And one more very important feature of metal floor beams is that such beams can be used to cover two, three or more rooms at once. Those. the metal beam can be either two-span or three-span. And although this does not happen often in low-rise private construction, we will nevertheless also consider a similar option.

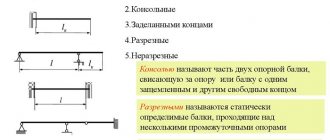

Let's start with a simpler one - a simplified calculation of a single-span metal floor beam with hinged supports made of solid rolled metal. How to make the most complete calculation in accordance with current regulatory documents is described separately.

Interfloor ceiling on metal beams

The task of floors in a building is to perform load-bearing and enclosing functions, to ensure the spatial rigidity of the structure, its stability, to separate floors, to connect walls to each other, transferring the load to them. In low-rise construction there are several options for arranging interfloor floors. One of them is flooring using metal beams. They can also be used for attic and basement floors.

Advantages of metal floors

Metal structures, unlike wooden beams, are more reliable in terms of fire safety and resistance to biological hazards (mold, mildew). They:

- much stronger than wooden beams, with a smaller thickness they can withstand heavy loads. Their use allows you to save space and provide more usable space;

- can be laid on spans up to 24 meters. The I-beam (channel) section of rolled metal remains static, is resistant to changes in the amplitude of the floors, and is not subject to deflection.

The disadvantages of metal floors include low thermal insulation and sound insulation parameters, as well as the likelihood of corrosion. The latter can be prevented by thorough anti-corrosion treatment of the metal before installation. To eliminate shortcomings in sound insulation, the ends of the I-beams are wrapped in felt, tightly sealed into brick walls with cement mortar, and fixed with anchor bolts.

The large weight of the metal may require the use of a crane when installing the structure. It will be very difficult to change the size of beams, cut or extend them using a welding machine. As a result, it is necessary to very accurately measure the dimensions of the spans before ordering rolled metal from the enterprise.

The only restrictions in the use of floors on metal beams are the financial side, as well as the size and type of structure. The load-bearing part of the building, the walls of the building, must withstand the weight of rolled metal, so before purchasing materials, you need to calculate the loads on the beam floors.

Calculation of beam floors

When choosing the section of I-beams, channel or angle, take into account the installation pitch (no more than one meter), the width of the span, the total load from the roof and roll-up. For the attic floor, the calculated value is 75 kg/sq.m. m. When installing interfloor and basement floors, the working load almost doubles (150 kg/sq. m), so the section of the long products is also increased. It must have sufficient load-bearing capacity.

Types of interfloor ceilings on metal beams

During the construction of private houses and cottages, rolls onto the floors using metal beams are done:

- wooden, when the openings between the channels are filled with boards. This is a combustible fill option;

- using a lightweight reinforced concrete slab (fireproof filling);

- monolithic;

- monolithic on the load-bearing corrugated sheet, the latter has a high profile and additional stiffening ribs.

When arranging wooden flooring over metal beams, wooden panels are laid between the I-beams. Shingles are nailed to them from below and the ceiling of the lower floor is plastered. To arrange the floor of the upper floor, wooden joists are placed on steel beams, and the floor is placed on them. In the space between the floor and the panels, waterproofing of the corresponding elements is arranged, and sound-proofing material is poured.

When using prefabricated reinforced concrete slabs, they are laid on the upper and lower flanges of the I-beam, caulking the lower reinforced concrete slabs with cement mortar and pouring sound insulation on them. A mesh is welded to the beams below, on which the ceiling is plastered. You can put OSB on top, and then the floor.

Reinforced concrete monolith has better characteristics in comparison with reinforced concrete slabs. Thanks to its monolithic structure, it has better thermal insulation and noise absorption parameters. When starting to calculate a monolithic floor using metal beams, take the outer perimeter of the load-bearing wall as a basis. To create the formwork, use waterproof plywood and support it with temporary supports. To independently calculate the thickness of the slab, select the range of reinforcement or mesh for reinforcement, use the relevant reference books and manuals on the design and reinforcement of reinforced concrete structures, SNIPs.

Interfloor steel floors and light load-bearing beams LSTK

Structural solution for floors using LSTK technology. The latest technical solutions using light steel thin-walled structures of LSTC will allow you to reduce installation time and the cost of installation work for various types of floors. These structures use galvanized steel profiles for the construction of interfloor floors and coverings in various buildings and structures constructed from LSTK, LMC, concrete, blocks or wood; these structures can also be used in the replacement and reconstruction of wooden floors, for the construction of external or internal balconies.

Interfloor slab made of LSTK

Advantages of using metal thin-walled profiles of Z and C shaped sections:

- special cross-section design ensures high strength

- high environmental friendliness allows the structures to be used in residential and public buildings

- reduction in construction costs due to low labor intensity, absence of lifting machines during installation, less massive foundation design

- profiles in the ceiling do not creak or make noise when walking on them

- wide range of applications in construction

- the length of beams up to 6 m allows you to cover wide spans

- installation of profiles at any time of the year

- fast execution of construction work

- strength and stability of structures

Attic floor made of light metal structures

General view of the interfloor slab of LSTK

Interfloor slab of LSTC building

Metal Z and C shaped profiles can cover spans of up to six meters. The cross-section of the profiles is in the form of the Latin letters Z and C with a width of 6 mm, the height of the profiles varies from 150 mm to 250 mm. The required pitch of beams in the floor is 600 mm, the profiles are manufactured in factories using cold deformation, the mechanical load on the floor of such a structure is allowed 500 kg/cm 2, the profiles have precise geometric dimensions without deviations.

LSTK floor structure

After installing the floor profiles with a certain pitch, they are sheathed on both sides with a steel profiled sheet with a thickness of 0.5 to 0.7 mm, and then the floor structure is built on it. The bottom of the floor beams is covered with sheathing made from a hat profile. Between the beams, mineral wool slabs and sheets of plasterboard are laid on the bottom layer of corrugated sheets for insulation and sound insulation. If necessary, concrete mixture is placed on top of the corrugated sheet on the reinforcing mesh. The final finishing of the floor on the ceiling is selected depending on the purpose of the room - it can be tiles, linoleum, parquet or laminate, laid on a foam backing for additional sound insulation.

Installation of floors on a large object

Floors using light steel thin-walled structures comply with the sound insulation values specified in regulatory documents, which are 53 dB for residential buildings, public buildings, administrative buildings and hotels. Sound insulation against impact noise can be achieved by selecting sufficiently insulating materials for the floor structure. To reduce the level of impact noise, for example, you can use linoleum with a thickness of more than 3 mm; when laying parquet or laminate, use a 20 mm thick underlay.

Ceiling in a residential building

The attic covering using the technology of light steel thin-walled structures will be profiles with a section of 150x0.7 mm or 200x0.7 mm, supported at a distance of no more than 600 mm with the installation of steel diagonal connections between the main beams. Thermal insulation boards are laid on the bottom layer of corrugated sheets, drilled onto the sheathing of the hat profile. The roof structure is laid on top of the insulation.

What is it and what sizes do they come in?

The beam is one of the main elements of any structure; its function is to increase the stability of the structure and strengthen it. A beam (or transom) consists of flanges and walls of various sizes, connected by butt seams using welding. Elements are manufactured at equipped factories using special machines.

The manufacturing procedure is carried out in several stages, after which the finished product is checked for compliance with GOST standards.

Metal structures vary in size; for convenience, they have numbers , with which you can select the necessary material for construction.

“10” is a small product, used as a ceiling to strengthen moving elements in construction. Can be used as a guide for small lifts.- “12” is a slightly larger structure size that can withstand a larger load. Used as a basis for frames, used in mechanisms.

- “14” - products of this size can be used in industrial production for installation in reinforced concrete structures.

- “16” is a durable structure that acts as a full-fledged support and can be used to move vehicles around the workshop.

- “18” is a reliable supporting element, used in the construction of buildings, it will ensure the stability of a large area.

- “20” is a large element that can serve as the basis for a column or frame. Often used in mechanical engineering.

- “25” - the product can serve as a support for large cranes and large-sized lifting mechanisms.

- “30” is the largest structure not used in residential construction. It is the basis for lifting mechanisms.

Scope of application

Metal floor beams have found their application in various fields. Can be used for :

- Roof strengthening in residential and industrial construction.

- Creation of interfloor ceilings.

- Construction of supports and various columns in industrial structures and architectural buildings.

- Installation of hangar frames.

- Mine shafts.

- Creation of various railway cars.

- Construction of bridges, overpasses.

- Construction of metal trusses.

Note : metal floor beams can also be used in the construction of low-rise private houses.

Calculation of a metal floor beam

There are cases when it is not economically profitable to use wooden beams for interfloor or attic floors. For example, when the span is too large and therefore large cross-section wooden beams are required to cover it. Or when you have a good friend who sells not lumber, but rolled metal.

In any case, it will not hurt to know how much the ceiling can cost if you use metal beams rather than wooden ones. And this calculator will help you with this. With its help, you can calculate the required moment of resistance and moment of inertia, which are used to select metal beams for the floor according to the assortments based on the conditions of strength and deflection .

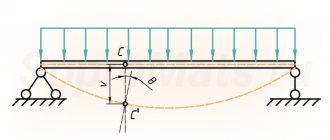

The floor beam is calculated for bending as a single-span simply supported beam.

How is installation done?

Poured concrete structures are created in several stages: preparing walls, laying load-bearing parts of the frame, installing formwork or laying corrugated sheets that perform this role, and the last stage will be pouring concrete. After pouring, it takes three to six weeks for the poured base to dry.

A prefabricated reinforced concrete base is most often mounted on I-beams and consists of the installation of load-bearing elements, with the previous preparation of walls and laying of slabs. Concrete panels are installed in such a way that their lower plane rests on the wide part of the load-bearing parts of the frame. This design will require additional sound and thermal insulation.

If reinforcement of floors is carried out, it is necessary to calculate the dimensions, as well as the load-bearing capacity of the mounted elements and support platforms - they will have to withstand the increased load, since such work is carried out in cases where it is necessary to strengthen existing floors due to increased load or weakening of existing load-bearing elements .

All of the above methods of arranging and strengthening floors are very difficult to implement. If you do not have special experience and construction skills, you should not take on such work - it is better to entrust all operations to a trained construction team. In addition, it will still be impossible to do without the involvement of assistants - even in the case of structures assembled from beams and wood, the weight of the individual elements will not allow them to be installed independently.

Instructions for the calculator

Initial data

Span length (L) is the distance between the two inner edges of the walls. In other words, the span that the calculated beams cover.

Beam pitch (P) is the step along the center of the beams through which they are laid.

Type of ceiling - if you will not live on the top floor, and it will not be heavily cluttered with things dear to your heart, then select “Attic”, in other cases - “Interfloor”.

Wall length (X) – the length of the wall on which the beams rest.

Beam length (A) is the largest dimension of the beam.

Weight 1 lm . – this parameter is used as if in the second stage (after you have already selected the desired beam).

Design resistance Ry - this parameter depends on the steel grade. For example, if the steel grade is:

- C235 – Ry = 230 MPa;

- C255 – Ry = 250 MPa;

- C345 – Ry = 335 MPa;

But usually Ry = 210 MPa is used in the calculation in order to protect oneself from various kinds of “force majeure” situations. After all, we live in Russia - they will bring rolled metal from the wrong grade of steel and that’s it.

Elastic modulus E - this parameter depends on the type of metal. For the most common ones, its value is:

- steel – E = 200,000 MPa;

- aluminum – E = 70,000 MPa.

The values of standard and design loads are indicated after they are collected on the floor.

Price per 1 ton – the cost of 1 ton of rolled metal.

Result

Strength calculation:

Wreq – required moment of resistance of the profile. It is located according to the assortment (there are GOSTs for profiles). The direction (x-x, yy) is selected depending on how the beam will lie. For example, for a channel and an I-beam, if you want to place them (i.e. the larger size is directed upward - [ and Ι ), you need to select “xx”.

Deflection calculation:

Jreq – minimum permissible moment of inertia. Selected according to the same assortments and according to the same principles as Wreb.

The number of beams is the total number of beams that is obtained when laying them along the wall X with a step P.

Total mass - the weight of all beams of length A.

Cost – the cost of purchasing metal floor beams.

Metal floors

MK Monteko LLC designs and manufactures metal floors for industrial and residential buildings, public and administrative buildings. The designs offered by the company are characterized by high strength and reliability, low weight and high installation speed. Calculation of metal floors is carried out in accordance with the current regulatory framework; high-quality rolled metal is used as blanks. If necessary, anti-corrosion treatment and coating with fire-resistant compounds are performed. The finished product meets the requirements of all technical regulations for the safety of buildings and structures.

Metal floors from MK Monteko company

Interfloor floors are most in demand today for frame buildings for various purposes. The company will manufacture all metal structures for such floors in accordance with designs or registered organization standards (STO). At the same time, production capabilities allow us to work on any project without any technical restrictions. If there is no project, then the necessary calculation of metal floors will be carried out by the company’s specialists, and metal structures will be manufactured in accordance with it. The company produces the following types of metal floors for frame buildings:

Steel interfloor ceilings made of rolled metal

A universal type of floors between floors, basements, attics and the corresponding floor, most often used in the construction of industrial buildings. A wide range of serial products makes it possible to easily design a floor designed for the installation of various equipment. The MK Monteko company will manufacture the floor exactly according to the design; compliance with the requirements of tolerance standards and GOST standards for welding guarantees the accuracy of the assembly and the reliability of the floor structure. If necessary, instead of rolled I-beams, welded I-beams or trusses of our own production can be used.

Interfloor metal ceilings made from LSTK profile

This type of flooring, which is becoming increasingly popular, is used mainly in individual housing construction, the construction of compact retail buildings and entertainment venues. It is based on a complex of profiles made of galvanized steel up to 2 mm thick; the connection of frame elements is carried out with self-tapping bolts. A profiled sheet is laid on top of the frame and then the floor can be installed. The ceiling in this design is suspended, mounted on a special “hat” profile (named after the cross-sectional shape). With high strength, the floor frame is rigid and, in general, can withstand loads of more than 500 kg.

Floors with load-bearing steel beams

During the process of repairing or reconstructing a building, it may be necessary to replace existing floors or divide the space into several floors. This issue can be solved by using metal structures, by installing rolled and welded steel beams; any flooring can be laid on top of them or a concrete screed can be made. We will take care of all the production and calculation of floors and structural elements.

Who is this service addressed to?

First of all, it is designed for commercial real estate holders. This can be any room where there are very high ceilings. So high that the owners of such buildings are forced to shell out huge sums, essentially paying for air.

Meanwhile, they have an excellent chance to profitably use this money for additional square meters. That is, for the construction of the second and even third floors. At the same time, we will do without dismantling the roof, performing other processes that are costly in terms of money and work, as is done with other methods of adding second floors over old buildings.

Anyone who orders prefabricated floors from us can adapt new surfaces, for example, for an office or similar building and for other internal needs:

- an empty hangar;

- inactive workshop;

- factory;

- closed warehouse and many other unused premises.