All about ball screws

A ball screw

is a type of linear drive that transforms rotary motion into linear motion, which has the distinctive feature of extremely low friction.

A shaft (usually steel - made from high-carbon types of steel) with a specific shape of running tracks on the surface acts as a high-precision drive screw interacting with the nut, but not directly, through sliding friction, as in conventional screw-nut transmissions, but through balls, through rolling friction . This determines the high overload characteristics of the ball screw and very high efficiency. The screw and nut are manufactured as a matched pair to very tight tolerances and can be used in applications where very high precision is required. The ball nut is usually slightly larger than the slide nut due to the ball recirculation channels located in it. However, this is practically the only point in which the ball screw is inferior to sliding friction screw drives.

Scope of application of ball screws

Ball screws are often used in aircraft and rocketry to move steering surfaces, and also in cars to drive the steering rack from an electric steering motor. The widest range of ball screw applications exists in precision engineering, such as CNC machines, robots, assembly lines, component installers, as well as mechanical presses, injection molding machines, etc.

Ball screw history

Historically, the first precision ball screw was made from a fairly low precision conventional screw, onto which a structure of several nuts was installed, tensioned by a spring, and then lapped along the entire length of the screw. By redistributing the nuts and changing the direction of the tension, the pitch errors of the screw and nut could be averaged out. Then, the resulting step of the pair, determined with high repeatability, was measured and recorded as a passport. A similar process is currently periodically used to produce ball screws.

Ball screw application

In order for the ball pair to serve its entire design life while preserving all, incl. accuracy parameters, it is necessary to pay great attention to the cleanliness and protection of the working space, to avoid contact of dust, shavings and other abrasive particles with the steam. This is usually solved by installing steam, polymer, rubber or leather corrugated protection, which prevents foreign particles from entering the work area. Another method is to use a compressor, supplying filtered air under pressure to an open-mounted propeller. Ball screws, thanks to the use of rolling friction, can have a certain preload, which removes the backlash of the transmission - a certain “gap” between the rotational and translational motion that occurs when changing the direction of rotation. Eliminating backlash is especially important in computer-controlled systems, which is why preloaded ball screws are especially often used in CNC machines.

Disadvantages of Ball Screws

Depending on the elevation angle of the raceways, ball screws may be subject to reverse transmission - low friction causes the nut to not lock, but to transmit linear force into torque. Ball screws are generally undesirable for manual feeds. The high cost of ball screws is also a factor that often inclines the choice of machine builders in favor of more budget-friendly gears.

Advantages of Ball Screws

The low coefficient of friction of the ball screw causes low dissipation and high transmission efficiency - much higher than that of any other analogues. The efficiency of the most common ball screws can exceed 90%, compared to a maximum of 50% for metric and trapezoidal lead screws. Virtually no slip significantly increases the service life of the ball screw, which reduces equipment downtime during repairs, replacement and lubrication of parts. All this, combined with some other advantages, such as higher achievable speed, reduced power requirements for the electric drive of the propeller, can be a significant argument in favor of a ball screw, as opposed to its high cost.

HIGH TECH

In single-thread screws, the balls can roll several turns before they exit into the recirculation channel. When calculating the load capacity of a ball screw, the number of balls in engagement is taken into account, without taking into account the balls in the channel for their recirculation. Ball screws are designed for axial load, and resistance to radial loads is largely provided by connection with the linear guides of the moving unit.

To determine the size of the electric motor, the required torque is important, which largely depends on the axial load on the propeller. Here it is necessary to take into account not only the cutting force, but also the force to move the unit, the friction force. The maximum torque occurs at the moment of acceleration.

Main characteristics of ball screws

The main characteristics of ball screws include: 1. Diameter of the helical groove (D). 2. Helical groove pitch (P). 3. The diameter of the balls (d), often it is chosen equal to d=6*P 4. The stroke per 1 revolution, in single-thread screws the stroke is equal to the pitch. 5. Single-pass or multi-pass. 6. Accuracy class. 7. Starting torque. 8. Noisy. 9. Angle of helical groove.

The accuracy class of a ball screw determines: pitch accuracy, roughness, dimensional tolerances, backlash, noise, starting torque, etc. You can read about the accuracy class here (it is recommended to know).

Ball screw accuracy class

Ball screws are divided into two main groups: ball screws of the transport group and positional group. They have different applications and, accordingly, different requirements for them, including accuracy classes. As a rule, ball screws of the transport group are less accurate and have more backlash. more about ball screw accuracy classes here (highly recommended).

Ball screw supports

Particular attention must be paid to ball screw supports; the unreliability of these components can reduce the advantages of even the most rigid and accurate ball screw. Based on their location, they are divided into vertical (BK and BF) and horizontal (FK and FF). There are other series, but to understand the issue, BK, BF is enough for us. more about ball screw supports here (highly recommended).

Ball screw manufacturing

Ball screws mainly made by grinding or rolling . These methods have their advantages and disadvantages. You can find out more about the methods for making ball screws by clicking on the link (highly recommended).

Ball screw preload

To increase the accuracy of the ball screw, preload the ball screw or preload the ball screw , i.e. the gaps between the nut and the ball screw are guaranteed to be selected, an additional load or interference is created in the ball screw. The topic is quite large, so you can learn more about it here (highly recommended).

Ball screw accuracy

High-precision screws usually give an error of the order of 1-3 microns per 300 mm of travel, and even more accurately. Blanks for such screws are obtained by rough machining, then the blanks are hardened and ground to perfection. Three steps are strictly required, because... temperature treatment greatly changes the surface of the ball screw.

Hard-whirling is a relatively new metalworking technology that minimizes heating of the workpiece during the process, and can produce precision screws from a hardened workpiece. Instrumented ball screws typically achieve an accuracy of 250 nm per centimeter. They are manufactured by milling and grinding on ultra-precise equipment with control by specialized equipment of submicron precision. Lines for the production of lenses and mirrors are equipped with similar equipment. Such screws are usually made from Invar or other Invar alloys to minimize the error introduced by thermal expansion of the screw.

High-speed or high-speed ball screws

High-speed ball screw

An increase in the speed of movement of the nut relative to the screw is achieved by increasing the pitch between the grooves, compared to a standard screw, by 3-5 times; for a conventional transmission ball screw with a diameter of 16-32mm, the pitch is 5-10mm, for a high-speed gear of the same diameters - 16-32mm and a multiple screw diameter.

Due to an increase in movement speed, there is a loss in rigidity and maximum load on the transmission (to a greater extent) and accuracy (to a lesser extent).

Ball recycling systems

Bearing balls circulate in the thread channels of the nut and the raceways of the screw. If you did not guide the ball after the end of its journey, the balls would simply fall out of the nut outwards after reaching the end of the track, so ball screws use several more expensive systems for returning the balls to the beginning - recirculation systems.

The external system uses a metal tube that connects the inlet and outlet of the channel nut.

The outgoing balls fall into the tube, and pushed by subsequent ones, they follow to the entrance. The internal system involves cutting a similar channel inside the nut, the balls coming out of the nut are directed by a special lining into the drilled channel, and at the exit from the channel, a similar lining transfers the balls to the inlet of the treadmill. A very common option is when the balls circulate through several looped channels, where the return is ensured by a special plug. DARXTON

Principle of operation

The screw is driven into rotation by a drive electric motor, the nut is fixedly fixed on the working part of the machine (support, carriage, spindle head, steady rest, and so on). In this case, an axial force arises acting on the balls located inside the nut, under the influence of which they begin to roll in closed helical grooves. The reaction force acts on the nut, and since it is rigidly connected to the part being moved, it forces the latter to move along the guides of the machine. What is the difference between the operation of a ball screw and a conventional screw drive with trapezoidal threads, which was previously used on machine tools?

- 1. When the lead screw of the previous design rotated, sliding friction arose in the contact zone of the two parts, characterized by a friction coefficient (bronze on steel, lubricated) f = 0.07–0.1. In a mechanism with ball elements, rolling friction operates with a coefficient f = 0.0015–0.006. As can be seen from the given values, helical ball gears require significantly less drive motor power.

- 2. To accurately position the carriage or support of the machine, before stopping the working element, it is necessary to slow down the speed of its movement. Upon reaching a certain minimum speed threshold, micro-stops—sticking—of the moving unit are possible. At the moment of resumption of movement, its character is determined by static friction, which during sliding significantly exceeds the friction of movement. This causes jerks that impair positioning accuracy. With rolling friction, this disadvantage is practically reduced to zero.

Application area

Ball screws are widely used in many industries: machine tool building, robotics, assembly lines and transport devices, complex automated systems, woodworking, automotive industry, medical equipment, nuclear energy, space and aviation industries, military equipment, precision measuring instruments and much more. Some examples of using these nodes:

- Feed drives for CNC machines. The first mass-produced machining center IR-500 in the USSR had 3 processing coordinates. Modern systems contain a significantly larger number of linear actuators. For example, Tornos multi-spindle longitudinal turning machines of the MULTI SWISS series have 14 controlled axes.

- Movement of the piston-rack of the steering mechanism of cars (MAZ, KAMAZ, Gazelle).

- Vertical movement of the carriage of the VECTORUS iPro and sPro series production 3D printer.

Classification

According to manufacturing technology, lead screws are:

- Rolled - with a helical groove obtained by cold rolling. These screws are produced at lower costs, therefore they have the best price-quality ratio with average manufacturing accuracy (C5, C7, C9).

- Polished - refer to precision products. After thread cutting and subsequent heat treatment, they are subjected to grinding. They have increased accuracy (C1, C3, C5) and a higher price.

By design:

- Ball screw - manufactured according to DIN standard. The balls return to the adjacent groove along a reflector groove built into the nut.

- Precision - made by grinding. They may consist of one or two nuts, have a preload (preload) - eliminating axial play in order to increase accuracy during reverse and increase drive rigidity.

- Precision with a separator - characterized by a ball return design (no impact) and a ground groove profile.

- Precision ones with a rotating nut have a built-in bearing, due to which they have increased movement accuracy.

- Splined shaft with flanged ball bushings. In this case, the shaft acts as the inner ring of the bearing. This design is compact and easy to install.

- Cantilever design of the propeller . Used for short lead screws that do not have a second support.

Ball screw technical characteristics

- Main parameters:

- The diameter and pitch of the screw are from 16 × 2.5 to 125 × 20 mm.

- Screw rod length. Lead screws for CNC machines are usually produced with a maximum length of 2.0–2.5 m, although up to 8 meters are made to order.

- Linear speed of movement - up to 110 m/min.

- Transmission accuracy - C1...C10.

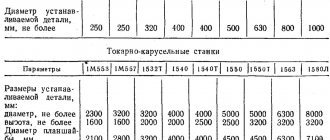

Power characteristics for some standard sizes are given in the table:

| Power parameters of ball screws | ||||

| Diameter × pitch, mm | Load capacity, N | Axial stiffness, N/µm | ||

| Static | Dynamic | Hull ball screws | Frameless ball screws | |

| 16 × 2,5 | 9600 | 5000 | — | 230 |

| 32 × 5 | 37500 | 17710 | 700 | 760 |

| 50 × 10 | 112500 | 57750 | 1000 | 1100 |

| 80 × 10 | 197700 | 66880 | 1700 | 1900 |

| 125 × 20 | 729000 | 278000 | — | 2850 |

| Note: Axial stiffness is specified for accuracy class C1. | ||||