For convenient organization of storage of tools and auxiliary equipment, special panels with perforations are produced, which are also called cabinets and layouts. Their design, composition of materials used and functionality allow you to arrange a compact storage facility for any need. In particular, perforated panels can be used for long-term storage of tools, as well as for temporary use on a repair or construction site. Depending on the nature of use, it is worth paying attention to the additional properties of the layouts. Some models have fire-resistant and water-repellent coatings, and there are also varieties with a decorative effect.

What is a toolbar?

In the traditional version, it is a sheet of metal or wood-based material. Its main difference from other panels is the presence of holes in the working area. Actually, these perforations allow you to comfortably place and subsequently use small-sized equipment, tools and building materials. The perforated tool panel is attached in different ways. In most cases, fixation is ensured by special hardware to the wall. But there are also cabinet panels that can be installed without additional fastening. The layout itself takes up virtually no space - merging with the wall, it only provides the opportunity for convenient placement of tools. However, a lot depends on the additional fasteners used to hang and hold the equipment.

Types of sheets depending on perforation

The sheet perforation dimensions, hole orientation, and perforation pitch on each sheet may be different. The customer can choose these parameters independently or buy one of the standard offers.

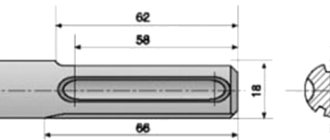

To make it easier to choose the type of sheet, they are marked. For example, a perforated sheet, the thickness and dimensions of which are standard, has the inscription Rg 8-18, which means:

- R - sheet with round holes;

- g — straight orientation of the notches;

- 8 — die-cut diameter;

- 18 — perforation step.

There are a great variety of such sheets, the main thing is to understand the markings and then it will be easier to choose.

Where are perforated layouts used?

The scope of application of such devices is not limited. We can say that wherever construction tools are used, their use will be justified. Another thing is that in each case a panel with certain characteristics is required. For example, a perforated panel for tools with small dimensions will come in handy in a garage or utility room. For professional workshops, it is better to choose a durable metal structure that meets the needs of workers in a particular industry. Multifunctional panels in the form of modules and screens are widely used in industry and manufacturing. In addition, in construction stores, such layouts have found their place in arranging display cases for displaying goods.

Panel sizes

A variety of standard sizes of tool panels allows you to organize storage space in almost any room. On average, the width of the sheets is 100 cm and the height is 200 cm. For garages and workshops, models with large dimensions are provided, in which the width can exceed 2 meters. However, the height limit, as a rule, does not exceed the two-meter level, since using such a device is not very convenient. If we talk about the minimum dimensions, then perforated panels can reach a width and height of 50 cm and 100 cm, respectively. It should be understood that the dimensions are calculated based on the overall dimensions of the structure. The working surface itself may have more modest dimensions. That is, if the height of the reshaped sheet is 150 cm, then, depending on the model, the surface with holes in use may only have 100 or 50 cm. These are standardized parameters, but the market offers many other standard sizes. The thickness of the panel varies on average from 1 mm (steel sheets) to 7 cm (wood-chip models).

Panels made of wood-based material

Material is one of the main criteria from which you should start when choosing a panel. Wood rarely provides adequate durability under heavy use, yet quality perforated MDF panels can provide some benefits. Taking into account the average strength characteristics of the material, manufacturers produce such sheets in small formats. The standard size for them is 60x60 cm. In this proportion, the sheet retains its integrity and does not bend or deform. In addition, it is easy to carry from place to place and secure.

There is one more feature that distinguishes such products. As the manufacturers write in the instructions, perforated MDF panels are designed to contain oversized hand tools, that is, screwdrivers, wrenches, hammers, etc. Also, when purchasing a model from MDF, operating conditions should be taken into account. High temperatures and high humidity do not contribute to the long service life of the product.

Metal panels

This is the most common type of perforated layouts. In this case, there are practically no restrictions on standard sizes and conditions of use. Perforated metal panels are made from galvanized steel. Therefore, there is no need to think about the development of corrosion. However, budget models often do not have such coverage.

In terms of operation, metal layouts are more profitable than their wooden counterparts, as they allow you to service fairly heavy power tools, massive spare parts and small building structures. But this applies to large-format versions, the thickness of which is at least 3 mm. For smaller panels, a relatively lightweight tool is still recommended. Among the disadvantages that perforated metal panels have, it is worth noting the need to install horizontal slats to fix the sheet, as well as the high cost compared to models from the same MDF.

Perforated panels - description and materials

The panel is a sheet of wood-based material or metal with stiffening ribs along the edges and perforations on the working plane. Such holes allow you to conveniently place and comfortably use tools, small-sized equipment, and building materials.

Layouts with perforation allow you to save workplace space, keep the necessary tool always at hand and control its availability. A workshop equipped with such panels will have a modern look, and various working tools will always be at hand.

Perforated sheets are attached to special brackets, and tools are placed on them using holders, shelves and hooks. However, on sale you can find panel cabinets that are mounted without any fastenings.

Dimensions of sheets with perforation:

- On average, the height of such products is 200 centimeters and the width is 100 centimeters. Sheets with large dimensions can be produced for various workshops and garages. Their width can exceed more than two meters.

- The minimum layout size is 50 centimeters wide and 100 centimeters high.

- The thickness of wood-shaving sheets can be up to 7 centimeters, and metal ones - from 1 millimeter.

- The perforation diameter is 5 millimeters, and the distance between the holes is 15 millimeters. This allows you to fill the panel as tightly as possible and at the same time arrange everything conveniently.

- The step between the centers of fastening the hooks is 30 millimeters.

However, we must remember that the dimensions are calculated based on the overall dimensions of the product, while the working surface itself most often has rather modest dimensions. That is, with a structure height of 150 centimeters, the perforated surface used can only account for 50 or 100 centimeters .

The building materials market offers many different standard sizes of panels, so there is plenty to choose from for arranging any workplace.

The areas of application of perforated layouts are unlimited, however, for each case you should select a product with certain characteristics:

- durable metal structures are well suited for professional workshops;

- small sheets will come in handy in a farmstead or garage;

- multifunctional layouts in the form of screens and modules are widely used in production and industry;

- Products with various additions have found their use in arranging display windows in hardware stores.

Metal perforated panels

Affordable layouts for storing tools are easy to install and easy to use.

Advantages of metal products:

- perforated panels are resistant to humidity and temperature changes;

- they are environmentally friendly, as they are produced without toxic compounds;

- there are practically no restrictions in the conditions of use and standard sizes;

- The layouts made of galvanized steel are not subject to corrosion;

- with their help you can service both small building structures, massive spare parts, and heavy power tools;

- The outer laminated layer of the products is resistant to minor damage;

- You can create special perforations in metal sheets, which allow you to attach various hooks and canopies to them.

Most often, perforated panels are made in two colors . They can be white or natural wood.

The disadvantages of metal layouts include:

- Mandatory fastening for fixing a sheet of horizontal slats.

- Compared to MDF models, the price is quite high.

Perforated wood-based panels

When choosing MDF layouts, you should keep in mind that under conditions of increased use they are not able to provide adequate wear resistance.

Due to the low strength of the material, tool storage products are manufactured in small formats. Their standard size is 60x60 centimeters. Such layouts are quite durable, do not deform or bend . In addition, they are easy to transport and install in the right place.

Perforated MDF panels are designed for storing oversized tools only. With their help, you can conveniently place and operate hammers, wrenches, screwdrivers, etc. At the same time, when choosing such products for your workplace, you must remember that with high humidity and high temperatures, their service life will not be long.

Panel placement methods

There are several approaches to installing perforated sheets. For example, rear layouts are installed vertically to racks made of pipes or corresponding profiles. Modular systems or screens can be located in the middle of rooms, also performing a zoning function. But the most popular type of such structures is a perforated wall panel, which is secured with special screws. It is fixed directly to the wall, which saves space without losing ease of use. It is worth noting that the approach to placing additional structural elements may also depend on the method of fastening the panel.

Methods for installing perforated layouts

The panels can be placed on various surfaces.

Wall sheets are the most popular type of design. They are fixed directly to the wall and secured with special screws. With the help of such layouts, you can save room space and, at the same time, comfortably use the work tool.

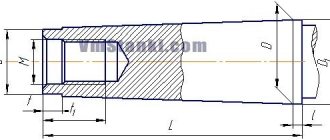

Panels with perforations for a bench workbench are made according to the length of the unit. Their size can be selected for a two-stand, single-stand or bas-stand workbench. The structures are fastened using special brackets and racks. In addition, two panels can be installed on the workbench at once.

In the middle of the room you can place modular screens or systems . They will also perform a zoning function.

Rear layouts can be conveniently placed on pipe racks or other suitable profiles.

It is worth noting that the placement of various additional elements depends on where and with what help the panel is installed.

Accessories for perforated layouts

One panel for containing and storing a tool is rarely enough, so they are initially equipped with special fasteners and holders. The most popular types of such fittings are:

- Fixation of hand tools and oversized equipment is provided by special hooks for perforated panels, as well as clamps and holders of suitable shapes and sizes.

- Tools with a cylindrical shape are effectively secured using multi-position profile holders. In particular, they are convenient for placing screwdrivers, cylindrical bits and various heads.

- The shelves allow you to conveniently place construction mixtures, jars of adhesives and other accessories. The parameters of such shelves are varied, but when choosing, you should take into account the load on the panel.

- To fix tools with any shape, multi-place hooks with grooves are used. They can be used to secure, for example, side cutters and pliers.

The fittings are predominantly made of steel and are fastened with self-tapping screws. It is advisable to equip perforated panels with holders of different sizes or universal fittings, which will allow you to place the maximum number of tools in a small layout area.

Accessories for panels with perforation

It is rare that only a sheet with holes is enough to contain a tool. Therefore, most often, perforated layouts are sold complete with various holders and fasteners.

- It is very convenient to use hooks on which you can hang tools, keys, and related materials. Most often they are made of steel wire. Special ties are included to attach the hooks to the sheet. Rounded hooks attached to a special surface can provide a reliable suspension, as they prevent the tool from easily sliding off. Special hooks for pliers will help you clean up and organize your set of technical tools. They are easy to fasten and thus ensure a reliable fixation of the tool.

- Multi-position profile holders are effectively used for fastening cylindrical working gear. It is convenient to place attachments, screwdrivers and various heads on them.

- One type of fastening is holders for drills and screwdrivers. They are made from steel coated with a rubberized coating, which protects the tool located on a perforated sheet from damage.

- Multiple hooks with grooves are used to store tools of any shape. They can be used to hold pliers, side cutters, etc.

- On the shelves and trays you can store small parts such as screws, bolts, nuts. To make it easy to remove small parts from the trays, their front edge is made beveled. On the shelves you can place various jars of adhesive, construction mixtures and other accessories. Trays and shelves are made from steel wire with a diameter of 3 millimeters, which ensures their reliable fastening. The parameters of such holders can be very diverse, so when choosing them you should take into account the load on the panel.

Mobile toolbars

The ability to move a structure with equipment or hand tools is not superfluous. In large industries, such a layout can be moved between work areas, and in a private home it is convenient when performing repairs. To ensure mobility, perforated panels are equipped with wheels or rollers. Roller systems are considered more convenient from the point of view of operation, but the arrangement of such models is much more complicated and expensive. Panels on wheels are not so stable and require delicate handling - in private households this is the best option if a mobile structure is needed.

Panels with decorative effect

One type of perforated panel is HDF sheets made from solid fibreboard. Their main purpose is to provide an aesthetic effect, as well as zoning premises. Along with increased strength and decorativeness, perforated HDF panels are environmentally friendly, since phenol is not used in the manufacture of boards. Such products can be used as camouflage elements of the interior. For example, HDF sheets are often used as grilles for heating radiators. The physical and operational properties of the material allow it to cope with temperature and humidity influences.

Types of perforated panels

Layouts with decorative effect

To ensure an aesthetic effect, HDF perforated sheets are made from solid fibreboard. With their help, you can mask some interior items, as well as divide the room into separate zones.

Such designs are durable and decorative . No phenol is used in their production, so they are environmentally friendly. Wood-fiber material is able to cope with damp and any temperature influences, so layouts made from it can be installed in almost any room.

Mobile structures with perforation

Sometimes it is necessary to move or transfer sheets of equipment to another location or room.

The most convenient way to do this is with the help of special mobile layouts equipped with rollers or wheels. Roller systems are more convenient for moving . However, they are more difficult to install and are quite expensive. Products on wheels are less stable and therefore require careful handling.

Mobile layouts can be used during renovations in an apartment, as well as in large industries between work areas.

Industrial screens

This is a complicated version of the tool panel, the design of which is formed by the same elements. A special feature of the industrial screen is the presence of several racks equipped with various holders and fastenings for tools. In large industries, such structures are often used as soundproofing barriers. Also, an indispensable condition for the operation of panels at industrial facilities is the presence of a fire-retardant coating. You can assemble such a screen from individual panels, but it is better to purchase a complete set with elements that match each other in size.