Types of pumps "KM" belong to the category of single-stage, monoblock, cantilever, centrifugal with one-sided supply of the working medium to the working type wheel, which is used to transport clean flows of the working medium, which has a technical or industrial purpose (sea water is not used) with a pH of 6 up to 9, and a temperature range of 0°-85°C and a number of other liquids that are similar in density to ordinary water, their chemical activity and viscosity index. They may contain a number of solid inclusions with a size not exceeding 0.2 mm, and the volumetric concentration of which does not exceed 0.1%.

What is it like?

KM centrifugal pumps are considered to be one of the most popular and at the same time numerous models of industrial pumps. Such a high demand is due to the design simplicity of the units used and the fact that they occupy the lion’s share of the domestic pump industry. Models of console monoblock pumping devices are also used in everyday life, for transporting water to reservoirs used in agriculture, water supply and heating systems. They have also found their application in other industries.

The equipment can also be used for transporting neutral liquids, whose temperature ranges from 0°C to +85°C, taking into account the presence of various solid inclusions, whose size will not exceed 0.2 mm and with a concentration of less than 0.1%. Gray cast iron is the main material used in the manufacture of individual elements of the flow part used. The possible temperature conditions of the selected model of KM pumps and the pressure indicator present at the inlet will directly depend on the existing seal.

The greatest demand is for monoblock cantilever pumps of the KM type, which are equipped with mechanical seals. Factories that are engaged in this production may produce them under a different name, but no design differences will be noticed. Among the distinctive features, it is worth mentioning the impossibility of carrying out repair work aimed at replacing the electric motor with a model with slightly lower power, which will be needed after turning the impeller.

BRANDS / CHARACTERISTICS of KM pumps

There are DISCOUNTS! CALL +7-953-812-16-31!!!

| Name | Supply, m3/h | Head, m | Engine, kW/rpm | In. pipe, mm | Exit pipe, mm | Dimensions, mm | Weight, kg |

| KM50-32-125 | 44328 | 20.0 | 401801 | 50.0 | 32.0 | 500x230x190 | 47.0 |

| KM50-32-125/2-5 | 44328 | 20.0 | 401801 | 50.0 | 32.0 | 500x230x190 | 47.0 |

| KM50-32-200/2-5 | 44328 | 50.0 | 401893 | 50.0 | 32.0 | 70.0 | |

| KM65-50-125 | 25.0 | 20.0 | 3.0/3000 | 65.0 | 50.0 | 550x272x210 | 62.0 |

| KM65-50-125/2-5 | 25.0 | 20.0 | 3.0/3000 | 65.0 | 50.0 | 550x272x210 | 62.0 |

| KM65-50-160 | 25.0 | 32.0 | 401893 | 65.0 | 50.0 | 578x272x230 | 75.0 |

| KM65-50-160/2-5 | 25.0 | 32.0 | 401893 | 65.0 | 50.0 | 578x272x230 | 75.0 |

| KM80-65-160 | 50.0 | 32.0 | 401895 | 80.0 | 65.0 | 635x435x265 | 105.0 |

| KM80-65-160/2-5 | 50.0 | 32.0 | 401895 | 80.0 | 65.0 | 635x435x265 | 115.0 |

| KM80-50-200 | 50.0 | 50.0 | 15/3000 | 80.0 | 50.0 | 790x720x265 | 185.0 |

| KM80-50-200/2-5 | 50.0 | 50.0 | 15/3000 | 80.0 | 50.0 | 790x720x265 | 185.0 |

| KM80-50-250/2-5 | 50.0 | 80.0 | 22/3000 | ||||

| KM100-80-160 | 100.0 | 32.0 | 15/3000 | 100.0 | 80.0 | 790x420x280 | 185.0 |

| KM100-80-160/2-5 | 100.0 | 32.0 | 15/3000 | 100.0 | 80.0 | 790x420x280 | 195.0 |

| KM40-32-200/4-5 | 44261 | 12.0 | 1.1/1500 | 40.0 | 32.0 | ||

| KM40-25-160/2-5 | 44261 | 32.0 | 401801 | 40.0 | 32.0 | 46.0 | |

| KM40-32-180/2-5 | 10.0 | 45.0 | 3.0/3000 | 40.0 | 32.0 | 502x297x280 | 48.0 |

| KM100-65-200 | 100.0 | 50.0 | 30/3000 | 100.0 | 65.0 | 865x460x320 | 260.0 |

| KM100-65-200/4-5 | 50.0 | 44328 | 4.0/1500 | 100.0 | 65.0 | 865x460x320 | 150.0 |

| KM100-65-200/2-5 | 100.0 | 50.0 | 30/3000 | 100.0 | 65.0 | 865x460x320 | 270.0 |

| KM100-65-250 | 100.0 | 80.0 | 45/3000 | 100.0 | 65.0 | 865x460x320 | 265.0 |

| KM100-65-250/2-5 | 100.0 | 80.0 | 45/3000 | 100.0 | 65.0 | 865x460x320 | 265.0 |

| KM100-65-250/4-5 | 50.0 | 20.0 | 5.5/1500 | 100.0 | 65.0 | 865x460x320 | 265.0 |

| KM150-125-250 | 200.0 | 20.0 | 18.5/1500 | 150.0 | 125.0 | 895x705x400 | 265.0 |

| KM150-125-250/4-5 | 200.0 | 20.0 | 18.5/1500 | 150.0 | 125.0 | 895x705x400 | 265.0 |

| KM150-125-315/4 | 200.0 | 32.0 | 30/1500 | ||||

| KM125-100-160/2-5 | 160.0 | 30.0 | 22/3000 | 125.0 | 100.0 | 255.0 | |

| KM125-100-250/4-5 | 100.0 | 20.0 | 11/1500 | 125.0 | 100.0 | 450.0 | |

| KM160/20-5 | 160.0 | 20.0 | 15/1500 |

Design features

For transportation and pumping of clean water, centrifugal-type cantilever models, which belong to the “K” category, are often used. The impeller they use, equipped with blades, will be mounted on a shaft, the return end of which will be mounted directly on the bearing assembly. One of the main design features should be the presence of compensation chambers in the “K” equipment category, which made it possible to avoid possible leaks in the future. They happen quite often and arise in cases where the actual pressure indicator significantly exceeds the permissible value.

Responsible for the required level of protection of the device from external and internal leaks are the seals that are equipped with all models of category “K” without exception. Also in the basic configuration you can find a replaceable protective sleeve, which is also present in such equipment. Thus, it was possible to reduce the wear rate of the used shaft on which the wheel is mounted.

With the correct distribution of the balancing force that is created during the operation of cantilever-type pumps, their power should not exceed 10 kW, which is provided by installed bearings. If the power of the device is greater, then to solve such problems it is customary to use special unloading holes, which are located on the impeller.

Cantilever water pumps type K, KM

Home \ Products \ Cantilever water pumps type K, KMPump K, Pump KM. Cantilever pumps.

Purpose: Console pump.

Cantilever pumps type K, KM are designed for pumping clean water for industrial and technical purposes (except marine) with pH 6...9, temperature from 273 to 358 K (from 0 to 85°C) and from 273 to 378 K (from 0 to 105°C) for KM type pumps and other liquids similar to water in density, viscosity and chemical activity, containing solid inclusions up to 0.2 mm in size, the volume concentration of which does not exceed 0.1%.

Construction and main materials

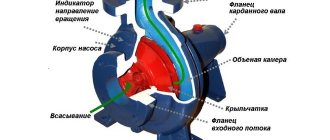

Cantilever pumps type K and KM are centrifugal, cantilever, single-stage, with a one-way liquid supply to a closed impeller. The pump shaft seal is single, double stuffing box or single mechanical. The dimensions of the hydraulic part of cantilever pumps vary depending on the pump size, but the design of all pumps is the same. The working chamber of the flow part of the cantilever pump is made in a housing and a cover and is an annular channel communicating with the inlet and outlet pipes of the pump. The movement of the liquid medium through the annular channel and imparting the necessary energy to it is carried out by the impeller. The holes in the impeller allow it to be unloaded from axial forces. The highest permissible excess pressure at the pump inlet: for pumps with a soft seal - 0.35 MPa (3.5 kgf/cm2), with a mechanical seal - 0.6 MPa (6.0 kgf/cm2). The material of the flow parts is gray cast iron. Technical characteristics of cantilever pumps.

Cantilever pumps are the most common among the pumps included in the Centrifugal pumps group.

Today, two types of pump modifications are produced: According to GOST, parametric - type (Pump K 20/30, Pump K45/30, etc.) the numbers in the abbreviation of this pump indicate the flow in cubic meters / hour and pressure, and in accordance with the International ISO standard 2858-78 (pump K80-50-200, Pump K 100-80-160, etc.)

The difference between the K and KM pumps is that the K pump is horizontal, supported on the housing and driven by an electric motor through an elastic bushing-pin coupling. The KM pump is a monoblock cantilever pump. These pumps are characterized by the fact that they are equipped with electric motors with an extended shaft, at the end of which an impeller is installed. The disadvantages of cantilever pumps with a gland seal include leakage of the pumped liquid through the pump gland. Therefore, in case of inadmissibility of leakage at the site, pumps with a mechanical seal are used, which have the following designations KM 65-50-160 / 2-5, as well as their imported analogues: cantilever monoblock pumps, Grundfos NB pump, SAER IR pump, (analogue of KM pump), Cantilever pumps Grundfos NK pump, SAER NCBZ pump, (analogue of pump K). With equal characteristics of cantilever pumps, overall, connecting, SAER pumps have a lower cost compared to Grundfos products. K-type cantilever pumps are widely available in our warehouse. We maintain the necessary stock of cantilever pumps to satisfy your requests.

The selection of a cantilever pump is carried out according to the parameters characterizing this pump, namely flow and pressure. Each cantilever-type pump has an operating characteristic curve, in which each flow point corresponds to a certain pressure. That is, the cantilever pump can operate within a certain characteristic. which can be clarified by examining the passport for the pump.

The installation of the cantilever pump after its delivery is carried out on a prepared foundation made in accordance with the passport for the pump, which should ensure that the unit does not move during operation.

Legend

Pump series produced since 1982:

Pump K 8-18a U2 K - pump type (cantilever)

- 8 — feed, m

- 18 — head, m

- a - presence of impeller turning

- U - climatic version

- 2 — accommodation category

Pump series produced since 1990:

Pump K 50-32-125a-S-U2

- K - pump type (cantilever)

- 50 — nominal diameter of the inlet pipe, mm

- 32 — nominal diameter of the outlet pipe, mm

- 125 — nominal diameter of the impeller, mm

- a - presence of impeller turning

- C - type of pump shaft seal: U - climatic version C - single gland seal

- SD - double gland seal

- 5 - single mechanical seal

- 2 — accommodation category

Technical characteristics of console pumps K

| Nom. head, m | Allowable cavitation reserve, m | Synchronous speed, rpm | Electric motor power , kW | Weight, kg | Suction Dy, mm | Discharge Dy, mm | Unit price | Pump price |

| pump K 8 18 | 8 | 18 | 3,8 | 3000 | 1,5 | 58 | 40 | 32 |

| pump K8 18 | 8 | 18 | 3,8 | 3000 | 2,2 | 61 | 40 | 32 |

| pump K 20 18 | 20 | 18 | 3,8 | 3000 | 2,2 | 61 | 50 | 40 |

| pump K 20 30 | 20 | 30 | 3,8 | 3000 | 4,0 | 78 | 40 | 40 |

| pump K20 30a | 18 | 25 | 3,8 | 3000 | 3,0 | 72 | 40 | 40 |

| pump K 45 30 | 45 | 30 | 4,3 | 3000 | 7,5 | 133 | 80 | 50 |

| pump K 45 30a | 35 | 22 | 4,3 | 3000 | 5,5 | 119 | 80 | 50 |

| pump K 90 20 | 90 | 20 | 5,2 | 3000 | 7,5 | 135 | 100 | 80 |

| pump K 50-32-125 | 12,5 | 20 | 3,5 | 3000 | 2,2 | 80 | 50 | 32 |

| pump K 65-50-125 | 25 | 20 | 3,8 | 3000 | 3,0 | 100 | 65 | 50 |

| pump K 65-50-160 | 25 | 32 | 3,8 | 3000 | 5,5 | 115 | 65 | 50 |

| pump K 80-65-160 | 50 | 32 | 4,0 | 3000 | 7,5 | 136 | 80 | 65 |

| pump K 80-50-200 | 50 | 50 | 3,5 | 3000 | 15,0 | 250 | 80 | 50 |

| pump K 80-50-200a | 45 | 40 | 3,5 | 3000 | 11,0 | 185 | 80 | 50 |

| pump K 100-80-160 | 100 | 32 | 4,5 | 3000 | 15,0 | 270 | 100 | 80 |

| pump K 100-80-160a | 90 | 26 | 4,5 | 3000 | 11,0 | 205 | 100 | 80 |

| pump K 100-65-200 | 100 | 50 | 4,5 | 3000 | 30,0 | 376 | 100 | 65 |

| pump K 100-65-200 | 100 | 50 | 4,5 | 3000 | 22,0 | 370 | 100 | 65 |

| pump K 100-65-200a | 90 | 40 | 4,5 | 3000 | 18,5 | 364 | 100 | 65 |

| pump K 100-65-250 | 100 | 80 | 4,5 | 3000 | 45,0 | 485 | 100 | 65 |

| pump K 100-65-250a | 90 | 67 | 4,5 | 3000 | 37,0 | 460 | 100 | 65 |

| pump K 150-125-250 | 200 | 20 | 4,2 | 1500 | 18,5 | 420 | 150 | 125 |

| pump K 150-125-315 | 200 | 32 | 4,0 | 1500 | 30,0 | 427 | 150 | 125 |

| pump K 200-150-315 | 315 | 32 | 4,2 | 1500 | 45,0 | 645 | 200 | 150 |

| pump K 200-150-250 | 315 | 20 | 4,2 | 1500 | 30,0 | 460 | 200 | 150 |

| pump K 200-150-400 | 400 | 50 | 5,0 | 1500 | 90,0 | 1005 | 200 | 150 |

| pump K 160 30 | 160 | 30 | 4,2 | 1500 | 30,0 | 420 | 150 | 100 |

| pump K 290 30 | 290 | 30 | 4,2 | 1500 | 37,0 | 550 | 200 | 125 |

Replacement table for console pumps type K

| since 1973 | since 1982 | since 1990 |

| 1.5 K-6 | K 8/18 | K 50-32-125 |

| 2 K-6 | By 20/30 | K 50-32-125 |

| 2 K-9 | K 45/30 | KM 65-50-160 |

| 3 K-6 | K 45/55 | K 80-65-160 |

| 4 K-12 | K 90/35 | K 100-80-160 |

| 4 K-8 | K 90/55 | K 100-65-200 |

| 4 K-6 | K 90/85 | K 100-65-250 |

| 6 K-8 | K 160/30 | K 150-125-315 |

| 8 K-12 | K 290/30 | K 200-150-315 |

Technical characteristics of console pumps KM

| Pump brand | Nom. flow rate, m3/hour | Nom. head, m | Allowable cavitation reserve, m | Synchronous speed, rpm | Electric motor power , kW | Weight, kg | Suction Dy, mm | Discharge Dy, mm | Price unit |

| pump KM 50 32 125 | 12,5 | 20 | 3,5 | 3000 | 1,5 2,2 | 47 | 50 | 32 | |

| pump KM 65 50 125 | 25 | 20 | 3,8 | 3000 | 4,0 | 62 | 65 | 50 | |

| pump KM 65 50 160 | 25 | 32 | 3,8 | 3000 | 5,5 | 75 | 65 | 50 | |

| pump KM 80 65 160 | 50 | 32 | 4,0 | 3000 | 7,5 | 105 | 80 | 65 | |

| pump KM 80 50 200 | 50 | 50 | 3,5 | 3000 | 15,0 | 185 | 80 | 50 | |

| pump KM 100 80 160 | 100 | 32 | 4,5 | 3000 | 15,0 | 185 | 100 | 80 | |

| pump KM 100 65 200 | 100 | 50 | 4,5 | 3000 | 30,0 | 260 | 100 | 65 | |

| pump KM 150 125 250 | 200 | 20 | 4,2 | 1500 | 18,5 | 265 | 150 | 125 |

Replacement table for cantilever monoblock pumps type KM

| since 1973 | since 1982 | since 1990 |

| 1.5 KM-6 | KM 8/18 | KM 50-32-125 |

| 2 KM-6 | KM 20/30 | KM 65-50-160 |

| 2 K-9 | K 45/30 | KM 65-50-160 |

| 3 KM-6 | KM 45/55 | KM 80-50-200 |

| 4 KM-12 | KM 90/35 | KM 100-80-160 |

| 4 KM-8 | KM 90/55 | KM 100-65-200 |

| 4 KM-6 | KM 90/85 | KM 100-65-250 |

Dimensions of K-type cantilever pumps

| Pump brand | L | l1 | l2 | l3 | l4 | l5 | H | h1 | h2 | B | b | D1 | d1 | n1 | D2 | d2 | n2 |

| To 8 18 | 768 | 120 | 466 | 113 | 308 | 508 | 321 | 185 | 125 | 257 | 215 | 100 | 14 | 4 | 90 | 14 | 4 |

| By 20 18 | 788 | 120 | 466 | 113 | 308 | 508 | 321 | 185 | 125 | 257 | 215 | 110 | 14 | 4 | 100 | 14 | 4 |

| By 20 30 | 832 | 120 | 466 | 113 | 337 | 543 | 343 | 197 | 150 | 357 | 257 | 110 | 14 | 4 | 100 | 14 | 4 |

| K 45 30 | 1030 | 150 | 577 | 147 | 413 | 665 | 415 | 215 | 150 | 332 | 290 | 150 | 18 | 4 | 110 | 14 | 4 |

| K 45 30a | 973 | 150 | 577 | 147 | 413 | 644 | 343 | 215 | 150 | 304 | 252 | 150 | 18 | 4 | 110 | 14 | 4 |

| K 90/20 | 1030 | 150 | 665 | 147 | 413 | 665 | 413 | 215 | 150 | 332 | 290 | 170 | 18 | 4 | 150 | 18 | 4 |

| K 50 32 125 | 800 | 80 | 465 | 120 | 450 | 710 | 297 | 172 | 140 | 368 | 270 | 110 | M12 | 4 | 100 | 18 | 4 |

| K 65 50 125 | 730 | 80 | 385 | 120 | 500 | 765 | 325 | 172 | 140 | 368 | 290 | 130 | M12 | 4 | 125 | 18 | 4 |

| K 65 50 160 | 865 | 100 | 465 | 135 | 480 | 765 | 338 | 192 | 160 | 397 | 320 | 145 | M16 | 4 | 125 | 18 | 4 |

| K 80 65 160 | 925 | 100 | 485 | 120 | 480 | 792 | 395 | 220 | 180 | 427 | 350 | 160 | M16 | 4 | 145 | 18 | 4 |

| K 80 50 200 | 1120 | 100 | 485 | 160 | 600 | 886 | 455 | 230 | 200 | 458 | 380 | 160 | M16 | 4 | 125 | 18 | 4 |

| K 80 50 200a | 990 | 100 | 485 | 160 | 530 | 834 | 425 | 230 | 200 | 428 | 350 | 160 | M16 | 4 | 125 | 18 | 4 |

| K 100 80 160 | 1235 | 100 | 600 | 167 | 680 | 1020 | 455 | 230 | 200 | 458 | 380 | 180 | M16 | 8 | 160 | 18 | 4 |

| K 100 80 160a | 1105 | 100 | 600 | 167 | 600 | 971 | 425 | 230 | 200 | 458 | 380 | 180 | M16 | 8 | 160 | 18 | 4 |

| K 100 65 200 | 1290 | 100 | 600 | 167 | 770 | 1094 | 510 | 250 | 225 | 498 | 420 | 180 | M16 | 8 | 145 | 18 | 4 |

| K 100-65-200a | 1265 | 100 | 600 | 167 | 700 | 1051 | 475 | 250 | 225 | 498 | 420 | 180 | M16 | 8 | 145 | 18 | 4 |

| K 100 65 250 | 1390 | 125 | 625 | 237 | 700 | 1194 | 605 | 270 | 250 | 568 | 490 | 180 | M16 | 8 | 145 | 18 | 4 |

| K 100-65-250a | 1345 | 125 | 625 | 237 | 700 | 1194 | 605 | 270 | 250 | 568 | 490 | 180 | M16 | 8 | 145 | 18 | 4 |

| K 150-125-250 | 1335 | 140 | 670 | 237 | 700 | 1102 | 455 | 320 | 335 | 475 | 395 | 240 | M20 | 8 | 210 | 18 | 8 |

| K 150-125-315 | 1375 | 140 | 690 | 275 | 700 | 1170 | 610 | 355 | 540 | 430 | 240 | M20 | 8 | 210 | 18 | 8 | |

| K 200-150-315 | 1665 | 160 | 830 | 350 | 770 | 1410 | 720 | 385 | 400 | 600 | 520 | 295 | M19 | 8 | 240 | 22 | 8 |

| K 200-150-250 | 1375 | 160 | 690 | 275 | 700 | 1170 | 610 | 350 | 375 | 540 | 430 | 295 | M20 | 8 | 240 | 22 | 8 |

| K 200-150-400 | 1790 | 160 | 830 | 150 | 600 | 1550 | 825 | 435 | 450 | 795 | 700 | 295 | M20 | 8 | 240 | 22 | 8 |

| K 160 30 | 1515 | — | — | — | — | — | 555 | — | — | 575 | — | — | — | 8 | — | — | 8 |

| K 290 30 | 1645 | — | — | — | — | — | 630 | — | — | 585 | — | — | — | 8 | — | — | 8 |

Dimensions of cantilever monoblock pumps type KM

| Pump brand | L | l1 | l2 | H | h1 | h2 | B | b | D1 | d1 | n1 | D2 | d2 | n2 |

| KM 50-32-125 | 500 | 80 | 226 | 230 | 112 | 140 | 190 | 140 | 110 | M12 | 4 | 100 | 18 | 4 |

| KM 65-50-125 | 550 | 80 | 247 | 272 | 112 | 140 | 210 | 160 | 130 | M12 | 4 | 125 | 18 | 4 |

| KM 65-50-160 | 578 | 100 | 267 | 272 | 132 | 160 | 230 | 190 | 145 | M16 | 4 | 125 | 18 | 4 |

| KM 80-65-160 | 635 | 100 | 272 | 435 | 160 | 180 | 265 | 212 | 160 | M16 | 4 | 145 | 18 | 4 |

| KM 80-50-200 | 790 | 100 | 293 | 420 | 160 | 200 | 265 | 212 | 160 | M16 | 4 | 125 | 18 | 4 |

| KM 100-80-160 | 790 | 100 | 293 | 420 | 160 | 210 | 280 | 212 | 180 | M16 | 8 | 160 | 18 | 4 |

| KM 100-65-200 | 865 | 100 | 293 | 460 | 180 | 225 | 320 | 250 | 180 | M16 | 8 | 145 | 18 | 4 |

| KM 150-125-250 | 895 | 140 | 335 | 705 | 250 | 355 | 400 | 315 | 240 | M20 | 8 | 210 | 18 | 8 |

Characteristics of KM cantilever pumps with a mechanical seal.

| Pump brand. | Nom. flow rate, m3/hour | Nom. head, m | Kavita tion reserve, m | Power el/dv.kW | Weight, kg | Dimensional Dimensions. |

| Pump KM 40-25-160/2-5 | 6,3 | 32 | 3,5 | 2.2 | 40 | 448x320x320 |

| Pump KM 40-25-160b/2-5 | 6,3 | 20 | 3,5 | 1.5 | 35 | 428x320x320 |

| Pump KM 40-32-180/2-5 | 10 | 45 | 4,0 | 3.0 | 53 | 467x290x345 |

| Pump KM 40-32-180a/2-5 | 6 | 40 | 4,0 | 2.2 | 36 | 486x290x345 |

| Pump KM 40-32-200/4-5 | 6,3 | 12 | 2,8 | 1.1 | 36 | 455x230x392 |

| Pump KM 50-32-125/2-5 | 12,5 | 20 | 2,5 | 2.2 | 38 | 488x210x373 |

| Pump KM 50-32-125a/2-5 | 12,5 | 16 | 3,5 | 1.5 | 36 | 463x210x373 |

| Pump KM 50-32-200/2-5 | 12,5 | 50 | 3,3 | 5.5 | 60 | 515x320x360 |

| Pump KM 50-32-200a/2-5 | 12,5 | 32 | 3,3 | 3.0 | 51 | 485x320x360 |

| Pump KM 65-50-125/2-5 | 25 | 20 | 3,0 | 2.2 | 42 | 490x270x370 |

| Pump KM 65-50-125a/2-5 | 25 | 15 | 3,8 | 2.2 | 42 | 490x270x370 |

| Pump KM 65-50-125b/2-5 | 25 | 12,5 | 3,8 | 2.2 | 42 | 455x270x370 |

| Pump KM 65-50-160/2-5 | 25 | 32 | 3,0 | 5.5 | 55 | 571x320x330 |

| Pump KM 65-50-160a/2-5 | 25 | 26 | 3,8 | 4.0 | 45 | 564x320x330 |

| Pump KM 65-50-160b/2-5 | 25 | 20 | 3,8 | 3.0 | 41 | 485x320x330 |

| Pump KM 80-65-160/2-5 | 50 | 32 | 4,0 | 7.5 | 82 | 603x334x362 |

| Pump KM 80-65-160a/2-5 | 50 | 26 | 4,0 | 7.5 | 82 | 603x304x362 |

| Pump KM 80-65-160b/2-5 | 50 | 20 | 4,0 | 5.5 | 82 | 595x304x362 |

| Pump KM 80-50-200/2-5 | 50 | 50 | 3,0 | 15.0 | 194 | 755x384x455 |

| Pump KM 80-50-200a/2-5 | 50 | 40 | 3,5 | 11.0 | 130 | 660x346x402 |

| Pump KM 80-50-200b/2-5 | 50 | 30 | 3,5 | 11.0 | 130 | 660x346x402 |

| Pump KM 125-80-200/4-5 | 80 | 12,5 | 3,0 | 5.5 | 110 | 648x324x447 |

| Pump KM 125-80-200a/4-5 | 80 | 7 | 3,5 | 4.0 | 100 | 570x294x420 |

| Pump KM 100-65-200/2-5 | 100 | 50 | 5,2 | 30.0 | 226 | 830x409x485 |

| Pump KM 100-65-200a/2-5 | 100 | 38 | 5,2 | 18.5 | 205 | 784x384x455 |

| Pump KM 100-65-200b/2-5 | 100 | 32 | 5,2 | 15.0 | 170 | 754x384x455 |

| Pump KM 100-65-200v/2-5 | 100 | 47 | 5,2 | 22.0 | 210 | 770x409x495 |

| Pump KM 100-80-160/2-5 | 100 | 32 | 5,2 | 15.0 | 182 | 740x384x455 |

| Pump KM 100-80-160a/2-5 | 100 | 21 | 5,2 | 11.0 | 140 | 645x346x402 |

| Pump KM 100-80-160b/2-5 | 100 | 18 | 5,2 | 7.5 | 110 | 590x320x382 |

| Pump KM 100-65-200/4-5 | 50 | 12,5 | 5,0 | 4.0 | 80 | 553x230x437 |

| Pump KM 100-65-200a/4-5 | 42 | 7,7 | 6,5 | 2.2 | 61 | 518x230x437 |

| Pump KM 100-65-200d/4-5 | 50 | 14 | 5,0 | 4.0 | 80 | 553x230x437 |

| Pump KM 160/20-5 | 160 | 20 | 3,5 | 15.0 | 290 | 806x340x545 |

| Pump KM 125-100-160/2-5 | 160 | 30 | 4,2 | 22,0 | 220 | 800x420x510 |

You can purchase console pumps by calling us at (495) 6-618-718, (495) 665-20-55 or sending a request by email to

Send a request

Advantages of our company

WORK GUARANTEE We provide long-term guarantees for all services of our company

FAVORABLE PRICES We cooperate directly with manufacturing plants

EXTENSIVE WORK EXPERIENCE We have been successfully working for more than 17 years

QUALITY SERVICE You will be pleased that you contacted us!

Units of categories “KM” and “K”

The following devices should be classified as the main structural elements of any cantilever centrifugal pump:

- support bracket;

- replaceable protective sleeve;

- stuffing box elements;

- impeller and shaft;

- bearing assembly;

- product body.

Pumping equipment has many varieties, but one of the most common is cantilever, monoblock pumps, the abbreviation “KM” will be on the body. Such models are characterized by high power, so they are usually used in production and when setting up utility networks. High-power industrial pumps belonging to the “KM” category have the following list of negative characteristics:

- the inconvenience and difficulty of carrying out the necessary replacement of the electric motor, provided that this is necessary;

- the necessary repair work will require more effort, time and money when compared with the work carried out with category “K” pumps;

- insignificant indicator of reliability of seal units;

- heavy weight and very large dimensions.

Operating principles

The operating principle of cantilever centrifugal pumps consists of the following sequence of manipulations:

- After connecting the device to the network, the electric motor drive will begin to rotate along with the impeller on which the blades are located.

- After passing through the space located inside the chamber where the pump pipes are located, a certain vacuum of air masses will be created, which will facilitate the absorption of a certain amount of the working medium through the existing pipe.

- The working medium entering the cantilever pump will move like the wheel blades, which will lead to an increase in the pressure of the transported liquid at the location of the discharge pipe and its subsequent expulsion through the pipeline system.

By rotating the wheel of a cantilever-type pump, which contains blades, a centrifugal force occurs, which affects the speed of movement of the working medium inside the system. You should also pay attention to the fact that if you are using a cantilever-type pump, the main task of which is to ensure water supply, then it is necessary to select it as correctly as possible. If you give preference to high speed, the vacuum in the system may be insufficient and this will not have the best effect on the efficiency of the entire system.

If the wheel rotates at a very high speed, then the water will no longer flow as a liquid, but in the form of steam, which will then begin to condense. This will inevitably lead to the formation of cavitation. That is why it is recommended to carefully familiarize yourself with the available data regarding the system used and only then select the necessary equipment, based, first of all, on the technical characteristics of the products.

Installation work

Carrying out the necessary installation work should be based on a number of basic parameters:

- if necessary, a barrier fluid can be used; its smooth supply should be ensured (it is also possible to install full-fledged drainage systems);

- at the outlet and inlet of the equipment, to carry out the necessary control over the pressure indicator of the working medium, a special pressure gauge is used;

- a check valve should be installed at the equipment outlet;

- the pipe located on the suction side can be installed with a slight inclination relative to the container being used;

- the pipeline must be fixed on free-standing supports to avoid significant load on the flange pumps;

- temperature compensators will be needed on all incoming parts of the system;

- the pump is installed in an easily accessible place.

Only after this should the system be checked for tightness and strength, which is regulated by the rotor. Before starting the system for the first time, you should check its serviceability and pressure readings using a pressure gauge.

Making the right choice

In order for a cantilever-type pump to be used for pumping clean water and to be as efficient as possible, it must also be selected correctly. And for this it is necessary to use the basic characteristics of the pipeline used, for which it is planned to purchase auxiliary equipment.

The list of manufactured products can be found in one of the many catalogs, which present a wide selection of all kinds of industrial equipment and give a clear description of the technical characteristics of the equipment presented. In addition, such catalogs also contain drawings of the equipment used and its installation dimensions. Such catalogs must be familiarized with at the planning stage of the water supply system.

Performance characteristics

The unit is suitable for use in temperate and cold macroclimatic areas with the third category of placement according to GOST 15150-69. Operation is permitted only in indoor areas with natural ventilation.

The products meet all safety requirements, as well as Russian and international quality standards.

The price of a KM pump ranges from 4 to 70 thousand rubles and depends on the modification and technical characteristics. The cost of the KM pump can be found in the price list.

To purchase high-quality equipment at the best price, contact the company's Sales Department or place an order online on our website.