I know that now eggs, rotten tomatoes and so on will fly at me... but I want to say one thing, I decided to make a winch, and I will... it doesn’t matter whether it succeeds or not, but I will try.

Yes, it’s a lot of work... you’ll probably also have to cut the face and bumper, but it’s probably worth it)

I got a starter for free today, 12th century. 1.5 kW A little shabby, but nothing) The engine works) that’s the main thing) And it was made in the USSR and not in China)

Soon I will make something like a drum, hook a gear,

there will be no gearbox, there will be a gear mechanism. The small gear will turn the big one.

In short, everything is in progress...

I attached the starter to the bumper, took a couple of photos... but it will be behind the bumper... it won’t stay that way... it will be different.

A winch is a very useful tool on the farm. With its help, you can perform a lot of work that is too difficult for manual labor, it can be used in rescue operations, and can be integrated into various types of equipment for specific purposes. That is why a homemade winch for a UAZ with your own hands is widely popular. There are a lot of options for them. Regardless of the design, device and other factors, this device performs one task - it provides a large force sufficient to lift various loads to a certain height or to pull out some heavy object from a low place.

Ural winch, conversion of the drive to a hydraulic motor.

Guys who converted the cardan drive of the Ural winch to a hydraulic drive, please respond.

Giganaut wrote in the manipulator thread, only he, in my opinion, put it on giga from the 66th.

Look on farmer.ru, there is someone there who has remade it

It seems like all Japanese hydraulic winches cost 50 in total.

Well, if a person got a swan from ulala for free, then why not

In my opinion, the whole modification consists only of installing a hydraulic motor on the flange

I made a hydraulic motor for the Zilov 131st brand, I don’t remember the strength of 12 according to the passport, it’s stupid, so dragging cars onto a tow truck. The gear ratio there is not large, 1:40 I don’t remember, the engine with the gearbox gives out all the torque.

Dim, if you got it for free, then why not try it out?

That's the point: it was on the ball, the pump on the MAN is an axial piston, the question is, will it pull the winch hydraulic motor?

Bison, let's make the topic very interesting. I also have a Ural winch lying around, the new one has never even been unwound. It might come in handy in case it comes in handy.

Tomorrow I will receive two Japanese winches for the cardan. I bought a pair of Sauer-Danfoss gerotor high-torque hydraulic motors. I will sharpen, mill, and install the hydraulic motors. There is little information on the topic.

Well, that’s why I created this topic, because there are no experts on how to convert a cardan shaft to a hydraulic motor. I even asked this question in the next thread “Cargo tow truck”; there are pros in this matter, but they are silent about something.

The farmer has a T40 tractor with a gas 66 winch, I don’t remember the model of the hydraulic motor, but they pump oil into it using a standard nsh32; its hydraulic motor turns the winch directly, and if it’s not enough, it can be done through a chain gearbox

If you can, take a photo of the hydraulic motor mounting to the winch.

I think that everything is easy and simple, but you can’t do without turning the pump through the adapter plate, depending on the swan https://www.gaz66.ru/forum3/viewtopic.php?f=35&t=5245

It is better to install not a pump, but a hydraulic motor. And not a gear one. As a rule, they are not reversible, the torque is lower and the operating pressure is lower. Reliability and resource too. I don’t like Russian axial piston engines - their parameters are also dead, and even the drainage from the housing needs to be diverted into a hydraulic tank.

Last edited by scorceni; 05/08/2013 at 01:44.

On a Japanese 10-ton evacuation ramp, the hydraulic winch has a gear-type reversible hydraulic pump (I will sell it inexpensively)

Thanks guys, interesting link! While I'm studying.

Hello everyone, I also got it from 131 free of charge. I started studying the issue.

Write how the process goes. I can't get my hands on it yet.

homemade collective farm hydraulic winch

#1 Nemo

In general, there is no air conditioning, but there is a free stream on the engine pulley. I’m thinking (in the vague future) of attaching a hydraulic winch.

Theoretically, there is nothing complicated: NSh-10 through the bearing block and the air conditioner coupling, distributor, reservoir, hose pump, and to the MGP-315 winch, for example.

The advantage is that it runs smoothly and is not afraid of dirt. The downside is that it only turns when the engine is running. Two winches (back and front) from one pump.

Maybe someone already has some experience? Or is all this a “corral”, and is it better like everything else – electric?

#2 als-a

Where will you put the distributor?

#3 Nemo

Into the salon between the front seats. Like this, for example:

#4 parik_07

#5 parik_07

#6 Nemo

The motor is planetary, not so expensive, it can be used without a gearbox. Of course, it won’t pull cars up a tree, but maybe it’s enough for a rut?

The pump is also inexpensive, in short the budget seems to be 15-20 tr.

#7 parik_07

#8 als-a

The motor is planetary, not so expensive, it can be used without a gearbox. Of course, it won’t pull cars up a tree, but maybe it’s enough for a rut?

The pump is also inexpensive, in short the budget seems to be 15-20 tr.

20 thousand? These are two Chinese winches with a pulling force of 12,000 pounds each. Two remote controls (regular and with radio control for each). IMHO. Considering the complexity of installing hydraulics, its weight and difficulty in repairing, it does not make any sense. You can order Chinese food directly from Vladivostok. For example HERE or on a bunch of other sites. Installation is much easier and faster. By the way, Chinese winches have improved significantly in quality over the past couple of years, and people have long given up on ComeUP and Warn for crazy money. Well, at least in our regional club.

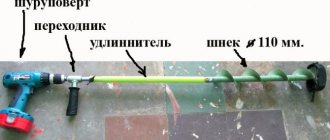

Homemade winches from starters

Before setting off, any car enthusiast must make sure that he has taken everything he needs with him. But, if ordinary drivers do not need to take a lot of equipment, then off-road conquerors gather with special zeal. Any car enthusiast who prefers to drive on the most extreme and difficult sections and roads takes with him the most necessary and necessary equipment that can help and facilitate movement, as well as provide a way out of the most difficult situations.

One piece of equipment that will help the extreme motorist is a winch. An experienced driver who is ready for all the vicissitudes of a road adventure will definitely take this important device with him on the road. In difficult conditions where there is a high probability that the vehicle will end up in a ditch or get stuck in the mud, a winch will help the driver pull his vehicle out of such road obstacles.

Of course, you can purchase such a device already in the form of a ready-made device, which, of course, is good news. But, if a car enthusiast doesn’t really want to go shopping and spend money on this device, and if he has all the necessary components, he can make a winch himself.

Application area

This mechanism is intended primarily for cars and drivers who spend most of their time off-road. A powerful car with a winch can overcome many more obstacles than a similar car without this device.

No matter how versatile a car is, sooner or later it will get stuck somewhere. This is where a winch comes in handy. One end of the cable is wrapped around a large rock or several trees and the car begins to be pulled out.

Factory winches, which are sold in auto stores, are quite expensive. On the other hand, the simplicity of the design of this device is quite simple, which allows you to create it at home and thus significantly increase the cross-country ability of any car.

What is a winch for?

A winch will be needed primarily for drivers of off-road vehicles. It is no secret that such cars are used specifically for traveling on those roads where there is no longer urban comfort and asphalt. Country roads can cause a lot of problems for an unprepared driver. But the presence of a winch can help out and overcome the most difficult sections of the path. Some off-road vehicle models are already equipped with a winch, which is installed on the front bumper.

If the car is not equipped with such a device, then you can purchase it and install it on your vehicle. But it is quite possible to make a winch with your own hands. Many car enthusiasts already use homemade winches from a starter. By the way, the majority claims that homemade winches are even more reliable than their factory counterparts.

There are several types of such a device. These types differ depending on the energy that drives the actuator. It is impossible to immediately say which of the existing types of winches can be called preferable and best, since they are used in different situations.

Types of homemade winches

As was written just above, there are only three types of winches. They are useful in different situations and also differ in the energy that powers the mechanism. But they are similar in one thing: the principle of operation. It consists of winding a steel cable around a drum. The drum can rotate thanks to a motor gearbox or through the use of its own forces, manually.

Homemade winches for cars can be:

- electrical;

- manual.

hydraulic;

Hydraulic drive

A hydraulic winch is considered a more complex mechanism, as it has some additional elements, namely: a hydraulic drive, an oil tank and an oil pump. The device itself is quite bulky, so it is more difficult to assemble than other types of devices. But a hydraulic winch has two big advantages : it consumes less electricity, but at the same time has more power than other mechanisms. Typically, winches of this type are mounted on very cool SUVs, as well as on tractors and walk-behind tractors.

Electric drive

As a rule, an electric winch can be found much more often, since it is the most popular option among craftsmen who assemble these devices by hand. Such high popularity can be explained by the high efficiency and simplicity of the entire design. As a drive, you can use either an electric motor or a tractor or car generator. The generator should be connected in such a way that it subsequently works like an engine. If you use a starter in the winch device, the device itself will be more compact.

A very important requirement for an electric drive is that it must have high torque. To prevent the battery from draining too quickly, care must be taken to ensure that the electric drive does not consume too much electricity , but still operates with sufficient power. By the way, this type of homemade winch is easier to build with your own hands.

Mechanical drive

A device with this drive operates on the same operating principle as other design options for this device. The main disadvantage of a mechanical drive is its dimensions - it is quite bulky. By the way, this is the largest drive among other device options.

The main difference between a device using a mechanical drive and other options is that instead of an electric motor, direct physical action is used. That is, to put the mechanism into action, you will have to make some effort. In principle, if you use a winch of this type, then you can note its main advantage, which is that such a winch can always be used in the absence of energy sources.

Electric winches

Often, the operation of these tools uses a car starter or a cargo generator. This homemade winch can also be powered by a separately installed electric motor. In other cases, car enthusiasts modify the starter and generator to operate in engine mode.

However, whatever the origin of this quinoa, it must have a high torque so that the mechanism can pull a 2-ton huge jeep out of a ditch. And since the main energy for operation is absorbed from the battery, car enthusiasts install batteries of higher capacity. However, an electric motor, no matter how powerful it is, should not discharge the battery so much.

Product design

In order to make a homemade winch, you should first familiarize yourself with the list of main parts that are used for its manufacture. The main elements of do-it-yourself devices include the following parts:

- drum with cable;

- engine;

- gearbox;

- base (chassis).

Before you start assembling, you should prepare everything for this. To begin with, it is recommended to understand all the necessary drawings and electrical diagrams. In this matter, it is better not to rely on your memory or let all the work take its course. Then you need to prepare a workplace and all the tools that will be needed during the work process.

How to make a winch yourself?

The above information allows you to evaluate how convenient and useful such a mechanism can be, especially in extreme situations when driving off-road. If your car is stuck, there is nothing else to do but pull it out, and in this case, a home-made winch using improvised materials can be useful. One of its manufacturing options is shown in the photo.

The basis is an axis, which can be a strong stick, a crowbar, a mounting tool, etc. It is driven into the ground or secured in any possible way. A piece of pipe is put on it, acting as a drum. One end of the cable is wound around a section of pipe, and a lever is inserted under one of the turns, which can be a strong stick, shovel, mounting tool, etc. Second, the end of the cable is attached to the car. So, if necessary, you can make a winch with your own hands from available materials.

The above is not the only option for how to make a car winch with your own hands. There is nothing surprising in this, because such a device is very useful, especially for “jeepers,” but its price on sale is sometimes prohibitive. First of all, numerous attempts to make a homemade automobile winch with your own hands, in one form or another, are associated with it.

And it must be said that sometimes homemade mechanisms can be very interesting, which can be confirmed by a video showing a self-made winch on a wheel, not an electric one.

For cars operated in urban areas, a winch is an exotic thing. But for real all-terrain vehicles, for whom off-road is their home, this is the number one thing.

And there is nothing surprising in the constant interest in such devices, as well as numerous attempts to make a car winch with your own hands.

Assembly technology

If a master assembles the entire structure with his own hands, then he will understand it much better than a purchased device. In addition, many car enthusiasts are inclined to believe that homemade winches are of better quality and more reliable. If you assemble such a device from a starter, then the entire procedure will take about an hour, but provided that everything necessary is prepared ahead of time.

The main working unit of the winch is a drum with a cable. If the user already has one, the work will take much less time. But not everyone is the happy owner of such a useful device. If there is no ready-made drum, you can make it yourself using a thick pipe and sheet metal with a thickness of 3 to 5 mm. The cheeks should simply be welded to the pipe on both sides. The gear is attached to one of them. This gear will subsequently receive force from the gearbox.

By the way, if there is no ready-made drum, then it can also be made from Zhiguli hubs , which have already served their purpose. This is not very difficult to do. You just need to cook them on the thin side. In order to ensure the alignment of the parts, you need to do this on a mandrel.

When choosing a gearbox for a device, many professional craftsmen recommend taking gearboxes that are used in trolleybuses to open and close doors. If the user is able to obtain such a gearbox, then it is recommended to use it. But if there is no such device, then you need to make the winch differently, that is, using a starter. It is recommended to use a special starter equipped with a planetary gearbox. Such a starter is more compact and lighter , which will subsequently be a positive factor.

Homemade winches are usually attached to the front bumpers of cars. But car enthusiasts also use portable versions of such devices. They are placed in the trunk and taken out if their use is needed in a certain situation. In principle, in any case, you should make the winch as compact as possible. Bulky devices can cause some inconvenience later on, making them more difficult to use.

How to make?

A drum with a cable is the key component that makes up any homemade winch. The drawings of this device must be as accurate as possible so that the mechanism works correctly and reliably. It’s good if you have such a drum ready-made, because it’s much more difficult to make it yourself.

How to make your own drum? To do this, you need to take a piece of pipe with thick walls, and using electrodes and a welding machine, attach cheeks 5 millimeters thick to it. The driven gear must be attached to one of the last parts. The pipe itself is equipped with seats for bearings.

You can make a drum for a winch in another way. To do this, you need to have several hubs from any Zhiguli or Volga. They should be machined into a place for welding and the halves should be attached to a mandrel of the required diameter in order to achieve alignment of all parts.

It is best to take a gearbox with a large gear ratio (worm type). The main advantage of such a mechanism is that there is no need to create a drum brake. Most often, motorists purchase a gearbox from trolleybus doors - it is easiest to mount on the site.

If you decide to make a homemade winch driven by a starter, it is best to take a model with a planetary gearbox. This is what early Zhiguli engines were once equipped with.

To create a mechanism with a starter, the first step is to prepare a platform from a metal sheet. It is necessary to weld seats onto it, on which the drum shaft will then be mounted. After this, the gearbox is installed here with the input shaft facing up.

A homemade adapter is mounted to the gearbox on top. We need it in order to install the starter. A gear with a certain tooth module is mounted on the input shaft. Afterwards the starter is finally attached to the structure. At the final stage, wiring is done. That's it, now such a winch can be installed on a car.

Tips for assembly and operation

- When assembling a homemade winch, you should pay close attention to all the details. This will avoid possible unpleasant consequences that may occur due to poor quality design.

- Under no circumstances should you force the assembly process. As they say, if you hurry, you will make people laugh. It’s better to spend an extra hour to get everything right than to reap the fruits of your haste later.

- You need to pay attention to the switching and installation of electrical wiring. It is recommended to secure the winch control panel away from rotating parts. This will reduce the risk of injury that may subsequently occur due to negligence or hasty actions.

conclusions

It is believed that homemade winches are less safe than their factory counterparts. In addition, they are in no way suitable for lifting loads. This is due to the fact that such devices do not have a stopper. But one of the main advantages of homemade winches is the fact that if assembled correctly, they can last even longer than factory-assembled winches.

Homemade winches made from starters are more compact, so when choosing an option before assembly, it is better to opt for these devices. The advantages of such winches will be noticed by the user immediately upon use.

Manufacturing instructions

The manufacture of the device in question takes a relatively small amount of time. The design consists of several blocks; a self-puller is also installed, but not always. The instructions for making a winch are as follows:

- The main mechanism is a Zhiguli starter. It is ideal for generating the required force. In addition, such a starter costs practically nothing.

- At the top of the device being created, a retractor relay with power contacts is installed. They are required in case there is a high load.

- In order for the winch to be compact, a gearbox from a small drill is selected. Finding this mechanism is quite simple, since there are a huge number of drills on the market with a burnt-out electric motor. There are no special requirements for the gearbox; the main thing is that it must be reliable and powerful.

- The gearbox shaft is paired with the mating part of the starter motor. For this purpose, the electric welding method is used, which allows you to obtain a high-quality and reliable permanent connection.

- Experts do not recommend installing dampers. This is due to the fact that the axle is always under heavy load during operation. The damping device used is in a closed position, so it may break.

- To increase the gear ratio, a starter with a planetary gearbox is used. The complexity of the design determines that adapting it to the task at hand is not as simple as the usual version.

- The gearbox housing must be firmly connected to the electric motor housing. To protect the winch from environmental influences, a special housing is created, preferably a split type. In many cases, it is recommended to create a split design, since from time to time it is necessary to carry out maintenance of the motor bearings and gear mechanism.

- The next step is to create the drum. It is on this that the cable will be wound. You can make a drum at home from a pipe that has a diameter of about 180 mm and a wall thickness of 2-3 mm. With a smaller wall thickness, the pipe can be severely deformed.

- To fix the cable on the drum, it must have cheeks. They are made simply: they are cut out of a steel plate, after which holes are created to accommodate the shaft. The cheeks are welded to the sides of the drum.

- A structural element of a decommissioned electrified valve is used as a power shaft. It is quite often used in the creation of oil pipelines. To transmit rotation, a pair of gears is installed.

- All used elements must be securely welded together. This is due to the fact that even a minor defect can lead to the appearance of a crack. Too high a load will cause the mechanism to fail at the most crucial moment.

- To attach the winch, a frame is created, the manufacture of which uses a channel and a steel plate with a thickness of at least 5 mm. The corner is attached from the bottom in order to make the structure more rigid.

- The side walls are made using sheet metal 3-5 mm thick. Thin sheets can become deformed when the cable is pulled too hard.

- The most important part of the structure is the fastening of the drum axis. It is to this that the high load will be transferred. To fix the axle, it is recommended to use bearings with podiums. They are highly resistant to mechanical stress. You can find such bearings in the workshops of abandoned factories or at scrap metal collection points. If ordinary bearings were found, then a cage is welded to the sides.

DIY winch

Driving over rough terrain, even in an all-terrain SUV, can create a lot of problems. To increase cross-country ability, additional equipment is often installed on vehicles, which allows them to overcome difficult sections of the road. Let's take a winch as an example. Today, a winch is installed on UAZ and many other cars. If desired, a winch can be made with your own hands and installed not only on the Niva, but also on other SUVs. It is worth considering that a homemade winch can be intended for lifting loads and other purposes. For example, there are portable versions that can be installed on a wheel or other element of the car. Let's look at the features of making a winch, its types and many other points in more detail.

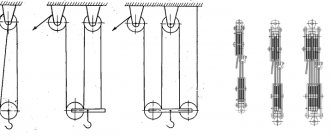

The principle of operation of pulley hoists

The only simpler device for moving heavy objects is a metal scrap. The main element is a wheel with a chamfer in the middle of the outer surface, the axis of which is fixed to the ceiling beam. You can throw a hoist over it, and the lift with a gear ratio of 1 to 1 is ready. To increase the leverage, let's pass the hoist through another loose wheel, the axis of which is connected to the load, and fix the hoist at the top of the structure.

The gear ratio will become equal to 2. Now we will attach another wheel to the ceiling, and pass the end of the hoist through it, securing it to the axis of the lower wheel. The gear ratio will become equal to 3. And so on, by adding one wheel at a time and changing the mounting location of the hoist, you can increase the gear ratio.

The location of the wheels relative to each other may be different.

The most compact designs are those with single-axle wheels. The design of such devices has two wheel holders. Having studied the drawings of the chain hoist, it will not be difficult to assemble it with your own hands. You will need two clips:

- traverse;

- carrying bracket;

- cheek for mounting parts;

- wheel (block);

- emphasis;

- bearing;

- sleeve;

- axis;

- axle holder;

- bearing oiler;

- hoist limiter;

- screw;

- bearing;

- cheek.

The end of the hoist is fixed to one of the clips.

Pulley hoists also have disadvantages. To increase the gear ratio by 1, you need to add one wheel each time, as a result the weight of the mechanism increases. In addition, bending the cable on each wheel requires force, reducing the efficiency of the device. You can reduce these losses by increasing the diameter of the wheels, but at the same time there will be an increase in the weight and dimensions of the pulley. Other types of lifts do not have these disadvantages.

Design

Before you start making a winch with your own hands, you should consider the design features. The design of a car winch can differ significantly, for example, in the type of drive used during manufacture.

The classic design of a car or motorized winch has the following features:

- The drum onto which the winch used is screwed. Homemade winches for cars can have different drum sizes. It is worth considering that as its size increases, a large amount of cable can be wound, but the load also increases.

- Drive unit. The design provides for the creation of force, due to which the cable is wound. There are a variety of drive schemes, all of them have certain advantages and disadvantages.

- Very often a gearbox is installed. It is designed to increase the transmitted force to the drum.

- The drawings also provide for the presence of a wide variety of bases. It is worth considering that the chassis must have high load resistance and be securely attached to the base.

- Homemade hoist.

You can download the drawings from which the structure will be created on the Internet. The assembly technology largely depends on the complexity of the project being implemented.

Types of structures

What types of winches are there for cars? According to the most general classification, car winches are manual and automatic. The latter are also divided into mechanical and electrical.

Mechanical. This type of device operates thanks to the power of the engine of the car itself. Thus, the driver does not need to make any physical effort. At the same time, the main disadvantage of this type of design is that if the motor is not running, it will not function.

Electric. This type of winch is equipped with a portable electric motor. Thus, the functioning of the device is absolutely independent of the condition of the car’s engine or the physical strength of its driver. This device is powered by a car battery. In part, this makes the device dependent on its charge level. Despite the rather complex design, this type of winch is characterized by relatively high reliability.

Hydraulic. It is driven by an oil pump, and is considered the most complex of all the listed structures. Its design includes an oil tank and a pump, as well as a special drive. This type of installation is quite powerful, but not as reliable as an electric one.

Manual. The design of this type of automobile winches is highly reliable, but also requires physical effort from the driver during operation. On the other hand, making such a device at home is quite easy. A special lever can minimize the load when dragging a stuck car, but this will not make the task much easier.

It is best to use a hand winch in pairs: one person outside, pressing the lever, and the other sitting behind the wheel and smoothly squeezing the gas. It is worth noting that structures of this type are significantly inferior to the previous ones in load capacity (up to 1 ton).

Manufacturing

Many motorists are of the opinion that homemade winches are more reliable and durable. If you purchase a similar design for a car, you should give preference to expensive versions from well-known manufacturers.

An important structural element is the drum on which the cable is wound. You can make a drum for a winch with your own hands using a pipe of a certain diameter as a raw material. The thickness of the pipe walls must be at least 3 mm, since otherwise the drum will deform under the influence of load. In this case, you will need a welding tool, since the cheeks are attached by welding.

When making a winch with your own hands, you also have to install the gearbox. Today, a homemade gearbox is extremely rare, since the easiest way is to remove it from another mechanism. In most cases, gearboxes are installed, which are used to open and close trolleybus doors. In the absence of such a mechanism, other types of gearbox can be adapted to the task under consideration.

The necessary parts are selected depending on the selected drawing. For example, a winch made from a drill has its own characteristics and is more suitable for a motorcycle, since the installed mechanism is not designed for high loads. When considering manufacturing methods, it is worth considering that in most cases welding is used to create a permanent connection. However, the structure itself is often bolted to the bumper, since it is necessary to ensure the possibility of maintenance.

Recommendations for use

For safe and long-term operation of homemade automobile winches, you should adhere to the following instructions:

- Any manipulations with the cable should be carried out only after the device mechanisms have been completely deactivated.

- Use structures only for their intended purpose.

- This device does not provide for vertical movement of objects.

- Do not handle the structure or its components without gloves.

- Before use, carefully check the fastening of the device and its components.

Creating certain types of car winches at home is not an easy task, but perseverance and careful implementation of all recommendations will help you create a reliable and effective design that will help you out more than once in difficult situations.

Source: metmastanki.ru

Hello! We are sincerely glad to see you on the website of our club! Most likely, the FULL DRIVE lifestyle is close and understandable to you.

Here you can meet and communicate with people who share and understand your aspirations and hobbies.

Before you start communicating, please read the Forum Rules

- All-4x4"

- Forum »

- Technician. »

- Tuning (Moderators: privateer, SUBSTANCE) »

- Topic: Homemade hydraulic winch

Interesting

Who ?

Welcome, Guest . Please login or register. Did not receive your activation email?

29 October 2022, 23:09:26

Statistics

Users

- Users: 22 Guests: 279 Total: 301

Author Topic: Homemade hydraulic winch (Read 36199 times)

0 Users and 1 Guest are viewing this topic.

- All-4x4"

- Forum »

- Technician. »

- Tuning (Moderators: privateer, SUBSTANCE) »

- Topic: Homemade hydraulic winch

The page was generated in 0.025 seconds. Requests: 43.

Source: vse-4×4.ru

Types of winches

On sale you can find a variety of winch options. The main classification is considered to be what type of drive is installed. Based on this indicator, the following structures are distinguished:

- Electrical structures are the most widely used today. This is due to the fact that such a design is capable of operating under very high loads. Typically, the installed electric motor is powered by the vehicle's battery, and the control unit can be located inside or outside the vehicle.

- A mechanical winch is the easiest to manufacture. The worm design has become widespread, when a gearbox is installed to transmit force and increase it. A small mechanical type auto winch is designed for low effort.

- Hydraulic. Hydraulic-type designs are also available. Their operating principle is based on the supply of liquid under high pressure, due to which the moving element moves. Typically, a hydraulic drive is installed on a structure intended to transport cargo.

Most often, a homemade design has a mechanical drive, since it is easier to manufacture and install.

Manual

A do-it-yourself manual winch is quite simple to manufacture, which has determined its wide distribution. The main disadvantage of the design is its rather large overall dimensions. A manual drum winch can extend significantly beyond the vehicle, and its installation requires a special bumper with a wide seat.

Do not forget also that the design is manually driven.

At the moment when the car is stuck, it will not be possible to pull and control it at the same time. That is why the design in question is becoming less and less common today.

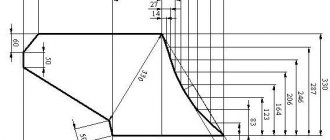

Drawing of a hand winch

Electric

As previously noted, electrically driven designs have become quite widespread. This is due to the fact that a homemade electric winch is comfortable to use and designed for a fairly high load. Let's call its features the following points:

- A high efficiency indicator determines that the design copes with the assigned tasks more effectively.

- A separate electric motor or generator can be used as a source of force. When choosing an option in which the winch is connected through the generator, you should be careful, since this component of the vehicle is important and cannot withstand overloads.

- An electric car winch must have high torque. In addition, quite a lot of attention is paid to energy consumption. This is because when the vehicle is stationary, most of the power will come from the battery rather than the alternator. Excessive power consumption can cause the battery to drain quickly. However, too low power consumption can cause a significant reduction in the power of the device.

Recently, versions that can be powered by a 12-volt energy source have become very popular. In such a case, the winch device is connected to the cigarette lighter or the corresponding socket in the car, if available.

Hydraulic

The hydraulic winch is considered the most complex design option, since the design is represented by a combination of the following elements:

- Drum with cable.

- A mechanical element that transmits rotation to the drum.

- Hydraulic drive.

- Oil pump or compressor.

- Oil tank.

In addition, such a car winch is quite difficult to manufacture and is large in size. The complexity of the design also determines the need for periodic maintenance.

The advantage of the hydraulic drive version is low energy consumption and higher power. It is advisable to install a winch of this type only on large SUVs that have a high curb weight. In addition, the design is suitable for vehicles that are often used for driving on rough terrain.

Types of winches

There are several types of winches available from different brands. There are devices special for specific tasks, but you can also buy universal-purpose units that can be installed on any type of transport, overpass or other type of structure.

For example, they are often used on car tow trucks, but if you are going to officially provide vehicle evacuation services, then your homemade device will have to be registered and regularly checked for wear. The logbook will need to be presented when the equipment undergoes maintenance. This applies to cables that have a degree of wear or a limited number of torn strands.

The following types of winches are known:

- An electric winch is a device whose winding drum is driven by an electric motor. It must be high-torque and low-speed, so a primarily reduction planetary gearbox is used with it. Other designs can be used, depending on the traction force. Automotive winches installed on tow trucks for passenger cars are designed for 4 tons. There are models on sale from 1 to 15 tons or more, produced by Chinese, Russian, Dutch and Finnish manufacturers: KDJ 9000 L, KDJ 8000 L, Delta DV 15000 winches and others.

- Hydraulic - a mounted unit connected to the vehicle’s hydraulic system. Accordingly, they are installed only on special types of equipment, for example, on MTZ tractors or Chinese models. They have high traction forces and excellent operational reliability in almost any extreme conditions.

- Mechanical winch with manual drive. A common design option, but inconvenient because it requires a long lever and time. This is the most reliable design, as it does not have electric or hydraulic motors.

As for the price, it can be very different, depending on the performance of the device. For example, units for passenger cars with a load capacity of up to 4 tons will cost about $500 with an electric drive.

Hydraulic ones are 2 times more, which is why many owners of Niva vehicles or other SUVs dream of making homemade winches for their cars.

Do-it-yourself winch from the starter

A design that uses a starter to transmit force has become quite widespread. A winch from a starter is made with your own hands in cases where it is impossible to select the most suitable gearbox.

Considering how to make a winch from a starter with your own hands, we note the following points:

- The chassis is created according to the downloaded or developed project. All elements are connected by welding.

- The drum is being made. To do this, you can use a pipe of the required diameter, but there are also more complex mechanisms.

- The drum is fixed on a shaft with an asterisk to which the force will be transmitted.

- The drum structure is mounted on the housing together with the starter.

- The starter is connected to the shaft.

- The power source is connected to the control unit and the operation of the device is checked.

- Protective elements of the main mechanisms are created. Do not forget that when driving over rough terrain, the winch can be subject to various types of impact. High-quality protection can significantly extend the service life of the structure.

- The winch is installed on the car and tested in action.

Winch from starter

A homemade winch from a starter is characterized by relatively small overall dimensions, as well as high efficiency in use. That is why it is created more often than other designs.

Making a drum winch

This design is the simplest and can be used in the field. A more practical type of winch would be portable equipment. The design involves the use of more complex parts that are manufactured independently. To improve operating efficiency, additional video reducer elements can be used.

You can find many drawings of homemade winches online. When choosing a specific drawing, it is necessary to take into account the conditions in which the equipment will be used.

If the winch will be installed on the roof or in the trunk of a car, then it is necessary to calculate the additional load that will constantly be placed on the device

If the winch is planned to be used in cold regions, then special attention must be paid to the quality of the metal

Low-quality metal can lead to device failure at the most inopportune moment.

Required parts and equipment

To make a winch we will need:

- rectangular pipe for the frame;

- finished shaft, or round pipe;

- steel sheet 3-5 mm thick;

- M10-M12 studs, 20-25 cm long, 6 pieces, nuts;

- hubs for the shaft;

- ready-made gearbox assembly or sprockets of large and small diameter with a chain, or gears;

- welding machine with electrodes;

- spanners;

- metabo with grinding discs.

Motorists note that homemade winches are reliable, practical and durable. For the drum, it is better to use a pipe with a diameter of 20-50 mm with a wall thickness of at least 3 millimeters. Using pipes with other parameters is impractical; then during operation they become deformed and the winch loses its functionality.

Assembly steps

First of all, we recommend sketching out a drawing of the device, where you indicate the dimensions of individual parts and their location. This will make it easier to navigate when assembling the entire structure.

Next you need to make the frame. To do this, we cut out blanks of the required length from a steel pipe with a diameter of about 2 cm, the ends of which are cut at an angle of 45 degrees. We weld the tubes together so that the angle of their connection is exactly 90 degrees. After this, remove the scale and polish the seams.

To create a drum, we need a sheet of steel about 3-5 mm thick, from which we need to cut two disks with a diameter of 30 cm. 7 holes are cut in each disk: one in the center of the disk, six around the circumference of the disk at a distance of about 7 cm. Diameter The hole in the center must correspond to the diameter of the device shaft.

The discs are fastened together using M10 or M12 studs, the ends of which are placed in holes along the diameter of the discs and secured with nuts and locknuts. You can also pre-fit metal tubes of the appropriate diameter onto the studs to increase the strength of the structure. Thus, the drum of our winch is ready. Next, we attach the shaft, which you can make yourself from a metal pipe or take a ready-made one from another mechanism. The ends of the shaft must be equipped with hubs to attach it to the frame.

The next step is to install a sprocket or gear on the drum shaft, depending on the gearbox being installed (chain or gear). Here the designs can be varied, especially with regard to gear transmission. The simplest ones are single-stage cylindrical or conical.

Depending on the gearbox you choose, provide a place to mount it on the frame of the structure, taking into account the location of the handle. Next, we mount the drum with the shaft and the gearbox on the frame, install the chain on the sprockets or gear train.

Don't forget to lubricate the gear teeth.

After this, we fix one end of the cable to the shaft and wind it onto the drum, and attach a carabiner to the other end of the cable. A hook or carabiner is also welded to the frame of the device for mounting on the frame of the car. Thus, a simple drum winch is ready for use.

Advantages and disadvantages of a homemade winch

Many motorists are wondering whether it is worth making a winch from scrap materials or whether it is better to purchase a ready-made version. To begin with, we note that a homemade winch has the following advantages:

- High maintainability. If the device is made by yourself, then repairing it will not be difficult. At the same time, it will also not be difficult to find all the necessary materials.

- Low cost. Purchased structures are quite expensive. You can make a winch yourself using scrap materials, which significantly reduces the cost of the product.

- Easier to install on a car. A homemade winch is initially made for a specific car.

As for purchased versions, they often have more compact dimensions and a high efficiency rate. Many structures are also suitable for repair. Their only drawback, of course, is the high price. In addition, some winches can only be installed in a prepared place, for which you will have to change the bumper or purchase a new one.

Communities › Garage Equipment and Tools › Blog › DIY hydraulic crane with winch

Good evening everyone! I'll post my version of the engine removal crane. According to the material it took: 1. Profiled pipe 60x60 - 6m 2. Profiled pipe 40x20 - 2m 3. Sheet 8mm - some was chopped. 4. Wheels for carts D-80mm, 100kg each - 4 pcs. 5. Bolts M8, M10, M14 (for 14mm rotary axles). 6. Sorokin winch. 7. Hydraulic cylinder in the future Sorokin. 8. Electrodes 3mm - 2.5kg 9. Hitachi cutting wheels 230mm - 3 pcs.

The design is completely collapsible into 4 parts. Stable when assembled. For easy assembly, a fifth wheel would be nice. Although the idea is to make the bottom completely different. One of these days I will make rollers for the cable. Hydraulic cylinder in perspective.