A chainsaw is a worthy replacement for hand saws and axes. Today, this tool is available in almost every household - it is indispensable when arranging a personal plot, construction and repair work. Intensive use and improper care of the tool can lead to premature failure. However, it is not at all necessary for the owner of a chainsaw to immediately contact a workshop - many of the malfunctions that can happen to it during operation can be easily eliminated on their own.

- 2 Starting the engine: checking the spark plugs

- 3 Do-it-yourself chainsaw repair: fuel supply system

- 4 Troubleshooting muffler problems

- 5 Repair of the cylinder-piston group (CPG)

- 6 Checking the carburetor and signs that it needs adjustment

- 7 Calibration algorithm and safety precautions when troubleshooting a chainsaw carburetor

- 8 Other malfunctions of chainsaws

- 9 DIY chainsaw repair, video

Repair of cylinder-piston group (CPG)

Sometimes it happens that the engine is not able to reach maximum power or start due to insufficient pressure in the cylinders.

The source of such problems is sometimes faulty piston rings, problems with the cylinder, bearings, or wear of the piston itself. Therefore, repairing a chainsaw should begin with a visual inspection of the engine cylinders. Inspection is possible through the hole where the spark plug is installed to ignite the mixture. The overview under such conditions will remain minimal, but a first idea of the state of the working group at this stage can be obtained. You can also insert a compression gauge into the spark plug hole. Rotate the starter or crankshaft. The pressure inside must be at least 8 atmospheric units. At lower values, the engine will not work due to insufficient pressure created inside. As the pressure decreases, the engine power itself also decreases.

A more detailed picture of what is happening inside can be seen by disassembling it. To do this, remove the crankcase and visually inspect the piston. If there are chips, dents or scratches, it should definitely be replaced. The piston pins must also be in good condition without damage and not loose. If this happens, then you should definitely change them.

A decrease in pressure inside the engine also involves failure of the piston rings. This can be immediately noticed, since the working ring is not covered with carbon deposits, it is located freely in the groove and does not dangle, and is pressed tightly inside the cylinder.

Replacing chainsaw piston rings

You should also examine the surface of the inside of the cylinder. If it is already worn out, then it should be squandered.

How to avoid scoring on a chainsaw piston

Greetings, dear readers! Spring is coming, and many will go to the countryside. This means that the time has come to share my experience as a garden motorcycle repairman. This article is only part of a small series. Here are links to other articles:

During the work of the workshop, I accumulated an impressive collection of photographs of various malfunctions, a special position in which is occupied by a collection of photographs of failed cylinder-piston groups.

Melting of the top of the piston.

The photographs show cracks and a hole in the piston crown, as well as splashes of molten aluminum in the inside of the piston. This happened because the owner of this trimmer put the wound tool aside and began chatting with a neighbor in the country. After chatting for about five minutes, he gave the gas full ( you can’t work at half throttle

) and started working, but the trimmer immediately stalled and stopped starting because the piston bottom began to overheat during idle time and simply melted.

Two-stroke engines of garden equipment are cooled due to two things: forced airflow into the cylinder by the flywheel impeller and the fuel-air mixture entering the crankcase. The first cools the cylinder more, the second the piston. Never leave your chainsaw idling for more than a minute; it is better to turn off the engine.

Seizures on the piston and cylinder.

They can arise for a number of reasons, the first of which is dry contact. As a rule, a large number of small scuffs on the piston indicates that pure gasoline was used during operation, and not a fuel mixture. Let me remind you that the operating speed of the chainsaw is in the region of 11-12 thousand per minute, at this speed the chainsaw will not work “dry” for even a minute. A similar picture will be observed when using old fuel. As a rule, scuffs appear on the side of the exhaust window, in the area that is most sensitive to oil starvation.

Specifically for this piston it is quite difficult to say from what it suffered more. Judging by the soot on its top, the oil was poured anyhow, without observing any proportions. The muffler of this unit was also clogged with soot, and clear fuel was drained from the tank. Apparently, it was pure gasoline, or a very old mixture. But the old mixture most often becomes cloudy, so two conclusions can be drawn: either the mixture is old, but the oil in it is not two-stroke oil (some unknowingly pour motor oil), or it is pure gasoline.

Sticking and breaking off of piston rings.

And here is an example of what happens if, when preparing the fuel mixture, you violate the proportions and pour in much more oil than the required amount. As a result of using a mixture with a high oil content, or a mixture with oil not intended for two-stroke engines, intense ash formation was caused, followed by the occurrence of piston rings, one of which broke off and caused critical damage to the piston. It should be noted that the rings do not break so often, I would even say that it is quite rare, but this does not make it any easier for the engine.

In the technical regulations for old Soviet motorcycles, I often came across two “recipes” for preparing the fuel mixture for the same device. One proportion was considered more environmentally friendly (the one with less oil), the other extended the engine life (the one with more oil). But this happened before, with old equipment and old oils. Nowadays, there is a continuous struggle to reduce exhaust emissions, oils have a completely different composition and the engine has a different design, so I recommend that you use the proportion that the manufacturer himself indicated on the canister of the oil you chose.

Here is an example of a piston with a coked ring and slight scuffing. Fortunately, this unit was restored without replacing the CPG, with only cleaning the piston from carbon deposits, minor grinding and replacing the piston ring. The entire surface of the piston is covered with tar and ash deposits; here the use of a low-quality fuel mixture is beyond doubt. The cylinder suffered minor damage, small wear and lack of honing are visible, but no scoring is observed.

Conclusion. Use only high-quality, always fresh fuel mixture prepared using oil for two-stroke engines. Do not overheat the tool or leave it idling for a long time. Perform timely maintenance, clean and inspect your tools after use.

Carburetor problems

A special feature of the Shtil chainsaw carburetor is the presence of one screw responsible for setting the idle speed

When using equipment, you should always pay attention to the idle speed. A few simple steps will help you adjust this: checking the air filter, as well as the spark protection grille

It is worth noting that repairing the carburetor of a Stihl chainsaw is considered a labor-intensive process. If for some reason it stops starting, you must do the following:

- open the gas cap and then close it;

- remove and dry the candle;

- ventilate the combustion chamber.

If such actions are unsuccessful, pay attention to the fuel supply air filter and the functioning of the spark plug. If, in your opinion, the problem was caused by a malfunction of the carburetor, then it is best to immediately take the chainsaw purchased with a warranty to service.

This is because disassembling it yourself is quite difficult.

Makita chainsaw carburetor repair. Adjusting the Makita chainsaw carburetor

Adjusting the carburetor of a Makita chainsaw affects the performance of the device and the quality of work

To correctly set up the working unit of the equipment, it is important to: understand the principle of its operation, have the necessary tools, take care of fasteners, as well as closely located elements responsible for the operation of the chainsaw

Features of setting up a Makita carburetor

The Makita chainsaw carburetor works on the same principle as carburetors produced by other manufacturers. This important part is responsible for mixing fuel with air. To ensure that there are no problems with the operation of the device, the Makita chainsaw is adjusted. This will help protect the equipment's motor.

By adjusting you can:

- eliminate the risk of the carburetor creating a “lean” mixture;

- minimize the risks of creating a supersaturated mixture, which negatively affects the operation of the engine, causing rapid wear.

If you need a new carburetor for a Makita chainsaw (you will set it up based on the standard instructions), choose one that is identical in structure to the original.

- The basis is a tube for air passage, which is connected to the damper (in the middle). The location of this part affects the amount of air that flows to the engine during operation.

- Diffuser. It is not difficult to identify it by carefully examining the components of the carburetor. This part looks like a narrow tube, the main function of which is to regulate the speed of air flow.

- A channel supplying fuel from the float chamber (connected to the nozzle).

- A separate design that stands out from the others is the float chamber, which looks like a standard reservoir for fuel liquids.

Screws for adjustment

Adjusting the Makita chainsaw carburetor is carried out with a set of adjusting screws, which are located in the body of this design:

- screw marked L – corrects low speed;

- a screw marked H, which is used to adjust high speeds;

- Screw T for adjusting carburetor idle speed.

Preparing for adjustment:

- The engine is left to warm up (run the chainsaw for 10 minutes).

- Checking the air filter and cleaning this part.

- Stop the chain by turning the screw marked T (turn until it stops).

Carry out the following settings:

- place the chainsaw on a flat surface;

- After removing the chain, set it aside.

To diagnose carburetor problems, use a tachometer.

Important! Experts advise listening to the sound the screws make when turning. A "squealing" sound may indicate that the mixture is oversaturated.

Algorithm of actions for configuration

The chainsaw carburetor is adjusted in two stages:

- basic stage (engine on);

- Stage two is to perform when the engine is warm.

Important ! Some setup steps need to be adjusted depending on the Makita chainsaw model. In order to do everything correctly, read the instructions. Standard algorithm of actions

Standard algorithm of actions.

- Turn the screws for adjusting high and low speeds until they stop (turn clockwise).

- At the moment of meeting resistance, make one and a half turns back.

The screw marked T is moved clockwise. Release it only when the engine starts to run stably. Please note that the chain should not move at this stage.

What should I do if the engine turns off during tuning at idle? In this case, it is important to quickly turn the screw until it stops (turn clockwise). If the manipulation leads to movement of the chain, the adjusting screw is rotated slowly to its previous position

How to check if the carburetor is set correctly?

To do this, you need to speed up the chainsaw. Start the engine at maximum speed to objectively evaluate its performance. When you press the accelerator, the rotation speed should reach approximately 15 thousand revolutions per minute. This indicator indicates that the carburetor adjustment was successful.

If you cannot achieve this indicator at high speeds, and acceleration is slow, you need to adjust the carburetor again, working only with the screw marked L. Rotate it counterclockwise. In this case, you need to rotate the screw slowly so that the rotation does not exceed 1/8 of a full rotation.

If the opposite problem occurs and the maximum rotation rate needs to be reduced to 15 thousand, you need to rotate the screw marked with the letter H. Rotate it gradually, slowly in the direction opposite to the clockwise movement.

Reducing the speed indicator to the optimal value will reduce the risk of engine wear.

Chinese chainsaws

Analogs of European and American brands produced in state-owned factories in China are not much different from the original ones. The build quality and internal filling are almost identical.

However, professionals prefer Europe and America, while summer residents and homeowners give credit to China. Still, the loads when working in a garden or on a plot of land are noticeably different from felling trees.

For short-term and short-term use, the resource of a Chinese chainsaw is quite sufficient. Regarding breakdowns, both are equally susceptible to them.

Repairing a Chinese chainsaw with your own hands is as easy as repairing its European counterparts. The only exception would be major engine repairs, which cannot be done at home.

In any case, disassembling and assembling the unit, without having special knowledge, must be carried out according to the instructions attached to it. Working carefully, slowly and carefully.

Questions about self-healing

The problem in many cases is complicated by the lack of complete information about repair techniques. According to foreign manufacturers, after the saw has exhausted its service life, it must be taken out of service, so the maintainability of many models at the budget level is a reasonable doubt.

It is more difficult to restore professional grade chainsaws.

- The problem is complicated by the high cost of spare parts.

- It is possible that special equipment will be required to restore the efficiency of individual components and mechanisms, in particular, for adjusting fuel equipment.

Replacing expensive branded spare parts with affordable but short-lived Chinese analogues is not economically justified. Practice shows that these components produce a resource of 50-60% at best.

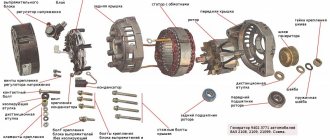

Chainsaw piston group

The dimensions of the cylinder-piston group are determined primarily by the diameter of the piston, made of heat-resistant aluminum alloy. Regardless of the model, the chainsaw CPG consists of a cylinder, a piston, a holding pin and two clamps.

Chainsaw cylinder mirror

When purchasing a piston chainsaw, you should pay attention to the inner surface of the cylinder, which should be polished and have a glossy shine. If there is damage or scratches, experts do not recommend installing such a cylinder.

In order to increase compression in the working unit and, as a result, increase power, many manufacturers install two piston rings. The chainsaw's compression rings, made of special cast iron, fit tightly to the cylinder, resulting in the tightness of the combustion chamber.

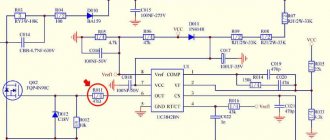

Checking the carburetor and signs that it needs adjustment

The rated engine power and savings in fuel consumption depend on the good condition of the carburetor. The carburetor of a chainsaw has no functional difference from a car. It mixes gasoline vapors with air entering through the pipe and delivers them further into the combustion chamber.

- air duct or tube for air supply;

- fuel line or fuel supply tube for mixing it with air;

- air damper.

A sign that the carburetor needs to be adjusted:

- strong vibrations due to unbalanced screws. An engine with a working carburetor runs smoothly and sounds like a four-stroke stroke;

- damage to the protection cap;

- wear of the piston system, which already requires a different mixture in composition;

- involuntary engine shutdown, inability to restart or initially start;

- an unreasonable increase in gasoline consumption, while engine power may remain the same, but most often decrease;

Read also: Tips for the DIYer of attachments for earmachine machines

Malfunctions of Chinese chainsaws: review of popular ones and ways to solve them

Buying a cheap chainsaw made in China is not particularly difficult: a huge number of gas-powered tools from the Middle Kingdom are available in markets, construction hypermarkets and online stores. However, a low price almost always hides poor quality.

The most popular malfunctions of Chinese chainsaws include:

- Poor performance of the lubrication system. Clogged oil channels are cleaned, and if the oil pump fails, replacement is necessary.

- The starter cable breaks.

- Breakage of the plastic starter axis. To replace it, a regular metal bolt will do.

If there is the slightest suspicion that the chainsaw is not working properly, you should immediately carry out a full diagnostic of the tool. Only with proper operation and timely maintenance can you count on a long service life of the chainsaw.

Other chainsaw malfunctions

If the diagnostics showed that everything is in order with the engine and its systems, then the cause of the malfunction should be sought in other components of the chainsaw. The most common problems are:

- starter failure;

- improper operation of the lubrication system;

- incorrect operation of the chain brake;

- saw chain wear, etc.

If the cause of tool failure is not visible to the naked eye, as is the case with the engine, it is necessary to carefully diagnose the faults and eliminate them in accordance with the manufacturer’s recommendations and safety regulations.

DIY chainsaw repair: fuel supply system

If the fuel mixture does not enter the cylinder, but the spark plug works normally, this may mean that:

- The fuel filter is clogged.

To clean this unit, remove the fuel hose and check the flow. If it is weak, the filter must be removed through the filler hole of the fuel tank and cleaned or replaced if completely worn out.

- The breather is clogged.

This is nothing more than a hole in the fuel tank cap, which is cleaned with an awl.

- The fuel mixture is not supplied or is supplied in insufficient quantities.

There may be several reasons for this:

- the air filter is clogged (in this case, it must be removed, washed with water, dried and replaced);

- the carburetor settings have gone wrong (which means this unit needs to be adjusted again);

- the integrity of the carburetor membrane is damaged (must be replaced);

- the carburetor channels are clogged (it must be disassembled and all parts and components cleaned).

Structural components of a chainsaw

All chainsaws are similar in structure, regardless of whether they are made in Europe (ECHO, Stihl, Husqvarna) or domestic (Kedr, Ural). Inside the body there are the main elements - the fuel tank and the engine, and outside there is a starter, a handle, a saw part (tire) with a chain. A sharp tug of the cable starts the engine, and it starts the saw blade.

To begin with, we invite you to familiarize yourself with videos that show how a chainsaw works and how it works:

From time to time, malfunctions occur in the operation of the saw, which require disassembly to eliminate. What can happen to such a simple mechanism as a chainsaw? At least the following:

- Stops starting;

- It starts, but soon stops;

- Stops functioning when cutting;

- Loses its power;

Most problems are associated either with interruptions in engine operation (fuel supply system, exhaust system, ignition, cylinder-piston part), or with malfunctions of other systems and components (clutch, chain brake, tire, lubrication system). Let's look at the most common breakdowns and methods for eliminating them.

A serviceable chainsaw starts with one pull and does not fail to cut

Chainsaw design

All gasoline-powered saws are structurally similar, so the causes of breakdowns are the same for both the expensive European Husqvarna unit and the popular cheap Chinese Champion 137 chainsaw. Do-it-yourself repairs can be carried out only with knowledge of the elementary laws of physics, the ability to read diagrams, drawings, and the presence of skills in working with mechanisms.

So, the chainsaw consists of:

- engine (mostly single-cylinder, two-stroke, carburetor);

- functional part (saw part with chain);

- servicing systems (starter, carburetor and other mechanisms).

Chainsaw device

Chainsaw with horizontal engine

The chainsaw has a fairly simple design. If you know the basic elements of the tool, then, if necessary, you can easily carry out repairs with your own hands. So, the following main parts can be distinguished in a chainsaw:

- engine;

- clutch;

- oil pump;

- chain;

- brakes and chain catchers.

Depending on the brand, each chainsaw has its own structural features. So, if we talk about the engine, it can be located both vertically and horizontally.

In professional tools, the motor is mainly located vertically. As for models with a horizontal power unit, they have compact dimensions. This was the main reason for their popularity and widespread use in everyday life.

DIY chainsaw repair Husqvarna 137, 142, 240, 365:

Starting the engine: checking the spark plugs

If the chainsaw does not start, the first thing to do is check for the presence of a fuel mixture in the tank. By the way, it must be prepared in the proportions specified by the engine manufacturer, otherwise the tool simply will not start.

After making sure that the fuel mixture is correct and available, you should check the ignition system. To do this, you need to inspect the spark plug.

Her condition can say a lot:

indicates that the fuel mixture does not enter the carburetor, which means the problem is not in the ignition;

fuel-spattered candle

is the result of an excess of the fuel mixture, which lies either in a violation of the engine starting algorithm or in incorrect carburetor adjustment;

This is a signal about the presence of low-quality oil in the engine lubrication system, incorrect carburetor settings, or an incorrectly prepared fuel mixture.

If the spark plug is splashed with fuel, it must be thoroughly wiped after removal. The fuel supply system should also be cleaned. To do this, it is closed, after which the starter is turned on. A candle covered with soot must be carefully cleaned using an awl and sandpaper.

When checking spark plugs, you should pay attention to the distance between the electrodes (the normal gap is 0.5-0.65 mm), as well as the condition of the gasket and the presence of a spark. A damaged or worn gasket will need to be replaced, and the spark can be checked by putting on the ignition cable, connecting the cylinder and spark plug nut and starting the starter

Troubleshooting muffler problems

If the chainsaw engine operates normally at low speeds, but starts to stall and smoke at high speeds, the problem may be hidden in the muffler.

To check the quality of its work you should do the following:

- dismantling (with mandatory closing of the outlet);

- disassembly (if the muffler is dismountable);

- cleaning from carbon deposits using special detergents or the dry method;

- drying (using a hair dryer);

- reassembly and installation.

To prevent clogging of the muffler during operation of the chainsaw, you should carefully monitor the composition of the fuel mixture and the quality of its components.

Carburetor and muffler malfunctions

Chainsaw carburetor

If the previous steps did not solve the problem, then you should move on to checking the carburetor. If necessary, it will be adjusted. If you have not encountered such a problem before and have not made adjustments at home, then it is better to use the services of a specialist.

Otherwise, making any mistake will lead to more serious problems. The carburetor is a complex device that consists of small parts. If disassembled carelessly, parts may be lost.

If you use the tool frequently, problems may also arise with its muffler. During operation, carbon deposits form on the pipe walls, which subsequently prevents the escape of exhaust gases.

To fix this problem, you need to remove the muffler and wash it thoroughly. For this purpose, special detergents are used. Before installing the muffler in place, it must be thoroughly dried.

It is important to know: when cleaning the muffler, it is worth considering that carbon deposits contain carcinogens. When dry cleaning, they can enter the respiratory tract, which can negatively affect your health.

The most common tool malfunctions

No matter how competently the unit is operated, problems occasionally arise in the operation of its systems. To fix them, you need to determine the cause. Knowing the structure of a chainsaw, we can say that most often problems arise with the operation of the engine. However, do not forget about other components that are also subject to wear.

Problems with the power plant

It can take quite a lot of time to identify the cause of an engine malfunction. Among the main signs of failure, several main ones should be noted:

- The engine does not start.

- The power plant starts to work, but quickly stalls.

- Maximum power is not achieved at idle speed.

- There are interruptions in work.

When diagnosing a malfunction, it is necessary to use the method of exceptions. It is better to start checking with those reasons that will require a minimum of time to eliminate. Most often, a power plant malfunction is associated with the ignition system. It is the condition of the spark plug that can say a lot about the operation of the entire engine. First, using a special key, you need to remove this element and then check its external condition. The performance of the ignition system can be easily determined by sparking. When a strong and stable spark appears, you should proceed to inspect the fuel supply system.

The following problems are possible in its operation:

- A clogged breather cap prevents fuel flow.

- The fuel filter is dirty.

- Insufficient fuel is supplied from the carburetor to the cylinder.

Lubrication system and chain brake

When using the tool, special attention should be paid to monitoring the operation of the chain lubrication system. Most often, problems arise due to clogging of the channels through which lubricant is supplied.

If there is a slight oil leak, you can continue working with the chainsaw. Otherwise, it is necessary to take urgent measures to eliminate the malfunction.

Troubleshooting common problems

The Partner 350 has popular faults that owners of these saws can diagnose and fix themselves. Let's take a closer look at popular faults and how to repair them yourself.

Stalls when you press the gas

If the Partner 350 stalls when you press the gas, then most likely there is a problem with the fuel system. The most common breakdown is an incorrectly adjusted carburetor or its malfunction, as well as extraneous air leaks.

Tip: If the chainsaw stalls when the speed increases, you should not immediately adjust the carburetor. Start by checking the engine for foreign air leaks. One of the signs of air leaks is increased idle speed.

Starts and stalls

If the Partner 350 starts up and immediately stalls, then, as in the previous case, there may be several reasons, but the most common is a difficult fuel supply. You should start troubleshooting by checking the condition of the fuel filter and lines. If the fuel flows normally, then check the spark and try to start the chainsaw on a new spark plug, as the saw may stall due to interruptions in sparking.

It is also necessary to check the draft of the air damper. If it does not open the air damper or does not open it completely, the engine may stall due to excessive fuel enrichment.

Lack of chain lubrication

There are several reasons for the lack of lubrication supply on the Partner 350 chainsaw, and in this case we can list them all.

- Oil line rupture.

- Oil filter clogged.

- Defective worm drive gears.

- Line or pump clogged.

How to solve oil pump problems is described above.

Pouring a candle

A very common problem that owners of Partner 350 have to face. The first place to start checking is to replace the spark plug with a known good one. If it doesn’t help, the spark is good, but the engine floods, then the reason is hidden in the carburetor settings. Instructions for diagnosing and adjusting the carburetor for the Partner 350 are on our website.

Fuel system

Malfunctions of the fuel system are also quite often the main reason that prevents a chainsaw from working as efficiently as possible. First of all, you need to check the quality of the fuel mixture.

Gasoline leaks from a chainsaw

If gasoline drops periodically appear on the body of the chainsaw, then it is necessary to check the tightness of the fuel tank. Over time, it may dry out. Or the gasket has become “stiff” and it can no longer perform its direct function.

If full-fledged gasoline streams appear, then there is a high probability that you will have to change the burst hose connecting the carburetor and the fuel tank.

Gasoline does not enter the chainsaw cylinder

There are several reasons why the fuel mixture stopped flowing into the cylinder:

- The air filter is clogged.

- The carburetor settings have been lost.

- The carburetor membrane is no longer intact.

- The channels through which gasoline is transported are clogged.

Chainsaw won't idle

In this case, you should start looking for a problem with the filter elements. For the most part, it is precisely because of the reduced capacity of the air and gasoline filters that the idle speed begins to “float”.

If everything is in order with the filters, then you need to check the components of the gas supply system, and also make sure that there are no spontaneous changes in the carburetor settings.

Malfunction of unspecified category

In some cases, owners of chainsaws have to solve more complex problems to fully restore the functionality of their cutting tool.

The chainsaw does not develop full power

In addition to the problem discussed above with a lack of gasoline or air entering the cylinder, the cause of low power may be a clogged muffler.

If you do not periodically clean the muffler clogged with combustion products, then the problem of poor engine power may not be the only one.

Carburetor depressurization and nozzle blockage

Over time, the screws holding the carburetor cover in place can become loose or the gaskets can become unusable. A clogged filter or improper replacement can lead to clogged injectors. All this also negatively affects the operation of the chainsaw and shortens its service life.

To prevent this, it is enough to periodically inspect the saw and, if necessary, evenly tighten the screws.

Chainsaw won't idle

It often happens that after long-term transportation and constant use, a chainsaw refuses to idle smoothly. As a rule, this problem is eliminated by adjusting the carburetor.

You can learn how to properly debug the carburetor from this video:

If the carburetor is tuned like a clock, then you need to check:

- Fuel system. It makes more sense to start with the fuel pump.

- Muffler. There is a high probability that due to the abundance of accumulated soot, the engine cannot function normally.

Chainsaw loses power under load

If during operation the power of the saw disappears somewhere, then the problem should be looked for in the following places:

- In the muffler. It, as you already understood, tends to get clogged.

- In a clogged fuel filter.

- A poorly functioning fuel pump.

Ignition system and its problems

Ignition system elements

Engine problems are often associated with ignition. That is why you need to start your inspection with this system. First you need to take out the candle and carefully examine it. Here you need to carefully remove the wire and unscrew the spark plug. This is done using a special key.

If the spark plug is wet, this is a clear sign of excess fuel. This is mainly due to improper operation of the ignition system or carburetor. As for the candle, it must be thoroughly wiped dry. It is also worth draining the cylinder. To do this, turn off the fuel supply and start the starter several times. Using these actions you can remove excess fuel. Next, the spark plug is installed in place and the engine starts.

Important: before installing the candle, you must make sure that it is free of dirt and moisture. This will directly affect its performance

If there is black carbon on the spark plug, this indicates the use of bad oil or the combination of oil and gasoline in the wrong ratio. In some cases, carburetor adjustment may be necessary. Here the candle must be cleaned of carbon deposits and installed in the socket.

If the tool still does not start, then it is worth checking for a spark: put a high-voltage cable on the spark plug and lean it against the cylinder. After this, you need to pull the starter several times. As a result, a spark should occur between the electrode and the cylinder.

If the above steps do not produce results, then it is worth replacing the spark plug and checking the tool in operation. If a spark does not occur, then the problem is probably hidden in the high-voltage wire.

Drum repair

If the flywheel and starter are in order, but the Calm 180 chainsaw does not start, the malfunction and repair of the drum must be disassembled in detail.

The main reason for the breakdown is the camera leaving. It is located next to the guide, which is located in the carburetor. With this type of malfunction, the pistons can also be damaged. To repair the drum itself, first disconnect the tire . It is also important to unscrew the protective cover and inspect the carburetor. If there is no visible external damage, remove the guide. Then you need to inspect the cam

It connects directly to the adjusting shaft. If it shows small cracks, that means it should simply be lubricated with engine oil. After this, the carburetor should be reinstalled and try to start the tool. A loud saw sound indicates that the cam is hitting the wall of the guide. In this situation, you should immediately turn off the device. Otherwise, the adjusting shaft may also be damaged. To change the cam independently, you will need to remove the restrictor located next to the carburetor. After this, you can completely turn the part over. In this case, the adjusting shaft can be left alone

Next you need to inspect the cam. It connects directly to the adjusting shaft. If it shows small cracks, that means it should simply be lubricated with engine oil. After this, the carburetor should be reinstalled and try to start the tool. A loud saw sound indicates that the cam is hitting the wall of the guide. In this situation, you should immediately turn off the device. Otherwise, the adjusting shaft may also be damaged. To change the cam independently, you will need to remove the restrictor located next to the carburetor. After this, you can completely turn the part over. In this case, the adjusting shaft can be left alone.

The cam in the presented saw is installed with a diameter of 1.3 cm. When replacing a part, it must be carefully tucked into its original location. The best way to do this is to use a hammer.

However, in this situation, it is important not to overdo it and follow the guidelines. New camera available on "Calm 180" (market price) $200

Engine

In most cases, the following problems occur in engine operation:

- the engine stopped starting;

- the engine starts, but after a while it stalls;

- the engine is not able to develop the required power;

- The engine is extremely unstable.

How to check crankshaft seals

The presence of oil seal leaks can only be checked by getting to the crankshaft itself and carefully examining it for leaks. You can see how to do this correctly in the video:

How to check compression on a chainsaw

At a compression level below 8 atmospheres, the engine will not have enough power, which means the chainsaw will not be able to fully function.

To measure compression you need:

- Remove the protective cover and unscrew the spark plug.

- Insert the tip of the compression gauge into the hole where the spark plug should be located.

- Using the starting cord, rotate the piston and remember the maximum readings of the measuring device.

How to properly install a piston on a chainsaw

The work of replacing the piston for most models of modern chainsaws is carried out according to the following algorithm:

- The top and side covers are removed.

- The candle is unscrewed.

- The stoppers are removed from the shock absorbers and the handle is disconnected from the body.

- The drive sprocket and starter are removed.

- A piston stopper is installed in the spark plug hole and the nut securing the flywheel and clutch is unscrewed.

- The flywheel, clutch, and worm drive of the oil pump, located immediately behind the clutch mechanism, are removed.

- The screws securing the carburetor and air filter are unscrewed, after which these components are removed along with the engine control lever.

- The ignition coil is removed, as well as the muffler.

- The saw is turned upside down and, by unscrewing the screws securing it to the body, the engine is disconnected.

- The pan is unscrewed and the piston is removed.

- Since the piston is removed only together with the crankshaft, to disconnect it it is necessary to remove the retaining rings.

- The old piston is replaced with a new one, but as carefully as possible. This is caused by the high fragility of compression rings.

- The crankcase is put in place, and sealant is used instead of a gasket.

All subsequent actions are carried out according to the reverse algorithm of disassembly.

Frequent malfunctions of Chinese saws 45-52cm³ - Forward, Redverg, Patriot, Prorab, etc.

5/5 — (22 votes)

In our country, inexpensive chainsaws made in China, produced under different brands, are becoming more and more popular every year: Forward, Redverg, Patriot, Prorab Baumaster, Champion and even Lesnik, Lynx and other saws with brutal domestic stickers. They all have approximately the same design and, accordingly, similar components. These are chainsaws with an engine capacity of 45-52 cm3. By the way, you often see these numbers in the model markings, so it’s not difficult to figure it out.

Of course, Chinese chainsaws are not so reliable, but they are still a good helper in everyday life, when collecting firewood, or in summer cottages, and for little money. These saws suffer from frequent minor malfunctions. Fortunately, most of them are eliminated quickly and do not hit the owner’s wallet too much.

Primary diagnosis of Chinese chainsaw.

The correct operation of the engine and the saw as a whole is influenced by a large number of factors that are interconnected. If you cannot determine the malfunction, contact a trusted service center. I would like to immediately note that before starting disassembly and serious repairs, check the basic consumables that affect the operation of the saw:

Spark plug - no carbon deposits, electrode gap, good spark

Air filter – no sawdust or dirt

Fuel filter – no contaminants, good flow rate

Let's look at the main malfunctions of these chainsaws:

Malfunction - The chain does not rotate, it jumps off. The chain breaks.

Cause: Worn drive sprocket.

To replace the drive sprocket, you need to remove the side brake cover and remove the saw set.

Remove the air filter housing and the filter itself, unscrew the spark plug.

We stop the movement of the piston with a special stopper. We unscrew the clutch (item 44), pay attention – the thread is left-handed!

Unscrew clockwise.

There is no need to disassemble the clutch; we move it to the side. Remove the protective washer (item 45) and the drive sprocket (item 46) with the bearing

There are two types of drive sprockets: one-piece - the whole thing can be changed, and collapsible (as in the figure) - the crown itself can be changed separately (item 47)

It is important to inspect the plastic drive of the oil pump (item 49). The threads on it should not be “licked”, as well as the splines for the drive sprocket.

If necessary, we replace it with a new one.

Lubricate the drive sprocket bearing (replace with a new one if necessary) Install a new sprocket (or crown), washer and tighten the clutch.

Malfunction - Oil is not supplied to the chain.

Cause: malfunction of oil supply system elements

Oil pump . The design provides an oil supply adjustment screw (indicated by an arrow in the figure).

Try increasing the oil supply. This may be the cause of the problem. It can be adjusted without disassembling the saw. It is located below. There is an adjustment pattern on the saw body.

If this adjustment does not help, inspect the oil filter in the tank, blow it out (if necessary, replace it with a new one)

Let's go further, remove the clutch and drive sprocket (see point 1)

The oil pump drive (item 49), the threads on it should not be “licked”, as well as the mounting splines for the drive sprocket.

This is an important point on which the oil supply depends.

After unscrewing the screws (item 53), remove the protective cover of the oil pump.

Unscrew the two screws (item 56) securing the oil pump and remove it.

We check the integrity of the oil hose (items 55, 116); if there are cracks, replace it with a new one.

You can disassemble the oil pump, wash it and blow it out, but we have not seen spare parts or repair kits for sale for such pumps, so if it is faulty, it is replaced, completely assembled, with a new one.

IF THE SAW OIL IS CONSTANTLY LEAKING:

A very common problem when storing a saw is oil leaking from the oil tank.

To resolve this issue, you must do the following:

Remove the saw set, oil pump drive, sprocket and cover (described above). Remove the oil pump (item 57) and oil hose from the tank (item 116)

We wrap the fume tape around the oil hose (marked in red) and when installing it, apply a small layer of sealant. We install an M6 washer on the oil pump pipe that goes into this hose to press the pump tightly to the hose.

Malfunction - Air leaking into the engine.

It is worth noting that many saw owners confuse air leaks with a carburetor malfunction. Symptoms of engine air leaks are a strong increase in speed, both short-term and permanent. Or the saw simply refuses to start.

Ideally, check the saw for leaks with a special tool, but the cost of such a tool is very high. Let's talk about the main “sources” of air into the engine.

Crankshaft seals are one of the main reasons for air leaks into the engine on these saws.

Crankshaft oil seal (15*28*4.5 small) – drive sprocket side

Crankshaft oil seal (15*35*4.5 large) – flywheel side

To replace the oil seal on the clutch side, remove the drive sprocket, clutch, oil pump (see paragraphs 2.3)

Let's inspect the surface of the oil seal - traces of moisture or wet contaminants, abrasions and other damage on it are a signal to replace it.

Using a thin flat screwdriver (an awl, or any similar object that is at hand), we remove the old oil seal (item 59), pry it with a screwdriver from the crankshaft side and remove it.

Before installation, apply a small amount of oil to the inner surface of the new oil seal (you can use the oil that we use to prepare gasoline mixtures)

We blow and degrease the seat under the oil seal, and evenly install the new oil seal.

To replace the oil seal on the flywheel side, unscrew the 4 screws securing the starter (item 104), remove it, and remove the protective cover (item 118)

We block the movement of the piston using a plastic stopper. Unscrew the nut (item 97) of the flywheel (item 95), but not completely. With a gentle blow to the nut, we “knock it off the crankshaft.” Unscrew the nut, remove the washer (item 96), flywheel (item 95) and key.

Unscrew the 2 screws (item 94) of the oil seal protective casing (item 93) and remove it.

Let's inspect the surface of the oil seal - traces of moisture or wet contaminants, abrasions and other damage on it are a signal to replace it.

Using a thin flat screwdriver (an awl, or any similar object that is at hand), we remove the old oil seal (item 89), pry it with a screwdriver from the crankshaft side and remove it.

The carburetor inlet pipe also causes air leaks. During operation, and also due to the poor quality of the material, cracks form on the rubber part of the pipe, resulting in air leaks.

To replace it:

Unscrew the fastening screw (item 40), remove the air filter housing (item 38) and the air filter (item 37). We inspect the air filter for mechanical damage and contamination.

Unscrew the spark plug. Unscrew the 5 screws (item 3) of the deflector (item 4), remove it

Unscrew the 2 screws (item 36) securing the carburetor adapter (item 34)

Remove the throttle linkage (item 35) and the fuel hoses from the carburetor. We take out the carburetor.

We remove the o-ring (item 32), flange (item 31) and gasket (item 30)

Unscrew the 2 screws (item 27) securing the carburetor adapter (item 29), remove it (carefully straightening the rubber intake manifold out of it)

Let's take it off. We carefully inspect it and the gasket under it; cracks or deformation can serve as air leaks; if necessary, we replace it with a new one.

Another source of air leakage can be fuel hoses.

It should be noted that on saws of this configuration, all rubber products (seals, hoses, etc.) are not of very high quality.

Very often the problem is caused by the fuel hose from the tank.

While the saw is disassembled and the hoses are relatively easy to access, we inspect them for cracks and, if necessary, replace them with new ones.

The hose from the fuel tank is of greatest interest. (Often it bursts where it fits into the saw body)

To make it easier to replace it, remove the rubber cover (item 147), and, if necessary, the gas traction (item 129)

We inspect the fuel hose, if replacement is necessary, disconnect the fuel filter in the tank.

Remove the old hose (it sits tightly in the groove).

We install a new one.

Another, albeit very rare, cause of air leaks can be loosening of the screws securing the cylinder to the crankcase.

While the saw is disassembled, you can check the tightness of the screws with a long hexagon.

If the screws are loose, you can remove them and apply split thread locker and screw them back in.

Malfunction - Starter.

A common occurrence on these saws is starter failure.

It should be noted that there are 2 types of starters for these chainsaws.

Regular and starter with easy start option (additional spring installed to facilitate the process)

Often this spring breaks (from excessive force during the winding process) and the ratchet rotates without moving the flywheel. At the same time, the starter seems to be working - it releases and winds the rope into place. To replace this spring, remove the starter by unscrewing the 4 mounting screws (item 105). Unscrew the screw securing the starter coil (item 98). We remove the upper part of the coil (item 100 (Y3)), inspect it for wear, and if necessary, replace it with a new one.

If the wide easy-start spring (item 100(Y2)) has broken off the mounting “whiskers” in the coil, replace it with a new one.

In a situation where the starting rope does not wind up at all, you will have to disassemble the starter completely and change the starting spring (item 101).

I would like to note that a starter without an easy start option has a spring of a different design, so when buying a new spring, it is better to have a sample with you.

It would be a good idea to check the condition of the pawls and springs on the flywheel. The pawls should spring back easily and return to their original position. If there is any damage to the pawls (or their springs), we replace them with new ones. To do this you will have to remove the flywheel (how to do this is described above)

Malfunction - Anti-vibration system.

The anti-vibration system of these chainsaws is based on 5 rubber shock absorbers and a shock absorber spring, the fastening of which is not carried out using a particularly reliable method, and besides, natural wear and tear will affect them over time. They do not affect the operation of the engine, but from time to time we receive chainsaws at our service center whose plastic handle literally barely holds on; it is not safe to work with such a saw.

This consumable is inexpensive, so it is better to replace it if necessary.

Shock absorbers are very easy to change:

We pull off the plastic stoppers on the handle (item 121), unscrew the screws (item 122), replace the old shock absorbers (item 123) with new ones.

On the crankcase, remove the starter and side brake cover, plastic stoppers (item 63), unscrew the screws (item 24), replace the old shock absorbers (item 64) with new ones.

In order to change the shock absorber spring, unscrew the screw (item 21) securing the chain catcher (item 20) and remove it.

Next, unscrew the spring screw (item 24), remove the spring (item 23), and if necessary, replace it with a new one.

A little about the air filtration system.

I would like to note the fact that the air filtration system is not well thought out - a loose connection between the air filter and the adapter and the poor quality of the air filter itself - allow many particles of dirt and sawdust to pass directly into the cylinder-piston group.

On the famous Aliexpress website they sell a worthy substitute that will help get rid of this problem and allow you to periodically service the air filter

Installed air filter with new adapter on the saw.

This design and quality of the air filter will provide decent protection to the carburetor and chainsaw engine

As you understand, a Chinese saw will require more careful care when compared with the famous brands Shtil or Husqvarna. They break down more often, even in small ways. With the help of this article, you can easily cope with any malfunction, and there will be no problems finding spare parts. If you want to know more about this, follow the link below.

Article: Replacing the piston group on a Chinese chainsaw 45-52cm³.

3.9 9 votes

Article rating

Chainsaw design and general classification of faults

Correctly find the source of the malfunction, as well as perform correct and high-quality repairs of chainsaws; for this you need to have a reliable understanding of its technical specifics. Repairing such equipment is not particularly difficult. Its schematic structure is quite simple. For convenience, the nodes in its composition can be divided into three types:

- The main and very important element, without which further work is impossible, is a two-stroke engine running on gasoline. Acceptable brands of gasoline are indicated in the device passport itself;

- the second equally important component is its working part, which is responsible for sawing the materials themselves. This includes sawing mechanisms;

- The third connecting unit includes a system for supplying and filtering fuel, oil, engine ignition, exhaust gas removal, etc.

Chainsaw engine malfunction

Problems are classified into two nodes:

- Malfunction of the engine itself. It cannot start, it stalls for no reason, it heats up excessively, it smokes a lot, it works unstably with minimum and maximum load. Therefore, repairs need to be carried out on these units.

- Peripheral problems. Here you can identify many symptoms that indicate malfunctions in its operation. For example, if the chainsaw stalls during operation or loses power, there may be a blockage in the gasoline supply system or filter. If it cuts poorly, then the chain may simply be dull. Repairs should begin with a study of the auxiliary components, which will require the least amount of time and equipment.

For convenience, before starting repairs, you should divide the chainsaw into sectors and look for a fault directly where the problem is suspected. The manual also provides a brief description of possible breakdowns and how to eliminate them.

It should also be borne in mind that several factors can serve as sources for the same malfunction. Therefore, it is important to be able to diagnose the cause of the breakdown in order to carry out repairs correctly and efficiently in the future. Before you start disassembling and repairing a chainsaw, you should estimate the possible causes and try to work only with them.

Calibration algorithm and safety precautions when troubleshooting a chainsaw carburetor

The main condition for successful repair is correct diagnosis.

Therefore, in order to determine why the chainsaw failed and, most importantly, how to make it work again, you first need to know the features of its design. It should be noted that it is not particularly complex, as it includes:

- engine (two-stroke petrol);

- functional part (saw bar and chain);

- systems that ensure the joint operation of these two components (ignition, filtration, lubrication, etc.), that is, the tool as a whole.

In order to simplify the diagnosis of faults, they are usually divided into two main categories:

- engine malfunction;

- malfunctions of other chainsaw components.

The most common failures occur in engine systems. however, other parts of the tool may fail at any time due to intensive use or improper care. How to determine exactly where the breakdown occurred? Simple logic will help us with this.

If the problem is in the engine, it will:

- won't start;

- stall;

- work unsteadily;

- overheat;

- smoke;

- develop insufficient power.

As for all other faults, as a rule they manifest themselves when the engine is running normally.

Carburetor adjustment is performed in two stages:

- Basic (carried out with the engine off).

- Finish (carried out with the engine running, preheated).

For basic adjustment, screw screws H and L until they stop and turn them back 1.5 turns. Final adjustment requires that the engine be warmed up for 5-10 minutes at low speeds.

The final calibration is performed by turning out the idle screw until the minimum engine speed is reached (its operation must be stable and the chain must be motionless). If the engine stops idling, the screw must be returned back, and if the saw chain still moves, you should continue turning it counterclockwise.

Calibration check is performed by test:

- Acceleration (when you gently press the accelerator, the engine should quickly gain speed to its maximum).

- Maximum speed (if there are misfires, screw H should be loosened slightly).

- Idling (the chain should not move, and the engine should pick up speed as quickly as possible).

If the owner of the chainsaw is not familiar with the carburetor structure and does not have the necessary tools to calibrate it, you should contact a specialist. A carburetor is a very complex unit, so any incorrect action can lead to irreversible consequences, such as complete engine failure.

If the diagnostics showed that everything is in order with the engine and its systems, then the cause of the malfunction should be sought in other components of the chainsaw. The most common problems are:

- starter failure;

- improper operation of the lubrication system;

- incorrect operation of the chain brake;

- saw chain wear, etc.

If the cause of tool failure is not visible to the naked eye, as is the case with the engine, it is necessary to carefully diagnose the faults and eliminate them in accordance with the manufacturer’s recommendations and safety regulations.

If the previous steps did not solve the problem, then you should move on to checking the carburetor. If necessary, it will be adjusted. If you have not encountered such a problem before and have not made adjustments at home, then it is better to use the services of a specialist.

Otherwise, making any mistake will lead to more serious problems. The carburetor is a complex device that consists of small parts. If disassembled carelessly, parts may be lost.

If you use the tool frequently, problems may also arise with its muffler. During operation, carbon deposits form on the pipe walls, which subsequently prevents the escape of exhaust gases.

To fix this problem, you need to remove the muffler and wash it thoroughly. For this purpose, special detergents are used. Before installing the muffler in place, it must be thoroughly dried.

It is important to know: when cleaning the muffler, it is worth considering that carbon deposits contain carcinogens. When dry cleaning, they can enter the respiratory tract, which can negatively affect your health.

The manual that comes with the chainsaw indicates the need to monitor the chain lubrication system. A common cause of the problem is clogging of the channels responsible for supplying lubricant. If the oil leak is insignificant, then the tool can continue to be used for its intended purpose. But, if you notice a significant leak, it must be repaired immediately.

First you need to check the tightness of the connection of the tubes with the fittings. If necessary, the tubes are replaced or the connection is sealed using special materials.

There is an interesting article with a review of different models of garden shredders.

Read an article on how to choose the right pruning shears for grafting trees here.

It is also necessary to check the oil pump. If cracks are visible on its body, it needs to be replaced.

In cases where the chain brake does not work, a thorough inspection of the brake band is necessary. During operation, it may become contaminated with grease or sawdust.

If your Chinese chainsaw does not start or it works but not efficiently or intermittently, carry out diagnostics to accurately identify the cause before disassembling the tool and looking for replacement parts.

If the engine is silent after starting the starter mechanism, the reason may lie in:

- malfunctions of the main components of the engine (improper fuel or exhaust supply, problem with the ignition system, with the cylinder and its piston group);

- malfunctions of the lubrication system, chain brake mechanism, problems with the clutch (its clutch) with the tire, etc.

The same reasons can lead to the following “symptoms”:

- the engine stalls a couple of minutes after starting;

- the main node works intermittently;

- The engine works well only at idle, and as the speed increases, it stalls, sharply losing power.

When a Chinese chainsaw stalls, inspect the spark plug. If it is completely dry, then this indicates that no fuel has entered the cylinder, which means that the cause of the malfunction of the tool must be sought in another unit. If the spark plug is filled with oil, then you need to adjust the carburetor.

In addition, you need to thoroughly clean the spark plug, turn off the fuel supply, ventilate the chamber after removing traces of fuel, and then start the starter system. When the spark plug is in place, the engine is checked.

Currently reading: Chainsaw Husqvarna 365 - features and advantages of the model

If you notice black carbon deposits, change the oil to a high-quality one or adjust the ratio of consumables. In this case, the spark plug is also cleaned (in some cases a needle or awl will be needed), as well as stripped using electrode sandpaper.

When you install the spark plug in place, be sure to set the gap between the electrodes correctly. The optimal width is 0.5 millimeters.

There may be several reasons for this problem:

- Dirty fuel filter. The cause can be easily identified by inspecting the fuel system after removing the hose. A weak stream of fuel indicates the need to clean the fuel filter. If cleaning does not help, a new hose is installed in this unit.

- The breather installed on the tank cover is clogged. You can clean it with a needle of a suitable diameter.

- Fuel mixture too rich. Again, cleaning the fuel filter helps solve this problem.

- Incorrect carburetor setting. You can set it up yourself, based on the instructions provided in the instruction manual for your power unit.

This problem is indicated by turning off the engine in operating mode (at the same time, the engine runs normally at idle). Check the spark arrester, which can be cleaned of combustion products of the fuel mixture. To do this, the muffler is dismantled and its seat is plugged with a clean rag. You can remove carbon deposits from the muffler using detergents. Before installing this part, dry it thoroughly.

You can suspect a problem when the engine is not running at full power. In addition, it may not start, since low pressure will be generated in the cylinder. In order to accurately identify the cause of the malfunction, check the crankshaft bearings, cylinder pistons, and the cylinder itself. All these parts can wear out.

Causes.

- You will notice oil leaks with the naked eye. In this case, you will need to check the connection between the pump tube and its fitting. Perhaps the cause of the problem is depressurization, as indicated by cracks. The malfunction can be eliminated by replacing the tube and sealant.

- Insufficient oil supply, which may be preceded by clogging of the channels supplying lubricant consumables. The problem is solved by cleaning them.

- Presence of cracks in the oil pump and its housing. Only replacement will help.

The brake system may not function properly or not function at all, causing problems in the operation of the power unit due to clogging of the surface hidden under the protective cover. Another possible cause is a worn brake band. The tape can be replaced, and if clogged, clean thoroughly.

In order to less often encounter various problems in the operation of the saw, check various parts of the device for wear, including the anti-vibration unit, guide, and all sprockets, including the main one.

We recommend watching

- Why does a chainsaw cut crookedly? There is a solution!

- Filling a spark plug on a chainsaw - solving the problem

- Chainsaw Shtil 180 will not start: causes and repairs

- How to change a sprocket on a chainsaw?

- Construction and repair of a chainsaw oil pump

- Replacing oil seals on a chainsaw: Shtil, Ural and others

Repair it yourself or send it to a service center

Most of the malfunctions of gasoline chain saws can be fixed with your own hands. True, this requires an understanding of the structure of the chainsaw and how the components function among themselves. As for the tools, the most often needed are:

- screwdrivers (slotted and power);

- combination wrench included in the kit or regular wrenches with heads of various sizes.

Quite often, such a malfunction as leaking gasoline is observed in a Chinese chainsaw with a volume of 38 cubic meters.

We invite you to familiarize yourself with Cherry plum wine: simple recipes for making a drink at home from red and yellow fruits, with and without seeds, and also how to make it in Polish?

Filter

A “rich” or “lean” fuel mixture will sooner or later cause a breakdown. Perhaps even expensive. To prevent this from happening, it would be a good idea to regularly check the filter for abrasions, as well as for breaks in the filter fabric itself.

How to check the fuel filter and replace it

To check the current condition of the fuel filter, you must perform the following steps:

- Remove the fuel hose from the carburetor fitting and direct it into a working container.

- Press the so-called “paging” button several times.

If gasoline flows unevenly and jerkily, then it’s time to install a new filter element. This is done quite simply:

- The fuel tank cap is unscrewed.

- Using tweezers or any other device, the filter itself is removed.

- After disconnecting the old filter, you need to install a new one and lower it into the fuel tank.

How to clean the air filter

If a sufficient amount of air is not supplied, the fuel mixture becomes too rich, which leads to disruption of normal engine operation. Regular purging of the air filter, and in particularly advanced cases, washing in a soapy solution will help avoid such problems.

Please note that washing in acetone, gasoline or other aggressive solutions is not allowed. This may damage the integrity of the filter element.

How a chainsaw carburetor works - features of air intake

The operating principle of a chainsaw carburetor also includes supplying an air mixture to the device. As you understand, not pure fuel (oil with gasoline) enters the combustion chamber, but a fuel mixture - oil with gasoline from the tank and air, which first passes through the filter element.

This is interesting!

The filter that is installed on the carburetor must be cleaned regularly, otherwise its clogging will reduce the flow of air into the system, which often causes the unit to malfunction.

Many inexperienced sawyers immediately start adjusting the carburetor, but it is enough to clean the filter and blow it with a compressor to eliminate the causes of uneven or unstable operation of the tool. So, the air passes through the filter and enters the device through membrane number 7.

During a cold start, air damper 7 is almost completely closed, as shown in the diagram. Through it, a small amount of air enters the system. Air enters diffuser 16. Number 12 indicates channels or jets for idle speed and medium speed. These channels are interdependent, that is, the medium speed channel is transitional from idle. These channels are constantly open, so fuel in the appropriate dosage enters the diffuser, where it mixes with air, heading towards the cylinder.

https://youtube.com/watch?v=RL2zxDpIQr8%3F

Number 15 indicates the maximum speed channel, which consists of a valve with a rubber base. Through this valve, fuel is supplied in one direction - into the diffuser chamber. Next, the throttle valve 8 enters the system, the movement of which depends on the force of pressing the gas of the unit. When starting, valve 8 is in a vertical position, so the chainsaw operates only on the fuel mixture coming from the XX channel. The amount of air in this case is insignificant, since damper 7 is also open by a few millimeters. When you pull the trigger of the tool, the damper is deflected by 10-15 degrees, as a result of which the fuel mixture is supplied from medium speed channel 12 in the diagram above.

When the sawyer starts sawing wood, the number of revolutions increases to maximum, so the damper moves at an angle of up to 90 degrees from its original position. There is an increase in the amount of fuel, which accelerates the combustion of the fuel mixture.

In order for chamber 14 to be filled with a fuel mixture of gasoline and oil, which enters through the channel closed by the needle, it is necessary to create a vacuum, due to which the membrane 13 will be drawn inward, thereby acting on the rod. A vacuum in chamber 14 is created when the starter handle is pulled when the crankshaft of the tool moves. The piston moves up and down when “blinking” or “poking” the starter handle, which provokes the creation of pressure inside chamber 14. As a result, the chamber is filled with fuel, which enters the diffuser through the corresponding channels, mixing with air and heading into the cylinder.

https://youtube.com/watch?v=5u1owJHDnYE%3F

After the engine of the unit is started, the piston will begin to move under the influence of the burning mixture, so a vacuum is constantly formed in the chamber, which actually provokes the bending of plate 13, which acts on the needle valve through which fuel enters the main chamber of the chainsaw carburetor.

Actually, this is the principle of operation of a membrane-type chainsaw carburetor, the functioning of which does not depend in any way on the angle of its location. Knowing the design and operating principle of the unit, you can begin setting it up, cleaning it and adjusting it.