In rolled metal, the most popular element is a metal corner. Its area of application is not only construction; this material is also often used in industry. In the construction of any structure one cannot do without this product. But what types of metal corners are there? This article will answer how to choose them correctly and what are their differences.

How to choose steel angles?

So, how should you choose the right metal corners?

The first is accuracy. You can recognize it by the letter in the marking. If there is a letter A, then this means that the corner has high accuracy. If Latin B is indicated, this means that this product has normal accuracy.

What can this parameter actually affect? It shows the parameters of the finished product (evenness, accuracy, thickness, as well as any deviations).

For small rolled metal products, high accuracy is an important characteristic. But for large products, completely different characteristics are important.

The second is the manufacturing methods. There are two types of manufacturing - cold rolling and hot rolling. That is, during hot production, products are rolled in special forms through hot machines (or the finished product is bent).

If we compare a cold-rolled product with a hot-rolled one, the former have low strength. Therefore, if high strength is required, then this steel angle will not work; it is better not to purchase it.

The third thing you should pay attention to is the shelves. There are two types - equilateral and non-equilateral. Option No1 is a metal strip that has an angle of 90% in the middle. The second No2 resembles the letter G because one side is longer than the other.

Corners that have equal sides are stronger, so they are used more often. But if it is necessary to individually calculate the length of both shelves, then non-equilateral corners are used here. This option also has high reinforcing properties.

And fourth is the steel from which the corners are made. In the manufacture of metal corners, more than one type of steel is used. If ordinary steel was used in the manufacture of the corner, then its price will be lower.

If in construction it is necessary for the structure to be reliable, so that it is not affected by the environment and temperature changes, then you should opt for products made of low-alloy steel.

Production specifics

Angle steel as a result of rolled metal production can be produced in different ways using different technologies. There are three main production lines.

- Hot rolled method. In this manufacturing option, a molten billet of carbon or low-alloy high-strength steel is passed along special rolls through a rolling mill.

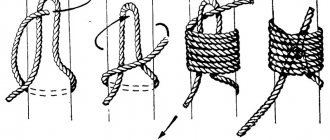

- Cold rolled method. The steel strip is formed using a cold bending method in a special press brake.

- Bending method. Products are formed from hot-rolled or cold-rolled sheets on roll forming machines.

All received products are certified and checked for compliance with GOST standards. For example, an equal-flange hot-rolled steel angle complies with GOST 8509 93. The documents always indicate the amount of permissible deviations in the dimensions, thickness or accuracy of the angle.

Types of metal corners

Hot rolled. It is made from a finished steel billet, which is heated and passed through a machine. And according to the dimensions that are given, the product is formed.

Bent. This type is made from a strip of steel; it can be used either cold or hot rolling, during which a bend is formed. This corner will suit any design idea.

Equal. The name speaks for itself. All sides of this angle are equal.

Unequal. This corner has different side sizes.

The metal corner has standard dimensions:

- 20x20 mm;

- 25x25mm;

- 50x50mm;

- 70x70mm;

- 75x75mm;

- 100x100mm;

- 120x120mm;

- 150x150mm;

- 200x200mm.

You can also classify metal corners by length. There are two types. This:

- Measured;

- Unmeasured.

The lengths of measuring metal corners are 6,7,9,10,11 and 12 mm. The price of this product varies not by unit, but by weight category. That is, the buyer will pay not for the quantity of products, but for its weight.

Unmeasured metal corners can have different lengths. Typically it varies from 4 to 12 mm.

Areas of application

The special cross-sectional shape of the steel angle gives it great potential for use in many technological processes. It is easy to weld, has particular strength and resistance to heavy loads. Thanks to these qualities, the product is used almost everywhere.

Its main area of application is construction. It is from steel corners that the main parts of loaded metal structures are created. The products serve as the basis for floors, spans and trusses of bridges. The angular section allows the parts to be used to form doors and windows. Angles of unequal type are used as bases for arches and other structures that require bends.

Small thin parts are used in furniture production to build frames or serve as material for the manufacture of decorative elements.

Corners are indispensable in the engineering field: in the automotive industry, in the production of cars and large-sized technical products.

In the electrical field, profiled angle bars serve as a structural basis for supports for hanging cable equipment and special equipment. Corners made of low-alloy steel can withstand high loads, temperature changes, exposure to chemicals and high humidity.

The steel angle is not strong enough to serve as the basis of powerful structures, but it is indispensable as an auxiliary element. With its help, reinforced concrete monolithic structures are strengthened, floors are reinforced, and lightweight metal structures are supported.

The corner is convenient for installing fences, installing communication towers, and when decorating curtain facades. It is also very important for the production of cranes and other special equipment.

It is also worth mentioning the use of rolled profile products in the installation of greenhouse structures, installation of flights of stairs and railings. Corners are required in children's playgrounds, where they are used to construct swings, benches and tables.

Warehouse equipment and shelving are also made using corners. Products can be seen in the designs of public transport stops on city streets, and at the base of shopping pavilions and kiosks, and on gazebos and billboards.

Galvanized steel corner

In metal structures that are exposed to moisture, this type of corner is used. Since an ordinary metal corner is subject to corrosion, in this case a galvanized corner is used. The cost of this type of corner is more expensive, but its operation will last longer. This type of corner has the same dimensions (thickness and width) as a corner made of ordinary steel.

Carbon steel is used in the production of this corner. They are galvanized in several ways. The first is when the corner is immersed in the melt.

Galvanization can also be carried out in a sealed container with high temperature when it rotates. Here the zinc gets onto the surface of the steel and at the same time it holds much better.

The second method is spraying. Here it is possible to apply a thicker layer of zinc, up to several mm.

You can look, get acquainted and imagine what this or that type of corner looks like on manufacturers’ websites and in online stores by looking at a photo of a metal corner. You can also view catalogs and prices here.

Make calculations on the number of certain types of corners. Decide on the choice and type of corner, calculate the required quantity and possibly order corners.

Features and Properties

Equal-flange steel angle is considered the most popular type of rolled metal products. Its precise compliance with standards allows for better interaction between producers and consumers. All dimensions and weight of products are determined by GOST 8509-93. This allows you to accurately calculate material consumption, which is especially important in repairs and construction.

A standard steel product with an L-shaped cross-section is considered very strong due to the angle that acts as a stiffener. This feature also allows for convenient stacking during storage and transportation.

The range of corners offered is very wide due to the variety of raw materials used for manufacturing. There are products not only made from ordinary steel, but also from high-strength, alloy and high-alloy steel. Heat-resistant, heat-resistant and corrosion-resistant alloys are also used. Carbon steel GOST 380-94 is especially common in the production of angles.