February 26, 2020

Bends GOST 17375-2001 and other types

Bends are a piece of curved pipe. The bending angle can be 30, 45, 60, 90 and 180 degrees. For the manufacture of bends, steel of different grades is used. Also, bends can be made of polymers.

Bends are manufactured using a seamless and welded method. They can be steeply curved and bent. Steeply curved bends have a small radius and dimensions. Bent elbows are larger and have a larger radius. They are used where the operation of steeply curved bends is impossible.

GOST 30753 bends and other types of bends are needed in those sections of the pipeline where it makes a turn to change direction. Steel bends can withstand the highest temperatures and adverse conditions, so they can be used in aggressive work environments. At the same time, their service life will be quite long.

Bends can have a variety of angles, but the most popular are 45 and 90 degrees.

Types of bends

Different types of products are used for different pipelines.

Main types:

- steeply curved;

- stamp-welded;

- welded sectional;

- welded sector (segment);

- bent;

- point.

Steeply curved bends are made in accordance with the requirements of GOST 17375-2001 and GOST 17375-83.

Most often, parts are made from stainless and carbon steel using the pipe drawing method. The part is of high quality and sealed.

The angle of such bends ranges from 30 to 90 degrees, and the section of the part is from 18 to 426 mm. The working pressure that the part can withstand reaches 16 MPa.

Stamp-welded bends have thick walls, and due to this they are considered especially durable; they are made from sheets of stainless and alloy steel by welding. Parts can be of different sections, which reach 1420 mm. They are mainly used in the oil and gas industry. This is due to their special strength and large range of sizes.

|

Description

A bend is a piece of pipe that is given a certain angle. Depending on the task, you can select a suitable outlet. There are many varieties, and this article is about them.

The bends are closely connected to the pipes by welding. According to GOST, such products are produced on special pipe bending machines.

WELDED SECTIONAL BENDS

Application

The scope of application of bends is very wide: from the installation of an oil pipeline to the installation of a boiler room in a residential building. Water pipelines, gas pipelines, oil pipelines - wherever pipes are used, bends are used.

Material for making bends

Most often, bends are made of steel, this is largely due to the loads that the part will have to withstand. The steel for making bends can be alloyed, carbon, or stainless.

Steel can withstand large pressure differences, is suitable for unfavorable climatic conditions, and is resistant to corrosion. Different steels for making bends have their own advantages. For example, 12x18n10t has increased resistance to corrosion, and steel 09g2s is suitable for pipelines located in cold or moderately cold climates.

Alloy steel bends can operate at temperatures from -60 to +40 degrees Celsius. Such parts are suitable for use in pipelines located in cold climates.

If the working environment is aggressive, it is better to use GOST 30753-2001 bends made of stainless or alloy steel. Carbon steel is suitable for general purpose piping.

Steel bends work with steam, hot water, chemically active substances, alkaline media and acids. The main important characteristic of parts for such a pipeline is corrosion resistance, and steel bends meet these requirements. In some cases, galvanized steel parts are suitable for the job. Their inner layer is additionally protected from corrosion by a layer of zinc.

Also, for some pipelines, bends are made of low-density polyethylene and polyvinyl chloride.

Polymer elbows are suitable for mild operating conditions. They cannot be used in pipelines with an aggressive working environment or in unfavorable conditions.

Bends GOST 30753-2001 and other similar parts have several advantages. They are versatile and suitable for a wide variety of systems to change the direction of pipes. Steel bends are resistant to climate conditions - temperature changes or precipitation. At the same time, the price of bends is always affordable. And the GOST requirements, according to which parts are manufactured, ensure their safe and efficient use.

|

Purpose and areas of application of pipeline bends

Steel bends are used in the installation of various technological and main pipelines. They smoothly change the direction of flow and are widely used in various fields:

- in the oil and gas sector;

- water supply, heating and fire extinguishing systems;

- energy industry;

- in metallurgical production;

- Housing and communal services, etc.

Most often, bends are used in industrial main and domestic pipelines, at pumping stations. The outlet material is selected based on operating conditions and the aggressiveness of the working environment. Another important parameter is the geometry of the connected pipes.

For pipelines operating with an aggressive environment at high pressure, seamless, steeply curved or welded products made of alloy or stainless steel, and galvanized bends are used. Welded bends are used when laying various communications with a medium pressure of up to 2.5 MPa and a pipe cross-section of up to 1 thousand mm.

Household communication systems are equipped with bent or steeply curved bends made of high-carbon steel with a diameter of up to 2 thousand mm.

Bends GOST 30753-2001: areas of application

The main function of bends is to change the direction of flow. Therefore, they are mounted on the pipe in the place where the pipeline must change direction. Installation of bends is possible using welding, flange and threaded connections.

Bends are used for assembling oil pipelines, at metallurgical and energy enterprises. They are also used in the housing and communal services system. These parts are necessary when installing water pipes and heating systems.

The bends are suitable for the operation of pipelines that pump liquid media, as well as for transporting gas, chemicals and steam.

The bends are connected to other parts by welding or threading. This greatly expands their use cases.

For example, seamless steep bends can be used in oil and gas chemical pipelines. Thanks to installation by welding, the entire pipeline system is sealed.

The bends can be operated at temperatures up to 450 degrees Celsius. The lowest operating temperatures are -70 degrees Celsius.

The parts are made in a variety of diameters. For example, DN 15, DN 25, DN 40, DN 45. Also, bends can have a larger diameter - from DN 426 and above.

Thanks to these characteristics and the bending angle (possible from 3 to 90 degrees), bends are used in a wide variety of pipelines. They are suitable for pipes with different wall thicknesses. This expands the possibilities of their use.

Examples of using bends

They are often used when wiring communications for various purposes. Only the types of taps differ. For example, in a pipeline with a large cross-section there will be high pressure for the movement of the working fluid. And in this case, steeply curved seamless bends or bent parts made of stainless steel are suitable.

In the housing and communal services sector and for other household communications, steeply curved and bent bends can also be used.

Bends are installed not only on pipelines that transport gases, oil, water and other working media. The parts are also used in ventilation systems and air purification systems.

Installation

Such pipes and bends can be installed without any additional tools. The parts are simply inserted into each other, forming a firmly connected, inextricable system. Installation of PVC pipeline parts is possible for novice builders.

Bends can also be divided into welded and cold-formed. Welded fittings can be made from different types of metal. This includes carbon steel, stainless steel, and low-alloy steel. Like other taps, they can be used in almost all areas of human activity.

In order to make segment bends, individual pipe rings made like a wedge are welded together. Such parts are used for gas and water pipelines, the pressure in which does not exceed low limits.

These bends are useful in cases where it is necessary to connect sections of large diameter pipes together.

Existing sizes and diameters of bends

There are several possible angles at which a pipe bend can be deflected. These are 15, 30, 45 90 and 180 degrees.

Welded sector bends 60° and 90°

To know what size elbow to purchase, you need to know the diameter of the pipes it will connect. The diameter can vary from 426 mm to 2000. Manufacturers can also produce bends that are non-standard in diameter and deflection angle.

Sector bends

Installation of bends using welding

Since the bend has a curved shape, welding the product requires certain skills.

Before starting welding, you must make sure that the parts are free of defects. The displacement at the junction of two pipes should not be more than 2 mm. You can center the outlet and pipe using a rotator.

If manual electric arc welding is used, processing of the first root weld is performed with direct current. Once the first seam is completed and sanded, the second seam is made. It is important to maintain a constant temperature at the welding site, so the break between two seams cannot be more than five minutes. After welding, facing seams are made, which should protrude by 1-3 mm. above the surface of the pipeline.

When are rotators used?

A rotator is a special equipment that can be used to make high-quality welding. Rotator welding is suitable for large diameter pipes, and the rotation speed can be adjusted. This method also helps to align the parts. The rotator is suitable for working with pipes and other parts of more complex design.

GOST 30753-2001 bends and other parts are suitable for use on various pipelines. Since the parts have different bend radii, wall thicknesses and internal sections. In addition, GOST 30753-2001 bends and other steel products are resistant to corrosion, withstand large temperature changes and are capable of operating at high pressure of the working environment.

You can order the production of bends GOST 17375-2001 and 30753-2001 from the MK NHTS company. The company's specialists have developed their own specifications, approved by Rostechnadzor.

| Read also: Transitions, tees and bends: review of articles

Pipe rotator

In production, welding of bends to pipes is carried out using special equipment. Typically, these special equipment are rotators. The parts to be welded are clamped in the device and rotate around their axis, which makes it possible to perform high-quality welding of the outlet.

Let's consider the main advantages of using a rotator when welding a rotary product with a pipe:

- allow you to weld pipes with large diameters;

- the use of an autonomous drive in the rotator design allows you to regulate the rotation speed of the part;

- ensure precise alignment of pipes;

- can work not only with straight parts, but also with more complex, from a structural point of view, elements (for example, tees).

Today, there are many types of bends that allow you to solve any problem when installing pipelines. At the same time, a wide range of these products obliges specialists to study a large amount of information in order to know and comply with the features and rules for using all such products.

How to make a 90 degree bend from a pipe

The easiest option is to find a reference book on the manufacture and installation of pipelines. It contains manufacturing drawings with reference dimensions. To make it, you will need to make patterns from cardboard or a thick sheet of paper, trace them along the contour on the pipe, and then use a grinder or gas to cut out the parts and weld them. Particular attention should be paid to the quality of the seams, since it is much easier to weld and check the product in an unassembled state than to then climb around the corners and look for leaks.

High quality seam

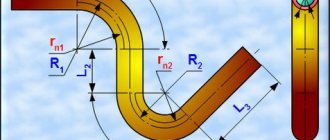

Pipes with a diameter of up to 100 mm can be bent using a pipe bender using the heating method, and as a rule do not require the manufacture of special fittings. Typically, 3-4 segments are used to make a 90 degree angle. If the pipe diameter is 100-159 mm, 3 segments are sufficient. For diameters greater than 159 mm, 4 segments are already used. Manufacturing 90 degree fittings for pipes with a diameter of more than 180 mm is possible using 5 or more segments so that the flow turbulence is not so large.

Fitting markings

A 90 degree 100 mm pipe bend can be made with your own hands and without using patterns. To do this, it is enough to cut off two pieces of steel pipe with an angle of approximately 30-35 degrees by eye, and adjust the third part in place. If the force of turbulence does not play an important role, you can get by with two pieces of 100 mm pipe at 45 degrees, welded together.

Three segment fitting

You can make a 90 degree bend on a 159 mm pipe with your own hands in exactly the same way as on a 100 mm one. The only difficulty may arise when cutting out the cut pieces, since the 159 mm pipe comes with reinforced walls and is quite difficult to cut with a grinder. That is why pipes with a diameter of 159 mm and 180 mm are easier to cut with a gas cutter, which will be faster and safer.

Dimensions of sewer fittings and recommendations for installation of sewer lines

The dimensions of sewer outlets correspond to the pipes to which they are connected and are regulated by GOST. It should be taken into account that for external sewerage, special orange-colored pipes are used, which are thicker than internal pipes (2 mm wall thickness of internal pipes and 3.1 - 3.4 mm of external pipes).

Rice. 9 Plastic sewer outlet - dimensional parameters

When laying an external sewer line, the following recommendations must be observed:

- The trench is dug in such a way as to prevent pipes from freezing in winter, while taking into account the slope, which is for a line with a diameter of 110 mm. is 20 mm. per 1 linear meter.

- If the depth is too large, the pipes are thermally insulated (you can use a built-in or external heating electric cable) and raised higher.

- A layer of sand 100-150 mm thick is usually placed at the bottom of the trench; for thermal insulation and reducing the load on the pipe walls, the pit is filled with expanded clay and then leveled to the ground with soil.