiple parts together, allowing threads to be created on thin material where threads cannot be cut. At the same time, they do not have any special restrictions in use and provide reliable fixation of all structural elements using a collapsible threaded connection of parts.

Nut samples of a threaded rivet have a thread on the inside, and bolt samples have a thread on the outer (protruding) part.

Basic properties

A rivet is considered a type of connection that is characterized by greater reliability than screws and screws. This device also takes up a minimal amount of space and is almost invisible after use. Rivets are lightweight and are usually used when surfaces are not intended to be separated. Most often, riveting is used where welding is impossible for some reason or where non-weldable surfaces need to be joined.

You can rivet not only metals, but also fabric products and all kinds of accessories. Consumers also say that a screw, bolt and nut can loosen over time, which cannot be said about a rivet. It tends to fit tightly and even if the metal is damaged, it does not come back out.

Peculiarities

Rivets are fasteners in the form of a sleeve or rod with a rivet head at one end and a head that closes during the rivet process at the other. Threaded rivets differ from blind rivets by the presence of threads. That is, they are hexagonal or cylindrical bushings with a supporting flange at the top and threads at the bottom. The upper part is made in the form of a thin-walled tube without threads and often has a longitudinal external notch. During installation it becomes deformed. The vertical notch on the top ensures uniform deformation and prevents tearing of the material.

The advantages of threaded rivets include:

- ease of use;

- strong bonding of elements made of fragile and thin materials such as sheet metal without deformation;

- the possibility of one-sided fixation if the total thickness of the parts being connected exceeds the length of the fastening element without loss of strength;

- maintaining the strength of the connection over time;

- mechanical and chemical non-aggressiveness;

- maintaining the integrity of the surface and paintwork;

- the ability to connect elements from different materials;

- absence of mechanical stress in the structure;

- Possibility of dismantling and reinstallation.

Despite the fact that nowadays, in most cases, instead of rivets, welded or glued joints are used, the fasteners under consideration have a number of advantages in comparison with them, which determine their indispensability in some assemblies. First, threaded rivets can withstand heat. Secondly, they do not cause structural changes in elements during installation, unlike welding, which is especially important when connecting parts made of different materials, the behavior of which can be unpredictable. Third, threaded rivets ensure mobility is maintained.

However, these fasteners have a number of disadvantages:

- installation is complicated by the need to pre-make holes;

- most threaded rivets do not ensure tight seams;

- installation is associated with a high noise level.

Installing threaded rivets without a rivet gun

It is not always possible to have an expensive professional tool at your disposal. In addition, if it is necessary to perform one-time operations, its purchase is impractical. In such cases, work is performed without the use of special tools. There are several ways to rivet a threaded rivet without a riveter. The easiest way to install threaded rivets without a rivet gun is to use a screwdriver. For this purpose, a special nozzle is used, the body of which houses a bolt with a collapsible thrust bearing. The bolt, through a notched end nut, is screwed into the rivet, which is then installed in the mounting hole. After this, the screwdriver is turned on and, due to the rotation of the bolt, a force is created that forms the collar and fixes the rivet. A knurled nut and a thrust bearing prevent the rivet from turning. After installation, all that remains is to unscrew the bolt from the fastener, turning the screwdriver into reverse rotation mode. This method makes it possible to use a regular screwdriver as an electric riveter. In the absence of a special attachment, such a structure can be assembled manually.

In general, the listed methods make it possible to perform the installation of threaded rivets quite efficiently without a riveter. The speed and complexity of installation depends on whether a power tool is used.

Subtleties of using threaded rivets

The most important condition for the correct installation of threaded or nut rivets is the correspondence of the sections of the component element and the mounting hole in the workpiece. If it is not followed, it may turn over. Then installing the rivet will be much more difficult, and the connection will be fragile. The selection of the drill is very important - its cross-section should be exactly 0.1 mm larger than the diameter of the riveting.

To avoid turning, you need to choose rivets with a longitudinal notch at the top. Such elements rotate much less frequently due to friction of the notches.

What other nuances do professionals advise to take into account?:

- To easily drill holes in workpieces, use a clamp or vice. They will protect the parts from shifting. Otherwise, the quality of the connection will suffer.

- When choosing a material for a homemade riveter, consider the load on the rod (bolt). You should not install many large-diameter steel components.

- The most reliable connection is provided by hex rivets, but it is difficult to prepare a mounting hole for such consumables. Hexagons are best used for fastening parts made of thin materials.

Making a rivet maker with your own hands is rational if the amount of work is small. If you need to install more than a hundred rivets, you should buy a professional tool. If you have a home workshop, manual equipment is sufficient. But if you put the work on stream, a manual device will require a lot of effort. For production purposes, pneumatic or power tools are used.

What is it used for?

A threaded rivet is similar to a blind rivet only with some nuances of fixation. Otherwise, its purpose is somewhat different. In some cases, it is necessary to install a product on metal. But its thickness is not enough to cut a thread or there is no way to crawl from the back side in order to substitute the nut. In this case, threaded rivets come to the rescue. Structurally, they are a small hollow cylinder, which already has a thread. The rivet is installed in such a way that it is securely fixed to a metal or other workpiece and provides the ability to install a bolt to fix any module.

Types and principle of operation of threaded rivets

Threaded rivets can be divided into two large subtypes:

- blind rivets bolts;

- blind rivet nuts;

Such rivets, in addition to creating a thread, create an internal threaded channel in the materials being fastened, in the case of a nut, and an external channel in the case of a bolt. Meanwhile, such rivets can well be used as blind rivets that connect two sheets or other surfaces. This ensures double connection reliability. Which makes such connections highly reliable.

Peculiarities

Initially, it is worth recalling that until relatively recently, rivets were one of the most common types of hardware products. Today, despite the active introduction of advanced technologies and innovative technical solutions, the relevance of such fasteners remains in many modern areas. The design features and operating principle of threaded rivets deserve special attention.

It is important to consider that regardless of the variety, they work the same

At their core, all rivets are fasteners in the form of a sleeve with a folding head. On the other hand, there is a head that closes during the assembly process. If we compare the more familiar exhaust systems and the fastening devices under consideration, it will become clear that the latter differ, first of all, in the presence of a threaded element. In this case we are talking about a compact structure in the form of a sleeve (rod) having a cylindrical or hexagonal shape. Its upper part is equipped with a support side, and the lower part has a thread.

When considering the features of threaded rivets, it is necessary to pay special attention to the following clear advantages of this type of fastening devices

- Maximum ease of use.

- The strength of the connections created, including, if necessary, the installation of structures from fragile elements. This refers, for example, to thin sheet iron, even slight deformation of which during the assembly process is unacceptable.

- Possibility of high-quality unilateral fixation. This point is most relevant in situations where the total thickness of the parts being fastened exceeds the length of the hardware product. In this case, threaded rivets are able to ensure reliable installation without loss of performance characteristics of the structure.

- Maintaining fastening strength for a long time.

- Complete absence of chemical and mechanical aggressiveness.

- Preservation of the paint coating of the surfaces of the parts to be joined.

- Possibility of durable connection of structural elements made of different materials.

- Absence of any stresses of a mechanical nature.

- Possibility of repeated dismantling with re-installation of fasteners.

At the moment, preference is increasingly being given to welds, soldering or gluing. However, despite all the undeniable advantages of this type of connection, in some situations the only rational solution is the use of rivets with a threaded element. In addition to all of the above, it should be noted that such devices can withstand significant thermal loads.

Also, threaded rivets do not cause structural changes in the mounted parts, which cannot be said about welding. This point is very important when joining different materials. And do not forget that the described hardware products, if necessary, ensure the preservation of the mobility of structural elements.

Naturally, there are certain disadvantages of such rivets, which include the following important points.

- At the preparatory stage, it is necessary to carry out the most accurate markings and make holes of the appropriate diameters.

- In the vast majority of cases, there is no tightness of the seams created. In some situations, the solution may be to install rubber gaskets or gaskets made of other materials.

- The work is accompanied by quite noticeable noise.

Advantages and disadvantages

Today, rivets are considered a universal fastener that provides reliable fastening of sheet materials. In addition, hardware has a number of other advantages.

Advantages of metal rivets:

- the connection is resistant to strong mechanical loads, vibration and shock;

- the possibility of durable fastening in places where it is impossible to use threaded options or welding equipment;

- Blind and threaded rivets are easy to install;

- A wide choice of materials reduces the risk of corrosion.

Disadvantages of rivets:

- the need to purchase special equipment for installation - a riveter;

- if the diameter of the hole and the rivet are not matched, the strength of the connection is weakened;

- impossibility of end-to-end connection without the use of additional pads;

- noisy installation of options with a closing head.

At the same time, the disadvantages of metal rivets are not always a contradictory factor. The noise can be tolerated, and overlapping installation is one of many options for assembling the structure.

Kinds

The type of hardware is selected in accordance with the connection requirements. Due to the fact that the modern fastener market offers a wide range of blind rivets, choosing the right element will not be difficult. Depending on their performance characteristics, hardware is divided into several types.

Combined models are considered the most common type. Hardware is capable of providing permanent connection of particularly hard parts subjected to mechanical, weight and vibration loads.

- Sealed models have a rather narrow specialization and are widely used in shipbuilding industries. A design feature of blind models is the soldered end of the rod. Products can be made of stainless steel, copper and aluminum.

- Multi-clamp models have several riveting sections and are installed in movable structures when it is necessary to connect three or more elements. Such a section is located between two adjacent elements, and installation is carried out using a pneumatic gun.

In addition to traditional models, there are reinforced versions of rivets, the manufacture of which uses stronger material with thicker walls.

Summary

As you can see, each type of rivet plays its role and is necessary. If conventional ones can be replaced with exhaust ones, then threaded ones are unique in their class and make it possible to install additional equipment where it is difficult to use any other method of fixation. The diameter of the clamp is selected depending on the needs. Factory riveters for threaded elements are most often supplied in a plastic case for greater ease of storage. If there is a need to install components of large diameters, then a model with two handles is better suited.

Threaded rivets are used when it is necessary to reliably connect various parts. This need arises especially often when installing products that will be subject to significant vibration loads during operation.

How to install threaded rivets, as well as the tool used to perform such an operation, will be discussed in detail below.

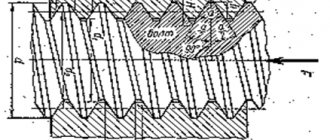

Types of rivet seams

If we talk about the method of joining sheets, then riveted seams can be overlapped (one sheet overlaps another) and end-to-end. Joint seams can have one or two overlays. With overlays they are more reliable and are used in critical and loaded places.

Types of rivet seams: overlapped and butted with overlays

According to the location of the rivets:

- single row;

- double row;

- multi-row.

They can be located opposite each other or in a checkerboard pattern. Seams can be strong, tight (sealed) or durable-tight. Dense ones are made using elastic gaskets placed between the parts to be connected. Durable and dense ones are used mainly in boilers. Now they are more often replaced by welding.

Types of threaded rivets

The assortment is so large that listing it in full is both impossible and makes no sense. Knowing what types of threaded rivets there are, it is easy to determine what exactly is needed for specific purposes.

According to the material of manufacture

- Copper.

- Aluminum.

Products made of non-ferrous metals are used in cases where the aesthetic component comes to the fore. Therefore, such rivets are used mainly for decoration.

- Steel.

- Made from stainless steel.

These samples provide greater joint strength and increased corrosion resistance.

By type of thread

- Nut (M4 – permanent connection. It is advisable to use when it is impossible to access the back side of the part or in conditions of limited movement.

- Screw (M3 – 16) – collapsible type.

By purpose

- Electrically conductive.

- With increased force (or pressing, or stretching).

- For highly leak-tight connections.

- With an enlarged head.

- With inch thread.

- With tags (allow for visual identification).

- With vibration isolation.

This list of varieties according to the specific application can be continued, but it is already clear that the industry produces threaded rivets for literally all occasions.

Dimensions

The selection of the optimal dimensions of a threaded rivet depends on several important factors. These include the type of hardware product, as well as the total thickness of the fastened elements of a particular structure. With the same thread parameters, the length will be determined by the type of fastener.

It is important to consider that most models are available in two versions - normal (standard) and extended. For example, a typical stainless steel rivet may have the following dimensions:

- Thread – from M4 to M10.

- Length – from 11 to 24 mm.

- The diameter of the rivet and hole is from 6 to 13 mm.

- The diameter of the collar is from 9 to 17 mm.

At the stage of selecting rivets, it is strongly recommended to use the corresponding tables, which indicate all their key parameters. Now you can easily find all the necessary information on specialized resources.

How to work with spot welding drills?

The drilling technology carried out is characterized by quite a large number of features. Recommendations for its implementation are as follows:

The selected drill is installed in a drill, which must be able to adjust the number of revolutions

In addition, attention is paid to the power indicator. It is not recommended to use the drill immediately. This is due to the fact that it is recommended to pre-mark the joints

The case where the pin pops out and breaks due to the applied load has become quite widespread. The drill used is set to minimum speed. After this, the drill or crown is installed strictly perpendicular to the surface being treated

This is due to the fact that it is recommended to pre-mark the joints. The case where the pin pops out and breaks due to the applied load has become quite widespread. The drill used is set to minimum speed. After this, the drill or crown is installed strictly perpendicular to the surface being treated.

After drilling the connection points, in some cases it is necessary to apply force to separate the part from the base. A chisel and hammer can be used for this.

Installation process

The algorithm for installing a threaded element can hardly be called overwhelming, but it is important to know certain nuances. If possible, it is better to use a factory riveter

If desired, you can assemble it yourself; one option will be discussed below. The first step is to determine the type of metal on which the rivet will be installed. Next, you need to know what the diameter of the bolt or module that will be fixed thanks to this rivet is. According to the specified diameter, the appropriate rivet is selected. Its outer diameter is measured and a drill is selected that will be one tenth in diameter larger than the rivet. This is necessary so that the latter fits into place without much effort or obstacles.

Electric or cordless drill. The metal is drilled in the required location. After this, the fastening element is inserted into the seat. If it needs to be placed in a certain position, then it is better to hold it with your hands. For hexagonal holes, you can use special punches if we are talking about thin metal. If the thickness of the metal is greater than the length of the fastener, then the hole must be drilled a little deeper than the fastener, but there is no need to make a through penetration. After this, a rivet maker core is selected that fits the thread to the element being installed. The handles are brought together or the bolt is rotated so that part of the rivet is deformed and fixed in the hole.

You should not apply too much force, as you can tear off the thread, which will later be used to fix the required part. It is necessary to ensure that the rivet is installed in the required position. After this, you can fix the required product using a screw or bolt.

Other types of rivets

In addition to threaded rivets, there are blind and standard types of rivets. Previously, the standard rivet version was more used. It is a cylinder, one of which has an extension. The latter is made in a semicircular shape or with a hidden part. Installing such a rivet requires more effort than with other types. Such clamps are practically out of use. The first step for installation is to fix the two parts in the position in which they will be fixed. Clamps are used for these purposes. After this, the location where the drilling will be done is marked. The diameter of the hole should be 10% larger than the diameter of the rivet itself.

Read also: How to check a battery with a voltmeter

After this, a rivet is inserted into the prepared hole; it must be placed on the reverse side so that the part without the head is directed upward. After this, the parts must be positioned in such a way that there is a good stop for the rivet head. After this, the straight section is riveted, as shown in the photo. To do this, you can use a hammer or a special electric tool. The protruding part of the rivet must be given the same shape as its head. Riveting must be carried out in such a way that the body of the rivet completely fills the hole in the parts. If this does not happen, then under the cutting force the rivet will fail and the assembly will be destroyed. The length of the rivet should not be too long or too short. In some cases, for greater ductility, a regular rivet can be heated with a gas burner.

The type of exhaust fastener is shown in the illustration above. Installing such an element is several times easier, since the entire process is automated. Each fastener has a steel or other rod, which performs the task. The rod is connected to a small ball, which is located at the end of the element. Selecting the diameter and drilling the hole is carried out as in the above option. After this, the latch is installed in its place. The riveter is installed in such a way that the core is fixed in its chuck. As the handles are squeezed, the rod pulls up the ball, which flattens the back side of the fastener and thus fixes the two parts. The rod is cut automatically as soon as the force reaches the limit value.

Riveting process

The principle of operation of the tool and the procedure for installing rivets can be understood by studying the structure of the rivet maker. By and large, this is a kind of pistol that has a spring and lever mechanisms. The first one, during the actuation process, retracts the rivet, and the second one flattens it. The algorithm of actions is as follows:

- tight connection of mounted parts and their rigid fixation;

- drilling holes of the required diameter, which should be slightly larger than the size of the hardware product;

- installation of rivets;

- installing the desired head on the riveter;

- placing the tool on the rivet up to the side;

- device startup.

The riveting process itself is quite simple. The gripper, which is driven by an electric motor, pulls out the rivet shank. As soon as the limit mark is reached, the shank is cut off. In rare cases this does not happen, but if it does happen, the procedure is repeated.

When analyzing the operating principle of the equipment described, it is worth taking into account the characteristics of the materials. Thus, the body of hardware products is made of soft alloys. The rivet rod must be steel. The strength of the connections depends on the length of the fasteners.

To see what types of electric riveters there are, see the following video.

Features of installation work

When you use mechanical special tools, significant physical effort will be required to obtain truly reliable connections of structural elements. The fact is that rivet nuts significantly counteract the tightening forces. A pneumatic riveter greatly simplifies the task, but its cost remains high.

If you have a special mechanical or pneumatic-hydraulic tool available, the installation process will be very simple:

- screwing the nuts directly onto the threaded rods in the riveter;

- the tool together with the hardware is turned until it stops in the hole made;

- the rod of the device is carefully pulled out, after which the fasteners are riveted independently;

- unscrewing the rod from ready-made connections.

Top 5 best riveters for blind rivets

In construction, not only threaded, but also exhaust fasteners are often used. They are highly durable and at the same time quite easy to install. Hand tools from different price categories with a power or automatic operating principle allow you to quickly install rivets.

Metabo NP 18 LTX BL 5.0

The compact yet powerful riveter works with pull-out fasteners up to 5mm in diameter and is suitable for use in hard-to-reach areas. Equipped with a backlight and a belt clip, it is very convenient to use and does not cause rapid fatigue due to its low weight. The tool comes complete with a wrench for quick replacement of attachments.

Important! The cordless riveter is compatible with all Metabo 18 B batteries and has a charge indicator to indicate when the battery is low. The average price of Metabo NP 18 is 47,000 rubles

Gross 40409

Two-handed reinforced riveter for pull-out fasteners up to 64 mm is designed for durable connections of sheet metal and steel profiles. Equipped with a collet mechanism for capturing pins, the working part is made of deformation and corrosion resistant chrome-molybdenum steel. The riveter provides a particularly tight grip on the fastener and puts little strain on your hands even during long-term use.

You can buy the tool complete with attachments for steel and aluminum pins of different sizes. The set also includes a key for quickly changing them.

You can buy a Gross riveter from 4,000 rubles

Milwaukee M12 BPRT-0

The cordless manual riveter works with fasteners up to 4.8 mm in diameter and is designed for steel, copper and aluminum rods. Supplied with several tips, it is equipped with LED backlighting, making it easier to work in limited and poorly lit spaces. The model has a battery charge indicator.

You can buy a manual riveter Milwaukee M12 from 21,000 rubles

Kraftool 31180

The manual riveter for pull pins has compact dimensions and a convenient lever mechanism. Among the advantages are the high strength of the tool, an ergonomic body and rubberized handles that prevent fingers from slipping during use. The model is suitable for any small-scale facade and repair work in a house or country house where high productivity is not required. Interacts with rivets made of aluminum and steel, guaranteeing strong, reliable and neat fastening of sheet materials and profiles.

The price of a manual riveter Kraftool 31180 is about 3,500 rubles

Kraftool 31170-H6

A very inexpensive power riveter suitable for repair work and reliable connection of sheet materials. It is reliable and simple, made of cast steel. The handles of the device are rubberized and equipped with finger restraints, so they do not slip in the palms and do not leave calluses on the operator. The kit includes replacement tips, spare connectors and a shipping container.

You can buy a manual riveter Kraftool 31170-H6 for only 800 rubles

Principle of operation

The principle of operation of threaded rivets is that after installing such a locking element, a thread is created. A screw or bolt is then screwed into it.

Installation of threaded rivets is carried out very quickly and efficiently, but only when using a special tool. Such devices can be purchased at different prices.

If there is a need to use this type of fastener, then each master can easily choose the most suitable type of riveter for himself.

The video shows the working principle of a threaded rivet:

The tool is ideal for installing rivets in hard-to-reach places, because the product weighs only 900 g. The Gesipa Firefly comes with a set of attachments that can be used to work with rivets of sizes from M3 to M6.

2. AirPro HN-911. Despite the high cost, this rivet model has a number of advantages, which is why it is most often preferred by professionals working with metals.

Among the advantages of the AirPro HN-911 are ergonomic handles, stroke adjustment, and a lightweight cast aluminum body.

Also, using this riveter model, you can install large diameter fasteners. Thanks to the attachments included in the tool kit, you can work with rivets of sizes M4 – M10.

3. Bralo TR-212. Powerful tool for installing threaded rivets.

The length of the riveter is 530 mm, so when force is applied to the handles, sufficient force is created to install large consumables. The range of sizes used when carrying out work using Bralo TR-212 is from M8 to M12.

Read also: How to cut PVC floor plinth

The manual riveter of this model is equipped with anti-slip handles, which allows you to work comfortably even when installing large threaded rods.

The tool is also well suited for work where it is necessary to frequently change the diameter of the consumables used. The design of Bralo TR-212 has a convenient mechanism with which you can quickly change the equipment used.

Models with battery

The productivity of installation of threaded rivets can be significantly increased by using special power tools. Considering the fact that the technician has to travel a considerable distance when installing this type of mount, models equipped with a rechargeable battery have become popular.

Among portable electric riveters, the following models are the most popular among buyers.

1. Gesipa Firebirg. This model of battery riveter is manufactured in Germany, so the quality of the product is at the highest level. Despite the total weight of 2 kg, the device allows you to operate with one hand.

The main qualities of this model also include good balancing and a comfortable handle, so you can easily hold the tool when working in hard-to-reach places.

Durability of use of Gesipa Firebirg is achieved due to the presence of electronic control and protection systems against overheating and excessive loads.

The tool of this model allows you to work with rivets made of various metals, the diameter of which ranges from 2.4 to 6.3 mm.

2. Scell-it E-480NB. This model of cordless riveter allows you to perform a large amount of work both indoors and outdoors. The absence of the need to connect to a 220 volt network makes the installation of threaded rivets as quick as possible.

The tool weighs less than one and a half kilograms, so you can work with one hand when performing complex operations. Among the useful options of the Scell-it E-480NB is an LED backlight, with which you can illuminate the holes to ensure more accurate installation of the fastener.

The device allows you to work with rivets made of steel or aluminum. When using aluminum parts, the maximum diameter of the rivets can be 8 mm, when working with steel – 6 mm.

3. Absolut SK 6000. This riveter model is ideal for work where mobility is required.

There is no need to connect to an electrical network or to a compressed gas cylinder, making it easy to carry out roofing work or install rivets when installing ventilation systems.

The charging time of the 1.4 Ah battery is only 30 minutes, so even when performing a large volume of work, delays will be minimal. With the Absolut SK 6000 you can install steel rivets with a diameter of 4 - 6 mm, as well as aluminum products with a diameter of 4 - 8 mm.

The main disadvantage of battery-powered riveters is the need to periodically take a break to recharge the battery. If you need to do a large amount of work, you will need to purchase 2 tools that will be used alternately.

Riveters operating on compressed air are completely free of this drawback, so if the product is necessary for professional activities, then it is better to buy a pneumatic riveter.

Pneumatic riveters

1. Airpro SA8907. Pneumo-hydraulic riveter made in Taiwan. It has high traction force and excellent ergonomic qualities.

The weight of the product is only 1.55 kg, so even if you need to work with one hand, this model will allow you to perform riveting operations with minimal effort.

The tool allows you to work with steel and aluminum rivets. The diameter of which does not exceed 10 mm.

2. VVG VNG 703. German riveter, which has increased productivity and excellent performance.

The tool has a high pulling force, but thanks to the ability to adjust this parameter, it is possible to install even small aluminum rivets without deformation.

Using VVG VNG 703, consumables are installed, both from ordinary steel and stainless steel. The maximum diameter of the rivet, regardless of the metal used, is 8 mm.

All of the tools presented above differ significantly in price, so you should carefully calculate the amount you will need to purchase a riveter.

- If the product is necessary for professional activities, then buying a cheap model will lead to the need to go to the store again, after a short period of time.

- Purchasing an expensive device for rare home use, on the contrary, will be a waste of money.

- You can also make a riveter for threaded rivets with your own hands, but such a product is unlikely to be able to ensure high-quality work.

Product advantages

Essentially, threaded rivets are hybrids of traditional nuts. But they should not be confused with exhaust vents. They have advantages, including:

- ease of installation work;

- you can reliably connect components made from fragile materials or those that have insignificant thickness (rolled sheet metal), because the rivet nut will not lead to deformation;

- if the total thickness of the products exceeds the length of the fasteners, then a one-sided fixation is made, without a through passage, and the quality of work will not be low.

Types of threaded rivets

The range is quite wide, there are many classifications of fasteners. So, they can have a flat or countersunk head, a nut or screw thread, a round or hexagonal leg (does not allow rotation in the mounting sockets)

If you take into account the purpose, then there may be:

- electrically conductive;

- having increased force (possibly indentation or stretching);

- for highly hermetic connections;

- with enlarged heads;

- with inch thread application;

- with special marks (for visual identification);

- with vibration isolation.

Materials used for production

The fasteners in question may have different sides. To get regular connections, buy nuts that have standard flanges. If you need to get a slight gap between the parts, it is better to use hardware with reduced or hidden sides. It is worth considering that before installation begins, the procedure of countersinking the holes into which the rivets will be placed is performed.

Threaded rivet nuts can be produced from several types of metal, in particular:

- Carbon steel. For the production of universal products and the creation of standard connections.

- Made of stainless steel. Production of hardware that will be used at high temperatures or in places with high humidity levels.

- Made of aluminum. Such rivets are distinguished by their low weight and excellent anti-corrosion properties.

- Made of bronze. This metal is used if fasteners with low spark generation rates are needed.

Rivets: purpose and materials of manufacture

After we have examined in detail all the types of options on the market, we can confidently highlight several aspects of the purpose of hardware:

- those places where it is impossible to carry out welding work;

- overheating and deformation of the material structure are undesirable;

- increasing vibration resistance properties;

- the need to create a connection of increased strength.

Materials used for manufacturing:

- aluminium-magnesium alloys*;

- bronze;

- copper;

- Monel (an alloy of copper and nickel);

- stainless steel A2 or A4;

- Cink Steel;

- polyamide.

* the difference is only in the magnesium content, the higher the percentage of magnesium, the stronger, the least durable and cheapest Al (Mg1%) and the most durable which is used in blind rivets and then, as a rule, for Al (Mg5%) rods;

In some cases, combinations of these materials are used, for example, the rod may be from one alloy, and the rivet from another. Galvanized steel and aluminum are often combined. In this case, the definition of “combined” rivet is appropriate.

The principle of selecting rivets is compatibility, or better repetition, of the material, in terms of mechanical and physical properties, from which the elements being connected are made.

Another important selection criterion is susceptibility to galvanic corrosion. It manifests itself at the junction of dissimilar metals under high humidity, for example, during rain. If you are not sure how to choose rivets for a riveter, then you can use a special table of electrochemical potential. The effect of moisture will be on the more electronegative material.

When choosing a material, the following features must be taken into account:

- Ideally, choose an electropositive material for the rivet itself, so that corrosion occurs on an element that can be easily replaced;

- check compatibility using the electrochemical potential table;

- use a dielectric barrier, such as a gasket.

When purchasing rivets, it is also worth considering the operating temperature of the finished product. The fastener material and product must be matched to ensure the same thermal expansion as the temperature rises and falls. Ignoring the selection rules may lead to premature rust or other damage.

In addition to the basic elements, there are coated rivets. Powder paint is used for this, and the shade corresponds to the RAL color chart.

Diameter and length

The sizes of rivets should be selected in accordance with the thickness of the materials that will be connected. In this case, the most important parameters are the length and diameter of the rod. According to the diameter of the drill, the master determines the drill he will need for the job. The diameter of the rivet rod can range from 1 to 36 millimeters.

The length of the rivet material varies from 2 to 180 millimeters. It is worth remembering that a large diameter does not always indicate good connection reliability. The shape of hardware can be varied, for example, round, hexagonal, cylindrical.

Threaded riveter, principle of its operation, step-by-step instructions

The most reliable connection is ensured using threaded devices. The principle of their operation is quite simple, but it causes some inconvenience - each rivet must be screwed onto the end of the tool before use. The instructions on how threaded devices work are as follows:

- Initially, it is necessary to drill a hole of the appropriate diameter in sheet steel - from 3 to 14 mm or M3-M14

- Install a threaded tip (rod) into the tool head of the appropriate diameter.

- Screw the threaded boss onto the tip until it stops.

- Install the rivet into the holes of the elements to be connected

- Perform riveting by acting on the levers (bringing them together)

- Next, to disconnect the tool from the resulting connection, you will need to unscrew it

- After this, the connection is ready for use, and a bolt of the appropriate diameter can be screwed into it

For clarity, below is a video that shows what a threaded tool is and how it is used.

https://youtube.com/watch?v=K8uBGFf7FDU%3F