Press catalog

Preparing juice is one of the most labor-intensive and important stages in preparing it for the winter and in winemaking. In a very short period of time, you need to process tens and sometimes hundreds of kilograms of fruits and berries, while you need to comply with certain sanitation conditions and not delay the subsequent processing of the extracted juice. Without special equipment, this process turns into not just a difficult task, but a real hell. Fortunately, progress does not stand still. In this material we will reveal all the secrets of seasonal juice harvesting, talk about winemaking in principle, and also talk about all existing types of equipment that will help turn a labor-intensive process, if not into fun, then at least into a pleasant and useful pastime. So, how to squeeze juice from berries and fruits, but at the same time maintain health and nerves?

1) Screw (mechanical) presses for apples, fruits, grapes and berries

Screw presses operate on the principle of a vice, squeezing crushed raw materials.

There are 2 types of screw presses:

1 - with a screw coming from the base of the press

This is the cheapest option for a manual juice press, which is most often made in China.

There are also Italian screw presses with a jacking mechanism on the market.

It is not worth buying a screw press of this design, since the screw has contact with the juice, and therefore the grease that coats the press screw can get into the juice. But you can’t not lubricate the screw, as it can “seize” or it will quickly wear out, and wear products will get into the juice. Also, in such presses, the tray is made of ordinary painted steel, and therefore, after several years of use, rust will begin to appear. Therefore, our company does not produce screw presses for apples of this type at all.

2 - frame screw press for grapes and apples

In this version of the screw press for fruit, the screw is on top and rests on a special pad on the press piston, so the grease of the screw does not get into the juice.

Screw frame presses are convenient to use, since the juice can be released in one go by tightening the screw all the way, without moving anything during extraction.

However, with a barrel volume of more than 10 liters, turning the screw is tiring, especially if a woman is working with the press.

Screw presses for juice of small volumes of 0.75, 3 and 5 liters are very convenient when used in the kitchen. They are small in size and will easily fit on a shelf in your kitchen.

In our online store you can buy a screw press for squeezing juice from apples, grapes, other fruits, vegetables and berries directly from the manufacturer with courier delivery to your door in your city. The price for delivery to Moscow, St. Petersburg, Krasnodar, Rostov-on-Don, Saratov, Voronezh, Orel, Yaroslavl, Pskov and any other city in Russia is the same. We also deliver goods to Minsk, Kyiv, CIS countries and anywhere in the world.

What to do next with the extracted juice?

Preserve! The extracted juice can be pre-filtered through a thick cloth, but this is not necessary. It is not worth standing to remove it from the sediment, since it is important to process the juice as quickly as possible, avoiding its oxidation. After pressing, the juice must be pasteurized. To do this, you need to pour it into a saucepan and heat it to 80-95 ° C, but do not boil, and then pour it into sterilized jars and roll it up. While heating, the juice can be sweetened to taste. You can also carry out pasteurization directly in storage containers: pour freshly squeezed juice into sterile jars, roll up the jars, and then pasteurize at 90 ° C in a water bath (for a 1-liter container, 25 minutes is enough, with increasing capacity, the duration of pasteurization increases proportionally). Pasteurized juice can be stored for up to 1 year in a cool, dark place.

Make homemade wine! First you need to study and correct the juice. Using a hydrometer or refractometer, the sugar content in the juice is determined, and using a pH tester, its acidity is determined. Based on the data obtained, the winemaker must decide whether he needs to add sugar to the must in order to obtain a wine of a certain strength, and whether he needs to increase (by adding acids) or decrease (by adding water) its acidity. After this, the juice is placed in a fermenter, treated with sulfur if necessary, fed with nutrients and infected with a pure yeast culture. But this, as they say, is a completely different story, which we will certainly tell in the near future.

2) Garden hydraulic presses for squeezing juice from apples, fruits, grapes and berries

1 - With jack

The hydraulic press for apples and grapes is a strong rectangular frame with a stop for the jack rod in the center. The jack can be located either from above, pressing on the piston, or from below, lifting the entire barrel with the piston and pan upward. The jack is easy and convenient to use. Such a press is easy to handle even for a woman, since the jack creates a big gain in strength.

The only drawback is that the stroke of the jack rod is not enough for the entire height of the barrel and wooden blocks must be placed during the process of squeezing the juice.

This problem can be solved by purchasing a two-stage jack, but the price of such a jack is about 30-40 euros (a regular 2t jack costs about 10-12 euros).

Watch the video of a homemade apple press with a two-stage jack:

2 - With hydraulic cylinder

This design already applies to an industrial apple press. In the frame of such a press there is a hydraulic cylinder, as well as a pump, which supplies hydraulic oil to the cylinder piston. This apple press has high productivity and barrel volumes of 50, 100 and 200 liters. With the help of such a press it is very convenient to squeeze out juice. After all, the piston stroke length is selected so that it is enough to cover the entire working height of the barrel.

However, due to the more complex design, the price of such a press is much higher, and such a press design is justified only for professional use, for example, for a line for the production of directly pressed juices.

Hydraulic cylinder presses are manual and semi-automatic. The semi-automatic press is an electric press for grapes and apples. Juice is extracted with the press of a button, and raw materials are loaded and unloaded manually.

Manufacturers of crushers and presses

Our store offers grinders from both domestic and foreign brands. The most budget crushers are produced by Sarmat LLC , “Yagodka” series . These are high-quality products made of food-grade stainless steel and rollers made of dense food-grade rubber. But the most important advantage of these grinders is the price, which is an order of magnitude lower than their foreign analogues such as the Grifo . The Italian company Grifo is a European leader in the production of equipment for winemaking. The grinders of the Italian manufacturer are equipped with reliable polyurethane rollers, which are complemented by stainless steel knives for gripping and primary crushing of raw materials. Our assortment includes Grifo “Small” and Grifo “Mini”. Grifo’s range also includes a grinder with an electric motor, which allows you to process up to one and a half tons of raw materials. But the only representative of fruit choppers in our store is equipment from a domestic company. Why the only one? Because the fruit chopper is not inferior in quality and performance to foreign analogues, but at the same time it costs two or even three times less.

As for presses, here you can choose a model of any type and, as they say, to suit any budget. The most budget models are produced in Russia. These are reliable screw and jack type presses, made of high-quality food grade stainless steel. Additionally, most domestic presses can be equipped with splash protection in the form of a metal casing. The basket of more expensive Italian presses is made of solid beech slats in the form of a drainage grid - it looks more presentable and authentic, and the pulp comes into contact with the metal only in the area of the auger, which is a big advantage. Also, in Italian presses the screw system is implemented differently - the piston is driven by reciprocating movements of small amplitude, due to which much less effort must be applied during the pressing process. Hydraulic presses are represented by “SOK”, 70 l and “SOK”, 35 l: the SOK offers equipment of the highest quality, while the price is an order of magnitude lower than its foreign analogues.

Buy a press and crusher

5) Hydropress for pressing juice from apples and grapes

Such a press squeezes out juice using water pressure in the water supply. The crushed raw materials are poured into the stainless steel basket and the lid is closed.

In the middle of the basket there is a rubber membrane, which expands under water pressure and squeezes out the juice.

Such presses for making juice from grapes and apples are produced with basket volumes from 20 to 200 liters, but the price of such a press is 20-40 liters several times more expensive than the price of a press with a hydraulic jack or the price of a screw press. Such a press pays off only if there is a large volume of juice being squeezed out, since it is semi-automatic and easy to use.

Also, the hydraulic press membrane may break over time and then you will have to buy a new one.

And such a press requires a water supply with a created pressure of 2-3 atmospheres.

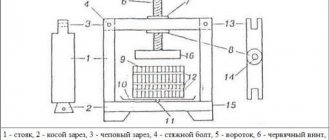

The process of creating a mechanical press

0

Source:

In order for a mechanical press to show high efficiency, you should adhere to all requirements when constructing it yourself. The following step-by-step instructions will help you complete the work of creating a press correctly: preparing a vessel into which the fruit will be poured (the amount of juice-containing raw materials per filling will depend on the volume of this vessel); small holes are made in the vessel using a drill, arranged in a checkerboard pattern (many people use the drum of a broken washing machine as a vessel); another container without a bottom is prepared, holes are also drilled along the bottom line of the walls (this container should be larger in volume than the previously prepared vessel); a smaller vessel is inserted into a prepared larger container, a wooden block is placed between the walls; a frame is created in the shape of the letter “P” (strong wooden blocks or steel pipe are used for manufacturing); a durable circle made of steel or cast iron is installed on the frame crossbar; prepare a basin of large diameter so that both connected vessels can be placed in it (the basin must be made of a material in which food products can be stored); a hole is drilled at the bottom of the basin, in which a tube is fixed for the juice to flow out or a tap is installed; To prevent the frame from tipping over during the process of squeezing out the juice, it is recommended to concrete it, and only then attach a structure of vessels to it.

This completes the construction process. You can begin the first juice squeezing procedure. It’s just important not to forget to prepare a container into which the finished juice will be poured. This container is placed under a constructed tap or a tube coming out of the press is directed into the neck of the container to drain the juice. It will be possible to construct a screw press without any particular difficulties if you can purchase or find a special screw that is externally identical to the screw of a meat grinder. It is in such cases that skills in working with metal will be very useful. You can turn to a professional turner for help, who can turn such a screw, focusing on the given parameters.

Hydraulic and screw presses for squeezing juices are:

— With basket and piston

A bag for filtration is placed in the barrel, then the crushed raw materials are placed, the edges of the bag are wrapped, a piston is placed on top and the juice is squeezed out. The barrel and piston are usually made of hardwood or stainless steel. Wooden presses look more beautiful and atmospheric, but a stainless steel press is more practical.

Press made of stainless steel and oak.

— With bars

This is a press with many grates, between which bags of chopped apples or grapes are placed. The number of such gratings can even reach 20. However, using such a press is not so convenient, since it takes a lot of time to fold all 20 layers.

What volume of press basket should I choose?

Mainly, all juice presses differ from each other only in the volume of the barrel and the principle of operation. The volume of the barrel only determines how much juice you will squeeze out at one time. The cycle of one spin is 5-10 minutes. The juice yield is 50-70% of the barrel volume. Therefore, you should choose a press based on how much juice you plan to make.

1) As a souvenir

The VP-075 press is suitable for squeezing several glasses of juice. This wooden press for apples and grapes is good as a gift or souvenir. And it will also decorate your kitchen. After all, natural wood always adds comfort and warmth to a home.

Buy a 0.75 liter screw press

2) For the kitchen

If you do not plan to prepare a lot of juice, but just want to treat yourself to delicious juices in the summer, then a 3 liter VP-3 or VP-5 (5 liter) press will be enough for you. This press takes up little space and can be freely used in the kitchen.

Buy a 3 liter screw juice press

3) For the dacha

If you want to prepare 10-20 three-liter jars for the winter, then a screw press for grapes and apples or a hydraulic press for squeezing juice for 10-12 liters will be enough for you.

Buy a hydraulic juice press for 12 liters

4) For the garden

If you have a large garden, you plan to prepare a lot of juice for the winter and supply wine, then in this case it is better to choose a 20-30 liter juice press. For one extraction you will receive 1 bucket of juice.

Buy a hydraulic juice press for 26 liters

5) For small production

If you are going to make juice for sale or you have a huge family, then you need a press with a capacity of 50 liters or more. With such a press you can squeeze out more than 200 liters of juice per hour.

Buy a hydraulic press for 50 liters

When choosing between a screw press and a hydraulic press, you need to consider the following factors:

1) Screw presses for squeezing juice with a barrel volume of up to 10 liters; when squeezing juice, it is enough to hold the frame with one hand and rotate the screw with the other. A screw press with a volume of 10-20 liters or more must be fixed with 4 screws to a fixed base so that it does not rotate. It is enough to place the hydraulic press on the edge of the table above the container where the juice will be drained.

2) With the help of a hydraulic press, you can create more force using a jack, therefore, more juice output. However, it is necessary to place planks under the jack as the piston moves in order to squeeze out the apple mass to the end, since the piston stroke is not enough for the entire height of the barrel, and the jack handle begins to rest against the edge of the barrel.

3) Using a screw press, the pressing process occurs in one step.

4) It is physically easier to work with a hydraulic press than with a screw press

Berry press

Small presses with a barrel capacity of 3-5 liters are better suited for squeezing juice from berries. Since it can be problematic to collect enough berries for juicing. In this case, many customers purchase, for example, a 30-liter hydraulic press and an electric chopper for apples, and additionally take a 3-liter screw press for berries.

Press for apples, fruits and vegetables

Any press is suitable for squeezing juice from apples; you should choose a press based on how much juice you plan to make.

Grape press

To squeeze grape juice, you usually buy a 10-20 liter screw press, of course it all depends on your harvest, but if you grow several buckets of grapes every year, then a VP-5 screw press will be enough for you.

Any press can crush grapes and apples with seeds without compromising their integrity. However, in order to use the press, preliminary preparation of the raw material is necessary, namely crushing (grinding). For this purpose, there are special crushers and shredders for fruits and grapes.

Read about their types, operating principles, pros and cons here: Which chopper for apples and grapes should you choose? - read here

Grinding fruits and berries into pulp

Preparing juice for winemaking and canning is always a two-step process. It’s not for us to tell you that the juice in fruits and berries is inside a fiber shell, so in order to more effectively extract the juice, the fiber must first be broken. This process is called grinding or crushing, and the result is the so-called pulp, a porridge-like mass, from which the juice is then extracted in a way suitable for a particular type of raw material. Of course, you can use ordinary household appliances for this. Berries are easily crushed with a wooden spoon in tubs, fleshy berries (for example, gooseberries) and fruits (pears, plums, apricots, etc.) can be crushed with a heavy wooden or metal pestle, and apples and other hard fruits can be grated. How long will your enthusiasm last if you need to process several tens or hundreds of kilograms of raw materials in this way?

This is where technological advancements come to the rescue: crushers, also known as crushers, and fruit choppers. Most crusher designs for fruits and berries resemble a two-roller malt mill: they are based on a rotating mechanism of two rollers, which are driven manually by a flywheel or an electric motor. Such grinders are equipped with a spacious hopper, a base made of perforated pipes for convenient mounting above the receiving container and transportation, and more advanced models for winemaking are equipped with a destemmer. More importantly, the rollers of most crushers are made of rubber or polyurethane. This allows you to knead berries and fruits without crushing the seeds, which is very undesirable and is the main disadvantage of household juicers - a crushed grape seed will make the future wine too tart and grassy, and the seeds of most berries and fruits contain amygdalin, a poison that is most dangerous for humans. To capture and crush raw materials, the rollers are equipped with stainless steel knives.

Grinding machines are widely used in winemaking for crushing soft berries and fruits, in particular grapes. They can also cope with hard fruits, but it is better to entrust this task to a special fruit chopper. Its operating principle is extremely simple: there is a hopper where processing raw materials are supplied, inside of which there are stainless steel knives driven by a powerful electric motor - they crush the fruit into a small fraction called pulp. A good shredder is capable of processing up to 500 kg of raw materials per hour or even more, which means that it is enough not only for home use, but also for organizing small production.

By the way, you can use the above-mentioned Neptune juicer as a fruit chopper - it gives out half of the juice immediately, which means that extracting the rest will take less time and effort. But here it should be taken into account that the output we get is too fine a cake, almost a puree, while grinders and grinders provide a more delicate crushing of raw materials into large fractions, which act as a natural filter during juice extraction and the juice is purer.