Types of welding inverters

Inverter-type devices are divided into three categories. Household inverters are designed for a short duration of switching on and operation from a single-phase 220 V AC network. This means that such a device can only be operated at maximum power for a short time - 20-30 minutes, giving it a rest equal to this time or exceeding it by an order of magnitude. Semi-professional devices allow you to increase operating time from 5 to 8 hours without interruption. For semi-professional inverters, rest time is reduced due to design features. Professional inverters are designed to consume 220/380 V current, often from a three-phase electrical network.

Modern types of welding machines.

Household, semi-professional and some professional welding units are designed to operate from a 220 V network. However, it should be remembered that for household electrical networks the maximum load current cannot exceed 160 A. The power consumption of all accessories, such as sockets, plugs and power circuit breakers, is not calculated to exceed this threshold.

Therefore, connecting an inverter welding machine with higher performance will either trigger the circuit breaker, or cause the contact at the plug-socket interface to burn out, or, most dangerously, lead to the electrical wiring to burn out. This is against all safety regulations. So, when powering a professional unit from a household electrical outlet to operate with a welding current of more than 160 A, be prepared for problems. But it's better not to allow this.

SELECTION OF EXTENSION CORDS

Particular attention should be paid to the use of extension cords when connecting inverters to the network. If the extension cord is incorrectly selected, the efficiency of the welding inverter decreases and the voltage drops.

The configuration of welding machines usually includes a cable about 2.5 m long. For simple work, this length is enough, but in case of frequent movement or welding at height, it will not be enough.

Therefore, it will not be superfluous to learn about connecting extension cables. Under no circumstances connect them at random! You will need to calculate the exact cross-sectional size of the extension cable.

This value is directly related to the maximum power that the wire can withstand.

Using the above diagram, let's give an example. The current we need when welding is 120A. We get 16A when using a cable with a cross section of 2.5 sq. mm.

Proportionally, for a welding current of 120A, the cross-section of the extension cable must exceed 12 sq. mm. Do not forget about safety precautions, remember about grounding and untangle the cables before starting welding, for faster cooling.

It is much more efficient to buy one cable of the required length than to connect several short ones to each other. This way, the contact connections of the extension cord will be more durable, and the possibility of losing the efficiency of the welding inverter will be reduced.

Which welding inverter is best for home use: review of models

Choosing a unit for welding on the modern market is problematic - the number of models on the market clearly exceeds demand. Experienced welders do not like various experiments and prefer to buy only work-tested specimens.

A serious manufacturer will never sacrifice its reputation and the quality of such a product will always be at its best. Therefore, when thinking about which company to choose a device with an operating current of 160 Amperes, first of all, inverter units with “authority” are considered.

Fast and Furious-161

The Ryazan Instrument Plant has developed the most compact manual welding machine in its line. Any household outlet can handle a power of 5.5 kW. The unit belongs to the “intelligent” class, it is universal and structurally thought out. Its cost is 11,900 rubles. The main parameters speak only about the advantages of the device:

- Mobility and portability, the ability to increase the standard network cable up to 50 meters.

- Low power consumption and the ability to operate from an autonomous voltage source.

- If additional equipment is available, it is possible to organize argon arc welding.

- Wide functionality and extended warranty period up to 3 years.

A real review about this household inverter will describe it better than any instruction:

“The maximum current of 160 A is set using a “twist” from the 15 A mark. This is enough to cook with electrodes with a diameter of up to 4 mm, and with any coating. I also took a TIG torch in the kit, now I can work with argon arc welding with cast iron and stainless steel.”

In terms of equipment, the unit is not the simplest - there are Arc Force, Hot Start and Antistick systems. All this allows it to function in the range from 188 to 245 Volts, and the “troika” can be cooked even at 140 Volts. Many craftsmen note a technological feature - “standby mode”, into which the device goes when the voltage is 100 V.

“The kit does not include a mask, gloves or brush. I also had to buy a cable separately. In principle, these problems are not so serious if you consider its functionality. Another feature is that the device can operate from a generator with a power of 9 kW or more.”

ARC 160 PFC

The unit for arc welding from in some tests tops the rating of welding inverters, it must be said that it is not in vain - it is capable of working with electrodes up to 4 mm. Tig welding and TIG welding are available as an option. The last mode is ignited by touch. A potential buyer may be confused by the cost of the structure - 20,750 rubles, but Alexander Sh. claims that it is worth it:

How to choose a normal car inverter and not miss the mark

There are frankly cheap, low-quality inverters that should be avoided. As for the rest, the correct choice of such a device will be different for everyone.

The inverter is selected for the specific devices that will be connected to it, and here are 6 points that need to be taken into account.

1) Check the power of the car's generator. There is a golden rule: the inverter power cannot be more than 50% of the generator power.

Only in this case, when your car is started, the inverter will not discharge the battery - at least with devices connected to it. About one half of its power will go to the needs of car systems, so you have the second left.

If you don’t follow this rule, you risk ending up somewhere in the forest with a dead battery. Doesn't sound too rosy, does it?

Look, a 750W converter operates at 13V - that's 58A. The VAZ 10 will not produce such current at idle speed, so the inverter will eat up the battery charge and will let you down at the most inopportune moment.

The maximum generator of this car can produce 80A, but this can only be achieved at 5000 engine rpm.

2) Define devices for it. It is advisable to carefully study the devices that you will connect to the inverter: how much power they need at startup, in normal mode and at peak.

Also keep in mind that the voltage depends on the power of the inverter, and only the most powerful ones can produce 220V more or less stably.

Xiaomi Mi Car Inverter Mijia from the inside

3) Understand its usage pattern. The cigarette lighter in a car usually produces no more than 100W, so when buying an inverter that will be connected to it, pay attention to this.

If you need something more powerful, think about what and how it will be connected, where the outlet should be: inside the cabin or not - all this will greatly influence your choice.

Xiaomi Mijia SMARTMI

4) Pay attention to his brand. A normal inverter is equipped with protection against short circuits and overheating, but a Chinese one of unknown origin is not.

It’s best to look for a suitable model in large chain stores; they definitely won’t sell you something outright wild there.

If you love AliExpress, be sure to pay attention to Xiaomi inverters:

- Xiaomi Mi Car Inverter Mijia (RUB 3,550) - inverter for cup holder

- Xiaomi Mijia SMARTMI (RUB 3,350) - traditional inverter

Both inverters are 100W - they connect to the cigarette lighter specifically for mobile gadgets.

Xiaomi Mi Car Inverter Mijia

5) Check the type of inverter socket. Look, for example, in Xiaomi Mi Car Inverter Mijia for the cup holder is not our socket, so you will need an adapter.

But Xiaomi Mijia SMARTMI has a universal input for any plug, but a completely different form factor. Choose what is closest to your liking if you are considering Xiaomi.

6) Check out the extras. inverter features. Expensive inverters offer a lot of auxiliary features: information screens, voltage changes and USB. If it's not necessary, don't overpay.

I like USB cigarette lighter inverters. On the one hand, you get a full-fledged outlet, on the other hand, you do not lose the interface for charging your iPhone.

Connecting the welding machine

If the problem of how to buy wires for welding has been solved, you can begin installation work.

A welding device is a device that makes it possible to convert current into voltage necessary for the device to produce a welding arc between the metal being welded and the electrode.

Connecting a two-phase device is carried out as follows: first you should connect the welding wires - the first to phase, the second to neutral, and the third to zero.

Connecting three-phase welding equipment occurs by connecting the first two wires to any two phases, and the third wire to the neutral conductor.

More on this topic on our website:

- TIG welding - buy and use for a beginner The use of aluminum in human life is very wide: it is used for the construction of aircraft and ships, cutlery and cooking devices. There is no way around this when designing these devices.

Which welding cable to buy - price and cable cross-section The welding cable is a very flexible conductor for current. Usually this is a cord woven from several copper wires (diameter ranges from 0.18 to 0.2 mm). Basics.

Chameleon welding mask - which one is better to choose for home welding When a welder, in addition to special protective clothing and shoes, has a reliable mask with an automatically darkening light filter, the welding process becomes safer and more productive. The lower.

Proper Welding Machine Holder and Magnetic Welding Holders As the welding industry has evolved, not only the basic welding tools have been modified, but also auxiliary tools have begun to appear. One of these devices was the welding holder.

Cellulose coating

The “cellulose type” electrode shell for inverter welding consists of the following components:

- organizational components that protect against gas;

- aluminosilicates, marble chips, salts and esters of carbonic acid - create slag protection during welding;

- ferroalloys, metal powders - alloy metal seams.

The “cellulose” rod is used for manual welding in any position. It prevents the penetration of oxygen and hydrogen into the metal being processed, ensures deep welding of seams, and forms a small amount of slag.

The “cellulose” consumable is very thin – it is convenient to use in hard-to-reach places. Due to the ease of insertion of the seam, it provides good working speed (up to 28 m/h).

But cellulose electrodes also have disadvantages:

- formation of coarse scaly seams;

- powerful metal spatter during welding;

- sensitivity to overheating during calcination.

Organic compounds in the electrode release hydrogen when burned, causing cracks to appear during contact with the metal.

Popular brands with cellulose coating: TsTs-1, VSTs-60.

Unit connection sequence

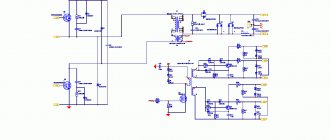

The general connection diagram is performed in the following sequence:

- Carry out the necessary calculations and make sure that connecting the equipment for welding to the building network is acceptable.

- Check the machines and the condition of traffic jams, make sure there are no bugs.

- Set the operating voltage required for specific work depending on the complexity, volume and type of metal. The setting adjusts the position of the transformer core.

- Turn the device switch to the 220 V or 380 V position.

- If it is possible to connect to 220 V, insert the plug into the socket.

- To connect the welding machine to a 380V network, two supply ends are supplied to the “phase”, the third – to the “zero”. It is recommended to use an industrial socket and appropriate plug.

Pages

Questions can only be asked after registration. Please login or register.

I bought a welding inverter Resanta 220a. Which machine needs to be connected to the network? The instructions say for 220A the current consumption is 24A. on the plug it says 16A. So if the machine is needed for 24A, the plug of the device will burn out if it is designed for 16A. what do they write there? or am I missing something?

I will use a triple electrode.

I bought a welding inverter Resanta 220a. Which machine needs to be connected to the network? The instructions say for 220A the current consumption is 24A. on the plug it says 16A. So if the machine is needed for 24A, the plug of the device will burn out if it is designed for 16A. what do they write there? or am I missing something?

set it to 16 ampere, you won’t have to cook the current for a long time, it will be better to knock out 25 less.

The deeper the rut, the greater the chance that you are on the highway.

I bought a welding inverter Resanta 220a. Which machine needs to be connected to the network? The instructions say for 220A the current consumption is 24A. on the plug it says 16A. So if the machine is needed for 24A, the plug of the device will burn out if it is designed for 16A. what do they write there? or am I missing something?

set it to 16 ampere, you won’t have to cook the current for a long time, it will be better to knock out 25 less.

Fine. I'll put it at 25. thank you.

Set the machine to 32A minimum, otherwise it will keep cutting out and the contacts at the machine will quickly burn out. Another question is with the network. https://www.asberg.ru/shop/avtomaticheskie_vyklyuchateli/avtomaticheskie. At 7 kW, the minimum wiring required is 4 mm square copper. And then it will warm up. If the network pulls, you need 16 Ampere ceramic spring-loaded sockets. And cook with a thin 3mm electrode and with long breaks. Cook for 1 minute, wait 15..30 minutes for the wiring/connections to cool down. It is better to cut off the plug of the device and connect it to the network via a bus, with screw terminals. 16 Amp plug/socket = 16*220=3520 W.

Set the machine to 32A minimum, otherwise it will keep cutting out and the contacts at the machine will quickly burn out. Another question is with the network. https://www.asberg.ru/shop/avtomaticheskie_vyklyuchateli/avtomaticheskie. At 7 kW, the minimum wiring required is 4 mm square copper. And then it will warm up. If the network pulls, you need 16 Ampere ceramic spring-loaded sockets. And cook with a thin 3mm electrode and with long breaks. Cook for 1 minute, wait 15..30 minutes for the wiring/connections to cool down. It is better to cut off the plug of the device and connect it to the network via a bus, with screw terminals. 16 Amp plug/socket = 16*220=3520 W.

Will the warranty still work if I cut off the plug? The cable going to the meter is 16 gauge, from the meter I’ll install it at 10. I have a copper one, I used it on a three-phase network, I connected it to a circular one.

There is a plug with a socket for a 25A electric stove. I'm thinking of installing them.

What are you planning to connect - a spaceship or a dead inverter? Some kind of nonsense - cut off the forks and so on. What kind of high-voltage cord is there? If I'm not mistaken, the maximum is 2.5 mm. sq. Is there a circuit breaker (fuse) on the inverter? How many amps? So do the wiring of 4 squares, the machine of the next rating from the inverter (let’s say it’s 25 on the inverter, so set it to 32). I have a 500A welder connected via a 6 mm cable. kv., automatic 32A. Nothing gets hot or knocks out, even when I cook all day with a 5 mm electrode.

What are you planning to connect - a spaceship or a dead inverter? Some kind of nonsense - cut off the forks and so on. What kind of high-voltage cord is there? If I'm not mistaken, the maximum is 2.5 mm. sq. Is there a circuit breaker (fuse) on the inverter? How many amps? So do the wiring of 4 squares, the machine of the next rating from the inverter (let’s say it’s 25 on the inverter, so set it to 32). I have a 500A welder connected via a 6 mm cable. kv., automatic 32A. Nothing gets hot or knocks out, even when I cook all day with a 5 mm electrode.

The original cable says 1.8 section. The plug says 16a. the book says if you set the welding current to 160A, the current consumption will be 20A; I weld with a triple electrode, so I’ll set the current to 140A; if I have to cut, I’ll set it to 160A, which means a 25-amp machine will be enough for me. I’m not going to cook with 5. I just bought 220 with the expectation of a safety margin. Do I get it right?