From the book "The Rise of Industrial Art" 1892

The edible seeds of ripe wheat are enclosed in a shell. And after the harvest, before they can be ground into flour, made into porridge, or planted in the field for next year's harvest, they must be husked. This process is called threshing, or threshing.

The seed shell is strong, so threshing requires a lot of effort. Traditionally it was carried out using a flail. A flail is simply a short stick connected to a long rope or chain. The grain was scattered on the ground and hit with a stick to open the shell.

Other methods include “trampling,” when the village cattle trampled their hooves on the grains or dragged a special sled over them (in Latin they were called tribulum, and from this word in English comes tribulation, which means “misfortune”, “disaster”).

Trampling

Sometimes the grains were rubbed against a wire sieve or poured into a bag and hit with stones. In English, threshing would be threshing, and the archaic spelling of this word is thrashing, which in modern language means “thrashing,” “flogging.”

Since threshing was one of the most energy-intensive stages of wheat harvesting, it naturally required mechanization. A threshing machine is a relatively simple device - like a cotton gin, a shuttle or a bicycle, it did not require any scientific discoveries. And yet, threshing machines were practically not used anywhere until the end of the 18th century in Britain and the beginning of the 19th century in the USA.

The question arises: why did we wait so long for the invention of the threshing machine?

Early applications and concepts

No, not because it never occurred to anyone to mechanize threshing.

It is generally accepted that the Industrial Revolution turned out to be an unprecedentedly inventive era, compared to which previous years saw no inventions. However, it is worth remembering that even before the 18th century there were inventions, many of which were then widely used - especially when they helped in the most necessary economic processes. The loom and the printing press appeared several centuries before the threshing machine, and it is not to say that any of them were much simpler than it [In Russia, artisans Andrei Terentyev and Moses Krik “figured out how to thresh bread with water” in 1655. In the Izmailovo estate of Tsar Alexei Mikhailovich, they built a threshing machine with flails and mortars, powered by a water wheel. / approx. lane]. The thresher was mentioned in English patents as early as 1636 (from a historical point of view, almost immediately after the work of Galileo and Francis Bacon). Sir John Christopher van Bergh, a Moravian knight (today part of the Czech Republic), having fled from the religious wars in Germany under the patronage of the English king Charles I, offered him and all of England his ideas about “various mechanical instruments and structures operating by means of scales.” By modern standards, the patent was too broad and vague. It listed an incredible variety of machines: for pumping water, washing clothes, cooking meat, inflating bellows, dredging rivers, raising sunken ships, measuring distances and depths—virtually every mechanical task. Near the end of the list there is mention of an invention "propelled by wind, water, or horses, for the clean threshing of corn (grain), by which much of the crop now lost may be preserved, producing straw of the quality of hay." At the time, patents did not require detailed descriptions, diagrams, or models, so it is unclear how such a machine could work, or whether the invention was even real. The point is that by the beginning of the 17th century, a thresher seemed necessary and possible.

Why not? Grinding grain into flour was mechanized by water mills back in ancient Rome. The threshing process was similar enough that a mill of a similar kind would have handled it just fine. A hundred years after van Bergh, inventors actually began to work on this problem. Michael Menzies from Scotland patented a threshing machine in 1734, and there were several other attempts in the 18th century.

So why haven't any of these machines become widespread?

Farming process

Threshing is just one step in the process of delivering grain to the mill and to the consumer. Wheat must be grown, crushed, melted (shocked, tied), pulled, threshed, shelled, straw baled, and then the grain hauled to the elevator. For many years, each of these steps was an individual process, requiring teams of workers and large numbers of machines. In the wheat country of the steep hills of the Palouse in the northwestern United States, steep ground meant that moving equipment was problematic and prone to rolling. To reduce the amount of work on slopes, the idea was to combine a wheat binder and a thresher into one machine known as a combine harvester. Around 1910, horse-drawn combines appeared and became a success. Later, gasoline and diesel engines appeared with other modifications and characteristics.

Reliability issues

One clue comes from test reports of early prototypes.

Some of these machines simply broke down. One historian wrote about one of Menzies’ machines: “due to the high speed required to achieve an ideal result, these machines soon broke down and the invention fell out of favor.” Another such machine was tested in Scotland at the end of the 18th century, but “after just a few minutes the model was torn to pieces.”

And when they didn't break, they often couldn't work properly. In tests in 1753 it was found that the machine "tears off the sprouts of barley and wheat, instead of cleaning the grain, and is at best suitable for oats." During another attempt at the end of the 18th century, it turned out: “As a result of experiments on this unit, it showed itself to be defective, both having done too little work in the allotted time and damaging the grain, moreover, it itself apparently suffered, and thereby significantly reduced its market value "

Overall, historian McClelland writes that threshing machines of the late 18th and early 19th centuries were “among the most sophisticated and expensive agricultural implements in America and Britain. Their high cost and frequent breakdowns did not contribute to their rapid adoption, when 'their least fault was the death of the entire machine'." He writes that both Washington and Jefferson were interested in threshing machines, but:

Washington's machine, built according to William Booker's plans, soon showed unsatisfactory results. The Maryland machine, built with the help of Colonel Anderson's plans, had a bent wheel and was abandoned. In 1802, an immigrant from Edinburgh demonstrated "six or seven" machines based on the "Scottish principle" in the Mid-Atlantic states, but all of them soon developed problems that the "ordinary workmen" could not cope with. The machine, patented in 1803 by Jedediah Turner and based “on entirely new and very simple principles,” was never produced. Washington may have been speaking to many would-be agricultural pioneers when he expressed his disillusionment with this new and promising technology in 1793: “I have seen so many inventions come and go that I am almost determined to stick to the old way of threshing.”

What was the problem?

One of the challenges was finding the right basic idea for the car's design. As is often the case, some of the early attempts tried to imitate human work too closely - these machines automated the movements of the flail while still threshing the grain lying on the ground. This principle was called “beating”.

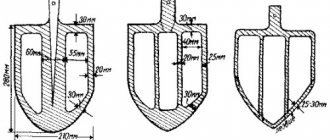

Diagram of the “beater” machine

“All machines that operated on the beating principle suffered from the same problem. The shock load caused by the mechanical movements that separated the grain caused rapid failure of parts of the machine, causing it to fall into disrepair,” McCleland wrote. This problem did not escape Menzies' 1734 machine.

Another "beater"

The "wipe" principle was the best idea. It was more like the operation of a mill or cotton gin: the grain was fed into a rotating drum, the pegs or other protrusions of which rubbed the husks off the seeds. And although debates about which way to thresh better - beating or grinding - continued until the 1830s, all successfully operating machines belonged to the second type.

Meikl's threshing machine, 1786

However, the impression remains that the threshing machine did not become widespread until one key breakthrough in its operation scheme. It is impossible to name one inventor of the thresher, or the exact date of its appearance. The sequence of inventions stretched over several generations: Andrew Meikle built the first such successful machine in Scotland in 1786: Joseph Pope invented its popular version in the USA in 1820: the Pitts brothers improved its drive and winnowing system (cleaning the grain from chaff and debris) in 1830s.

Pope's threshing machine, 1832

It also cannot be said that any one scheme has become the most popular. History tells us of gradual improvements in efficiency, reliability and cost that brought the machine to acceptance by more and more farmers. This trend of incremental improvement applies to most inventions - even those that have their own “hero” and the exact date of invention. But even from this point of view, the thresher has an unusually long and gradual history of development.

In my opinion, the scheme of operation of a successful thresher was just slightly above the threshold of complexity of the combination of sufficiently large force and fairly delicate handling of the material. A loom is a fairly complex machine that does intricate work without putting much effort into the material. A mill that grinds flour, or a falling hammer in a forge, have a very strong effect on the material, but there is nothing complex or subtle in their work. The devices mentioned were in use long before the Industrial Revolution. But the thresher required both of these qualities, and in such a combination that the quality of the mechanism became critically important. Only in this way could the machine meet high standards of reliability and become a practical tool suitable for real-world use. This was facilitated by a simple and reliable work scheme - but its competent execution meant no less.

Design Features

All modifications of threshing machines work on the same principle: agricultural crops are fed into the threshing hopper, and the output is a purified product.

From here we can highlight the main design elements: a drum with a concave, a straw walker and a beater device.

Some modifications consist of a multi-stage cleaning system, which includes a fan, elevator and sieve mill. Let's look at units designed for processing various crops.

For grain

The productivity of such technology directly depends on the complexity of the design. In addition to threshing, complex units can perform additional functions, including sorting the purified product. This is what it looks like:

- At the first stage, the plant mass is fed into the threshing hopper. After this procedure, an unusable mixture consisting of chaff, grain and straw is obtained.

- This mixture enters the straw walker, where fractional separation occurs. Here the straw is sifted out, and the chaff and grain are sent for further processing. Usually this is a fan, complemented by several grid frames. Here, excess impurities are removed: damaged grain, soil residues and plant particles.

- The cleaned grain is sent to the next stage - polishing. Here films and adhered particles of dirt are removed. The grain is supplied for polishing via an elevator.

If the design consists of one drum with a pre-drum (simple models), the output is a mixture of grain with plant matter, which requires manual separation. This is quite enough for preparing feed for livestock and poultry. For other needs, more modernized units will be required.

For flax

Flax processing consists of separating the seed ovaries from the stem, followed by cleaning the seeds from foreign impurities. Let's consider the operating principle of such units using the example of the mobile model ML-2.8P. The technical side of the process is as follows:

- Sheaves of flax are sent to the clamping conveyor. In this case, only seed boxes should enter the stripping chamber. The seed part is separated from the stem by a stripping drum, the stems are thrown to the opposite side by a clamping conveyor.

- The seed pods are thrown into a grinding apparatus, where they are destroyed, and the plant mass enters the screen. Here large plant debris is removed.

- Grain and small debris enter the grain winnower, where air cleaning occurs.

- The finished and purified product is poured into a special bag.

Production problems

And here is some evidence in favor of this, taken from historical sources:

The agricultural periodical Genesee Farmer in April 1831 writes in an article on threshing machines:

One of the most important reasons for the failure of such machines of various designs is the unreliable, cheap and careless manner in which they are manufactured.

They are often made by ordinary carpenters, if you can call them that - people who can barely make a handle for a barn door. As a result of all this, the farmer often ends up with a poorly designed, flimsy and shaky machine, which after each revolution has to be welded, strengthened with nails and staples.

Continuing the article, the author gives specific advice on assembling and using the materials of these machines:

A moving machine, whether powered by horses or water, must be as well constructed and with as good materials as a flour mill. Making the main wheel and gear out of wood is worse than useless. You can only rely on the softest and best cast iron.

It has already been noted that the use of iron instead of wood was one of the key steps taken by Henry Maudsley to increase the accuracy of machine tools.

In an 1843 book, Ransom defends the thresher, refuting its bad reputation due to its poor workmanship:

There are warnings against the use of such machines because they break the stem, scratch and damage the barley, making it unsuitable for malting;

however, all these troubles happen not because of the principles of the machines, but because of the state into which they often come in the hands of workers; and sometimes it is due to lack of skill or desire, and poor decisions of those who manage them. Many such machines are made by people who cannot boast of any knowledge of mechanization. They buy worthless castings and, with the help of village craftsmen, make imitation high-quality mechanisms. The improvement of these machines must rely on the fitting of all their parts with mathematical precision, on the clear and precise alignment of all their parts. It is therefore unreasonable to expect that the construction of such a machine can be carried out in a place where there is only a forge and a workbench. The result is a certain degree of distrust in these machines, which is unfairly transferred to the principles of their operation.

If manufacturing quality was a critical factor, how were the very first machines made?

Cereal thresher

Questions can only be asked after registration. Please login or register.

There is a need to thresh a certain number of sheaves. Who has a small thresher? Share your experience and drawings.

Remember: it’s better to lose a day, then fly to my channel in five minutes https://www.youtube.com/channel/UC1vTkviCAeiA9Z4yTOHM7uQ

Thank you. My great-great-grandfather had a micro-thresher for sheaves, although it was manually driven, back in 1800. Nothing is clear on mw.djvu, but one thing is clear: you can’t take so many spikelets in your hand, you have to take one at a time! I can’t see what’s on https://www.vim.ru/imag/catalog-13/16/ other than “welcome to our website.” For some reason it doesn't open for me. Probably because the Internet, in our Gadyukino, is worse than any crap.

Best regards, Nikolai Petrovich.

Thank you. My great-great-grandfather had a micro-thresher for sheaves, although it was manually driven, back in 1800. Nothing is clear on mw.djvu, but one thing is clear: you can’t take so many spikelets in your hand, you have to take one at a time! I can’t see what’s on https://www.vim.ru/imag/catalog-13/16/ other than “welcome to our website.” For some reason it doesn't open for me. Probably because the Internet, in our Gadyukino, is worse than any crap.

Production systems

Today, agricultural equipment is produced by large specialized companies that distribute their products throughout the planet.

But in the 18th and 19th centuries there was nothing like this. “Agricultural equipment” meant plows, sickles and carts, and they were made by local craftsmen - city carpenters, blacksmiths and carriage makers. Not only were there very few large producers in the world, but until the major expansion of railroads in the mid-19th century, there were no efficient networks for delivering produce to large numbers of farmers. From the advertisements of early threshing machine inventors it is clear what methods they envisioned for acquiring their machines.

"The Virginia Gazette", Williamsburg, 1772

In many cases, inventors offered to send plans and/or models, suggesting that the machine would be built by local craftsmen - a carpenter or millwright (the latter being the closest equivalent to mechanical engineers in the 18th century). A 1772 advertisement from The Virginia Gazette praised an invention "that any carpenter of the slightest ability" or even "the master's servant can carry out." More than 50 years later, in 1823, little had changed. An American Farmer article describing Joseph Pope's threshing machine quotes a letter from the deceased inventor's son, who says the machine "can be assembled very cheaply - materials, including frame, cost $13, and can be made by any skilled worker (carpenter or joiner) ) in 12 days."

In other cases, inventors offered to send not plans, but spare parts “with the need for self-assembly.” In 1735, Andrew Good Wright of Edinburgh advertised his threshing machine as follows: “Those who wish to purchase them, send applications to Edinburgh. The mill master must receive the parcel so that he understands how to assemble the machine; any such specialist will cope with this task, having once seen this machine in action.” He also mentions the possibility of acquiring a license for distribution: "Millmasters, with recommendations from gentlemen, can come to Edinburgh to understand the principle of the machine, and can manufacture them throughout the country under license." In a 1796 advertisement, "John Jubb, millwright and machine maker," offers both options: he will "send a machine to any part of the Kingdom" for 25 guineas plus postage, or send the plans together with "a machine made at Leeds, disassembled, with with carefully marked parts so that any worker can easily assemble it.”

The National Gazette, Philadelphia, 1823

There is evidence that threshing machines flourished where and when they were assembled by their inventors, or by skilled mechanics who decided to specialize in them. One source reports that by 1800, "almost all the threshing machines in England" were made by one "industrial worker named Stevenson." The article praised these machines for being easy to turn by hand and for their low friction—“an unambiguous guarantee of quality work.” Inventor Joseph Pope, shortly after the publication of this article, agreed with a machine manufacturer to produce his thresher.

From May to October 1823, an advertisement was published in the Philadelphia National Gazette stating that “Messrs. S. V. Merrick & Co. Engine Manufacturers, Philadelphia" are privileged to manufacture and sell his machine; potential customers were encouraged to “come to” them for a car. At that time, the engine manufacturer had a well-equipped machine shop with precision tools and skilled workers, which was essential to making reliable machines.

As a result, in the first decades of its existence, the thresher suffered from poor workmanship due to the lack of specialized mechanics.

Homemade design

If you decide to make a thresher with your own hands, you can use the design of L. A. Ditke. This is a three-section model, where the drive units are located on the first tier, the fan is located in the middle, and the threshing mechanism and winnowing machine are located in the upper part.

Here is the assembly diagram:

- A frame is welded from a metal corner. Recommended parameters: 925*565*410 millimeters.

- Then the housing and the receiving hopper are made from a metal sheet. To make a threshing drum, we take two steel disks (radius about 300 mm), weld metal corners onto them, and tighten the structure with oak whips.

- To make a deck you will need two pieces of sheet iron and fine mesh. The mesh must be bent to the desired radius and supplemented with six oak sticks. The structure is attached to the thresher frame using threaded connections. This approach allows you to adjust the distance between the whips of the threshing drum and the deck. This is necessary to configure the unit for various crops.

- Sieves are made by analogy with a straw walker. A two-level cleaning system is used here: the upper sieve has 3 mm holes, the lower one has 1 mm holes.

- The structure is driven by an electric motor, from which there is a belt drive to the threshing drum. In addition, you will need another motor to operate the sieves.

The design is quite complex, but in principle any farmer with minimal knowledge of mechanics can cope with it.

Contrast with the header

For comparison, consider a related piece of agricultural equipment, invented several decades later: the reaper.

McCormick's reaper, 1831, Scientific American

The reaper cut the stalks of cereals in the field, automating the step immediately preceding threshing. As with the thresher, reliability was a critical feature of the header—early models failed to cut tangled stems, clogged if the stems were damp, or did not handle hills well.

One of the most successful reapers was invented by Cyrus McCormick. He began selling them in the 1840s, but did not rely on local craftsmen or manufacturing partners. He made the first machines himself, and eventually created a large central factory.

McCormick tried to enter the national market, but was hampered by primitive freight networks. One of his biographers, Casson, wrote in 1909:

To bring the seven reapers sold in 1844 to the West, they first had to be wagoned to Scottsville, then by canal to Richmond, then along the James River to the Atlantic Ocean, around Florida to New Orleans, there to be loaded onto a riverboat going up the the Mississippi and Ohio rivers to Cincinnati, and from there in different directions to the farmers awaiting supplies. Four reapers were late for the 1844 harvest, and two of them were not paid for.

McCormick later moved from Virginia to Chicago, opening an office in the heart of the transportation network, connecting railroads and waterways—and closest to his largest market, the flat-land, labor-scarce Midwest.

He also introduced several innovations in business practices: he advertised heavily in newspapers, organized field demonstrations, offered farmers a written guarantee and interest-free installments until the next harvest, and built a network of distributors in each region.

None of the inventors I've read about did anything like this with threshing machines - at least not until the 1830s, when they were already quite common.

Recommendations

- Clark, Gregory (2007). Farewell to alms: a brief economic history of the world. Princeton University Press. item 286. ISBN 978-0-691-12135-2.

- "US Patent: 0000542." Retrieved July 18, 2013.

- "When threshers were the kings of the harvest." Small business development.

- H. J. Finnis (1967). "Ridley, John (1806 - 1887)." Australian Dictionary of Biography, Volume 2

. MUP. item 379. Received 2007-08-19. - https://www.bardis.ie/composers.htm#duggan

- Songs Text: Old Thresher

Why did it take so long?

The issue of the spread of the threshing machine is included in a more general question that interests me: why did we wait so long for the Industrial Revolution?

Some inventions depended on theoretical concepts discovered only during the Scientific Revolution—the electric generator or the steam engine. Others were independent: a threshing machine, a cotton gin, a spinning jenny. What is the difference between these and other, seemingly similar in complexity and importance, inventions adopted by society centuries earlier - the loom, the spinning wheel, the printing press?

One of the reasons is the ability to produce affordable and reliable cars. This same capability was probably important for the advent of the bicycle - and probably even more important; I already wrote about this in one of the articles. Another example is given by Robert Allen in his 2009 book - the production of precision watch parts was necessary for the emergence of an early version of the spinning machine, known as the "water machine" (and powered by a water wheel). “The watch industry became the source of gears - in particular, brass gears - and it was these gears that became precision parts of the water engine. Without watchmakers, it would be impossible to design a water machine.”

The second reason is that for any invention there must be prerequisites. If special production is required, the centralized manufacturer needs access to a large market. This requires a communications infrastructure, such as newspapers, to advertise products, and a transport infrastructure, such as railroads, to deliver them.

Another reason why mechanization came to the textile industry decades before agriculture was probably due to different business models. Richard Arkwright did not make his spinning wheels in order to sell them to others, like McCormick's reapers, but in order to produce cheap thread. He himself was a market for his cars; they were investments in a new type of business. This business model was not available to early agricultural equipment manufacturers.

Another instructive comparison would be the steam engine, which also required high precision and quality manufacturing. moved to build centralized factories for special purposes in the 1770s, decades before this model came to agricultural equipment. My guess is that the farmers' market consisted of a large number of small and geographically dispersed customers - as opposed to the mining, smelting, brewery, and other customers who purchased Watt engines. Therefore, in agriculture, the problems of marketing and distribution were significantly more complex. Not to mention that, for example, ore mining provided more opportunities for investment in equipment than farming.

Flywheels

All of this can probably be summed up in one word: infrastructure.

The ability to produce hardware lies in infrastructure, such as railroads and newspapers (and today, trucking and the Internet). The infrastructure reduces the amount of energy required to activate any development. Sometimes the developments themselves improve the infrastructure, creating a self-sustaining cycle that generates exponential growth. Is this enough to describe the rate of progress in our history? Do we need to introduce cultural reasons - a common factor of ingenuity - Joel Mokyr's "idea of progress" versus Deirdre McCloskey's "ancestor worship" and "bourgeois honor and prestige"? It seems clear that it matters whether people thought progress was possible and necessary. If this is not so, it seems an amazing coincidence that the Industrial Revolution began shortly after the work of Bacon and the beginning of the Scientific Revolution, and in the same part of the world. However, now that I have a better understanding of the problems of the 18th century threshing machine inventors, I am inclined to favor infrastructure as the main reason for the delay.

Or, more broadly speaking, I imagine there to be a set of overlapping flywheels, each creating its own virtuous cycle. Improving infrastructure speeds up progress, which in turn creates more and better infrastructure. Belief in progress generates real progress that reinforces the belief. Increasing income allows you to invest in progress, which generates even more income. Science leads to progress that helps advance science. And since all these wheels intersect on progress, they all reinforce each other indirectly, and perhaps directly.