The device is supplied in a cardboard box along with welding components. I spent a long time deciding which inverter was best to buy in order to quickly learn how to work with it; my friends advised Resant.

The undoubted advantage of household welding inverters like SAI is the ease of their connection. All beginners will like them, since they immediately eliminate many problems when welding.

We wish you good luck in your work! Another solution to this problem is to buy new transformers, which is not economically feasible - after three years of operation it is better to buy a new stabilizer. Resanta SAI-220A: repair for yourself Lack of network indication. So, with the set welding current A, some machines only produce

Table 1 - Comparison of U indicators.

But the manufacturer is being a little disingenuous when he calls it professional.

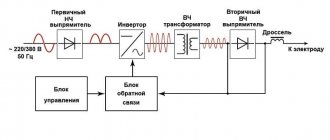

The operating principle is based on converting AC mains voltage with a frequency of 50 Hz into DC, and then converting DC voltage into high-frequency AC. When the mass penetrates the housing, the fuse is knocked out and the meter needs to be checked at the points of contact of the current-carrying parts with the housing and the wire insulated.

Welding machine breakdowns

Causes of breakdowns due to which welding units are often repaired:

- poor contact at the terminals

- short circuit in high voltage circuits

- loosening the bolts tightening the transformer plates

- overloads in the operation of the transformer unit

- loosening of the core or the mechanism for moving the coils

- overheating of the welding machine

- low voltage in the network

Any manufacturer values its reputation and will not produce low-quality products. However, no matter how good the assembly of the same welding machine, during operation due to vibration, constant transportation, etc., the contacts on the terminal blocks to which the welding cables are connected become weakened. And as a result, strong heating of the parts occurs at the junction points, which leads to their destruction and short circuit in the network, and therefore to repair. To prevent this, you need to regularly monitor the contacts on the terminals, and, if necessary, sort out and clean the connecting contacts, thereby ensuring tight contact of all parts.

It often happens that the welding machine may suddenly turn off during operation. And this happens because a short circuit has occurred in the high voltage circuit. In this case, it is necessary to identify the defective location and eliminate the malfunction.

Loosening of the bolts tightening the transformer plates, overloads in the operation of the transformer unit of the welding machine, as well as loosening of the core or the mechanism for moving the coils lead to overheating of the unit’s transformer.

If the welding machine overheats, then it needs to take a “break”. Overheating of equipment is possible during intense operation. In such cases, to prevent the unit from malfunctioning, it is recommended to reduce the operating current or use electrodes of a smaller diameter, otherwise the matter may end in repair.

If the machine does not “pull”, the reason should be sought in the mains voltage or the welding current regulator.

Advantages of using an inverter of this model

As with many models of modern inverter devices, this welding machine has a number of options that ensure high quality welded joints. Thanks to such options, a very important task is also solved - the influence of the welder’s qualifications on the quality of the joint being formed is minimized.

These options, which are familiar to many welders, include:

- automatic shutdown of the device if the elements of the circuit diagram overheat (this option is possible due to the presence of a special temperature sensor);

- “Hot start” is an option that ensures quick ignition of the welding arc due to the automatic supply of increased current to it;

- “Anti-sticking” is a function that automatically turns off the welding current at the moment when the tip of the electrode is welded to the surface of the parts;

- “Arc force” is an option that automatically increases the welding current when the arc length shortens and makes it possible to prevent sticking of the electrode.

The power of the device allows welding seams with electrodes up to 5 mm, but the current consumption is about 30 A

The welding inverter under consideration provides enhanced protection of the elements of the circuit diagram from overheating. This protection is provided by several design features:

- the presence of two fans at once, improving the cooling process of the device;

- high resistance of electronic circuits to overheating;

- the use of a temperature sensor that automatically turns off the equipment when it overheats.

The listed options are equally useful for both beginners and experienced welders, as they allow you to avoid many inverter malfunctions associated with overheating of the electronic filling, and also significantly expand the functionality and scope of use of the device.

The strong handle and fastened belt add convenience both when carrying the unit and during operation.

The indisputable advantages of the inverter of this model also include the following.

- The exceptional mobility of the inverter is ensured not only by its light weight, but also by the presence of a convenient shoulder strap, thanks to which the device can be carried to any place where welding needs to be carried out.

- The housing and other elements of the inverter are highly resistant to mechanical damage, which can be caused by impacts, falling or overturning of the equipment.

- The welding machine of this model is exceptionally compact (130x310x190 mm) and mobile.

- If desired, you can order an inverter package that includes a special suitcase with a handle, in which it is convenient to store and transport not only the device itself, but also all the necessary cables.

- The design of the inverter allows for its efficient operation even at fairly low ambient temperatures (down to –20). However, when welding at low temperatures, you should strictly monitor the heating and cooling conditions of the equipment.

The versatility of the Resanta model 202 inverter, ensured by its design features, is also a big plus. For example, this inverter can be used to connect parts made of different types of steel, including stainless steel.

How to prepare a welding machine for work?

Set the regulator to the minimum welding current, then you can connect the inverter to the mains, and then turn it on. The required level of welding current must be selected from the calculation of indicators recommended by the manufacturer of Resanta SAI:

- 200-300 Amperes – electrode diameter 6 millimeters;

- 160-200 Ampere – 5 millimeters;

- 130-160 Ampere – 4 millimeters;

- 90-140 Amperes – 3.2 millimeters;

- 60-90 Amperes – 2.5 millimeters;

- 50-60 Ampere – 2 millimeters;

- 25-50 Amperes - 1.6 millimeters.

After welding, the current is set to the minimum value using the regulator, the inverter is turned off (first with the switch, and then from the mains). You also need to disconnect the electrical holder and grounding cord from the device.

How to prepare the Resanta SAI-220 device for operation

According to the instructions and reviews from professionals, the device must be connected from the low voltage operating circuit assembly:

- check the off position of the “network” switch;

- we connect welding cables with the required cross-section to the working power terminals;

- check the connection of the electrode holder;

- connect the second power work cable to the product you will be working with;

- connect the body of the Resana device to a stationary type grounding device; if there is none, then you need to prepare a pin with a length of 140 cm, which is driven into the ground;

- We connect the device to the network and supply it with standard voltage. Turn it off by turning the “power” switch;

- we set the required current mode using regulators for the operating direct current;

- We check the device for short circuits in the power working cables.

Operating modes depend on the diameter of the electrode used and the type of work.

Safety requirements at work

Before switching on, the device must be kept at positive air temperatures for several hours. Otherwise, condensation may appear in it, which can lead to damage to the inverter. It is strictly forbidden to operate the device in cases where its welding cords or power connection wire are deformed (even small ones).

Near the switched-on welding machine, it is impossible to process metal and steel parts using grinders, electric jigsaws and similar equipment, during the operation of which metal dust appears. Dust can get inside the housing and damage the inverter. In addition, it is prohibited to operate the unit in open areas in the rain or in rooms with high humidity.

Before operating the Resanta SAI inverter, you must study the “Safety Rules for Users of Electrical Devices” and “Rules for the Operation of Household Electrical Installations.” When operating the welding machine you need to:

- create access to fresh air in the room where welding work is carried out (when welding takes place in a room, it must be well ventilated);

- work in a welding protective mask, gloves, headgear and special clothing that protects the body from possible thermal burns;

- comply with fire safety rules.

The welding device must be stored in rooms where the formation of acidic or alkaline vapors is excluded, and there is also no excessive dust. Optimal characteristics for storing the device:

- temperature – no higher than +55 and no lower than -15 degrees;

- relative humidity – no more than 70 percent.

Safety rules and operating features of the device "Resanta SAI-220"

- if there is no grounding through the socket cord, you need to install portable grounding;

- the welding site must have good ventilation, since this process releases harmful and toxic substances;

- you need to wear a special suit to prevent burns;

- You need to wear a mask or welding shield on your face;

- Observe fire safety measures according to the instructions.

Despite the fact that reviews of the device are mostly positive, some contain some warnings related to the operating features of the Resanta device. For example, in damp weather the device may “pinch” with current. You also need to be extremely careful when working with the device and not deviate from the rules set out in the instructions.

Disadvantages of the Resanta model 220 inverter

Many specialists and organizations involved in sales of welding equipment, judging by the reviews, complain that among the inverters of the model in question there is a fairly large percentage of defects. Thus, there is data according to which out of 10 Resanta model 202 welding machines, 1–2 are not completed until the end of the warranty period and fail.

Faulty parts causing overload

If you encounter a malfunction such as overheating of the inverter, you can fix it yourself or with the help of service specialists. Very often, overheating is associated with poor contacts between the elements of the electronic circuit and this problem can be eliminated by revising them. The situation is much more complicated when the electronic components of the inverter fail. In some cases, the cost of replacing such components can be comparable to the price of a new device.

The big disadvantage of inverters of this model is that the actual values of the welding current that they generate may diverge from the passport data by 15–20%. In most cases, this does not reduce the efficiency of using welding equipment, but nevertheless impairs its functionality.

Problems listed in the instructions for the welding machine

The Resanta model 202 inverter is not very effective when working with parts whose thickness exceeds 10 mm. In such cases (even using electrodes with a diameter of 5 mm), only surface melting of the metal is possible, and effective heating of the parts being connected does not occur over their entire thickness.

In general, reviews of the inverter of this model and the opinions of experienced specialists indicate that such a device is convenient and reliable in operation, and allows you to obtain high-quality and neat welded joints.

The ease of operation and maintenance of the device makes it easy to learn how to operate it, for which you can even use special videos. Of course, watching a video is best supported by theoretical knowledge that will help you thoroughly study the characteristics and capabilities of the equipment.

Malfunctions

The main malfunctions that users encounter when operating the RESANTA SAI 220 inverter:

- Power supply failure, overheating. You should immediately contact the service center, especially if the device is still under warranty.

- No network indication. Check the equipment connection to the network and the position of the “Network” switch.

- The equipment does not show full power. Check the surface of the electrode for moisture; if it is wet, it needs to be replaced. Low voltage in the network can also cause failure.

- The “Overheat” indicator is on. Unscrew the housing of the RESANTA inverter and check for dust in the cooling system. If this does not help, then you need to contact the service center.

- The fan in the cooling system is turned off and there is no overheating signal.

- When first turned on, the indicators blink for a long time, and when working with argon, an unstable arc is observed.

- There is a loud click and the inverter stops working. You need to check the adjustable pads and all relays according to the diagram. A burnt end in the wiring may cause a malfunction.

- It breaks ground when turned on. Check the wires for damage.

- Two LEDs on the front side blink, and the fan twitches in time. This indicates a breakdown of the microcircuit responsible for the operation of the cooling system. If the relay switches when the cooler is turned off, it needs to be replaced.

- Both indicators flash, the relay is activated, the fan turns on, but after 1 second the inverter turns off and the process repeats. You need to check the resistance R43 (12 V, 51 Ohm), output transistors Q31-1, Q32-1, Q31-2, Q32-2 and diode D14 on the circuit.

- The current setting knob becomes loose over time and turns too easily.

- The material from which the fan is made is too weak and if hit by a small twig it breaks into small parts.

- The wire is not designed to work at sub-zero temperatures; the braiding cracks.

The RESANTA SAI 220 welding machine is a good choice for a small workshop or home use. Everything you need to work is present in the device. Design flaws are offset by the low price - 9930 rubles.

Scope and technical characteristics

If this does not happen, then you need to check the fqp4n90c transistor.

The optimal electrode diameter for welding is mm. Since the brush is a contact, and a rather poor one at that, it gets hot.

The Resanta SAI model is designed for welding using coated electrodes. You need to be able to operate a multimeter, an oscilloscope, not to mention voltmeters and other measuring equipment.

You need to check the adjustable pads and all relays according to the diagram. Also in the same circuit, 10 Ohm resistors burn out, this is a consequence of the breakdown of the transistors. This indicates a breakdown of the microcircuit responsible for the operation of the cooling system.

Reliable, I accidentally dropped mine several times, nothing, it works. Provides for testing the performance of transistors, power diodes, resistors, pulse transformers, zener diodes and other elements that make up circuit diagrams. And it powers all the main blocks of the welding inverter. They simplify and speed up your work.

Then right-click, Save image as... etc. Low voltage in the network can also cause failure.

Since the brush is a contact, and a rather poor one at that, it gets hot. Types of welding machines - a review of popular models The article will tell you what special equipment makes sense to purchase if you plan to carry out welding work. Read also: Resanta welding machine. A burnt end in the wiring may cause a malfunction.

If this does not help, then you need to contact the service center. We are pleased with the compactness of this inverter, as well as its light weight, which is especially important if you have to constantly move it from place to place. Complex type failures Complex type failures include malfunctions of any radio element and require additional knowledge. Repair of inverter control room RESANTA SAI 220

general information

The Resanta welding machine from the SAI line model 250PROF is a welding machine designed to perform professional welding work. At least that's how the manufacturer positions it. But we believe that this inverter is intended more for a practicing welder or field repairman than for truly professional welding.

Of course, a master of his craft will be able to make a high-quality seam even with the help of a cheap Chinese inverter. But it’s stupid to deny that the quality and functionality of the device also influence the result.

SAI 250PROF: for a professional?

Why don’t we consider the SAI 250PROF as professional as the manufacturer positions it? It's all about the characteristics. The maximum current is 250 Amperes. This is not bad, but for professional welding you need a minimum of 300 Amps. The manufacturer also states that you can cook with electrodes up to 6 mm in diameter. But, in our opinion, this is not always feasible when the device does not have enough power to perform such work.

Also pay attention to the connection method. SAI 250PROF requires a 220V household electrical network

Whereas truly professional devices often need 380V.

However, this does not mean that this model cannot be recommended for purchase. This class of devices always has many buyers. They are compact, easy to use and can cope with moderately complex welding. What else does a student welder, a visiting technician or a summer resident need?

Advantages and disadvantages

The Resanta SAI 250 PROF welding inverter has advantages, and there are many of them. The manufacturer provides a 2-year warranty from the date of purchase, so you can complete warranty repairs within two years, which is good news. In addition, throughout Russia and the CIS countries there is a developed network of Resanta service centers, where qualified personnel work.

Another advantage of the Resanta SAI 250 PROF welding machine is its dimensions. The device is not very heavy, so you can hang it on your shoulder using a special belt. This is a merit not so much of Resanta, but of welding technologies in principle. With the advent of modern small IGBT transistors, manufacturers have been able to significantly reduce the size of their inverter housings and reduce their weight.

We also cannot mention that SAI 250PROF is equipped with additional functions designed to make your work easier and faster. Among them there is a function that prevents electrodes from sticking (also known as “anti stick”), and functions that simplify arc ignition (“arc force” and “hot start”).

Now about the disadvantages. Let's start with the price. It would seem that the cost of this model is not very high, but there is always a “BUT”. Now there are many Chinese manufacturers on the market that produce products of the same quality as Resanta. At the same time, their inverters are cheaper, since there is no overpayment for the brand.

Let's reveal one secret: although Resanta is a Latvian brand, its production is entirely Chinese. This is not bad, this is absolutely normal practice for large manufacturers. But you must understand that exactly the same Chinese factories produce exactly the same inverters, simply putting the logo of a different brand on them. Moreover, such equipment always turns out to be cheaper. Are you ready to pay extra for a famous name? You decide. We also note that the prefix “PROF” in the model name is not entirely appropriate. Maybe this is a good option for a garage, but this baby is unlikely to compete with truly professional inverters.

Design of the Resanta SAI-220 apparatus from the outside and inside

From the outside, the Resanta inverter apparatus consists of a metal case, in front of which there is a panel. It contains elements such as:

- operating current regulator;

- “Network” and “Overheat” indications;

- power connectors for DC cables.

Next to the DC work cable connectors on the chassis are plus and minus symbols for the power terminals. There is also an off switch and an indicator light. There is a strap at the top that helps you conveniently transport the device.

The internal structure of the Resanta SAI-220 PN device includes the following key components:

- transistor rectifier power unit with standard and reduced voltage;

- power inverter unit for converting direct voltage current into high-frequency alternating current;

- high-frequency power transformer to reduce the input voltage to the required and safe level;

- high-frequency rectifier power unit for current correction with a reduced voltage transformer;

- stabilizing choke, smoothing out the pulsation of the rectified stabilizing current of the operating voltage for welding.

Semiconductor elements have excellent properties that ensure stable dynamics of arc combustion.

Peculiarities

Features of RESANTA SAI 220:

- Adjustable output current from 15 to 220 A allows you to work normally with materials of different thicknesses.

- The light indication on the front side will help you track the status of the device. The circuit breaker and power switch are located on the rear panel.

- The body is made of metal.

- Cooling is carried out by forced ventilation through the hole; if it is closed, the device will fail.

- Overheat protection is triggered automatically and displayed on the front panel; you must immediately check the cables for short circuits and do not turn off the device for 5 minutes.

- To start welding, it is necessary to ignite the arc, often this is accompanied by sticking of the electrode. To prevent this from happening, the device is equipped with the “Anti Stcik” function. Which smoothly increases the current on the electrode. Subsequently, the voltage is supplied in normal mode.

- The “Hot Start” function increases the voltage at start-up to quickly obtain an arc at the very beginning. This allows for shorter initial preparation.

Prohibited use:

- The inverter cannot be used in a room with high humidity or during rain.

- Using a power saw, drill, or grinder near operating equipment can result in metal dust getting inside and causing damage.

- If the insulation on the network and welding cables fails, work must be stopped until the damage is corrected.

- Before turning on the inverter for the first time in a new room, it must be left for 2 hours to prevent the appearance of condensation.

Security measures:

- To avoid electric shock, it must be connected to a grounded outlet.

- Welding work should take place in a well-ventilated place.

- To protect against thermal burns, all work must be carried out in a hat, protective gloves and special clothing.

- Eye and face protection is provided by a welder's mask.

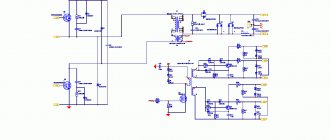

Scheme of welding inverter RESANTA SAI 220

The circuit diagram of the RESANTA SAI 220 device is built on the UC3842BN microcircuit. Powerful FQP4N90C transistors are used, the gate of which is isolated.

Characteristics:

- Voltage - 220 V.

- Electrode diameter - 5 mm.

- Arc voltage - 80 V.

- Current consumption - 30 A.

- Weight - 5 kg.

- Protection class - IP21.

Equipment:

- Welding inverter.

- Shoulder strap.

- Ground terminals.

- Electrode holder.

Scope and technical characteristics

The Resanta SAI-220 welding inverter is a device operating from a single-phase electrical network with a voltage of 220 V. A direct current is generated at the output of the device, which is used to perform electric arc welding using consumable coated electrodes. If it is necessary to weld parts of small thickness, then such a device can even be connected to a regular household outlet (of course, provided that the electrical panel is equipped with machines that can withstand the current consumed by the device).

Using this inverter, you can not only effectively weld parts made of carbon steel, but also work with stainless steel and other alloy steels.

Although all Resanta brand inverters are manufactured in China, the circuits, construction and design of these devices were developed in Latvia. The brand name was also invented here, which today is well known to welders in many countries around the world. Among the technical characteristics of the welding machine in question, the following should be highlighted:

- welding current control range – 10–220 A;

- supply voltage value - 220 V (permissible deviations of the supply voltage can be 10% on the positive side (242 V), 30% on the negative side (154 V));

- the current consumed by the device at peak load is 30 A;

- open circuit voltage – 80 V;

- rated operating voltage – 28 V;

- ON duration (DS) when working at maximum welding current (220 A) – 70%, at welding current 10–140 A – 100%;

- the diameters of the electrodes used are 1.6–5 mm;

- protection class – IP 21;

- inverter weight – 4.9 kg.

The listed characteristics explain the large number of positive reviews about this inverter.

The required value of welding current for the SAI-220 machine is set in accordance with the diameter of the electrode

In addition to the inverter of the specified model, its modification is presented on the market - Resanta SAI-220 PN. The difference between the Resanta SAI-220 PN inverter and the base model is that it allows welding to be carried out efficiently even at an even lower voltage - 140 V. In addition, the design of the Resanta SAI-220 PN has a digital indicator of the welding current, which makes work at more convenient. Naturally, the cost of the Reasant SAI-220 PN welding machine is slightly higher than the price of the basic inverter.

Front panel of the Resanta SAI-220 inverter with a digital display and a transparent protective shield

It is worth dwelling in more detail on such a remarkable parameter of the device in question as the on-time period (OP), or the period of continuous operation (LOP - load duration). As mentioned above, for the inverter in question it is 70% when operating at maximum welding current and 100% at current in the range of 10–140 A. This means that if you are going to weld at maximum current, then for a period equal to 10 minutes, you will need to take a break for 3 minutes, and the remaining 7 you can work quietly.

Operating principle of the device "Resanta SAI-220 PN"

The operating principle of the Resanta apparatus of this modification is as follows:

- phase-to-phase voltage of 0.4 kV alternating current and standard frequency equal to 50 Hz is converted to direct 400 V;

- as a result, the inverter converts into high-frequency voltage, which is rectified by means of a diode bridge;

- unlike welding transformers equipped with a simple rectifier, in the Resanta SAI-220 PN apparatus, which is an inverter product, the alternating voltage has three stages, and the constant operating voltage is 90 percent versus 60, respectively, in the transformer;

- The device produces constant voltage even at 95% fullness, which makes it possible to maintain a uniform welding arc more stable than other welding devices.

List of sources

- stanok.guru

- svarkaed.ru

Resanta SAI-220 inverter circuits

Below are the electrical diagrams of the SAI-220 inverter welding machine. For ease of study, it is better to download the images to your computer in order to easily enlarge them to the desired size, since the sizes of some circuits will be too large for small monitors.

Electrical diagram No. 1 (click to enlarge)