Welding with MP-3S rutile electrodes is easy. Many beginners feel like experts until they switch to other brands with more complex operating parameters. MRs have their own characteristics. Welding characteristics are generally positive. The advantage is the ability to stitch over rust and connect raw parts.

Electrodes of the MP-3 brand are the main ones for welding pipelines, building and other critical structures in all weather conditions. The main purpose of electrodes with a rutile coating of grade 3C is to weld together rolled products and parts made of medium-carbon steel.

Where are they used?

Welding electrodes MP-3S are designed for joining parts made of low-alloy steels with low carbon content using manual arc welding. They are used for welding such critical structures as pipelines, tanks, pipe fittings, and handling equipment.

When installing pipelines, it is possible to form non-rotating joints. Tanks that operate under high pressure can be serviced and repaired. Application areas include the oil and gas industry, shipbuilding and engineering industries. They also find application in everyday life.

MP-3S electrodes can be used regardless of the climatic conditions in which the welding process takes place.

Characteristics

In construction stores you can easily find LEZ MR-3S electrodes, manufactured by the well-established Losinoostrovsky Electrode Plant. They comply with the requirements of GOST 9466.

LEZ MR-ZS electrodes have a rutile coating, which consists mainly of titanium dioxide, which is the mineral rutile. In addition, the coating may contain other elements that increase the toughness of the deposited metal. This reduces the likelihood of defects such as pores and cracks appearing in the weld. Rutile coating ensures rapid ignition of the arc, both primary and secondary.

In this case, the weld pool is reliably protected from the harmful effects of oxygen and nitrogen. LEZ electrodes MR-ZS have technical characteristics:

- An electrode with a rutile coating is classified as a consumable element.

- The internal rods are made of Sv-08 wire.

- The main alloying elements included in the rod are carbon and silicon. It contains small amounts of manganese, sulfur and phosphorus.

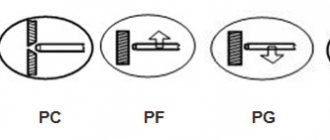

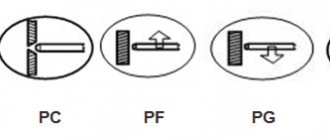

- Welding can be carried out in all positions, with the exception of moving the electrode from top to bottom.

- Possibility of working with different types of current.

- Long arc welding is acceptable.

- The spray coefficient is in the range of 9-13 percent.

- Good meltability of the edges of the metal being welded.

- Electrodes can weld parts with a thickness of 3 to 20 millimeters.

The diameters of the electrodes are in the range of 3-6 millimeters. As the cross-sectional size increases, the length of the electrodes increases.

The welding current is set depending on the diameters of the electrodes used and the spatial position during the welding process. So, for example, if MR-ZS 3mm electrodes are used, then in a vertical position a current of 90-110 Amperes is set. In lower and ceiling positions, these values can be increased.

Welding electrodes MR-ZS 3mm have different packaging. For example, if you need to use a large number of consumables, it makes sense to purchase welding electrodes MR-ZS 3mm 5kg. The number of electrodes that fits in one package depends on the weight. The weight of one electrode with a diameter of 3 millimeters is 30 grams. If you purchase a pack whose weight is two and a half kilograms, then it will contain 86 electrodes with a cross section of three millimeters. A five-kilogram package will hold 54 electrodes with a diameter of 5 millimeters.

Technical characteristics of MP-3S electrodes

The largest number of LEZ MR-3S electrodes from the Losinoostrovsky Electrode Plant is on sale. They are produced with a diameter of 3–6 mm in accordance with GOST-9466, have a blue coating, and belong to group E-46. The rod is made of low-carbon steel type SV-08 with the addition of alloying elements:

- manganese;

- silicon;

- nickel;

- copper;

- chromium.

Rutile coating – titanium dioxide with special additives.

Seam characteristics:

- high viscosity;

- no cracks form;

- a lot of slag covers the cooling joint.

The work speed is high. The electrode can touch the steel being welded and melt with a short arc at a distance.

In addition to Losiny Island, electrodes of the MR-3S brand are produced in the Moscow region, Kostroma region, St. Petersburg, Shadrinsk and Syzran. Foreign analogues are produced in Cleveland (USA).

Technological characteristics of MP-3S series electrodes:

- the minimum thickness of the welded sheet is 3 mm, the maximum is 20 mm;

- designed for medium-carbon and low-alloy steels;

- the optimal carbon content in the steel being welded is 0.25% (St-25, St-3);

- operate on alternating and direct current;

- the arc is easily ignited by tapping;

- the arc is maintained at low voltages;

- consumption per 1 kg of seam - 1.7 kg of wire;

- at a minimum current of reverse polarity, welding is performed along the gaps.

The tensile strength of the seam is within 490 MPa. The edges of the welded metal melt well. Work is possible in all positions. The exception is the vertical at the top. A lot of slag flows in front of the melting bath, impairs the combustion of the arc and gets into the seam.

Calcination before use - from 2 hours at a temperature of 150–180 °C. The coating on wet rods breaks down and falls off.

Designation

The letter “E” indicates that we are talking about electrodes intended for manual arc welding. The numbers “46” provide information about the value of tensile strength, which is measured in kgf/mm2. MP-3 is the brand of designated electrodes. “LUX” is a trade name assigned to its products by the manufacturer.

Next comes the cross-sectional diameter of the electrode. The letter “U” indicates that low-alloy steels with a low carbon content can be welded with these electrodes. The next letter “D” means that the electrode has a thick coating. The letter "E" refers to the designation of coated consumable electrodes, according to the international classification.

The number “43” is the value of tensile strength after the welding process is completed. “0” means that the elongation does not exceed 18 percent. (3) refers to the impact strength value of the deposited metal.

The letters “RC” stand for rutile-cellulose coating. One letter “P” will mean that the coating is purely rutile. The last two digits “11” indicate that welding with these electrodes can be carried out in all positions, excluding the movement of the electrode from top to bottom. The designation is applied to a tag glued to the packaging. This allows you to find out what characteristics the MP-3C electrode has and make the right choice.

Electrodes mr-3s are blue.

- Classification of electrodes

- About Electrodes

- Electrodes by Brand

Today, buying electrodes is not difficult.

In a store or market, highly qualified specialists will help and advise you on what is best to choose. The main thing is to know exactly what needs to be welded or fused, what material the structures and main products are made of. Since the choice of electrode depends on the type and chemical and technical composition of the source material. MP-3s electrodes are intended for manual welding. Depending on the type of work and the steels used, they differ from each other in color. Today they are widely used with blue and green coating . The blue color scheme indicates the rutile-basic composition of the electrode. Used when carrying out welding work on structures consisting of carbon and low-alloy steels. They are characterized by a temporary tensile strength of up to 450 MPa. Can be used when creating a weld seam in the ceiling position, when setting tacks and welding fixed joints of pipelines. Thanks to their technical characteristics, MP-3s electrodes are light and easy to use, allowing work to be carried out at low currents and from a household power source. When welding in various spatial positions, alternating and direct polar current is used.

Electrodes of the MR-3s brand have a deposition rate of 8.5 g/Ah; as a consumable material, 1.7 kg of electrodes are obtained per 1 kg of deposited metal. The mechanical composition of the metal seam has a temporary tensile strength of 480 MPa, a relative elongation of 22%, and an impact strength of 100 J/cm2. The deposited metal has a chemical composition: carbon up to 0.10%, manganese 0.50-0.70%, silicon 0.10-0.20%, sulfur and phosphorus no more than 0.040%.

When performing welding work in the lower position of the finished seam, electrodes with a diameter of 2.5 to 6 mm are used, in a vertical position from 2.5 to 5.0 mm, and for the ceiling spatial position, electrodes with a diameter of 2.5 to 4.0 are used. This, of course, requires different current strengths, from 60 to 250 amperes. The moisture content in the electrode coating before use is allowed according to standards of no more than 1%.

- Decoding the electrodes

- Electrodes golden bridge

- Electrodes Sormite

- Lincoln electric electrodes

- Plasmatec electrodes

- Castolin electrodes

- ProfHelper electrodes

- Capilla electrodes

Electrodes for tool steel Universal electrodes Rotex electrodes Phoenix electrodes

Advantages

LEZ MR-3S electrodes have characteristics due to which they have undoubted advantages:

- The resulting connection is highly durable.

- Ignition of the arc is easy, as is its re-ignition.

- The arc can be short or medium length.

- The seam formed is smooth and has a good appearance.

- There are no clearly defined transition zones between the surfacing and the base metal.

- The rutile coating protects the seam from slag getting into it and the formation of oxidation on the surface.

- Spattering of metal during welding is insignificant.

- Easy separation of slag crust.

- It is possible to connect parts of considerable thickness.

- Connecting wet surfaces and those with traces of corrosion.

- No release of harmful substances during combustion of the coating.

- The seam is resistant to corrosion.

- The welding process is highly productive.

- Electrodes can be used to make not only long seams, but also short tacks.

These advantages are the reason for the widespread use of electrodes of this brand.

Lez mr-3s electrodes

The electrode is a metal rod about 45 cm long and coated with a special compound. One end of the electrode is clamped by an electrode holder, and the other is designed to make direct contact with the workpiece by igniting and maintaining the arc. In the process of welding work, complex, highly technical processes occur. The properties of electrodes are characterized by the properties of the scale, which is formed from the base of the electrode coating.

The electrodes should ignite easily and ensure good combustion of the welding arc, melt evenly and cover the seam with slag. C positively characterizes the composition of the electrodes and the absence of cracks, pores, and splashes during operation.

Electrodes are classified depending on the type of welding work, the basic materials used, the current used, and so on. Thus, LEZ MR-3S electrodes have found wide application in welding work using manual arc welding. In this case, there must be structures and products made of carbon steel. This type of welding consumables is used when making a seam in various positions: bottom, vertical, ceiling and top to bottom. A direct current of reverse polarity and an alternating current with an open circuit voltage of about 50V are used. The current strength depends, as a rule, on the diameter of the electrode and the position of the seam. The larger the diameter of the Lez MP-3s electrode used, the higher the current required.

Today, in specialized stores you can purchase MP-3s electrodes with a diameter of 2 to 6 millimeters. At the same time, for welding a seam in a top-down position, only a diameter of 2-3 mm is used. Melting of MP-3s electrodes is characterized by deposition coefficients of 8.5 g/Ah. About 1.7 kg of electrodes are consumed per 1 kg of deposited metal. The seam formed when using electrodes has the following basic mechanical properties: tensile strength up to 460 MPa, relative elongation 20%, impact strength 80 J/cm2. The chemical composition of the weld metal in percentage terms consists of carbon, about 0.12%, manganese, silicon, sulfur and phosphorus.

MR-3S LEZ electrodes with rutin coating are used for welding work where the original steel has a high carbon content, as well as low-alloy steel. The rutile coating, represented by a conspicuous blue color , protects the finished seam from oxidation and the ingress of slag during the work process.

LEZ welding electrodes are manufactured at the Losinoostrovsky Electrode Plant. The products of JSC LEZ meet the requirements of all European quality standards. The finished products of the plant have received certificates from such well-known quality control companies as Gosstandart of Russia, TUV, VNIIST LLC and many others.

For steel pipes Welding Electrodes For inverter welding

Varieties

There are several types of electrodes of this brand. This sometimes leads to a dead end when faced with a choice. Therefore, it is necessary, for example, to understand how the MP-3 electrodes differ from the MP-ZS. These species have a lot in common with each other. Their composition and main characteristics are identical. However, there is one feature that answers the difference between the MP-3 and MP-ZS electrodes.

Consumables of the MP 3C brand contain additives, due to the presence of which the arc is ignited more easily and the stability of its combustion increases. They can be used when using a low-power welding inverter. During the welding process, less manganese is released, the seams are more uniform, and their formation is easier.

The MP 3C brand has proven itself well in household use. But MP 3 electrodes can be called more universal. They are used both in everyday life and in industrial work.

Technical process

Welding can be carried out with both types of currents. If direct current is used, then reverse polarity must be installed on the equipment. The current strength is selected depending on the cross-sectional value of the consumable and its position in space.

It is advisable to pre-clean the surface to be welded, but welding surfaces with traces of contamination and oxides is allowed. During the welding process, the electrode should be held at an angle of approximately 45 degrees. This will reduce the formation of slag and its entry into the weld pool.

Movements with the electrode should be made quickly, moving from the edge of one edge to the edge of the second. When welding large-sized products, it is advisable to fix them with tacks using the same electrodes.

Features of application

Rutile electrodes grade 3C are used primarily for welding critical metal structures, pipelines and other parts made of sheet metal, profile pipes, and shaped steel. Welding is performed in the tear-off weld mode:

- An arc is lit at the left edge of the joint.

- The electrode is passed from left to right.

- It comes off and goes to the left.

Cook very quickly so that the seam does not have time to cool.

A lot of slag is formed; it completely covers the bathtub and the entire width of the seam. The melting point of the coating is significantly higher than that of the steel being welded. Therefore, it floats and is easily separated after cooling, even in multi-pass seams. The welding pace must be high so that the metal and slag do not have time to harden.

When operating on direct current with MR electrodes, reverse polarity is preferred.

The peculiarity of using MP-3 electrodes is, first of all, that it is possible to weld untreated edges of parts. Scale, dust and moisture do not affect the quality of the seam. They evaporate during the melting of steel and combine with the slag. The seam is obtained with high technical characteristics:

- impact strength – about 8 kgf m/cm²;

- elongation – 17–19%;

- tensile strength – up to 46 kgf/mm².

The current strength is selected according to the diameter of the electrode. For a 3 mm MP, 100–140 A is sufficient; the largest ones (6 mm) require a current of 300 A to be set.

Metal spattering when welding with MR electrodes is small. The slag lays down evenly and is easily removed.

During the welding process, the MR electrode must be held at an angle of approximately 45°. When titanium dioxide melts, a lot of slag is formed. When the electrode is positioned straight, it enters the melting bath and remains in the seam, forming slag cavities. The movements of the arc should be fast, from left to right, from one edge to the other.

Storage

The quality of the weld, as well as the shelf life of the electrodes themselves, depends on compliance with the rules of their storage. The main condition is storage in a room where there is no dampness and the required temperature is maintained. A thermometer and a device for determining humidity will help fulfill these requirements.

If the electrodes are stored in cardboard packaging, then they must be installed on a rack at some distance from the floor. It is also permissible to store them in special plastic tubes.