Sometimes a car may end up in a place where an ordinary car cannot reach. This situation is especially common among lovers of active automotive recreation. And then you have to overcome difficult off-road conditions, and for this you need to rely on the physical strength of passengers, who, by the way, may not be there, or use the power of powerful tractors. In this case, the car owner cannot do without a winch, with which you can pull the car out of any kind of difficulty in the form of mud or sand. Therefore, it will be useful for every car enthusiast to learn how to make a winch from a starter with his own hands, which will be discussed below.

Tips for assembly and operation

When assembling a homemade winch, you should pay close attention to all the details.

This will avoid possible unpleasant consequences that may occur due to poor quality design. Under no circumstances should you force the assembly process. As they say, if you hurry, you will make people laugh. It is better to spend an extra hour to understand everything exactly than to later reap the fruits of your haste. You need to pay attention to the switching and installation of electrical wiring

It is recommended to secure the winch control panel away from rotating parts. This will reduce the risk of injury that may subsequently occur due to negligence or as a result of hasty actions.

Types of winches

There are several types of winches available from different brands. There are devices special for specific tasks, but you can also buy universal-purpose units that can be installed on any type of transport, overpass or other type of structure.

For example, they are often used on car tow trucks, but if you are going to officially provide vehicle evacuation services, then your homemade device will have to be registered and regularly checked for wear. The logbook will need to be presented when the equipment undergoes maintenance. This applies to cables that have a degree of wear or a limited number of torn strands.

The following types of winches are known:

- An electric winch is a device whose winding drum is driven by an electric motor. It must be high-torque and low-speed, so a primarily reduction planetary gearbox is used with it. Other designs can be used, depending on the traction force. Automotive winches installed on tow trucks for passenger cars are designed for 4 tons. There are models on sale from 1 to 15 tons or more, produced by Chinese, Russian, Dutch and Finnish manufacturers: KDJ 9000 L, KDJ 8000 L, Delta DV 15000 winches and others.

- Hydraulic - a mounted unit connected to the vehicle’s hydraulic system. Accordingly, they are installed only on special types of equipment, for example, on MTZ tractors or Chinese models. They have high traction forces and excellent operational reliability in almost any extreme conditions.

- Mechanical winch with manual drive. A common design option, but inconvenient because it requires a long lever and time. This is the most reliable design, as it does not have electric or hydraulic motors.

Hydraulic ones are 2 times more, which is why many owners of Niva vehicles or other SUVs dream of making homemade winches for their cars.

Installation of basic elements

First, the drum shaft is mounted. As an additional element, you can make a simple type of cable guide. It consists of two plates with a roller between them. The cable will slide along it, which will prevent it from tangling and will promote uniform winding on the drum.

If the transmission from the starter to the shaft is carried out using a gear pair, the input shaft must be located on top. It is advisable to provide the ability to adjust the location where the starter is mounted. This way you can achieve optimal coupling between the gears.

Belt driven design

The final stage of making a winch with your own hands is the installation of electrical wiring. To do this, you can use simple wires to connect to batteries with crocodile terminals. Be sure to install a switch between the wiring and the starter. As a result, the resulting mechanism should be powered by a car battery.

The operation of the winch is checked in stages. First, you need to apply a small load to ensure the reliability of the transmission mechanism. By gradually increasing the degree of load, you can experimentally determine the maximum mass that the resulting winch can “overpower.”

Features of installing a winch on a car

Each car has to come up with its own mounting structure. It should ensure installation of the winch to the machine even after it gets into deep mud. In addition, the mounting points must be extremely reliable so as not to compromise the integrity of the vehicle during towing.

- The best option would be to install a winch on the upper surface of the bumper. This scheme becomes possible only if you have a reliable and durable metal bumper. For installation, you first need to place the winch at the mounting location and make markings. Then, using an electric drill, through holes are made in the bumper. The mechanism is attached to the car using bolts and nuts.

- Not all bumpers are made strong enough to accommodate a winch. In such cases, it is necessary to make special brackets that are attached to the frame or side members of the vehicle. However, it is best to place the platform for installing the winch above the bumper. If the car gets stuck deeply, you can attach a winch and pull the car out of the quagmire. If the mount is low, it will be more difficult to install the mechanism and free the car from the mud captivity.

- It is advisable for the car owner to provide a platform for attaching a winch in the rear of the car. After all, a suitable support for tying the cable will not always be located in front.

When choosing a winch, the motorist should be guided by the characteristics of his car. Not every industrial model will fit the machine perfectly. Therefore, you will have to modify store-bought products or make your own design. In any case, the made and installed winch should be able to easily remove the vehicle from the swamp or sand.

Features of application

The winch is a highly specialized, but at the same time universal type of traction mechanism, which has become widespread not only for use as a winch. They are used in the following areas:

- During construction, for lifting heavy loads to heights. Both mechanical and electrical devices are used.

- To evacuate cars stuck in a quagmire, then a winch is installed on the car itself.

- In agriculture, for dragging and lifting logs and other heavy objects to a height.

The list is not limited to these three positions; a good unit will always find application. That is why many people make a homemade winch for a Niva or other domestic SUV with their own hands. In any case, it must be reliable, durable and strong, so its production should be approached with responsibility. At its core, it will be a useful upgrade for your car, which will always find its use. For example, you can pull your own car out of the mud by clinging to a thick tree, or help out your friend.

Do-it-yourself winch - price

If you have your own garage or shed with rubbish accumulated over several years of home plumbing, the cost of the product is determined by the price of a can of spray paint for final finishing.

Basically, the components are as follows:

- Starter from a VAZ 2101 car without a planetary gearbox (working, lying in the garage);

- A gearbox in a housing from a domestically produced electric drill (purchased at a flea market for the equivalent of 0.5 vodka);

- A piece of water pipe found in a barn;

- Metal for the frame, body walls, drum. Also found in a barn;

- Drum axle - purchased at a scrap metal collection point for pennies;

- The rope and hook were purchased at a tourism supply store.

Taking into account the cost of a new winch, the cost of the issue can be considered zero. At the same time, the owner can vouch for the safety of the device. Every detail and weld is personally checked by the manufacturer.

How to make a simple feather removal machine for home use from a washing machine with your own hands

The time of slaughtering a bird is a troublesome stage. This is usually done in the fall, when the ducks and broilers have reached the desired weight, and it is no longer profitable to keep them in the winter. You need to pluck several dozen or even hundreds of carcasses very quickly. You can get rid of hard labor with the help of a feather removal machine, and it’s easy to do everything from the same parts of the washing machine.

The only thing that can cause difficulties is the search for rubber fingers with threads - beaters. You will have to order them, so keep in mind that you need to think about making the machine long before slaughter

The device does not require disassembling the washing machine. It is especially convenient to use machines with vertical loading. You just need to fix the beats in the drum so that they point inward. Before plucking, the chicken carcass must be scalded with boiling water and then simply thrown into a rotating drum. Here's what happens:

And the last point - the feather removal device must be firmly fixed, since the vibration when loading the carcass will be very strong.

Drum hand winch

The easiest way to make a winch with your own hands is to make a manual drive that drives the drum. To do this, you can use improvised means. The most commonly used parts are bicycle parts.

The drum is operated manually, so this unit is not designed for high loads, but is quite suitable for domestic use.

The design includes the following elements:

- drum;

- gearbox;

- support;

- lever.

The following types of drums can be used:

- toothed;

- worm.

If you plan to move heavy loads, it is better to use a worm drum. It significantly increases the force applied to the handle. Such a drum does not require manual braking; it locks automatically when the force is no longer applied to the handle.

The downside is the worm mechanism itself, which has a complex design. The unit requires regular lubrication. A manual winch, made with your own hands from a toothed drum, is less demanding in maintenance, easier to repair, but is designed for lighter loads.

Types of homemade winches

Winches are divided into three main types: electric, mechanical and hydraulic. The fourth is manual. Each design has its pros and cons, both during the design and installation process, and during operation.

A hand winch is a popular option. The downside is that its use requires physical effort. The advantage is complete autonomy, no electricity required. In order to pull out a car, all you need is a firmly standing tree or just a crowbar driven into the soil. Hand winches are divided into 3 main types:

- Lever.

- Assembly and traction.

- Drums.

Lever ones use a ratchet or ratchet mechanism. Their main drawback is the traction force - from 0.7 to 4 tons. The advantage is that there is no need for rigid fixation; you can work on weight. This is the simplest type of winch.

Assembly-traction winches are almost similar to lever winches, but are not equipped with a drum. This is the most common type, and not only for cars.

Drums are the most effective option. The drum can be toothed or worm. The first wears out much more slowly.

Advantages of drum winches: traction force from 0.25 to 5 tons; a brake that is activated in an emergency situation; cable length (up to 40 meters with a diameter of 15 mm). If the thickness is greater, you can pull out any heaviest car from anywhere, and the cable will not break, even if you give full throttle.

Drum winches use:

- Single speed gear drive. The main gear is attached to the drum, which takes on the main load. The clutch houses the drive gear. The gain factor is the ratio of the number of their teeth. The gain is also affected by the length of the lever - the longer it is, the less force is required. This winch allows one person to pull out a car weighing up to 3 tons.

- Multi-speed gear drive. Such a mechanism consists of two or several pairs of gears, due to which the gain increases many times over. The downside is low speed under heavy loads.

- Worm drive. Rarely used for cars in “camping” conditions due to high maintenance requirements - the worm pair requires constant lubrication. In addition, this type does not work most effectively with high loads and is not suitable for heavy vehicles. The advantage is compactness.

Electric winches

The most popular type of homemade winch for a car. This is justified by its power, ease of operation and reliability. In addition, this option does not require large expenses for assembly and installation on the car. Such an electric winch can operate either on its own autonomous electric motor or receive power from a generator installed in the car. In the second case, you need to look and calculate the installation so that power is supplied from it not only to the winch, but also to the vehicle systems.

A popular option is using a starter; such a winch is easier to build with your own hands. The Zilov ST230 starter is often used.

Mechanical winches

Mechanical winches are powered by a motor. Manufacturers often install them already at the stage of completing SUVs (for example, such an automobile self-extractor is installed on an army UAZ). This winch is connected to a shaft and operates through a transmission. The winding speed can be changed by lowering or increasing the speed. The main advantages are stability and traction power. The main disadvantage is that it only works with a working engine.

Often this option is used for installation on MTZ - skidding, for example, forests is much easier.

Hydraulic winch

The most structurally complex option, since in addition to the standard ones it must contain additional elements: a hydraulic drive, a tank and an oil pump. In addition, the device can hardly be called compact. Assembly and installation will require considerable effort. However, such a winch consumes much less energy than electric power, and its power is much higher.

Homemade winches for cars and households

The winch is a mechanism that is widely used in many areas of life. The principle of its operation is to transmit traction force from the drive drum using a flexible element (chain, cable, rope).

Depending on the source of applied force, winches are divided into mechanical and electrical. You can make both of them yourself with a little effort and patience.

Homemade ratchet winch

Quite often there is a need to lift a heavy load and fix it in this position.

This could be, for example, a massive basement lid or large parts of a car.

A homemade ratchet winch will help you cope with such a difficult task.

Most often, a worm mechanism from ZIL is used to make homemade ratchet winches - it is the most compact and can support a weight of up to half a ton.

Ratchets from KamAZ and MAZ can withstand weights of up to two tons or more.

This is the most suitable winch option for home use. A solid load capacity will allow you to cope with relatively large loads if necessary. Lifting or dragging them. Let's take a step-by-step look at the entire process of creating a winch from KAMAZ ratchets.

To make a lifting device of this type you will need:

Two rear ratchets of a Kamaz car: left and right

Hooks for towing, 2 pcs.

Cable with a diameter of 4-5 mm.

Fist for releasing brake pads on a Kamaz vehicle

Hook bolt

Next, cut off the pawl from the expanding fist and, using an angle grinder, popularly called a grinder, cut slots identical to those located on the other side. The ideal option would be to manufacture such a shaft in a mechanical workshop on a milling machine.

Take covers from an unnecessary used ratchet and make two washers for the future winch.

Weld the structure as shown in the photo and drill a hole along the diameter of the cable to fix it.

Install the ratchets on the splines, install the bolt and hang the tow hook on it. The structure can be strengthened by putting a bushing on the bolt. I did this using a bushing from an internal combustion engine mount.

We install a second towing hook on the free end of the cable.

We make and install a handle for easy operation of the winch.

Let's test the resulting mechanism. The winch is ready for use.

If you frequently use a homemade ratchet winch, the worm mechanism can quickly fail; in this case, it is better to replace the gears with stronger and more wear-resistant ones.

Drum hand winch

How to make a muffler with your own hands? DIY muffler repair without welding

The easiest way to make a winch with your own hands is to make a manual drive that drives the drum. To do this, you can use improvised means. The most commonly used parts are bicycle parts.

The drum is operated manually, so this unit is not designed for high loads, but is quite suitable for domestic use.

The design includes the following elements:

- drum;

- gearbox;

- support;

- lever.

The following types of drums can be used:

- toothed;

- worm.

If you plan to move heavy loads, it is better to use a worm drum. It significantly increases the force applied to the handle. Such a drum does not require manual braking; it locks automatically when the force is no longer applied to the handle.

The downside is the worm mechanism itself, which has a complex design. The unit requires regular lubrication. A manual winch, made with your own hands from a toothed drum, is less demanding in maintenance, easier to repair, but is designed for lighter loads.

Winches classification

Winches are divided into several types according to the following criteria:

- design;

- connection type;

- technical features.

Depending on the design and drive, the following types are distinguished:

- Manual. It has small dimensions. Usually equipped with a drum that is rotated manually using a crank. Not suitable for scales above 1t.

- Mechanical. It does not have its own drive, so it is connected to a separate motor. It is heavy and is not used in cars.

- Electric. The most convenient and practical model. The drum is rotated by an electric motor. Can lift up to 4 tons.

- Hydraulic. It features a complex design, quiet operation, high power and load capacity,

They are also stationary and removable.

Homemade winches

Ratchet from Kamaz How many people know how to make a winch from a brake ratchet? And what exactly is this Ratchet?

Many trucks (our products for Kamaz are popular) use a self-leveling mechanism to adjust the brakes; in common parlance, a brake ratchet is used. A worm gearbox is located inside the device.

All that remains is to adapt the handle to the end of the worm pair, and the drum to the main axis - and the winch is ready. Gear ratio 1:20. The drum can be mounted on the standard brake axle by cutting it with a grinder. If you use a block connection with one elbow, the power will double. Don’t forget to lubricate – and the device will serve you for many years.

Such a winch in the garage will not help you pull out the engine, but it will save a lot of effort during repairs. This device is especially useful for lifting heavy objects from a pit.

Video - how to make a ratchet winch for Kamaz with your own hands.

Chainsaw in a winch If you are busy building a summer house where there is no electricity yet, you can build a winch from a chainsaw with your own hands. Initially, such a device was invented by lumberjacks to facilitate the procedure of tying felled trunks.

The photo shows the classic “Friendship” with the body removed. A motorcycle chain is connected to the drive sprocket. The drum is not difficult to make. A large sprocket from the wheel of the same motorcycle is attached to it.

We get a double gearbox - our own on the chainsaw, and a chain gear made of two sprockets with a gear ratio of about 1:10. This design will serve for many years, extending the life of the components from which it was made.

Manual lever winch The simplest device for moving loads is a lever winch. With its help, you can pull a load into the body, drag the carcass of an animal killed while hunting, or pull out a stuck car.

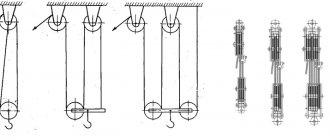

The device is not very expensive, but even Chinese samples cost some money. For those who like to do things with their own hands, we offer a drawing of a lever winch, from which the principle of its operation is very clear.

A drum is fixed inside the frame, with a ratchet sprocket. There is a stop on the lever that rotates the sprocket. The longer the lever, the more force you apply. This is only a small part of the structures that can be made from scrap materials. Perhaps you will come up with something completely original.

A winch is a device for lifting, lowering or moving a load. Why do you need a winch in the garage? The answer is simple. For lifting and lowering various loads. Avid auto repairmen can't do without it. The price of a regular electric winch starts from 10,000 rubles. For this considerable amount, you will receive a winch of dubious quality, with a lifting capacity of up to 1 ton. This is quite enough for you to repair and maintain cars.

If you want to save your money, you can make an electric winch with your own hands, and for the remaining money buy a good set of keys for your garage. To make such a device, we will need a car starter, a suitable gear drive, a drum, an iron cable and some sheet metal of various thicknesses, a pipe, studs and nuts. We will provide you with do-it-yourself winch drawings, tell you and show you how to do everything as quickly and reliably as possible, and most importantly, from scrap materials. You may not have some parts, but this is not a big problem - such things can be bought at the flea market for a few pennies. Let's not drag our feet, and let's go to the workshop to make this wonderful and irreplaceable tool for the garage.

How to make a winch from a starter

Let's take the Zhiguli starter as the initial donor. It is quite reliable and at the same time has a compact size. Another advantage of this choice is that a VAZ starter can be found almost for free at any dismantling of domestic cars.

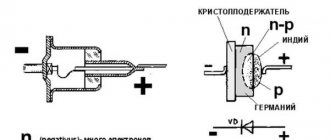

The drawing shows the device and components of the starter. In the upper part there is a retractor relay with power contacts. They can be used if large loads on the winch are expected. On the left is the bendix mechanism, which must be removed along with the cone housing.

Since we are talking about a compact, low-power mechanism, it makes no sense to make a gearbox for a winch from a flywheel gear. It is enough to pick up a unit from a large drill. Finding one will also not be difficult, since there are more tools with a burnt out motor at flea markets than with a broken gearbox.

Read also: Do-it-yourself knife from a rapid saw

There are no special requirements for the gearbox, the main thing is that the diameters are more or less suitable.

For our adaptation, of course, we need to reduce the speed.

We separate the Bendix housing from the winch, and we are left with only an electric motor with a rotor shaft. The coupling of the gearbox shaft with the mating part of the starter motor is done locally. There are many ways - from banal electric welding to making a transition coupling with cotter pins.

If it is necessary to increase the gear ratio, you can use a starter with a planetary gearbox. Adapting it to your design is not much more difficult than connecting the shafts directly, and the useful power of the winch will increase significantly.

To protect the operator from rotating parts, the space between the gearbox and the engine is closed with a pipe of a suitable size, possibly made of plastic. The casing does not carry a power load, so the gearbox housing must be firmly connected to the motor housing.

Simple threaded studs will not work here; you need to work on the design. In this case, the housing must be dismountable for periodic inspection and maintenance (cleaning, lubrication) of the motor bearings and gearbox mechanism.

Next we make the drum. You can make it at home from a piece of steel pipe with a diameter of 120-180 mm and sheet iron 2-3 mm thick.

We cut out round cheeks and weld them to the pipe. In the center of each sidewall we drill a hole for the power shaft.

The power shaft with the working gear in this design is borrowed from a decommissioned electrified valve mechanism, which is used on gas and oil pipelines. Be sure to use a standard pair of gears, otherwise it will be difficult to pair the main sprocket with the gearbox output.

All elements must be securely welded together; any weakness will sooner or later crack, and the structure will fall apart at the most crucial moment.

A channel or steel strip with a thickness of at least 5 mm is used as a frame. The winch elements should not have any play relative to each other.

The side walls are made of sheet iron 3-5 mm. Thinner sheets may become deformed when the cable is pulled under load.

The most important part is attaching the drum axis. For this, powerful bearings with podiums from some mechanism from the times of the USSR were used. You can find such spare parts at scrap metal collection points or in the workshops of abandoned factories.

The podiums are welded to the side walls. If you managed to find only bearings, weld the outer race. Nothing will happen to the rolling mechanism; the bearings simply cannot be replaced.

We attach the gearbox to the frame so that its gear meshes with the power gear on the drum shaft. We remind you that initially we had a set of a shaft and a set of gears. We install an eyelet between the walls - a leash for the cable.

We connect the gearbox with the electric motor from the starter, put the winch in good shape: we clean the welds with a grinder, remove rust, and cover the tool with paint.

The design has been tested to lift weights up to 200 kg. In this version, two gearboxes are used - from an electric drill and a homemade one from a gas electric valve. It feels like there will be enough traction for another 100-150kg.

If you install a starter with its own planetary gearbox, the gear ratio of which will be added to the two existing ones, the capabilities of the device will double.

The video shows an example of a winch using a starter.

How to use the device?

Be sure to provide for the possibility of reversing the power supply to the winch. Reverse is necessary in such devices. Since this is a regular car electric motor, changing “+” to “-” will change the direction of rotation of the shaft.

Let the power starter be the old one, from the solenoid relay. And the start buttons come from ancient electromechanical devices. The button block can provide for polarity reversal.

If the winch is used in a car, do not connect it to the standard battery with the engine turned off. With a good load, you will drain the battery in 10-15 minutes.

The dimensions allow the winch to be placed on the bumper of an SUV prepared for off-road use.

Homemade winch from a car starter

It is enough to fix the winch cable to any nearby tree and turn it on so that the vehicle can freely get out of any swampy area. But if a jeep, for example, a UAZ, has the ability to overcome a crossroads without using outside earnings, then ordinary passenger cars, the owners of which often go to a place where there are no roads as a class, are not in such an advantageous position. Without the help of a winch, they will not be able to get out, even if they get stuck in a shallow puddle. A winch will cost a decent amount of money, but it can pull a massive car out of a quagmire. Not every car owner can afford to purchase a strong and small-sized model. A good way out of this difficult situation would be to make a winch from a car starter.

A significant number of cars built for off-road driving have high ground clearance and a very powerful engine. This allows them to overcome difficult road obstacles without much effort. But there are situations when, despite the powerful characteristics of SUVs, they are still unable to pull themselves out of the quagmire. In order not to be lost in a hopeless alteration, such cars at car factories can be additionally equipped with strong electric winches as an additional function. This significantly increases the vehicle’s chances of overcoming impassable off-road conditions on its own.

Another version of a winch from a starter for household needs

For production you will need:

- Used car starter with a working motor;

- Flywheel with gear;

- Steel wheel disc, or two brake discs - for making a drum;

- Powerful bearing with a podium (a used hub assembly is suitable);

- Corners, channels - for making a frame;

- The usual tools are a grinder, a welding machine, a drill.

The starter can be taken from a Zhiguli if you do not need to move trucks. The rest of the design elements are whatever you find. In this case, a flywheel from a Gazelle, a hub and CV joint from a VAZ 2108, and brake discs from the same were used.

We twist the disks together in the form of a drum for the cable,

the remaining structural elements recreate the front wheel axle assembly. The only difference is that the hub body will be welded to the winch frame, and the flywheel gear will be attached to the CV joint “grenade”.

The bed is made from a powerful channel and angles. There is no point in dwelling on this structural element, unless we pay attention to strength.

We weld the finished structure of the drum and support bearing to the frame. Please note that the entire power part is supported on one support. There is nothing wrong with this; the hub assembly can withstand such loads constantly.

We weld the outer “grenade” of the CV joint to the flywheel. The quality of welding must be high, since this unit will be heavily loaded. In this embodiment, gear architecture was used. The coupling is machined to accommodate the CV joint.

“Having measured seven times,” we weld the eye to secure the starter housing.

The design is ready, testing can begin. The solenoid relay bendix must be locked in the maximum engagement position. This can be done by welding. The relay itself performs the function of a starter.

A nice feature of this winch is the presence of reverse. By switching the polarity on the power supply, we can start the starter motor in the opposite direction. The design of the reverse trigger mechanism can be achieved using power relays.

Source

Manufacturing a system with a universal drive

The manual system is easy to manufacture. Of the special skills the master is required to do, only own a welding machine. Any metal will do the job. The appearance of the device is not so important, the main thing is performance and resistance to heavy loads. The frame should not be deformed.

Materials and tools:

- Rectangular tube for frame.

- Shaft for the drum, you can use a round tube.

- A sheet of metal with a thickness of at least 3 mm for the manufacture of drum disks.

- Threaded rods M10-M12, 24 cm long – 6 pieces, nuts.

- Tube diameter 14 mm - 6 identical pieces of 20 cm.

- Asterisks - large and small. Chain.

- Hubs to secure the drum to the shaft and secure the shaft to the frame.

- Drive lever.

- Cable with carabiner.

- Welding and electrodes.

- Grinder and grinding disc for it.

- Paint and primer.

- Wrenches included in the set.

Manufacturing procedure:

They sketch out a drawing, because this will make it easier to navigate during assembly - you won’t have to stand guessing over the half-finished product and think about what to do next. Cut out the frame parts from a pipe with a cross-section of 2 by 2 cm. Connect the frame parts together strictly perpendicularly. The cut on the workpieces is made at an angle of 45 degrees. Lay the frame blanks on a flat surface. The joints are spot-tightened by welding, after which they check whether everything is installed correctly. The angles of the connections must be strictly 90 degrees. If there is a lack of accuracy, corrections are made and then the parts are welded. Scale is removed with a grinder and a grinding wheel. The finished frame is sanded and then coated with a primer. After the latter has dried, the metal is painted with enamel in 2 layers. You can use regular paint. The goal is to protect the metal from corrosion, since operating conditions will be difficult, with dirt and moisture. Creating a drum. Take a sheet of metal and cut out 2 circles, their diameter is about 30 cm. On each circle you need to make 7 holes: One in the center. The diameter must match the shaft size. 6 holes at a distance of 7 cm.

The discs are fastened together using pins. The pin is inserted into the hole of one disk in a vertical position. Tubes with a diameter of 14 cm are put on the studs, and a second disk is installed on them. The studs must not only be secured with nuts, but also additionally reinforced with locknuts to ensure reliable connections. The drum is ready, now the shaft is mounted. It is made from a metal pipe, but you can take a finished product from any mechanism. The latter option is preferable: since the accuracy of the factory part is higher, vibrations of the drum will be small or absent altogether.

A large diameter sprocket is mounted on the shaft on the outside of the drum. A sprocket from a motorcycle gearbox will do. To secure the drum to the frame, the outer sides of the shaft must have hubs. The drum assembly with the shaft is mounted through the hubs on the frame. The structure is secured with bolts. Before installing the drum, you should prepare a platform on the frame. A drive will be installed on it - manual or electric. When using an electric drive, a motor is placed on the platform with a small sprocket attached to its shaft. A universal drive is often installed: a handle is placed on the reverse side of the output shaft of the electric motor

In the absence of electricity, the winch can be turned manually. It is important to properly tension the chain. It should not sag, but strong tension is also unacceptable - this will cause the sprockets to wear out faster, and the chain may break.

Check the chain tension by rotating the drum - the chain should not hinder its rotation when the cable is unwound. The end of the cable is secured to the shaft and wound around the drum. A carabiner is hung on the other, free end of the cable. A shank is attached to one end of the frame. With its help, the winch is secured to the car frame.

The winch is created in a day. Since it will be installed on an SUV, the operating conditions will be appropriate. To prevent dirt and sediment from getting on the drum, it is covered with a casing. This way the mechanism will last longer and the cable will not wear out.

The design is simple, reliable, and easy to make yourself. Yes, it does not have the ability to change the gear ratio, there is no reverse or other additional functions. A self-made electric winch is capable of dragging a heavy load across the terrain, be it a car or something else.

Types of winches

Depending on the situation, you can use different types of winches, which differ in the energies driving the mechanism. The principle of operation in this case is the same - the steel cable is wound on a drum, which can be rotated manually or through an engine gearbox. Both factory and homemade winches from the starter can be manual, hydraulic or electric.

Let's look at them.

The action of a mechanical or manual winch is based on the force of the motor. In terms of reliability, this option has no equal. However, those who like to relax in off-road conditions are not particularly fond of such a mechanism due to its large dimensions. If such a winch is initially provided in the vehicle, the driver will feel as protected as possible, but will not choose this option when installing the mechanism on his own. Despite the fact that a DIY hand winch will be powerful, it takes up too much space in the car.

Electric options are the most popular among SUV drivers. The drum is rotated by an electric motor powered by a car battery.

When working with such mechanisms, it is important to monitor the battery charge and leave enough battery life to get home. These winches are practical and are designed to lift loads weighing up to 4 tons.

It is the electric option that is most often chosen if you do the winching yourself. The design of a hydraulic winch is the most complex due to additional elements in the form of an oil pump, an oil tank and a hydraulic drive. Assembling such a mechanism yourself is more difficult than others, and the winch turns out to be too bulky. Nevertheless, this option also has advantages, including minimal energy consumption combined with high power. The feasibility of using hydraulic winches is observed when operating walk-behind tractors, tractors or SUVs.

Assembly Tips

Design development is carried out carefully, as well as assembly. The task is to treat each operation as responsibly as possible. The goal is to complete the assembly with high quality. This will avoid troubles when operating in extreme conditions. Therefore, there is no need to force the work, even if it is really necessary.

Steps to achieve high build quality:

Negative results often arise due to hasty actions. The issue of moving cargo in a horizontal plane with its own device will be successfully resolved. To lift loads above the ground, the cable must be pulled over a strong support.

Do-it-yourself manual winch: detailed drawings and photos of making a homemade winch from a ratchet from Kamaz.

In this article we will look at the step-by-step production of a homemade winch made by a craftsman from Samara.

To implement the idea, the author decided to use a KAMAZ ratchet, here it is in the photo.

The design will be made on a carriage that will move the winch along the channel. The figure shows drawings of a winch for self-production.

The shaft was cut to length, two round plates 4 mm thick were welded, and a cable would be laid between the plates.

One side of the shaft needed to be ground so that a 207 bearing with a diameter of 35 mm could be pressed onto it. Made a plate.

The ratchet is put on splines, a washer is put on and a cotter pin is placed diametrically through the shaft. On one side I installed a plate with a bearing.

I welded the stud onto the shaft, put a washer on the stud and tightened it.

I assembled the carriage using 8 mm thick steel, cut out 3 plates and welded them together.

I drilled 25 mm holes in the plates, welded pipe sections to them and placed 205 bearings on them. Then I tightened the bearings with bolts and washers.

I drilled a couple of 12mm holes in the bottom plate. and pulled two plates together with bolts through the pipe.

A hand winch is used in the garage to lift the engine and other needs.

Read news about the new Niva

- Do-it-yourself installation and connection of a tow bar on a Lada 4×4 » Lada.Online - all the most interesting and useful about LADA cars

- Buy Niva 4×4 Moscow price 2019-2020 for Lada 4×4 new, official dealer - all configurations

- Right-hand drive cars in Russia, what changes are happening

- CONTROLS Chevrolet Niva

- Ford Expedition - Wikiwand Ford Expedition

- spare parts Tianma Century (Tianma Century) (page 7 of 9)

- Repair manual for Suzuki Grand Vitara (Suzuki Grand Vitara) 1998-2005. |

- The check light came on for a Niva Chevrolet reasons

Safety regulations

Do not step over any stretched rope. During work, you cannot do without specialized gloves that have sealing elements on the fingertips, or high-quality canvas gloves. The use of regular gloves is strongly discouraged.

Do not forget about the possibility of the cable breaking, as this is extremely dangerous for both equipment and people. It is advisable to place a load in the center to ensure safety. The cable is fastened only to strong, high-quality elements.

Before using a car winch, the cable must be completely unwound, after which it is carefully, but as tightly as possible, wound back with the necessary tension. This avoids entanglement, which can cause the drum to jam. Full unwinding ensures maximum efficiency, low damage and proper elasticity

Full unwinding ensures maximum efficiency, low damage and proper elasticity.

Types of winches

On sale you can find a variety of winch options. The main classification is considered to be what type of drive is installed. Based on this indicator, the following structures are distinguished:

- Electrical structures are the most widely used today. This is due to the fact that such a design is capable of operating under very high loads. Typically, the installed electric motor is powered by the vehicle's battery, and the control unit can be located inside or outside the vehicle.

- A mechanical winch is the easiest to manufacture. The worm design has become widespread, when a gearbox is installed to transmit force and increase it. A small mechanical type auto winch is designed for low effort.

- Hydraulic. Hydraulic-type designs are also available. Their operating principle is based on the supply of liquid under high pressure, due to which the moving element moves. Typically, a hydraulic drive is installed on a structure intended to transport cargo.

Most often, a homemade design has a mechanical drive, since it is easier to manufacture and install.

Manual

A do-it-yourself manual winch is quite simple to manufacture, which has determined its wide distribution. The main disadvantage of the design is its rather large overall dimensions. A manual drum winch can extend significantly beyond the vehicle, and its installation requires a special bumper with a wide seat.

Do not forget also that the design is manually driven.

At the moment when the car is stuck, it will not be possible to pull and control it at the same time. That is why the design in question is becoming less and less common today.

Drawing of a hand winch

Electric

As previously noted, electrically driven designs have become quite widespread. This is due to the fact that a homemade electric winch is comfortable to use and designed for a fairly high load. Let's call its features the following points:

- A high efficiency indicator determines that the design copes with the assigned tasks more effectively.

- A separate electric motor or generator can be used as a source of force. When choosing an option in which the winch is connected through the generator, you should be careful, since this component of the vehicle is important and cannot withstand overloads.

- An electric car winch must have high torque. In addition, quite a lot of attention is paid to energy consumption. This is because when the vehicle is stationary, most of the power will come from the battery rather than the alternator. Excessive power consumption can cause the battery to drain quickly. However, too low power consumption can cause a significant reduction in the power of the device.

Recently, versions that can be powered by a 12-volt energy source have become very popular. In such a case, the winch device is connected to the cigarette lighter or the corresponding socket in the car, if available.

Hydraulic

The hydraulic winch is considered the most complex design option, since the design is represented by a combination of the following elements:

- Drum with cable.

- A mechanical element that transmits rotation to the drum.

- Hydraulic drive.

- Oil pump or compressor.

- Oil tank.

In addition, such a car winch is quite difficult to manufacture and is large in size. The complexity of the design also determines the need for periodic maintenance.

The advantage of the hydraulic drive version is low energy consumption and higher power. It is advisable to install a winch of this type only on large SUVs that have a high curb weight. In addition, the design is suitable for vehicles that are often used for driving on rough terrain.

Homemade electric winch

A homemade electric winch will come in handy in the most difficult situations.

It will help pull your car out of a deep quagmire, saving money.

Its work is based on the principle of using the power of all kinds of devices, such as:

— generators from tractors;

— starters converted for engines.

Making an electric winch with your own hands is not difficult. You can use it for housekeeping, for example, use it in the process of plowing a personal plot, construction work, as well as in any other operations related to the movement of goods. Let's look at step-by-step instructions for creating this mechanism.

First you need to determine the necessary components:

Electric motor. For a home winch, it is not advisable to use a heavy-duty motor designed for a three-phase network. A small motor with a power of 2.2 kV and a voltage of 220 V is quite sufficient. We offer an electric motor more powerful than in the video. Practice has shown that a device with a power of 1.1 kW cannot cope with plowing. And the 2.2 engine was tested at the dacha.

Electromagnetic starter PM2 16A, remote control, capacitor, wire PVA 3X1.5

Pulleys (2 pcs) and a belt for arranging the transmission from the electric motor to the gearbox.

Bearing 180306 in housing (2 pcs).

Splined part from the outer grenade (2 pcs).

Rolled metal of various thicknesses and sections for the manufacture of frames and drums.

Hardware for mounting the engine, gearbox and drum.

To carry out work on the manufacture of the mechanism, you will need: a mechanic's tool, an angle grinder, a drill and a welding machine.

Kinetic diagram of a winch with an electric motor

Before you start making a frame for the unit, you need to sketch a sketch of the future metal structure indicating the dimensions. To do this, you need to take a sheet of paper and draw a frame, then use a measuring tool to take all installation dimensions and plan the placement of the electric motor, gearbox and drum on the sketch.

We weld a common frame from a rectangular pipe, onto which we mount an electric motor and gearbox with installed pulleys and a screwed base made of a profile pipe. To ensure that the belt does not sag, we make the engine platform on canopies, then spot weld the canopies to the frame of the unit, as shown in the photo.

We install the gearbox on the corners. We put on the drive belt and check its tension. We weld the base of the gearbox.

Let's move on to making the drum. We weld metal washers to the pipe with a diameter of 159 on both sides, as shown in the photo.

Also interesting: LADA Niva Travel – Prices and configurations, review, photos – – Lada Center Oskol: LADA dealer in Stary Oskol

Next we proceed to welding and assembling the shaft. We weld the splined part of the grenade into the end of the shaft as shown in the photo and insert the shaft inside the drum. We stuff bearings and housings onto the shaft and spot weld the shaft to the drum. We weld the second splined part of the grenade to the gearbox shaft.

We align the drum using available means to maintain the alignment of the gearbox shaft and the drum. Next, using a corner, we secure the drum bearing housings with spot welding.

We connect the electrical equipment of the winch and do a test run.

If the testing was successful, turn off the power supply, remove the electric motor and gearbox and weld the joints. Then we put the winch mechanisms in place. We fix the cable on the drum. On the other side of the cable we install a tow hook. The homemade electric winch is ready.

This mechanism has a fairly large load capacity, but requires time for assembly and lack of humidity.

For safe work with heavy weights, it is advisable to equip the electric winch with a small and simple remote control.