A bolted connection can rightfully be called the most common type of fastener. But even the highest quality carvings become unusable over time. The way out of this situation may be to contact a mechanic or cut the thread yourself.

In both cases, this will require a set of dies or dies - hand tools for cutting external threads. With their help, you can quickly restore worn-out hardware or obtain a replacement part for an existing stud or bolt.

Design

The first feature that distinguishes one lehr from another is the design of the body. In accordance with this, they distinguish:

- Round dies. The body is a solid ring through which the workpiece passes. Thanks to high rigidity, a high-quality thread with a good thread profile is obtained.

- Sliding dies, consisting of two parts, are designed to produce threaded surfaces of various diameters.

- Split - the range of thread diameters is 0.1-0.3 mm. Therefore, it is advisable to use them for imprecise threads.

Best answers

Kajakas:

A die is a thread-cutting tool for cutting external threads manually or on a machine.

A die and a die are a thread-cutting tool for cutting external threads manually or by machine. Currently, the division into dies and lerks has ceased to exist. Previously, the name die was used in relation to a typesetting and adjustable threading tool, preferably of large diameters. The term ladle was used to refer to a plate with a threaded hole and grooves for removing chips. Lanyards were used to make more precise carvings of small diameters.

Dies are designed for cutting or calibrating external threads in one pass. The most common dies are for cutting threads with a diameter of up to 52 mm. The die is a hardened nut with axial holes that form cutting edges. As a rule, 3-6 chip holes are made on the dies to remove chips. The thickness of the die is 8-10 turns. The cutting part of the die is made in the form of an internal cone. The length of the fence part is 2-3 turns. Dies are made from alloy steels (9ХС, ХВСГФ), high-speed steels (Р18, Р6М5, Р6М5К5, Р6М5К8), and more recently from hard alloys. They are marked with the designation and degree of accuracy of the thread being cut, and the grade of steel (9ХС is not indicated).

Seryozhka Votsenzuk:

The die and the lerka are the same thing, they are just called differently. Apparently, whoever had any accent was called that.

MwenMas:

Nothing

Sasha Novikov:

Same

Nikolay:

Die tool for turner, tool for plumber

Thread direction

The thread can be right-handed (threads are cut clockwise) or left-handed (counterclockwise). Dies are also distinguished:

- Rights. Used for thread cutting on bolts, axles, screws.

- Left. They are used relatively less frequently in specific automotive elements, rotational mechanisms, and where right-hand threads will unwind. In the photo of the dies you can see the markings with the Latin letters “LH”.

Tips for choosing a tool

The cutting die can last for a long period. In its manufacture, as a rule, tool steel is used, which is characterized by high wear resistance.

The tool is selected according to the following parameters:

- Outer diameter of the workpiece.

- Accuracy class.

- Pitch and other thread parameters.

- According to the type of material being processed.

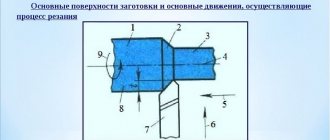

Die threading

Cutting threads using a die

The highest quality and most accurate cutting, as a rule, is carried out when using the split version. The design is characterized by the presence of a locking ring. In addition, there are simply a huge number of different sets on sale, which are represented by products with different diameters and parameters. All the necessary information can be determined by deciphering the markings. All designations, as a rule, are applied to the body of the product.

Profile

According to the profile, there are metric, pipe inch dies, and trapezoidal threading tools. Each variety has its own characteristics:

Metric. As the name suggests, they cut metric threads. They are designated by the letter “M”, followed by a number indicating the thread diameter in millimeters. The standards provide for sizes up to 68 mm, each corresponding to a small or large step. Dimensions, designation examples, acceptance rules for such dies according to GOST 9740.

Read here: How to choose a hacksaw for wood: how to choose the right household and professional tool

Pipe cylindrical. Visually easy to identify by the letter “G” on the body. This type of thread is measured using the English inch unit, which is 25.4 mm.

So, the designation G 1/2” means that we have a half-inch pipe thread. They are widely used for pipes of heating equipment and water supply systems. Size range from G 1/8” to G 2”.

Pipe conical. In order not to confuse them with other varieties, they are marked with the symbol “K”. They are used when it is necessary to obtain a conical threaded surface - in critical connections operating under pressure or machine components.

Trapezoidal. The cross-section of the threads is an equilateral trapezoid. They are common in power pairs that convert rotation into translational motion. The simplest example is the lead screw and nut of a machine and bench vice.

Rules of procedure

When working with pipes, it is important to stock up on dies with a pipe clamp and a wrench. The die is selected taking into account the type of thread required

This can be determined by checking the stamp or inspection. The dies must be marked. The data on them will give an idea of what brand the tool is made from.

Most pipes require straight threads. Also, before working, you need to determine its direction: right or left. To do this, a letter indicator is depicted on the dies: “L” is left, and “P” is right. The die also indicates what grade of steel it belongs to, this makes it possible to choose the right tool for cutting stainless steel pipes.

The cutting rules are quite simple:

1). Prepare the pipe for cutting. To do this, the chamfer is removed with a file, and the area is treated with an oil solution.

2). Insert the die into the holder, securing it with screws.

3). Bring the die to the product and make several circular rotations in the required direction of the thread.

4). Lightly press down the die to embed it into the material.

Scrolling algorithm:

- 2-3 turns in one direction;

- half a turn to the other.

And so on until the end of cutting

In this case, it is very important to keep the pipe and die strictly perpendicular. Otherwise, the thread will “walk”, which will affect the quality of the connection.

The arrangement of elements, as well as thread cutting, is demonstrated on video and photo materials for better results. Checking thread quality is easy. To do this, it is enough to screw the nut if it is screwed along the outer diameter of the pipe. The most accurate cut is obtained with a sliding die. It will help out if you urgently need to replace a piece of pipe that has a threaded connection.

Also, when choosing dies, it is important to consider what kind of thread will be made, external or internal. High-quality work will allow you to make a sealed threaded connection even in pressure water pipes

Let's sum it up

As you can see, making your own carving using dies is not at all difficult. To do this, it is enough to choose the right tool, put in a little effort and accuracy. Probably, many representatives of the male half of humanity remember how similar problems were solved in labor lessons at school. Therefore, for the majority, it will only be necessary to remember the acquired skills and apply them in adulthood. It’s like riding a bicycle: you only need to learn once to feel confident in the saddle even after a long break.

Die holders

To cut a thread, one tool is not enough. You will also need an auxiliary device for clamping and holding the die body - a die holder.

One device is designed for several standard sizes at once - for small, medium and large threads. The die is installed inside the holder and secured with a screw.

All about dies

A die or die is a device used to cut external threads of various types. It is represented by a small nut on which there is an edge and a chip outlet. The threaded device can have thread pitch sizes from eight to ten.

Thread pitch is the distance between adjacent threaded threads.

The working area of dies is iron pipes and rods. Threads come in conical and cylindrical shapes. To obtain a high-quality thread, you need to cut in one pass. The die has a cutting edge. To make cylindrical threads, dies with two parts of the working area are used - calibrating and cutting. The calibrating part forms the final diameter and thread profile.

Classification of dies

Ledgers are divided into: tubular, square, round and hexagonal.

They are also divided by structure:

- solid;

- sliding (prismatic);

- cut.

The round lecher is the most widely used. It is threaded in one pass, and not in several, like sliding ones. These dies can cut threads at different pitches. They can also be used to cut pipe and inch threads. The working part of round dies is not subjected to grinding. The outside diameter will depend on the size of the chip guards and the size of thread required.

Material

For manufacturing, high-speed steels R6M5 and R18 are used. They are optimal in terms of price-quality ratio, have a long service life and cope well with household tasks and minor repairs.

For production conditions, tools with carbide cutting edges are more suitable. With their help you can obtain threads on high-alloy steel.

Purpose of the device

To connect two metal pipes, welding or threaded connections are used. The disadvantage of a welded connection is the impossibility of disconnecting it when the need arises. When working with welding, experience is required, since the connection must not only be strong, but also reliable. The presence of threads does not require the use of a welding machine, which simplifies the process of connecting two pipes. Such a connection is reliable, durable, and can also be disconnected at any time using two keys.

To connect a pipe using a threaded connection, you need to cut a thread. For this purpose, a tool called a clamp is used. Its use makes it possible to obtain threads of the following diameters:

- half an inch;

- ¾;

- inch;

- an inch and a quarter.

The advantage of a threaded connection is that this method does not damage the zinc layer, as with welding. This protects the pipe from the negative effects of corrosion, extending its service life. The tool is used to obtain a strong connection between water and steam pipes that can withstand heavy loads of temperature and pressure.

What does the device in question look like?

The pipe clamp is a prototype of the die, or rather, it came from the die. This is a simplified version of the cutting blade, although there are products that are quite expensive. The product differs from the lecher and die in that it has a collapsible design. The die is made entirely of durable steel, and only the cutters are cast from it in the die.

To ensure efficient threading of the pipe, the tool uses durable cutters and a holder made of ordinary metal. The main structural elements of a pipe clamp include:

- A holder that acts as a base. The cutters can be replaced in the holder, since the design is collapsible.

- Incisors. They are available in various diameters and must be replaced in the holder when grinding the cutting edge.

The design of the simplest product has the shape of a guide with clamps for cutters. The force is applied to the handles with which the device is equipped. If there are no handles, then threading is done by moving the die with a pipe wrench or wrench.

Types of instruments

Usually the kit comes with a set of dies for cutting threads of different diameters, and the kit looks like this.

Threading tools for pipes are classified into the following types:

- Manual thread-cutting die. The product is driven by two handles or wrenches. Using this type of product, it is convenient to cut threads on pipes with a diameter of up to one inch.

- Manual clamp with ratchet. The ratchet allows for reciprocating movements of the cutting tool when performing work. The advantage of such products is that they simplify the work of producing large-diameter threaded connections. Using such a device is similar to screwing a nut onto a bolt using a ratchet wrench.

- Electric tool. The electrical device ensures maximum operating comfort. It is rational to use such a tool only when you have to perform the corresponding work on a daily basis in large volumes.

Some technical characteristics

To begin with, we note that the type of tool in question can only be used in conjunction with special holders. This is due to the fact that a lot of force must be transferred to the die during machining. One holder can be used to work simultaneously with different types of lechers.

The following information should also be taken into account:

- Left-handed dies are used to produce left-handed threads. Today they are used extremely rarely. To identify the tool, the designation “LH” is applied. Such a thread is required when the element is constantly in rotation during operation.

- Pipe versions differ from metric ones; for identification, the symbol “G” is applied to the surface of the body.

- To obtain a cone thread, a conical pipe tool is used. Most often used on production lines for the production of machine tools or fuel pipelines. Indicated by applying the letter “K” to the surface of the body.

When choosing a tool, you should pay attention to the concept of pitch - the distance formed between two adjacent turns. It is worth considering that the die has a main and an additional step.