A winch is a unit that is used to move or vertically lift heavy structures using a flexible cable, rope or chain. The latter are connected to a drum, which can have several drive options.

The simplest of them is manual: it is more durable than the others, but it is not suitable for daily use and heavy loads: the operator will quickly get tired. Electric winches are reliable, structurally perfect and solve a much wider range of problems than manual ones. The only negative is the dependence on power supply, which is not always available in the field or on rough terrain. The most practical and trouble-free unit is a winch based on an internal combustion engine: it creates high power and works in any conditions, even in places where no one has gone before.

Unfortunately, production models of such equipment cost a lot, and not everyone can afford them. In this case, homemade products come to the rescue - homemade winches driven by a chainsaw or special ready-made adapters that will turn an ordinary household chainsaw into a miniature analogue of a crane - a motorized winch. Let's take a closer look at how you can do this at home.

Winch attachment for a chainsaw - advantages and functions

Making your own towing mechanism from a chainsaw requires the use of certain tools.

However, not everyone has the necessary dexterity when working with a drill and welding machine. In this case, you can buy an attachment that is equipped with a household chainsaw. The winch attachment for a chainsaw is small in size and simple in design. It is easy to install by connecting the elements necessary to transmit torque to the engine. If necessary, the product can be removed. On average, this takes no more than 5 minutes.

Today, towing attachments are produced by many well-known manufacturers. These structures can be used for towing cars weighing up to 2.5 tons, as well as for clearing the local area and roadway from fallen trees or concrete damage.

The “Winch” attachment for a chainsaw is a simplified way to make a traction structure out of a chainsaw

Designing and assembling a winch from a chainsaw with your own hands, although it does not require global technical knowledge, does require a certain skill, which not everyone has. For most, an easier way is to purchase a ready-made set - a “Winch” attachment.

Additional devices - “Winch” attachments for chainsaws are produced for most modern chainsaws and differ in traction force, cable length and dimensions. With their help, you can easily move a fallen tree from the roadway, pull a car out of a ditch, moor it to the shore, or clear debris in case of an emergency.

Types of homemade winches

Any drawing will tell you how to assemble a useful device. A car winch remains a necessity, so don't give it up. First, you should get acquainted with the available options that guarantee ease of assembly. There are the following types of these devices:

Homemade winch - a simple device

In accordance with the schemes used, it will be possible to select the optimal winch. If desired, a person will independently make a suitable model that will meet his needs. This is why it is worth considering each type in detail, giving it a general description.

Manual

A homemade hand winch is an excellent choice that guarantees ease of operation. This is its main advantage, allowing you to freely use the device without facing the problem of a low battery. The only problem is that it requires a lot of effort.

The design of such an accessory becomes complex. Calculations must be made to obtain sufficient power. Otherwise, it will correspond only to the physical strength of a person. He will not be able to pull the SUV out of the ditch, so the installation will not give successful results.

A manual winch from the starter is the most affordable option that you can choose for your own car.

By using it, you will be able to quickly assemble a reliable structure that can cope with the task in any weather.

How to extend the life of a homemade mechanism?

The reliability of a homemade winch directly depends on the quality of its assembly. In addition, there are a number of other factors that affect the duration of the application of the mechanism.

These include:

- well-coordinated clutch operation. To do this, the owner of a chainsaw winch must constantly monitor the condition of the main parts of the unit. If necessary, any worn part must be replaced;

- ideal engine condition - operation of the mechanism is not allowed if the engine is not running well. This will not only lead to increased wear on the internal combustion engine, but will also increase the risk of damage to the object that needs to be pulled out. The engine must operate equally stably, both at idle and at high speeds;

- reliability of fastening of safety elements. During intensive use of a homemade winch, you need to regularly check the condition of the anchor hooks, belts and other parts. If at least one of the spare parts is faulty, this will increase the risk of injury to the operator and loss of the towed object;

- correct operation of the starter. If the trigger mechanism works intermittently, then this will turn the use of the winch into a real test for its owner;

- reliability of the tow rope. Safety when working with the mechanism depends on its serviceability. If one of the cable strands breaks, it will need to be completely replaced;

- proper quality of fuel and oil. In order for the engine to last for a long time, you need to use only high-quality branded oils and gasoline with an octane number not lower than that specified in the instructions to refuel it.

A winch driven by a chainsaw can last much longer than its full-fledged branded counterparts. However, to do this, you need to regularly check it and replace faulty parts immediately after detecting a breakdown.

Preparing for self-assembly

Immediately before making a homemade device, you will need to study the drawings. The diagrams must indicate the mounting capabilities of all parts used, as well as their dimensions.

To work you also need to first prepare:

- engine from a household chainsaw complete with fuel tank, carburetor and drive. The required petrol engine power is from 3 liters. With. and higher;

- gearbox - this mechanism is necessary to reduce the generated torque that the engine generates;

- drum - you can find it at the old equipment market. An element from an old winch or a homemade device made from sheets of forged steel will do;

- cam clamps - required to fix the drum in a stationary state;

- lever - needed to turn the engine on and off;

- clamps - with their help the gearbox is connected to the internal combustion engine of the chain saw.

A winch driven by a chainsaw must be equipped with a reliable metal cable that can withstand significant tensile strength and abrasion.

Chainsaw winch - design, features, attachment

A winch is a stationary or portable equipment whose main function is to pull or tow large objects.

This device can be made from available materials, for example, from an old chainsaw.

In the future, the finished winch can be installed on a car or tractor in order, if necessary, to remove a stuck vehicle or tow another agricultural implement to the nearest workshop.

What are the advantages of homemade winch assembly?

A homemade chainsaw winch allows the manufacturer to save a significant amount of money.

In addition, assembling the necessary device with your own hands gives the designer several other advantages:

- the ability to manufacture a winch with the dimensions needed for further unhindered installation and operation;

- the ability to use during manufacturing those components that are at hand;

- ease of regular maintenance;

- ease of self-repair.

In addition, a winch driven by a chainsaw does not need to be constantly connected to an electrical power source. It does not need to be connected to a battery, which saves battery life. It is enough to fill the device with a small amount of fuel mixture prepared from high-quality gasoline and branded semi-synthetic motor oil.

DIY chainsaw winch

Having collected everything necessary for work, the manufacturer can begin directly assembling the winch.

To do this you will need:

- Weld a strong frame that is highly resistant to vibration and shock. The base of the frame is a thick steel plate, to the back of which the internal combustion engine from the chainsaw will be attached, and to the middle - a drum with a cable wound around it. The gearbox, control mechanism and other auxiliary elements must be attached to the plate using bolted connections and ties;

- Attach the motor and drum. If there is another chainsaw on the farm, then the power unit from the gas-powered tool used can be welded with a thick continuous seam. This will give the overall structure stability and increased endurance. It is also best to secure the drum by welding;

- Connect the gearbox used to the motor. Mechanisms must be secured using clamps. The connection of the element itself must be done using a shaft - it will play the role of a link connecting the motor and the moving drum with the cable;

- To be able to automatically start the drum, you need to connect the winch control lever to it. The lever must be connected to the shaft using cam clamps. Thus, when moving the lever to one side, the drum will begin to rotate, and when changing the position of the lever, it will stop and lock in the position required for towing;

- To assemble the anchor, you can use pointed corners. With its edges, the element must firmly and motionlessly stick into a stationary object;

- The anchor must be attached to the frame using hinges. A steel holder will be responsible for lifting the element in the winch device.

After assembling the device, it must be tested. The operator should first test the equipment with light weights. If, while dragging, the chainsaw winch does not make any extraneous sounds and confidently copes with the load, then you can proceed to checking the homemade product with a larger load.

Winch attachment for a chainsaw - installation and operation features

Some well-known brands produce ready-made accessories for their chainsaws, technologically manufactured in the form of small portable attachments. These manufacturers include Stihl, Husqvarna, Patriot, Champion and AL-KO.

The winch attachment for a chainsaw is easy to install and remove. To install the equipment, you will need to first dismantle the cutting parts of the chainsaw. In this case, the clutch elements of the tool must remain in place. Next, you need to install the winch on the shaft, first putting the standard gearbox on it, and then all the other elements of the attachment.

Despite its relatively small size, the branded winch for a chainsaw stands out for its fairly high traction characteristics. It is capable of short-term towing of vehicles weighing up to 1 ton, as well as gradual removal of a stuck object weighing 1.2–1.5 tons.

Ready-made attachments in the form of winches do not require regular maintenance or frequent repairs. All the operator needs is to monitor the condition and winding of the tow rope, and also check the level of fixation of the standard bolted connections of the equipment.

Homemade chainsaws

Russians have long been distinguished for their ingenuity. Even the most primitive objects, using imagination and ingenuity, can be turned into a work of art or some useful item.

Motorized winch made from a chainsaw

Many owners living in the private sector have an old chainsaw in stock, usually a “Druzhba” or “Ural”. However, they sometimes use a saw when preparing firewood.

Folk experts found another use for it, coming up with the idea of making it into a motorized winch with a set of rope-traction tools.

From now on, it has become easier to plow the ground for planting vegetables, hill up, dig, and plow the land.

The traction device with a saw weighs approximately 40 kilograms, so it will be quite easy to master the new tool on the site. The implements used in processing are equipped with wheels, and therefore the device can be rolled across a field or piece of land with ease and ease.

The plow is able to stay in the furrow on its own, without requiring the use of physical force by the plowman. So, thanks to the tool, the plowed strip has a depth of 20 centimeters.

When planting potatoes in ridges at the end of plowing, the plow is replaced by a hiller, equipped with the same wheel drive. Thus, the motorized winch can cut even ridges. As soon as the time for hilling comes, the winch will quickly float across the site, leaving behind only loosened rows.

As soon as the opportunity arises to dig up potatoes, we enrich the device with a redeemer, attach it to a winch, and then work through each row of land.

You can also use a chainsaw to make a sawing tool like a huge grinder. It is worth noting that the idea of creating such a tool is quite popular.

Bulgarian

A portable power station from a chainsaw engine is quite possible when you have the time and desire.

How to make a scooter that runs on gasoline

Using a regular old scooter and a chainsaw engine, you can build your own gasoline-powered vehicle.

What you will need:

- Chainsaw engine (in a metal or plastic case)

- Chain

- Various bolts, nuts and washers

- Manual accelerator from a mountain bike

- Switch

- Electric drill

- Chain link removal tool (to ensure good bike chain tension)

- Optional: welding equipment

- Make sure you have a handbrake!

1. Find a scooter with a hand brake and inflatable wheels. Scooters with hand brakes have better stopping power. Inflatable wheels allow the vehicle to better overcome uneven terrain. You can also assemble the scooter frame (welding will be required).

2. Prepare the chainsaw engine by removing the bar and chain. Leave the remaining parts untouched. Keeping the motor in the housing will make it easier to attach to the scooter platform.

3. Unscrew the centrifugal clutch from the crankshaft. The power from the motor will be transmitted through sprockets and a bicycle chain. The obvious problem is the fact that you will not be able to stop the running engine with the scooter stationary, and you will also have to lift the rear wheel off the ground to start it.

You can also keep the clutch and use a chain that fits the sprocket on the clutch flange. If your chainsaw has a two-stroke engine (you will have to add oil to gasoline), then keep the centrifugal clutch.

Rolling down a slope without a clutch will eventually cause the engine to burn out, as the engine will be forced to run without the lubrication of the mixture of gasoline and oil.

4. Bolt the remaining sprockets to the rear axle of the scooter. This may be easier said than done - choose your scooter carefully, understanding that you may need to modify the rear wheel mount and also install sprockets on it.

5. Place the motor on the back of the scooter platform to make sure the stars are in line.

6. Drill holes in the platform and motor housing of the chainsaw so that they can be bolted together. Note that the body is usually made of plastic, so you will need to be extremely careful about where you are going to attach the bolts and the size of washers you use (to prevent them from going through the plastic)

7. Pull the bicycle chain onto the sprockets. Remove the required number of links to keep the chain tight.

8. Attach the hand accelerator to one of the handles.

9. Connect the electric hand accelerator to the on and off wires on the motor from the chainsaw. This allows the scooter operator to control the power supplied to the motor.

The motor provides enough torque to the gears. If the gear slips and does not turn with the axle, the gear may need to be welded. This will provide maximum power and ensure that the transmission will not spin again.

If problems arise when installing a manual accelerator, a small pedal can be used as an option.

You can protect yourself from injury by adding chain guards, open sprocket guards, and protective covering to prevent hands, clothing, and other objects from getting caught in the drive mechanism.

Be careful when using the scooter. It is capable of accelerating to high speeds, which can be dangerous. Try to drive only on relatively smooth roads.

Potholes can lead to unpleasant consequences.

Motorcycle made from chainsaws

This Dolmette chainsaw bike was built a while ago, but I've never seen any build information. What a wonderful design!

The combined power of 24 engines from DOLMAR chainsaws is transmitted to a five-speed Harley Davidson transmission using a set of twelve timing belts. For use in the Dolmette, the motors were tuned and tuned to provide 5.2 kW (7.1 metric hp) power at 10,000 rpm.

The maximum torque is 5.5 newtons per meter at 7,750 rpm. When all 24 engines are put together, the result is a 24-cylinder unit with a total displacement of 1.9 liters, a power output of 125 kW (170 metric hp) and a torque at the centrifugal clutches of 130 newton per meter.

The twelve motors are mounted in two rows of six on each side of the drive belt housing. Each motor is held in place by threaded rods, which are typically used to secure the bar to the power head of the chainsaw. The individual motors are held together in sets of three via double-sided drive belts, creating eight modules.

The individual motors are not rigidly connected - instead they transmit torque through a centrifugal clutch, which is a standard part of every chainsaw.

We make a winch from a chainsaw with our own hands

A winch is a unit that is used to move or vertically lift heavy structures using a flexible cable, rope or chain. The latter are connected to a drum, which can have several drive options.

The simplest of them is manual: it is more durable than the others, but it is not suitable for daily use and heavy loads: the operator will quickly get tired. Electric winches are reliable, structurally perfect and solve a much wider range of problems than manual ones. The only negative is the dependence on power supply, which is not always available in the field or on rough terrain. The most practical and trouble-free unit is a winch based on an internal combustion engine: it creates high power and works in any conditions, even in places where no one has gone before.

Chainsaw winch - design, features, attachment

A winch is a stationary or portable equipment whose main function is to pull or tow large objects.

This device can be made from available materials, for example, from an old chainsaw.

In the future, the finished winch can be installed on a car or tractor in order, if necessary, to remove a stuck vehicle or tow another agricultural implement to the nearest workshop.

What are the advantages of homemade winch assembly?

A homemade chainsaw winch allows the manufacturer to save a significant amount of money.

In addition, assembling the necessary device with your own hands gives the designer several other advantages:

- the ability to manufacture a winch with the dimensions needed for further unhindered installation and operation;

- the ability to use during manufacturing those components that are at hand;

- ease of regular maintenance;

- ease of self-repair.

In addition, a winch driven by a chainsaw does not need to be constantly connected to an electrical power source. It does not need to be connected to a battery, which saves battery life. It is enough to fill the device with a small amount of fuel mixture prepared from high-quality gasoline and branded semi-synthetic motor oil.

DIY chainsaw winch

Having collected everything necessary for work, the manufacturer can begin directly assembling the winch.

To do this you will need:

- Weld a strong frame that is highly resistant to vibration and shock. The base of the frame is a thick steel plate, to the back of which the internal combustion engine from the chainsaw will be attached, and to the middle - a drum with a cable wound around it. The gearbox, control mechanism and other auxiliary elements must be attached to the plate using bolted connections and ties;

- Attach the motor and drum. If there is another chainsaw on the farm, then the power unit from the gas-powered tool used can be welded with a thick continuous seam. This will give the overall structure stability and increased endurance. It is also best to secure the drum by welding;

- Connect the gearbox used to the motor. Mechanisms must be secured using clamps. The connection of the element itself must be done using a shaft - it will play the role of a link connecting the motor and the moving drum with the cable;

- To be able to automatically start the drum, you need to connect the winch control lever to it. The lever must be connected to the shaft using cam clamps. Thus, when moving the lever to one side, the drum will begin to rotate, and when changing the position of the lever, it will stop and lock in the position required for towing;

- To assemble the anchor, you can use pointed corners. With its edges, the element must firmly and motionlessly stick into a stationary object;

- The anchor must be attached to the frame using hinges. A steel holder will be responsible for lifting the element in the winch device.

After assembling the device, it must be tested. The operator should first test the equipment with light weights. If, while dragging, the chainsaw winch does not make any extraneous sounds and confidently copes with the load, then you can proceed to checking the homemade product with a larger load.

How to make a winch from a chainsaw

For plowing, a chainsaw-driven winch has a number of advantages. The main advantage over a motorcycle engine is the speed of installation of the chainsaw. There is no need to design engine cooling, install a fuel tank, air filter, electrical equipment (switch), or wiring. Make a homemade exhaust system. Secure the muffler.

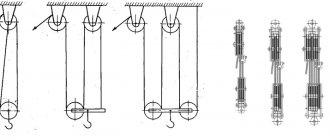

1 – chainsaw; 2 – gearbox; 3 – drum; 4 — drum control lever; 5 – frame; 6 – anchor.

Chainsaw attachment winch

The attachment or attachment is a reduction gear. If you remove the cover and look inside, you will see a whole series of different gears, small and large. With the help of which the number of drum revolutions changes depending on the number of revolutions of the engine crankshaft. In this regard, the load on the power unit is reduced. That's what we need in hard work.

The connection between the attachment and the chainsaw is made using a clamp and a stand. Due to this, the winch is compact and lightweight, easy to use during assembly and repair.

3 – drum; 4 — drum control lever; 5 – frame.

The torque, from the crankshaft, passing through the reduction gearbox, is transmitted to the shaft on which the drum with the cable is located. The drum has the ability to be connected and disconnected from the shaft. It occurs using a lever and special cams located both on the shaft and on the drum. We move it, use the lever towards the chainsaw to connect it, reverse it, and turn it off.

We selected material for the supporting frame of the entire homemade product. Old used water pipes and an unwanted metal bed. For ease of use, the frame is made in the form of a sleigh. During plowing, you do not need to lift the winch, you just need to move it.

It takes a lot of effort to cultivate the soil. Our homemade product turned out to be light, so it needs to be firmly secured to the soil to prevent spontaneous movement towards the plow. For this we installed a special anchor. Attached to the frame using a hinge. By pressing the anchor from above, special knives easily sink into the soil. Hold the homemade product firmly in one place. You can and should press with your foot, and pull it out with your hand using a special bracket.

8 — hinge; 9 — bracket; 10 - knives.

The control of a homemade winch is very simple. We only have two levers, one on the chainsaw and the other on the attachment. Plus anchoring and dragging towards an unplowed area. Even a woman can easily figure this out. BUT for all this to work you need:

- perfect clutch operation;

- trouble-free easy starting of the power unit;

- stable engine operation at idle speed;

- precise operation of the chainsaw starter.

Cons: Long-term operation of the power unit often becomes unstable. High fuel consumption compared to engines from light motorcycles Minsk or Voskhod.

Making an angle grinder

An angle grinder is a multifunctional tool necessary for a number of jobs. Despite its availability and prevalence, craftsmen made an angle grinder from a chainsaw (a sample is shown in the photo below).

Assembling an angle grinder using a special device for a chainsaw goes like this:

- remove the chain and bar from the gasoline saw;

- install a pulley on the gearbox shaft;

- instead of a tire, they mount a special attachment, also with a pulley, after putting a belt on it;

- tension the belt drive like a chain;

- attach the protective casing;

- install the disc.

The entire process is shown in detail in the video below.

A self-assembled grinder-petrol cutter will help in performing many practical tasks. Its power is sufficient for productive work on concrete.

Why does a chainsaw need attachments?

There are special attachments for chainsaws on sale, with the help of which the functionality of the tool is significantly increased.

Using additional equipment from a chainsaw, you can make a wood splitter; it will help you cope with logs that are difficult to split with an ax, or a boat motor, for trips on a rubber boat.

Essentially, attachments are necessary to get the most out of your chainsaw so that it doesn't sit on the shelf gathering dust, but is used every day to solve a wide variety of tasks.

No special education or skills are required to install the attachments; everything is simple and easy.

Are old chainsaws still needed today?

Probably, many people have old chainsaws of the “Friendship” type lying in their sheds and storage rooms. For a long time it was a pity to throw away the saw, but it came in handy for making a drill

This saw has a fairly powerful and, importantly, low-speed engine. There should be no difficulties with mounting such an engine.

We install the fuel supply control handle on the upper (smaller) frame. The soil is very uneven in its structure - layers of varying density and viscosity, stones, roots, etc. The drill can jump off, suddenly increase speed, or move to the side, so we strongly recommend placing an emergency engine shutdown system next to the fuel supply control mechanism.

old Druzhba chainsaw

Some old Soviet saws are quite large, which requires an increase in the size of the gas drill. Before starting work, consider whether it will be convenient to operate such a structure. Otherwise, the Druzhba, Ural and similar chainsaws are quite suitable for our task.

Moped with motor

All chainsaw crafts are distinguished by their practicality, but where would we be without it if the power unit is a real engine.

|

Happy chainsaw crafts to everyone and don’t get bored.

How to make a winch from a chainsaw

For plowing, a chainsaw-driven winch has a number of advantages. The main advantage over a motorcycle engine is the speed of installation of the chainsaw. There is no need to design engine cooling, install a fuel tank, air filter, electrical equipment (switch), or wiring. Make a homemade exhaust system. Secure the muffler.

1 – chainsaw; 2 – gearbox; 3 – drum; 4 — drum control lever; 5 – frame; 6 – anchor.

Chainsaw attachment winch

The attachment or attachment is a reduction gear. If you remove the cover and look inside, you will see a whole series of different gears, small and large. With the help of which the number of drum revolutions changes depending on the number of revolutions of the engine crankshaft. In this regard, the load on the power unit is reduced. That's what we need in hard work.

The connection between the attachment and the chainsaw is made using a clamp and a stand. Due to this, the winch is compact and lightweight, easy to use during assembly and repair.

3 – drum; 4 — drum control lever; 5 – frame.

The torque, from the crankshaft, passing through the reduction gearbox, is transmitted to the shaft on which the drum with the cable is located. The drum has the ability to be connected and disconnected from the shaft. It occurs using a lever and special cams located both on the shaft and on the drum. We move it, use the lever towards the chainsaw to connect it, reverse it, and turn it off.

We selected material for the supporting frame of the entire homemade product. Old used water pipes and an unwanted metal bed. For ease of use, the frame is made in the form of a sleigh. During plowing, you do not need to lift the winch, you just need to move it.

It takes a lot of effort to cultivate the soil. Our homemade product turned out to be light, so it needs to be firmly secured to the soil to prevent spontaneous movement towards the plow. For this we installed a special anchor. Attached to the frame using a hinge. By pressing the anchor from above, special knives easily sink into the soil. Hold the homemade product firmly in one place. You can and should press with your foot, and pull it out with your hand using a special bracket.

8 — hinge; 9 — bracket; 10 - knives.

The control of a homemade winch is very simple. We only have two levers, one on the chainsaw and the other on the attachment. Plus anchoring and dragging towards an unplowed area. Even a woman can easily figure this out. BUT for all this to work you need:

- perfect clutch operation;

- trouble-free easy starting of the power unit;

- stable engine operation at idle speed;

- precise operation of the chainsaw starter.

Cons: Long-term operation of the power unit often becomes unstable. High fuel consumption compared to engines from light motorcycles Minsk or Voskhod.

Helicopter

This type of homemade product is considered complex and therefore has not been implemented to date. She is in the dreams of enthusiasts, in invented stories. One of them claims that back in the USSR, a prisoner who understood mechanics made a helicopter with a chainsaw engine and was able to escape from the colony.

Making a homemade helicopter requires, unlike a snowmobile, outboard motor, bicycle, grinder and even a snow blower, more complex engineering calculations. They also show that one, even powerful, engine is not capable of lifting such an aircraft into the air. At least 4 motors are required, moreover, forced and working in concert at the highest possible speed. But it is difficult to implement this with chainsaw engines in practice.

Winch attachment for a chainsaw - installation procedure

If the owner of a chainsaw does not want to assemble the device himself, or he does not have the necessary skills for this, then he can buy a special device. It is a unit that includes a drum with a cable, a drive and a gearbox. The working mechanisms of the winch are placed in a shock-resistant housing that protects them from accidental falls.

The winch attachment for a chainsaw is easy to install and remove yourself. To install the device, a pipe is provided in its device, inside which a shaft is placed, which plays the role of a drive. To install the device, it is enough to remove the standard saw set of the chainsaw. After this, the shaft is connected to the motor. The winch body is secured by bolting.

When operating a chainsaw with an attachment, the motor creates torque and transmits it through a reduction gearbox to the drive shaft. He, in turn, begins to spin the drum with a metal cable. To stop the reel, the operator must turn the ignition switch to the "Off" position and turn off the engine of the garden tool being used.

The main advantage of the winch attachment is its small dimensions. At the same time, it is equipped with a fairly reliable cable that can withstand high tensile loads. Thanks to this, the device makes it possible to pull objects weighing up to 1–1.5 tons out of ravines or holes.

In addition, the nozzle has a fairly simple design. This makes it easier to independently maintain and repair.

https://youtube.com/watch?v=tjnFNns9RYc

Attachments for Shtil and Husqvarna chainsaws

There is no special attachment that would be suitable only for the Shtil chainsaw and would have any unique functionality that others do not have. Everything that can be installed on Shtil saws has analogues for other chainsaws, the same with Husqvarna chainsaws. For this reason, when choosing a chainsaw, you should not pay attention to the advice of sellers regarding the purchase of a specific model, due to the possibility of installing additional equipment on it that expands the functionality.

The only thing you should pay attention to when choosing is power, because to work with attachments it is recommended to have a more powerful chainsaw.

Gas winch made from a chainsaw and gearbox

Hello everyone, in this instruction we will look at how to assemble a chainsaw-based winch with your own hands. Such a useful device can be used for various purposes, because it is mobile and runs on gasoline. The author uses it to drag logs from the ravine. This is very convenient and useful when preparing firewood, building materials and other things. Also, such a winch can easily be used as a lift, which will be convenient during construction work. For example, you need to lift several buckets of cement, this winch will easily cope with the task.

The author used a chainsaw as a motor. You will also need to obtain high torque for the winch. For these purposes, an old worm-type reduction gearbox from some equipment was used. All other materials are easy to find or make. So, let's look in more detail at how to make such a winch.

List of materials:

- chainsaw; — reduction gearbox; - bicycle spare parts; - Sheet steel; - corner; - steel pipe; - screws, nuts, etc.; — cable for control; - cable for winch.

List of tools:

- lathe; - drill; - Bulgarian; — welding; - screwdrivers, wrenches, hammer and so on.

The process of making a homemade winch:

Step one. Disassembling the chainsaw

Let's start by preparing the chainsaw. First of all, we need to remove the clutch and sprocket. To unscrew it, the engine needs to be fixed; for these purposes we need to remove the top cover and unscrew the spark plug. Insert a cord, a piece of leather or something similar into the spark plug hole. Now the engine will rest against the skin with the piston and will no longer turn. Using a special wrench, unscrew the clutch and remove the sprocket. An angle grinder wrench will do if the clutch is not tightened too tightly.

Step two. Drive sprocket installation

As a result, after installing the structure on the saw, we have a drive sprocket equipped with a clutch, which is very convenient.

Step three. Drive sprocket installation

The author fastens the pulley itself with three screws, two of them secure the pulley from turning in a circle, and another one is screwed in so that the pulley does not come off the gearbox shaft.

Step four.

Install the chainsaw on the gearbox Step five.

Protective shields Step six. Making a winch pulley

The winch pulley is needed so that the cable can be wound around it and the desired work can be done. To make it, we first take a piece of steel pipe of a suitable diameter so that it can be put on the gearbox shaft. Next, drill holes and cut threads for the screws. Using screws we will secure the pipe to the shaft; there is a groove there. The ends of the screws will need to be ground to the diameter of the groove.

Step seven. The basis

Also attach a cable to the winch, with which you can tie it to a tree, car, and so on. At the end of the cable, install a hook for quick attachment.

Step eight. Handle for control

Finally, paint the metal parts of the structure. When working in the forest, moisture will quickly cause the metal to rust.

Step nine. Tests

You can start testing the winch! We tie it to a tree, car or other reliable support. We tie one end of the cable to a log that needs to be pulled out of the ravine. Well, we wind the other end onto the winch and turn on the machine! Slowly adding speed, we ensure that the log begins to crawl towards you from the ravine. The author has made quite a few columns this way. In any case, it will be much easier than carrying them by hand, after which you get very tired and your muscles hurt. And to prevent a forester from catching you doing this, it would be useful to install a muffler on the chainsaw.

Source

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

What attachments are there for chainsaws?

Today, a large selection of chainsaw attachments have been developed by manufacturers and are commercially available. More specifically, for your saw you can buy:

- Boat motor attachment.

- Winch.

- Pump.

- Motor drill.

- Wood splitter

- Device for cutting boards.

If you like to make things with your own hands, then the saw will be an excellent assistant, because it can be used as a power unit for your inventions. For example, the video below shows how you can make a go-kart for your child from a simple chainsaw. It's very interesting and not as difficult as it seems.

And the next video shows a homemade snow blower, the engine of which is a Shtil chainsaw. The idea is very good, but the snow blower is a little unfinished, but it is still able to make cleaning the territory of a private house easier.

Now let’s look at each of the attachments in more detail, look at the pros and cons of use, and draw a conclusion about how the use of the attachment affects the life of the chainsaw and its performance.

boat motor

The attachment is designed for installation on small rubber boats with a transom. Characteristics:

- Gear ratio 1:2.

- Maximum speed in still water is 20 km/h.

- Three-blade propeller with a diameter of 150 mm.

- Fuel consumption is 1 liter per hour.

- Weight when assembled is 8 kg.

Such characteristics allow the nozzle to be used by those who do not need high speed movement through the water, but simply need to get from point “A” to point “B”. It is popular among fishermen because it is light and compact and fits into the trunk of a passenger car.

All necessary fasteners are supplied with the nozzle. There are instructions for installing the nozzle and its proper use.

The main advantage of using such an attachment for a chainsaw is saving on the purchase of a boat motor.

You can learn how to install a chainsaw on a boat motor attachment by watching the video.

Winch

Another useful attachment for a chainsaw is a winch. It can be used to lift loads weighing up to one and a half tons. A conventional electric winch requires an electric current to operate, which significantly reduces its capabilities. A chainsaw with a winch can be used anywhere.

Having such an attachment on a firewood harvesting site, you can load tree trunks, cross-cut into several logs. Also, if necessary, such an attachment will allow you to pull out a stuck passenger car; it is not suitable for trucks.

The cost of a winch for a chainsaw is a little more expensive than an electric one, but its mobility and ease of use make up for the difference.

There are several models of chainsaw winches on sale, which may differ in cable length, size and weight. On average, the length of the cable is about 30 meters, weight no more than 12 kg.

This is interesting: using a plow together with a chainsaw winch, you can cultivate a plot of land with a minimum of effort.

How to plow the ground with a chainsaw and winch is shown in the video. The advantages of this method are that in this way it is possible to cultivate land in suburban areas where there is no possibility of connecting to electricity.

water pump

A special attachment called a chainsaw pump will help pump out water from a flooded cellar, pump up a water tank for irrigation from a well, or simply pump water from one place to another.

The device is quite simple and does not require special skills to install on the saw. Its advantage is mobility and connection speed. In addition to the nozzle, you will need to purchase hoses. Pumps, like other saw attachments, are produced by several manufacturers, so they can have different performance and other characteristics.

This attachment is universal and can be installed on chainsaws of various models and brands. For those who are not used to paying for additional equipment for a chainsaw, you can make a pump yourself.

Motor drill

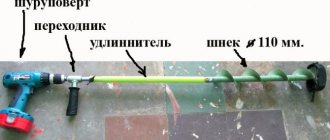

Another useful attachment in everyday life is a motorized auger (ice auger). There are a lot of options for this console, including homemade ones. It can be useful not only for fans of winter fishing, because it can be used to drill holes for installing fence posts.

The advantage over electric options is mobility, since the drill can be used regardless of the availability of electricity.

Important! To install the drill attachment, you will need to remove the standard clutch and drive sprocket from the chainsaw, for which you need to lock the crankshaft. You can find information on how to properly remove the clutch from a chainsaw on our website.

An adapter coupling is supplied with the saw drill, which is installed instead of the drive sprocket.

Wood splitter

Thick lumps are difficult to split with an ax; to make the process easier, you can install a wood splitter attachment on a chainsaw. It is screwed into the block and, due to its cone-shaped shape, splits it.

The attachment is universal and can work on various models of chainsaws. User reviews about this device are positive, because it really facilitates the process of splitting large lumps.

The cost of the wood splitter attachment is reasonable, currently it does not exceed 1000 rubles. You can buy it on specialized websites or in petrol stores. Installation of this gadget does not require any specific skills; the manufacturers provide instructions.

Jointer

If you need to plane a small number of boards, but you do not have a specialized machine, then the jointer attachment will help you do this.

The attachment is mounted on standard bolts for fastening the tire; instead of the clutch, a drive pulley is installed on which the belt is put. Through the belt, a force is transmitted from the drive pulley to the driven pulley, which causes the planing shaft with two knives to rotate.

The system is very simple and reliable; the quality of processing depends on the maximum number of revolutions of the chainsaw on which it is installed.

Important! Manufacturers do not recommend using a jointer attachment, since with it the chainsaw operates for a long time at maximum speed with virtually no load, which can cause the engine to overheat.

In order to compensate for the lack of load on the engine when using the jointer attachment, you can slightly reduce the maximum number of revolutions. You can find instructions for adjusting the carburetor of a chainsaw on our website.

The attachment is not universal; for it to work, you need to replace the drive sprocket with a pulley; the mounts are different for all chainsaws. Therefore, when purchasing, you need to consult and choose a model of attachment suitable for your chainsaw.

Bark beetle

Another attachment for a chainsaw, which is designed for cleaning tree trunks from bark.

It is very similar to a jointer, is attached in a similar way and has two pulleys and a belt. The main difference is that the bark beetle does not have a stop bar that prevents the knives from going deep, as a result of which they only remove a certain amount of chips.

Bulgarian

One of the most popular attachments, about which users leave only positive reviews, is an angle grinder, or it is also called an angle grinder, but it is not one, because it is intended only for cutting.

Attaches to the standard place of the tire. Not universal, it is selected for the model of chainsaw for which it is intended. Not expensive and easy to use. Consists of the following elements:

- drive pulley;

- frames;

- driven pulley with shaft and disk mount;

- force transmitting belt;

- protection.

The simplicity of the design and standard grinder consumables (discs) made this attachment very popular. Its advantage is mobility, the ability to be used in places where there is no electricity.

By the way, you can read in one of the articles on our website about how to make an angle grinder from a chainsaw.

In place of the cutting disc for metal, which is shown in the photo, you can install carbide ones for cutting concrete and use a saw with an attachment as a wall chaser.

Advice. When working with an angle grinder attachment, the engine experiences significant load, so it is not recommended for chainsaws with a power of less than 2 kW.

The following video shows how to assemble, install, configure and operate the attachment. The video shows that the Shtil MS 180 chainsaw with a power of 1.5 kW cannot cope with the load, and a drop in speed is noticeable. To prevent this from happening again, use more powerful saws.

What determines the durability of homemade motorized winches?

The main factor that influences this is the build quality

Therefore, please pay attention to the following:

- reliability of the clutch of motorcycle tools;

- no problems with starting the motor part of the saw - slipping, unexplained shutdowns: the saw should run smoothly and hold idle and high speeds equally well;

- trouble-free starter - otherwise a minute’s work will turn into many hours of agony;

- the presence of safety systems, hooks, belts, which should help bring the structure to perfection.

Diagnose gasoline saws for malfunctions, and only then adapt them for homemade projects: this way you will ensure your safety and save time.

What is needed to make a winch?

Despite the simplicity of the initial design and ease of self-assembly, the winch designer will still need to prepare a certain list of parts and mechanisms. Their installation in the overall structure of the device will allow you to assemble equipment that will work as stably as possible and will not let the owner down at the most inopportune moment.

To assemble a winch based on a household chainsaw, the manufacturer will need:

- a fully serviceable and ready-to-use gasoline saw - domestic models Druzhba and Ural, as well as high-quality brand saws Stihl, Husqvarna, Patriot and Al-Ko, are very popular among assemblers. The main requirement for the engine is that its power must be at least 3 liters. With.;

- gearbox - this mechanism will connect to the power unit of the chainsaw and reduce the initial torque created by the internal combustion engine;

- metal pipes, couplers, brackets, steel sheets - needed to assemble the support frame and winch body;

- drum and reinforced metal cable;

- steel hook;

- cam metal clamps;

- fastening clamps;

- lever for controlling the winch.

It is best to pre-coat metal and steel components with a primer and several layers of paint. It will protect parts from the formation of pockets of corrosion and rotting caused by regular use of the device under conditions of constant exposure to moisture.

Generator

A chainsaw with a 2-stroke engine with a power of 2-3 liters is suitable for production. With. Electric motors from old washing machines are often used as electric generators. The combination of these devices makes it possible to obtain an output voltage of 220 V. The power of such a gas generator is sufficient for lighting, powering electrical appliances and tools, and household appliances.

Order of operations:

- A bracket is made and the electric motor is attached to it. Install the resulting structure on the outer end of the chainsaw bar. At the same time they provide:

- perpendicularity of the electric motor axis to the plane of the tire;

- the location of the pulleys of both devices in the same plane.

- The output shafts of the engines are equipped with pulleys of suitable diameter.

- Put a belt drive on the pulleys.

- A device is made to regulate the speed of a chainsaw motor. A bolt is used, which is attached to the handle of the latter using a clamp. Tightening it leads to an increase in the number of revolutions, unscrewing it leads to a decrease.

- The external starting winding of the electric motor is supplied with 2 capacitors, which are designed for a voltage of 400-450 V and have a total capacity of 10 μF. Their connection is parallel.