I live in a house where grapes have been growing for over 40 years and I don’t know what to do with them (they have seeds, so I don’t eat them very much). I also have a great basement and project room and this year I decided to try making wine. Having tried to make grape jam last year, I realized that using a potato masher is inconvenient and ineffective.

I visited a local winery and asked about the brewing process and basic materials. The store manager said that 50 kg of grapes can make 35-40 liters of wine. From what I remember last year, we took about 7 kilograms of grapes (including stems) and got about 3 liters of juice after 45 minutes of rubbing and squeezing through a cloth. If we want to process all 50 kg, we need a more efficient processing method.

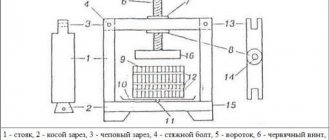

My basic crusher plan was to use a car jack to push a disc into a perforated pot to press the grapes. A little later you will see drawings of what I got and how to make a grape press with your own hands.

1) Screw (mechanical) presses for apples, fruits, grapes and berries

Screw presses operate on the principle of a vice, squeezing crushed raw materials.

There are 2 types of screw presses:

1 - with a screw coming from the base of the press

This is the cheapest option for a manual juice press, which is most often made in China.

There are also Italian screw presses with a jacking mechanism on the market.

It is not worth buying a screw press of this design, since the screw has contact with the juice, and therefore the grease that coats the press screw can get into the juice. But you can’t not lubricate the screw, as it can “seize” or it will quickly wear out, and wear products will get into the juice. Also, in such presses, the tray is made of ordinary painted steel, and therefore, after several years of use, rust will begin to appear. Therefore, our company does not produce screw presses for apples of this type at all.

2 - frame screw press for grapes and apples

In this version of the screw press for fruit, the screw is on top and rests on a special pad on the press piston, so the grease of the screw does not get into the juice.

Screw frame presses are convenient to use, since the juice can be released in one go by tightening the screw all the way, without moving anything during extraction.

However, with a barrel volume of more than 10 liters, turning the screw is tiring, especially if a woman is working with the press.

Screw presses for juice of small volumes of 0.75, 3 and 5 liters are very convenient when used in the kitchen. They are small in size and will easily fit on a shelf in your kitchen.

In our online store you can buy a screw press for squeezing juice from apples, grapes, other fruits, vegetables and berries directly from the manufacturer with courier delivery to your door in your city. The price for delivery to Moscow, St. Petersburg, Krasnodar, Rostov-on-Don, Saratov, Voronezh, Orel, Yaroslavl, Pskov and any other city in Russia is the same. We also deliver goods to Minsk, Kyiv, CIS countries and anywhere in the world.

Examples of the most popular grape juicers

When choosing a suitable model, you should not only take into account the type of design, but also pay attention to the functionality and technical characteristics. “KITFORT” KT-1101 is an electric screw device with fairly small dimensions. The motor power is 150 W. The volume of containers for liquid and cake is 800 ml each. The device has an automatic pulp selection function. The electric drive operates very quietly, so it can be used even in a small apartment. "Bosch" MES25A0 is a powerful centrifugal device. The motor power is 700 W. There are 2 operating speeds, which greatly simplifies operation. But when passing grapes through a juicer, their brushes and peels can still jam the rotational elements of the device. Therefore, the kit comes with a special brush, which is designed to clean a clogged centrifuge. The juice container is closed with a convenient lid. The neck diameter is 75 mm, which allows you to load even large fruits into the centrifuge without pre-cutting. This model will fit perfectly into the kitchen of a cafe or restaurant. Lurch is a manual auger juicer that is well suited for home use. This mechanism has a well-thought-out design and compact dimensions. Thanks to several filter meshes, you can get the purest juice from fruits with seeds. This model is easy to clean and makes virtually no noise. The device comes with a 500 ml liquid reservoir.

2) Garden hydraulic presses for squeezing juice from apples, fruits, grapes and berries

1 - With jack

The hydraulic press for apples and grapes is a strong rectangular frame with a stop for the jack rod in the center. The jack can be located either from above, pressing on the piston, or from below, lifting the entire barrel with the piston and pan upward. The jack is easy and convenient to use. Such a press is easy to handle even for a woman, since the jack creates a big gain in strength.

The only drawback is that the stroke of the jack rod is not enough for the entire height of the barrel and wooden blocks must be placed during the process of squeezing the juice.

This problem can be solved by purchasing a two-stage jack, but the price of such a jack is about 30-40 euros (a regular 2t jack costs about 10-12 euros).

Watch the video of a homemade apple press with a two-stage jack:

2 - With hydraulic cylinder

This design already applies to an industrial apple press. In the frame of such a press there is a hydraulic cylinder, as well as a pump, which supplies hydraulic oil to the cylinder piston. This apple press has high productivity and barrel volumes of 50, 100 and 200 liters. With the help of such a press it is very convenient to squeeze out juice. After all, the piston stroke length is selected so that it is enough to cover the entire working height of the barrel.

However, due to the more complex design, the price of such a press is much higher, and such a press design is justified only for professional use, for example, for a line for the production of directly pressed juices.

Hydraulic cylinder presses are manual and semi-automatic. The semi-automatic press is an electric press for grapes and apples. Juice is extracted with the press of a button, and raw materials are loaded and unloaded manually.

Pressers and crushers

A grape press or crusher is a relatively simple device that helps extract juice and pulp from berries.

Speaking about specific models, it is worth recommending a DB-3 mechanical crusher for purchase. She managed to earn a lot of good reviews.

In particular, it is praised for its ease of use and maintenance and good performance - meaning it would be an excellent choice for private use or maybe even a small business.

The only disadvantage is the small number of control and adjustment options.

Materials

The most popular material options here are:

- steel-stainless steel;

- plastic;

- varnished wood.

Without considering in more detail the pros and cons of other options, as it is unnecessary, we will immediately highlight that in most cases, stainless steel is the best. In this case, the components are easier to wash and disassemble. Longer service life, less odors.

If more than five hundred to seven hundred kilos of berries are processed, then it is definitely recommended to use a crusher with a motor.

destemmer

The second is the presence of a comb separator. Raw materials must be cleaned of ridges. Because the ridges ripen much earlier than the berries and they contain much more tannins, which results in excess bitterness.

Therefore, the use of a comb separator is often justified - a device made of helical blades and a shaft. The raw material first hits the shaft, then onto the pressing elements.

Expert opinion

Kislyar Yuri Borisovich

61 years old, Voronezh, has been growing grapes for 15 years

For some red varieties, such as Cabernet Sauvignon and Merlot, the destemmer is not used because the quality of the raw material deteriorates.

Control

The advantages of mechanical/manual ones are compactness and cost-effectiveness. If you crush some grapes at home or on your personal farm, then these are the ones worth recommending. A simple attache includes something like the following:

- square bin;

- 2 smooth rollers;

- lower wooden frame;

- gear system;

- handle on the side.

Thanks to its light weight, it can easily be placed even on a table. But electric crushers make it possible to almost completely automate the process. As a rule, they even have an additional destemmer.

Here, as specific models, it is worth recommending crushers from Grifo; they have exactly the same destemmer and their quality is confirmed by many positive reviews.

Full automation of the process makes it possible to greatly reduce the time and effort spent on work. Various models of electric crushers have the following performance:

- 1200-1500 kilos of grapes per hour;

- 1500-2000 kilos of grapes per hour;

- 2000-2300 or more kilos of grapes per hour.

Pros and cons of using

- large volumes are processed quickly;

- all resources are used as wisely as possible;

- the resulting pulp is of excellent quality;

- The cake is automatically cleaned;

- it is easy to control the process.

- some variants of Atregata are not suitable for Muscat varieties;

- the price may seem expensive to some (although the quality more than justifies it).

It should be noted that with minimal skills, it is quite possible not to buy a crusher ready-made in a store, but to make it yourself (but this, of course, is already associated with certain risks and is a topic for a separate article. By default, we recommend purchasing the product).

5) Hydropress for pressing juice from apples and grapes

Such a press squeezes out juice using water pressure in the water supply. The crushed raw materials are poured into the stainless steel basket and the lid is closed.

In the middle of the basket there is a rubber membrane, which expands under water pressure and squeezes out the juice.

Such presses for making juice from grapes and apples are produced with basket volumes from 20 to 200 liters, but the price of such a press is 20-40 liters several times more expensive than the price of a press with a hydraulic jack or the price of a screw press. Such a press pays off only if there is a large volume of juice being squeezed out, since it is semi-automatic and easy to use.

Also, the hydraulic press membrane may break over time and then you will have to buy a new one.

And such a press requires a water supply with a created pressure of 2-3 atmospheres.

Hydraulic and screw presses for squeezing juices are:

— With basket and piston

A bag for filtration is placed in the barrel, then the crushed raw materials are placed, the edges of the bag are wrapped, a piston is placed on top and the juice is squeezed out. The barrel and piston are usually made of hardwood or stainless steel. Wooden presses look more beautiful and atmospheric, but a stainless steel press is more practical.

Press made of stainless steel and oak.

— With bars

This is a press with many grates, between which bags of chopped apples or grapes are placed. The number of such gratings can even reach 20. However, using such a press is not so convenient, since it takes a lot of time to fold all 20 layers.

Procedure for making a press

To make it easier to make a grape press with your own hands, you can take a drum from an old washing machine. Holes are drilled in the drum for attaching wooden planks. Drainage strips can be sawn from bars or use parquet planks.

Drawing of a press based on a car jack

A “pancake” is made from the same strips, which will act as the bottom of the basket. A block is screwed onto the “pancake” across the slats, which will provide a gap between the basket and the metal barrel.

Next, a U-shaped frame is made from a metal profile. It is important that the profile thickness is at least 3 mm. The frame is concreted in the ground, ensuring its stable position. If you need to make a mobile device, legs made of metal pipes are welded to the frame.

A “pancake” made of stainless steel or cast iron is installed on the frame crossbar, which acts as a press. To fix the “pancake”, a hole is drilled in the frame. A lever or handle is installed on the press. Further turning the handle, the press will lower into the basket.

The barrel is installed at the base of the frame on a pallet, for example, in a basin. A hole is made in the basin into which the hose is inserted. The juice will be drained through the hose into a receiving container.

It is also necessary to make a wooden shield that will cover the grapes loaded into the basket. This completes the process of making a homemade press.

What volume of press basket should I choose?

Mainly, all juice presses differ from each other only in the volume of the barrel and the principle of operation. The volume of the barrel only determines how much juice you will squeeze out at one time. The cycle of one spin is 5-10 minutes. The juice yield is 50-70% of the barrel volume. Therefore, you should choose a press based on how much juice you plan to make.

1) As a souvenir

The VP-075 press is suitable for squeezing several glasses of juice. This wooden press for apples and grapes is good as a gift or souvenir. And it will also decorate your kitchen. After all, natural wood always adds comfort and warmth to a home.

Buy a 0.75 liter screw press

2) For the kitchen

If you do not plan to prepare a lot of juice, but just want to treat yourself to delicious juices in the summer, then a 3 liter VP-3 or VP-5 (5 liter) press will be enough for you. This press takes up little space and can be freely used in the kitchen.

Buy a 3 liter screw juice press

3) For the dacha

If you want to prepare 10-20 three-liter jars for the winter, then a screw press for grapes and apples or a hydraulic press for squeezing juice for 10-12 liters will be enough for you.

Buy a hydraulic juice press for 12 liters

4) For the garden

If you have a large garden, you plan to prepare a lot of juice for the winter and supply wine, then in this case it is better to choose a 20-30 liter juice press. For one extraction you will receive 1 bucket of juice.

Buy a hydraulic juice press for 26 liters

5) For small production

If you are going to make juice for sale or you have a huge family, then you need a press with a capacity of 50 liters or more. With such a press you can squeeze out more than 200 liters of juice per hour.

Buy a hydraulic press for 50 liters

When choosing between a screw press and a hydraulic press, you need to consider the following factors:

1) Screw presses for squeezing juice with a barrel volume of up to 10 liters; when squeezing juice, it is enough to hold the frame with one hand and rotate the screw with the other. A screw press with a volume of 10-20 liters or more must be fixed with 4 screws to a fixed base so that it does not rotate. It is enough to place the hydraulic press on the edge of the table above the container where the juice will be drained.

2) With the help of a hydraulic press, you can create more force using a jack, therefore, more juice output. However, it is necessary to place planks under the jack as the piston moves in order to squeeze out the apple mass to the end, since the piston stroke is not enough for the entire height of the barrel, and the jack handle begins to rest against the edge of the barrel.

3) Using a screw press, the pressing process occurs in one step.

4) It is physically easier to work with a hydraulic press than with a screw press

Berry press

Small presses with a barrel capacity of 3-5 liters are better suited for squeezing juice from berries. Since it can be problematic to collect enough berries for juicing. In this case, many customers purchase, for example, a 30-liter hydraulic press and an electric chopper for apples, and additionally take a 3-liter screw press for berries.

Press for apples, fruits and vegetables

Any press is suitable for squeezing juice from apples; you should choose a press based on how much juice you plan to make.

Grape press

To squeeze grape juice, you usually buy a 10-20 liter screw press, of course it all depends on your harvest, but if you grow several buckets of grapes every year, then a VP-5 screw press will be enough for you.

Any press can crush grapes and apples with seeds without compromising their integrity. However, in order to use the press, preliminary preparation of the raw material is necessary, namely crushing (grinding). For this purpose, there are special crushers and shredders for fruits and grapes.

Read about their types, operating principles, pros and cons here: Which chopper for apples and grapes should you choose? - read here

Introduction

You can, of course, squish grapes in a bowl with your hands and feet the old fashioned way, or even use a recycled washing machine. But such methods have a number of disadvantages:

- tiring

- less effective

- not always aesthetically pleasing

“You need health for this! Or good helpers!” (c) Nikolay Kurdyumov

It is better to use specially designed devices. What is more suitable - crushers or presses? The table below will give you a little idea about this.

| Crusher (crusher) | Press |

| Relatively easy to do yourself | Self-production is more difficult, but the efficiency is slightly higher |

| More budget options | The price is on average more expensive, but this is a price to pay for quality |

| Manual work is often expected | More automation |

| More compact | Less compact (on average) |

| Relatively easy to maintain, assemble and disassemble | It’s more difficult to care for, but it’s still not the most complicated mechanism for this. |

Based on the information above, you can make a preliminary conclusion about what is most suitable for you, and then we will move on to considering the advantages of specific varieties.