Definition

Pressure devices consist of a container containing a punch, mold, needles and other components. What is a blow? It plays an important role in the stamping or marking process and is one of the main elements of the pressing device. The purpose of a punch is to press down on a metal piece to highlight certain symbols or holes on it. In addition, this equipment can be used to extrude the required part, apply standard or mirror markings, and print the required number of elements.

This is how they “joke” on the Internet, offering fables in all seriousness.

We read:

“Do you want to build a cottage in a month? Having spent only 48 thousand rubles on the walls? And the installation for the production of heat blocks will help you make heat blocks!”

Hello!

You will spend only 48 thousand rubles on material for heating blocks for your cottage with an area of 100 meters!”

I go to the website https://dom-bloki.ru/ - a cold sweat breaks out and my eyes immediately become square: Wow!

I grab the calculator:

A 100 m2 cottage is approximately 6x8 two-story with a wall area of approximately 150 m2. It turns out 1 m2 of wall is only 48,000: 150 = 320 rubles. Hooray! I buy without talking!

Sensation! How could I have made a 10-fold mistake when analyzing heat blocks (thermal wall technology) in the book “Walls of a House – What Are We Building From?” (You can download this book from the link https://yadi.sk/i/Z1Va04L5cGv3e ). There the cost of a m2 wall made of thermal blocks was 2500 rubles, but here it was only 320 rubles.

It’s clear: here we make heating blocks ourselves in 2-3 minutes, a piece on an installation that will cost you only 2980 rubles! In 10 days I made blocks and in another 10 days I welded together the walls of the cottage.

The square eyes gradually take on a normal shape when you take a closer look at everything that is written on this site. It turns out that:

1. In this installation, heat blocks (blocks containing a layer of hard foam plastic in the middle, and load-bearing layers of some kind of concrete on both sides), it turns out, are not made, but any other blocks 150x190x390 are made. On the website there is a constant confusion between “heat block” and “building block”, although these are fundamentally different things - the first contains insulation in the middle, the second is solid, without insulation.

2. “Installation” is a mold for the block plus a mysterious tamping punch for wedge (patented) tamping of the semi-dry mixture.

3. If you consider that before pouring the semi-dry mixture into the mold, you also need to prepare this mixture, then there is no way to squeeze it into 2-3 minutes per block.

4. A two-story cottage, it turns out, is a wall 200 mm thick. without external and internal finishing and without insulation.

To clarify all these discrepancies, I call the manager at the phone number indicated on the website. After many attempts to find out how it is possible to make a heating block in the dimensions of 150x190x390, and not just a building block, and what thickness the walls of the house will be, the manager admitted that he is not a builder, that these questions need to be clarified from the builders, and they just sell the installation.

That's it, we've arrived!

A short search on Yandex revealed a bunch of other sites that also sold the same “Installation” with reviews copied from the main site from the happy owners of this unique product. This means that the matter is on a grand scale. The 80% discount and colossal cheapness of “Installations” do their job.

I did not bring this information in order to criticize someone and praise, like a sandpiper, my swamp. I just once again convince you - when analyzing technologies, pick up a calculator and turn on your “thinking device”. Of course, it is tempting to lay down blocks in 10 days and build the walls of the house in another 10 days.

So, let's get back to our sandpipers. The above option for building a house seems to be simpler and faster than fiddling with making wall slabs using the “Your own house 3.0” technology.

But what do you get in the end is the big question!

Let me remind you that a huge discount on closed training in building a house to the end - before building the box of a house - using the “Your Own Home 3.0” technology ends in May - in a few days. If you have an urgent need to build a good house on a very limited budget, then you need to go here https://38.sam-sebe-dom.com/index.html , get acquainted, weigh everything and fill out the form. And all this must be done before the end of May.

Good luck and good health to you!

Best regards, Sergey Lapko.

Tweet

Types of punches

According to the type of design and method of exposure of the part, the following types are used:

- perforated elements;

- stamping machines.

- punching devices;

- stabbing fists;

If you need to create a large volume of parts, you can place the punch in a specially made holder.

Concept and characteristics

The punch is the key element for marking the surface of a product using press pressure. This design is the same in size as the matrix profile (limiting box) and is used for extruding parts of a certain shape, marking a surface or stamping blanks.

Based on the type of impact on the material, the following types are distinguished:

- Punching and piercing punches are used to make a hole of a given shape in a flat workpiece;

- cutting or perforating punches are needed to cut a part of the required size and shape from the workpiece. They are also sometimes called jewelry.

Partner

An equally important detail in printing products is the matrix. This is the box that the hammer drill should fit into. The matrix is directly involved in the process of forming the shape on the surface of the product. In direct stamping equipment, the mold is a chamber into which the pressed material is loaded. The bottom of the box forms the image on the parts, and the impact is aimed at the contents from above. Depending on the complexity of the part being manufactured, there are solid and composite forms.

How does the press work?

During operation, the punch (we discussed what it is at the beginning of the article), pressing on a special washer, acts on a metal part, which in turn passes through the matrix. In this way, a workpiece of the required shape is obtained. During operation, parts of pressing equipment are subjected to enormous pressure, reaching up to 500 kg per 1 square meter. Mm. They also constantly heat up to levels above 200 degrees. This causes wear on the stamping and press parts. And due to the additional impact of the processed products, punches and dies lose hardness over time. Therefore, their durability depends on the material from which they are made.

The main purpose of the matrix

In order to make a workpiece of the required shape, a matrix is used, which can be made from:

- polyurethane;

- rubber;

- various metals.

To make an iron part, the matrix must be made of specialized strong steel, which has high wear resistance. Such a structure should be equipped with polished walls and not have a lid.

Experts distinguish the following types of matrices:

- simple;

- complex;

- universal.

The most complex design solutions are used quite rarely, so they are produced to individual order. An example of simple matrices is molds for the production of various blocks and small bricks.

Making punches

High-precision computer-controlled machines are used in the production of stamps. Initially, milling machines are used, which mechanically produce and process parts. Then they are polished and then the working contour of the stamp is applied to the surface using hydraulic equipment. After the punch is made, it is placed in a special hardening furnace.

The produced punches can be cylindrical or shaped, the manufacture of which requires a longer and more complex process. Stamps containing letters or numbers are also produced. This is a square piece of steel with a sawn tip on which the required mark is engraved. A punch of this shape is used for marking various numbers, metal parts, machine elements and other products.

The matrix, in turn, is made after the stamp according to its imprint. The container should be slightly larger in width and size. Thus, the required distance between parts is adjusted by self-processing.

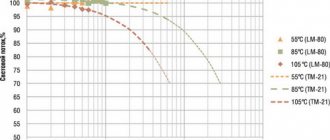

Press equipment parts wear out quickly and require periodic replacement. The use of dies is influenced by mold production methods and industry. The average service life of press components is approximately 6 years.

Features of dies and punches

In order for the manufactured products to have the proper high quality, the geometric dimensions of the tooling modules must be extremely accurate, match each other, their surface is absolutely smooth, the cut line is even, precise, and the press must be precisely centered. To ensure these indicators, the tool undergoes double grinding (roughing, finishing), polishing, and sharpening. Modules of shaped type are produced by technological imprinting, and complex contour ones are made on milling and planing machine units. Then the equipment is hardened at high (about 780°) temperatures.

In cases where the configuration of the punch is more complex than the matrix, it is first manufactured, and then a base is created based on its impression. Special control is carried out to ensure that the gap between the nodes is maintained. Clearance is maintained through independent processing or mutual adjustment.

If the quality of the set is decent, it will last a long time, will give an accurate cut line, and the parts made on it will not require additional processing.

The punch and matrix in the die are advantageous for their versatility, versatility, and practicality. During operation, such equipment can be easily mounted/dismantled without additional effort, the coatings applied to it are uniformly deposited over the entire surface, and the planetary rotation function is available.

Servicing the equipment is not difficult: it is necessary to systematically clean the surface of metal, concrete and other residues (using scrapers, brushes), rinse with water jet pressure and then dry.

Worn sets are not restored, but are promptly replaced with new ones, since their surface wears out and their dimensions lose the required value and accuracy. A tool made from a material selected for a specific task functions without loss of quality for up to several years (4-6 maximum). Therefore, purchasing equipment with a large margin of safety and service life is more rational than frequent replacement of less durable sets.

What are punches made of?

An important requirement for stamps and hole punches is a competent choice of the material from which they will be made. The worse the steel, the lower the productivity of the pressing equipment. Volumetric punches of complex shape are made of steel alloys with a high content of chromium and carbon. The most common material is steel marked X12F1. It has high wear resistance, excellent hardenability and is not subject to significant deformation during operation. To make simple forms, tool carbon steel U8A - U11A is used.

Parts made of heat-resistant metals retain their hardness during operation and do not lose their shape. To increase the service life of molds, materials from hard and high-speed alloys have been introduced into production. The cutting edge is applied to the mold or mold body. The best results in the production of molded parts were shown by alloys such as stalinite and stellite. They guarantee the hardness of the elements without the need for hardening.

Wood and metal processing

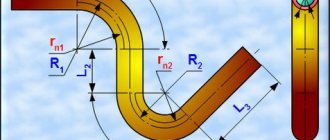

In dies for cold stamping (Fig. 1, a) only the forming parts, i.e., the punch and the matrix, are made of tool steel; in dies for hot stamping, either all parts are made from tool steel (Fig. 1, b), or only inserts (Fig. 1, c). Tool steels, hard alloys, plastics and other materials are used as materials for the form-building parts of dies.

Carbon tool steels U7, U8, U9 and U10 of reduced hardenability are used for the manufacture of dies and punches of dies for cold stamping, which have a simple shape of their working contour (in such dies there are no sharp transitions between elements; there are no narrow slots, thin bridges of metal between holes, etc. . P.). This is due to the fact that steels of reduced hardenability are deformed during hardening, resulting in the formation of cracks.

Punches and die matrices for cold stamping of more complex shapes are made from steel grades X, 9ХС, ХВГ, ХГС and other with increased hardenability.

Punches and die matrices for cold stamping of very complex shapes are made from steel grades X12F, X12T, X12M of high hardenability. These steels, similar in their properties to high-speed steels, contain about 1% carbon, 12% chromium and about 1% vanadium (titanium or molybdenum), and are characterized by high strength, wear resistance, and heat resistance (about 500°C). An important advantage of high-hardenability steels is low deformation and, therefore, the preservation of the dimensions of their working contour during hardening. Disadvantages include a tendency to carbide heterogeneity and poor machinability. X12F steel is almost 2.5 times more expensive than U10 carbon steel.

Thin and long punches of perforation dies for cold stamping and other non-rigid parts are made from steel grades 4ХС, 5ХС, 4ХВ2С, 5ХВ2С, etc. of high viscosity. The reduction in brittleness of these steels is achieved by reducing the carbon content (no more than 0.5%), and high wear resistance is determined by the presence of chromium and tungsten. The heat resistance of steels in this group is about 300 °C; They are quenched in oil; through quenching is obtained for samples with a diameter of up to 50 mm.

Punching of sheet parts

The operation of punch printing is quite simple. In this case, part of the material placed in the device is separated from the main one along a given contour. The cutting process creates internal holes. The process of using stamps and punching dies is reminiscent of cutting out parts with scissors. In this case, the cutting elements are a matrix and a punch with sharp edges.

The design of the punch clearly shows how the metal is pressed into the lower part of the matrix, followed by bending and deformation of the material. At the end of the work, as soon as the maximum pressure is reached, the metal fibers are torn and a corresponding cut is made on the product.

In the article we looked at what material the hole punch is made of, what it consists of and where it is used. They are used to mint coins, medals, badges, seals, structured designs, medicines and many other products.

Main characteristics of the product

Absolutely any type of stamps has a certain warranty period. The main components of this device are the matrix and the punch, which wear out quite quickly. These units must be changed regularly because they can last about 5 years without replacement. The equipment of vibration presses and stamping devices has a different design. This is done so that it is possible to carry out various technical operations.

For this reason, extensive grinding is performed when producing cylindrical dies. Craftsmen do rough processing of the device, and then clean grinding. The device is sharpened and polished at the last stage of its manufacture.

To make shaped punches, a technological impression is used. The device is hardened in a hot oven for 10 minutes. Next, the final sanding begins. To obtain a product of complex shape, a large amount of specialized equipment is used. It is almost impossible to do without the use of milling and planing machines.

Similar equipment is needed for matrix production. When the molds for the press are made of very high quality, and the punch is equipped with an accurate cut line, the stamp will have a high degree of wear resistance and a long service life. Experts believe that making stamps with your own hands is very difficult. To do this, you need to have a lot of knowledge in the field of metal processing.

Steels used for the manufacture of main parts, both dies and molds, belong to the group of tool steels. The technological and mechanical properties of tool steels are determined by the presence of chemical elements included in the steel. Based on their chemical composition, tool steels are divided into carbon, alloy and high-speed. The latter are used primarily for the manufacture of cutting tools, and therefore are not considered further.