Very often, farmers are faced with a problem when they need to buy a loader, but the purchase can cost quite a large sum. If you have enough tools on your farm, as well as quite a lot of metal, you can make your own loader for the rear linkage of the tractor.

Homemade loader for the rear linkage of the MTZ tractor: materials, tools, instructions, drawings

Very often, farmers are faced with a problem when they need to buy a loader, but the purchase can cost quite a large sum. If you have enough tools on your farm, as well as quite a lot of metal, you can make your own loader for the rear linkage of the tractor.

As an example, you can take the MTZ tractor, since it is one of the most common equipment on the farm, and also has its own hydraulic system and the ability to install attachments at the rear.

Also, although a front loader can carry significantly larger loads than a rear loader, it is much more difficult to mount. For this reason, we will consider a mounted loader on the rear canopy of a tractor.

So, what are the advantages of a homemade forklift:

- If the farm has the necessary tool or was planning to buy it, and also has the necessary metal that is simply lying idle, then you can save a lot of money;

- You can choose the length and unloading height of the future product yourself.

Disadvantages or what problems may arise:

- If you still don’t have tools and metal, then it would be more advisable to purchase a new or used loader, since independent production may not only be comparable in cost, but also significantly exceed it;

- Such a loader will be weaker than the factory ones;

There is a possibility that the tractor will rear up when the rear part is overloaded, so you need to correctly calculate the boom reach or add additional weight to the front part.

Necessary materials

You will need a small amount of tools and materials for a homemade loader on the MTZ rear linkage, but the main factor is the ability to handle all the necessary tools.

Tools:

- The main tool will be a welding machine. It is very important to be able to use it, since the strength, reliability and durability of the entire structure, as well as the safety of the tractor driver, will depend on this.

- You need a precision tool to cut metal. In this case, a grinder, a gas cutter, and the like are suitable. The main thing is that the cut is accurate and even.

- Next, you just need a variety of tools that are usually available on all farms: these are adjustable wrenches, a sledgehammer, hammers, and the like.

Details:

- It is necessary to purchase or remove 3 hydraulic cylinders from unused equipment: one large one, which will raise the boom with the bucket, and two small ones to change the angle of inclination of the bucket itself. The power of the cylinders is selected depending on the length of the boom and what weight needs to be worked with.

- It is necessary to obtain metal profiles and plates, of which the further structure will consist. Their thickness is also selected to suit the tasks assigned to the loader.

- Cylindrical hinge joints are needed, but their selection should be done only after drawing up a drawing of the entire structure. This is necessary not only in order to obtain the required quantity, but also to know the load that they must cope with in the future.

- First, you need to prepare a drawing of the entire structure, and only then cutting the metal, welding and assembly. This is necessary not only in order to use the material as efficiently and economically as possible, but also to better understand the future design and achieve maximum strength. About the design below.

Step-by-step instruction

If you follow the instructions, you won’t have any problems creating your own loader for the MTZ attachment:

- First you need to make the frame of the base of a homemade loader for a tractor. It is a rectangle, the lower part of which extends beyond the edges, since it must be installed on the rear canopy of the tractor. In the center of this frame there is also a rectangular frame, which is made of two plates and welded to the upper and lower edges. A large hydraulic cylinder will be attached to this frame at the bottom, and at the top there will be a strut that is attached to the back and holds the entire frame in place. There should be four hinge joints on the top face: two in the center for the upper cylinders and two outer ones for the boom. The height of the base is determined according to needs.

- The boom is a prefabricated structure. From the side attached to the base, this is the main and longest part, which represents approximately 70% of the total length. An extension is attached to it at an angle of 30 degrees, which should look up. Thus, a shape similar to a boomerang is obtained. You should get two curved profiles, which are connected to each other in three places - at the ends and in the center. Also closer to the central part, but from the side of the base (approximately 25% of the total length), a frame is welded to which the second end of the main cylinder is attached.

- The central part of the boom is made in the form of a hinged cylindrical joint, since the bucket control lever is attached to it. It consists of two elbows (40 degree bend), to which two small cylinders are attached on one side, and on the other side a crossbar for further connection directly to the bucket. All the described parts are connected on hinges, and the two elbows have one common one.

- Now it's just a matter of the bucket. You can either purchase it or make it yourself according to ready-made drawings. You can also use a forklift for pallets or bales instead of a bucket.

- If the boom has a reach of more than two meters, it may be necessary to additionally weight the front part. To do this, you will need to weld a basket for sand, concrete blocks or metal weights onto the frame.

Drawing of a homemade forklift lift frame

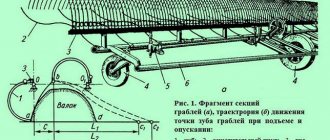

1 – stand; 2 – boom lift hydraulic cylinder; 3 – support; 4 – lifting frame; 5 – hydraulic cylinder for tipping the bucket; 6 – ladle; 7, 11 – traction; 8, 10 – bracket; 9 – pointer; 12 and 13 – high pressure hoses; 14 – bracket; 15, 17 – lever; 16 – clamp; 18 – sidewall.

It is very important to make the central part immediately assembled with the hinge joint, since it will not be possible to put it on later.

Drawing of a rack for fixing attachments

1 – sidewall; 2, 3, 4 – bracket; 5 – catcher; 6, 10 – lever; 7 – clamp; 8 – rod; 9 – spring; 11 – latch; 12 – axis.

The video shows a homemade loader on a tractor in action:

Source: https://allspectech.com/stroitelnaya/pogruzchiki-dly-stroitelstva/frontalnye/samodelnyj-na-navesku-traktora-mtz.html

Device for row-spacing processing

The most common household equipment is the row ripper.

The relevance of using such a product is due to the need to process narrow areas. This, in turn, requires such a cultivator to be compact, simple and easy to use.

The “Hedgehog” model copes well with the cultivation of such plots.

To make such a device yourself, you must adhere to the following sequence of actions:

- Buy a cutting.

- Mount the bracket in the shape of the letter U with holes at the ends.

- Prepare the wheels and shaft.

In this case, the rotating elements can be made with your own hands. Old steel pancakes of small dimensions with welded metal pins are perfect for such products. The last parts can be made from reinforcement with a cross section of 8-10 mm. When installing such spikes, it is necessary to give them a cone shape.

Prepared cutting elements - cutters are mounted on the axis. In this case, the fixation of such a structure is carried out by means of a bolted connection through prepared eyes.

At the moment, the use of special miniature devices is a fairly common activity in suburban areas.

We invite you to watch a video about a homemade cultivator on the MTZ 80 designed for hilling:

Do-it-yourself MTZ rear-mounted loader – Special equipment

Mounted loaders are multifunctional devices used for mechanized movement and transportation of piece and bulk cargo, as well as the development and transfer of soils of the first and second categories.

Loading devices produced in various modifications are used in agricultural production, industry, road, industrial and housing construction, municipal and forestry.

Loader Metal Fakh on the front linkage of the MTZ tractor

Inferior to specialized excavator and loading complexes in terms of productivity, mounted loading devices are significantly superior to them in terms of seasonal loading and functionality.

Classification of mounted loaders

Types of loaders based on MTZ

Depending on the type of working parts and the specifics of the operations performed, loaders are divided into:

- Bucket loading devices equipped with a bucket articulated with a boom, used for developing and moving soil and loading operations with bulk cargo.

- Tractor quick-release hydraulic front loaders with a two-level hydraulic frame of the KUHN lifting device. KUN is one of the most common types of mounted tractor loading equipment, which received its common name from the successful model of the universal hay hauler, which is aggregated with BELARUS tractor equipment. Equipped with various replaceable working elements, KUNs, which differ from other types of loaders in the speed of changing working elements and dismantling the entire mechanism, are used for developing and moving soil, operations with agricultural products - straw rolls and ricks, haylage, silage, manure, fertilizers, and performing warehouse work with packed and unpacked cargo, snow removal, etc.

- Equipped with lifting forks that carry out picking up, transporting and unloading piece goods - forklifts.

- Jaw loaders with working bodies in the form of massive metal jaws that close when gripping are used to move long loads in logging and when performing warehouse operations with bulk substances.

- Equipped with a grabber mounted on a lifting frame, consisting of a rake and cap grating, for picking up and placing hay.

- Rake grids designed for the selection and transportation of light haylage, which are loaders with working elements made of long fingers. Unlike drag rakes, rake grates select light haylage, lifting it up and moving it in front of you.

- Hydraulic manipulator loaders are designed for lifting and moving solid and packaged cargo in warehouse and field conditions, using a two-part crane device with rigging that rotates around its axis as a working mechanism.

Among the mounted loading devices, telescopic loaders equipped with a telescopic load boom with variable reach are also distinguished. Models of such loading mechanisms, with dimensions comparable to other types of loading equipment, have a large coverage area.

According to the type of drive of the working elements, loading mechanisms are divided into electromechanical devices that use the booms of the working element, mechanical loading units and hydraulic loaders equipped with hydraulic cylinders.

Using tractor attachments to install loading equipment

Depending on the specific conditions of work, loading mechanisms aggregated with tractor equipment can be installed on both the front and rear linkages of base machines.

Thus, hydraulic manipulators are often installed on the rear linkage along with the trailed or semi-trailer transport platforms they serve, and haystacks, rake bars and bucket loading mechanisms are installed on the front linkage.

The choice of installation option also depends on the technical capabilities and operational characteristics of the base tractor and their compliance with the parameters of the loading mechanisms.

Design and principle of operation of mounted loading bucket and fork devices and KUNS

The main structural elements of mounted loaders are:

- Sliding lifting mechanism with a carriage (forklifts) or a working boom with universal or special mechanisms for fastening working parts (bucket loading devices);

- Working elements - pick-up fork, articulated buckets of various types, jaw grips, rake grids, soil and snow dumps, rigging equipment, etc.

A special feature of the KUN design is the ability to quickly install and dismantle loaders of this type and their replaceable working parts without the use of additional equipment.

Source: https://spectehnica-mo.com/pogruzchik-na-zadnyuyu-navesku-mtz-svoimi-rukami/

Kun on MTZ (tractor hitch)

KUN at MTZ is a front-mounted attachment that is driven by the tractor’s hydraulic system and allows you to perform a wide range of earthmoving work.

A mini tractor with a KUN (front-end loader, an abbreviation for “universal mounted hay hauler”) is an indispensable assistant in country construction, repairs, and agriculture.

Features of the device and purpose of KUN 10

The MTZ KUN 10 front loader (the most popular model) is produced at Salskselmash, one of the first Russian factories specializing in the production of special equipment.

This enterprise was founded on the basis of the Gigant state farm in 1934 and is still successfully operating today. The agricultural direction in production became the main one in the 60s of the last century, and the first KUN 10 appeared in 1973.

Since then, the model has been repeatedly improved - today it is a functional universal-type mounted boom.

Despite the fact that the KUN was originally intended for the MTZ tractor (in particular, for the MTZ 80 and MTZ 82), the design allows it to also be used to complete tractors of other models, for example, as a KUN for the T-40 tractor and some modifications of YuMZ and LTZ .

The MTZ 80 tractor with KUN, as well as its more modern modification MTZ 82 with KUN, have the following advantages:

- versatility - machines can perform the function of a loader, excavator, leveler or bulldozer, thanks to which this compact equipment can be used in construction, agriculture, and landscaping;

- high performance;

- reliability.

KUHN at MTZ

The front-mounted KUHN for tractors has been successfully used for more than 50 years and has proven itself to be undemanding in maintenance and easy to operate. KUN for MTZ 82/80 tractors can be included in the machine package or purchased separately.

Design

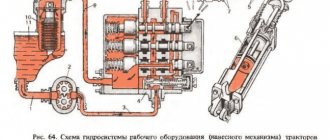

The KUN for a mini tractor is made in the format of a boom, which is controlled using 4 hydraulic mechanisms - 2 of them are involved in the process of lifting the load and 2 regulate the angle of inclination of the bucket.

A chassis system is used as a drive, which also serves as a connector for aggregating the KUN to the main machine.

The control panel for the loader's operating parameters is located in the driver's cab and is simple.

The manufacturer also offers a wide selection of additional replaceable equipment that can be equipped with the MTZ 82 tractor with kun:

- buckets with a volume of 0.35 to 1.5 cubic meters. m.;

- forklift equipment for agricultural and loading operations;

- rake grids for working with mown grass, hay, straw;

- grip for breve, thanks to which KUNs for MTZ 82 are also applicable in logging;

- grips for working with bales and rolls;

- jaw dump.

The universal KUN for a mini tractor, in particular the most popular modification KUN-10, has the following basic characteristics:

Attaching the bucket to the KUN at MTZ

- the load capacity of the rake grid and other aggregated working parts is 500 and 800 kgf, respectively;

- the loading height when using a bucket and rake grid is 2.5 m 3.5 m, respectively;

- The unloading angle of the bucket varies in the range of 55-65 degrees.

The dimensions and performance indicators of the KUN are determined by the parameters of the chassis, which is used to attach the unit directly to the self-propelled unit.

Homemade KUN for MTZ

The cost of the equipment, including compact models with lower productivity, is high, however, the KUN for the rear linkage of the MTZ or Uralets tractor can be made independently from available materials.

Tractors of this brand are equipped with a hydraulic system that allows the KUN to be mounted on the MTZ rear suspension - this is convenient, and the installation of such a loader is simpler than its front-end counterpart.

The advantage is the ability to select the optimal boom length and material unloading height.

It should be noted that making a forklift yourself is justified if you have a sufficient amount of metal; sometimes buying a used product is more profitable.

In the process, you will need a welding machine, a tool for cutting metal, a hammer, a sledgehammer and a set of adjustable wrenches. Experience with a welding machine is desirable - the quality and reliability of welding, which affects the performance characteristics of the future loader, may depend on this.

Structural elements:

- profiles and sheet metal, the thickness of which corresponds to the planned load on the unit;

- hydraulic cylinders - one larger to create a lifting mechanism and two smaller ones to adjust the bucket tilt parameters;

- cylindrical hinges for assembling the structure.

Homemade KUN at MTZ

Drawings of KUN loaders for MTZ 80 and 82 of various capacities are presented on the Internet - we recommend that you carefully read them in order to cut metal with minimal waste.

The frame of the future loader consists of 2 rectangular frames. External and, accordingly, larger in size, it is aggregated to the rear canopy of the tractor. The internal one consists of sheet metal. A large hydraulic cylinder is fixed in its lower part, and a spacer is welded to the upper part, which acts as a stiffener.

The boom structure is prefabricated. The main part of the structure makes up 70% of the length of the product, is placed as close as possible to the frame and is aggregated with the cylinder.

The middle part of the structure is attached to this fragment of the product using hinges, and the bucket is attached to it.

An important parameter is the boom radius - if it is more than 2 m, the front semi-frame must be equipped with a counterweight.

The bucket can be purchased or made from sheet metal. the final design looks like a boomerang with three attachment points - central and one at each end. Installation of KUN on a tractor can be done independently. Before testing the device, be sure to check the reliability of the connections and fastenings.

Source: https://moezerno.ru/texnika/loaders/kun-na-mtz.html

How to choose

When choosing equipment that is necessary for loading operations, it makes sense to compare the characteristics of construction machines of the same type: DT-75 and MTZ.

For DT-75

This machine can have several sets of attachments: for agricultural work, for general construction work, and drilling. A front-end loader on the DT-75 can be installed thanks to the installation of side-mounted semi-mounted equipment.

The updated modification of the DT, the engine for which is now produced in the city of Vladimir, has a new, more ergonomic cabin.

Loader specifications vary by model. PG 2 has a bucket with a capacity of 1.5 m³, the unloading height reaches 2.7 m with an angle of 50°. The width of the bucket edge (grip) is 2028 mm.

The PFP 1.2 front-end loader has a narrower specialization. It is designed for loading bulk materials and fertilizers. Its parameters:

- bucket capacity 0.9 m³;

- unloading height 2.5 m;

- working width 2035 mm.

In addition, combined and homemade loaders are used.

For MTZ

A loader based on the MTZ produced by the Minsk Tractor Plant is obtained by installing mounted units on the tractor. Its basis is a wide bucket with a grab for bulk materials. In the standard version (for example, the MTZ-1221 front loader) consists of:

- a controlled frame with a hydraulic system is the main part of the structure;

- chassis;

- nozzles

The MTZ-82, which has a kun as additional equipment, has also proven itself well. This is a swept unit controlled by four hydraulic drives. Two of them work in the horizontal plane, and two more regulate the movement of the bucket.

Do-it-yourself loader for the rear linkage of a tractor

For many owners of private farms (personal subsidiary plots), a loader on the rear linkage of a tractor is very, very interesting.

Why? Because purchasing a highly specialized unit (loader) is too expensive, and a thrifty owner is unlikely to spend a lot of money on it.

It is much easier to modernize an existing tractor on the farm.

What is needed for this? First, metal (you will need a lot of it). Secondly, a special tool. Thirdly, straight arms.

Best base

As practice shows, a homemade loader on the rear linkage of a tractor works best on the equipment of the Belarusian MTZ. In addition, it is very common in Russia. Before starting work, you need to familiarize yourself with the pros and cons of the solution in question.

Let's start with the first ones. The undeniable advantages of the created attachments are:

- the ability to select the length and height of unloading as needed in specific conditions;

- savings - just look at the current prices for loaders to appreciate its scale.

The second - disadvantages - include:

- less power compared to factory loading and unloading equipment;

- the need to have a special tool, as well as a large amount of metal.

By the way, in the absence of the latter, experts recommend abandoning the idea of creating a loader yourself and purchasing an inexpensive used model. It's both faster and cheaper.

What will you need?

So, you finally decided to make a loader for the rear linkage of the tractor with your own hands. Here's a list of the tools you'll need:

- equipment for cutting metal - cutter (gas) or grinder (angle grinder);

- adjustable wrench, hammer, sledgehammer, etc.;

- welding machine.

The welding unit must be working properly. The fact is that the main characteristics of the future loader depend on the quality of its work: durability, strength, reliability.

If we talk about materials, you will need the following:

- plates and profiles (in both cases metal) are the basis for the future design. The thickness of the elements should be selected in accordance with the tasks that will be performed;

- hydraulic cylinders - at least three pieces: two small and one large. The first will be responsible for changes in the angle of inclination of the bucket, the second - for lifting;

- cylindrical type hinge joints.

At the preparation stage, it is also necessary to develop a drawing of a loader for the rear linkage of the tractor. Of course, the task is not easy. However, below you will find all the necessary materials.

Step-by-step instructions for creating a loader

Step one is making the frame. It will have the shape of a rectangle, and the lower part (which will be aggregated with the rear canopy) should extend beyond the edges. In the center of the frame there will be another frame (the same shape). It consists of two plates.

A cylinder and a spacer are subsequently attached to it - at the bottom and at the top, respectively. There should be 4 joints (hinges) on the top edge: 2 outer ones for the boom, 2 central ones for the cylinders.

The height of the boom should be chosen based on your own preferences.

The frame shown in the figure includes:

- Rack.

- The lifting cylinder is hydraulic.

- Support.

- Lift frame.

- Tilting cylinder.

- Working body (bucket).

- Traction.

- Bracket.

- Pointer.

- Bracket.

- Traction.

- RVD.

- Same as 12.

- Bracket.

- Lever arm.

- Latch.

- Lever arm.

- Sidewall.

Now about the arrow. It is a prefabricated structure. Its central part should be a hinged joint (cylindrical).

It is to this that the lever will be attached, through which you can control the working body. These are two elbows to which a crossbar and a pair of small cylinders are attached.

In general, an arrow is two curved profiles, connected in three places at once: in the center and at one and the other end.

A finished boom length of 2,000 mm or more is a good reason to equip a counterweight. It is placed in the front part of the tractor, welding a basket onto the frame, in which, if necessary, blocks (concrete), metal weights or sandbags are placed.

If you have extensive experience working with metal, you can make a ladle yourself. Otherwise, you will need to buy a ready-made one. If you occasionally have to work with bales or pallets on your farm, consider making a forklift at the same time.

by HyperComments

Source: https://vsepogruzchiki.ru/frontalnie/pogruzchik-na-zadnyuyu-navesku-traktora.php

Universal mounted bucket

A homemade KUHN for a mini tractor is one of the types of front loaders. It is indispensable when you need to transport or load large volumes of bulk (and other) materials, such as sand, crushed stone or grain.

The mini tractor itself differs in size from a full-fledged tractor. Using a bucket allows you to turn a simple tractor into a universal vehicle for a wide variety of types of work.

Front loaders have a number of advantages:

- easy maintenance;

- reliability;

- ease of installation and dismantling of equipment;

- serious load capacity for a small-sized tractor;

- ease of control due to enhanced hydraulics.

Making a ladle

You can buy a bucket for a mini tractor at any hardware store, but this is not the cheapest pleasure, so it’s easier to make it yourself. You don't need any special knowledge or materials here. To work, you need to stock up on drawings, a grinder, a welding machine and the material itself.

Advice! A metal sheet with a thickness of 6 mm or more and pipes of various diameters are best suited for these purposes.

- First you need to make the fasteners. It is welded to the box and engine, and a metal corner is welded underneath for reinforcement.

- The KUN itself is made from pieces of sheet metal. There is no point in bending the sheet to fit the shape of the ladle. It is much easier to cut rectangles of the required size and weld them together to form a ladle. The durability of the product depends on the quality of the seams. It is better to use pipes with a diameter of 100 mm for racks, and 50 mm for rods.

- The next stage is the installation of the hydraulic booster. For greater mobility, it is recommended to use a pipe with a diameter of 30 mm (it should not be more than 50 mm, otherwise the pipes will not move well inside each other).

- Now the support is welded to the front of the tractor and combined with the racks; gussets are used for reinforcement.

- A cylinder is used to control the rotation of the bucket. It is usually installed to the right of the bucket.

Safety precautions when working with a bucket

Making a bucket for a mini tractor is not very difficult, the main thing is to have knowledge and experience in working with welding, and be able to work with drawings. In order for the attachments to work correctly, you need to approach the work responsibly and do everything strictly according to plan, otherwise the result may not meet expectations, and the mini tractor itself with KUN will pose a danger to the operator.

Advice! If you have doubts about the success of the event, you should refrain from making the KUN yourself and purchase it in the store.

To ensure safety during operation, you should follow the operating rules:

- KUN can be used only for its intended purpose;

- When working, you should carefully monitor the bucket;

- When driving with a loaded bucket, you need to keep it lowered, that is, near the ground.

Coon for the rear linkage of the MTZ tractor

What is a KUN on a MTZ tractor? This is one of the types of attachments that is widely used on the MTZ tractor and not only. This device, due to the hydraulic system, allows you to perform various works. The decoding of KUN is as follows - “universal mounted hay hauler”.

One of the most popular models of this equipment is considered to be KUN 10. The model is manufactured at the facilities of Salskselmash, an advanced Russian plant specializing in attachments.

The first model KUHN 10 came off the assembly line in 1973. As a result of constant improvement, KUN 10 has significantly increased its functionality.

For reference: the versatility of the model allows it to be used on T-40, LTZ and YuMZ tractors.

Advantages of KUHN

The MTZ 80 tractor equipped with KUN is characterized as:

- Universal - can perform partial work instead of a bulldozer, loader and even an excavator. In view of this, KUN is used during construction and installation work in the agricultural industry.

- Productive.

- Reliable unit.

Homemade rear KUN at MTZ

The cost of factory KUN for a tractor is not affordable for everyone. Therefore, it makes sense to cover the topic of making a homemade KUN.

Thanks to the hydraulic system, you can install a homemade KUN on the MTZ tractor, and you will not need many materials and tools.

The human factor plays a big role, because not everyone knows how to handle a tool. The main equipment for the technological process is a welding machine.

Experience with this equipment is important, because high-quality seams affect the strength and reliability of a homemade kun.

You will also need a metal cutting tool. As a rule, a grinder or even a gas cutter is used. Well, the standard ones will come to the rescue: a hammer, a set of keys, sledgehammers.

About the nuances

- Three hydraulic cylinders are required. Two of which will serve to rotate the bucket. The task of the third (largest) cylinder is to lift the bucket along with the boom. How to choose the power of hydraulic cylinders? — the selection of power depends on the weight of the loads and the length of the boom.

- You need to take care in advance of the metal elements that will represent the basis of the entire structure - these are trusses, corners, plates. The thickness of the listed elements directly depends on the future perceived load.

- As soon as the drawing of the homemade KUHN is ready, you need to purchase hinged cylindrical joints.

- The first step is a drawing, then a search for equipment and parts, tools. Thus, you can save money if you have information in advance about the required amount of materials.

Manufacturing instructions

- Initially, you should weld the frame of the future homemade KUN. The frame is a rectangle, the lower part of which is below the level of the edges. Installation on the MTZ tractor is carried out by the lower part of the frame.

In the center of the KUHN structure there is also another rectangular frame, it consists of two plates. Its fastening is carried out by welding to the lower and upper edges. This frame is designed to hold a large cylinder (at the bottom). A spacer will be permanently attached to the top.Four hinges are installed on the top edge. For cylinders changing the angle, two central hinges are installed. The outer two hinges serve for the boom. The selection of the height of the base depends on the needs, in each case individually.

- The arrow consists of several components.

The part of the arrow that is attached to the base is about 65% of the length of the entire arrow. The next part of the arrow is attached to the long part, the angle between them is 30 degrees. People call an arrow of this shape a “boomerang”. The result is two curved profiles with three connection points.Down the center and at each end. Another end of the main cylinder enters the frame, which is secured to the central part by welding seams.

- The central part is a hinged cylindrical joint.

Why articulated? – is explained by the need to attach a lever to it, which controls the bucket. The lever consists of two elbows; on one side it is connected to a bucket, and on the other side to two small cylinders. The fasteners of the previously listed parts are mounted on hinges.You need to know: experienced mechanics advise performing the central part together with the hinge joint. Otherwise it will be difficult to put it on.

- Let's move on to the bucket.

The ladle can be welded or bought from a factory, which is optional. It is not uncommon to see a forklift instead of a bucket used to pick up bales. - Is it necessary to weight the front part if the stem length is more than 2 meters? - Yes need. In this case, a box or basket is welded onto the frame, where concrete blocks are stacked and sand is poured.

The choice is yours: buy a factory-made KUN or start developing homemade equipment. The final choice depends on financial capabilities and, of course, desire. It is also proven here that it is quite possible to make and install KUN at MTZ. Good luck to you.

Source: https://traktorspec.ru/oborudovanie/kun-na-zadnyuyu-navesku-traktora-mtz.html

Difference in attachments

If the PKU - 0.8 is attached directly to the tractor frame, naturally disrupting the uniformity of the load during operation and putting pressure on the frame with the entire loaded mass, which leads to premature breakdowns when working with heavy loads, then the PF - 1 is equipped with its own frame, attached under the tractor to the rear axle , which evenly distributes the entire load.

In addition, PF-1 uses slightly more powerful cylinders, while the boom and other parts with mechanisms are made from reinforced (thickened) metal. Consequently, despite all the external similarities, the KUN on MTZ of different models still has significant differences in operation.

Note

Many skilled mechanics make the KUNS they need with their own hands, producing quite working and acceptable attachments. This does not mean that it is necessary and possible to refuse to purchase a high-quality factory product, but it does not exclude this possibility.

However, any homemade KUHN, even one manufactured according to all the rules and regulations, is certainly technically inferior to its factory-made counterparts.

How to make a homemade loader for the rear linkage of an MTZ tractor: drawings

To make a homemade loader for the rear linkage of an MTZ tractor, drawings, you should carry out an audit in your utility rooms. You need to evaluate whether you have enough materials and tools to make such a unit for the tractor.

The role of loaders in subsidiary farming and preparation for production

Every farmer needs a front loader for his mini tractor on his farm. Unfortunately, not everyone can purchase it, given the high cost.

The way out of the situation is to reorganize your equipment.

You can make a homemade tractor loader if you have the skill to carry out such work, as well as a sufficient amount of materials and tools.

Based on practice, a loader for a mini tractor goes very well when paired with an MTZ tractor, which is manufactured at a Belarusian plant. These machines are most often found on farm plots. It is equipped with hydraulics and is suitable for mounting attachments.

A loader on a mini tractor will save money. Having selected the necessary tools and materials from your own storage facilities that have been lying around for a long time without use, with skillful hands you can make this equipment for the rear linkage. You can set its parameters yourself, which is an advantage.

If there are no materials and funds to make such an addition for a mini-tractor, then the cost of purchasing them can exceed the price of a ready-made factory loader. And homemade loaders cannot be compared in quality to purchased ones. But you can purchase a used unit with a rear suspension much cheaper.

You need to start working on creating the necessary equipment with your own hands from the drawings. It is necessary to think through all the subtleties and dimensions.

If you don't have experience designing graphics, look for standard drawings. The assembly drawing must consist of a specification that lists all included assemblies and parts, as well as materials.

Using this documentation, calculate the amount of materials and fasteners.

You will need the following tools:

- welding machine (the conditions for safe operation on the tractor will depend on the reliability, strength and durability of the structure, so this operation should be carried out efficiently and professionally);

- grinder or gas cutter for metal;

- handy tools - you can’t do without hammers, adjustable wrenches, sledgehammers, etc.;

- to create the structure, you will need rolled profiles and metal strips; their parameters are determined based on the load the installation will be subjected to, based on the planned functions;

- since the loader will be equipped with a bucket with a boom, in order to lift it, a large hydraulic cylinder will be required; to be able to control the bucket at different angles of inclination, 2 small cylinders will be required.

Having determined the load of the installation, you should calculate the required number of articulated joints that help the unit operate under load.

Cutting materials with your own hands should be carried out strictly according to the drawings; this will contribute to the economical disposal of them and will help to better imagine the future product and make the right decision to give the greatest strength and reliability.

Technology for creating a homemade loader

Manufacturing begins with 2 rectangular frames. The first of them - the main one - is made with your own hands with a lower element that extends beyond the edge. They will also attach the base to the rear of the tractor.

The second frame for the rear linkage is made of strips and fastened with a spacer, which is located at the top, and with a hydraulic cylinder at the bottom. Thanks to the support, a stationary position of the frame is ensured.

Hinges are attached to the upper edge: in the central part there are 2 hinges for the upper hydraulic cylinders and a pair of hinges for the switch mechanism. The height of the frame is determined by expediency.

The boom mechanism is a prefabricated structure. A working element, a lever, is attached to its center, the hinge. The entire mechanism is a triple folded double structure that is secured to each other at the ends and in the center.

The finished boom can have a final length of 2 m or more, so it is equipped with a counterweight. The counterweight is placed in a basket welded to the frame at the front of the machine. Concrete blocks and sand in bags will be used as a counterweight.

To produce a ladle you need to have sufficient qualifications. If you don’t have one, it’s better to purchase a ready-made one in a special store. The bucket can be replaced with a forklift for bales or pallets.

Valentin Kozhedub | Topic author: Rebeca

testing a loader as a crane.

V (Caris) why suddenly? ! the hitch is designed for lifting loads! from the front frontal you can break it faster. and in this version, if you start to take a heavy load, then the tractor just rears up and that’s it.

Maxim (Rebeca) and my papalam was breaking the gap

Read also: Perennial Rudbeckia from seeds

V (Caris) is it really from the rear load? This means the gap was cracked, and the loader finished it off.

Maxim (Rebeca) didn’t stick a knife in the front, but pushed the loaded cart and broke it. Who did I buy this tractor from? I tore out the central screw with a piece of the hydraulic tank; he had a bucket hanging on it

V (Caris) I sympathize... anything can happen...