Metallurgy of ferrous metals Rolling technology (part 2 of 3)

- Preparation of ingots and billets for rolling

- Roll calibration

- Process control

- Technological schemes of rolling production at a metallurgical plant

- Bloom production

- Production of blanks

- Large-grade steel production

- Production of medium grade steel

- Production of small-grade steel

- Wire rod production

- Production of rails and beams

- Special purpose mills

- Technical and economic indicators of the operation of long rolling mills

- Production of plate steel

- Production of wide strip steel

- Production of cold rolled sheets and strips

- Production of rolled products from metal powders

- Technical and economic performance indicators of sheet rolling mills

Large-grade steel production

Blooms with a cross section of 300×300 mm and a length of 6 m are used as the source material in large-section rolling mills (Fig. 6). Blooms from the warehouse are loaded by crane onto the receiving grids of 1 large-section mill 500. From the receiving grids, the blooms one by one fall onto the loading roller conveyor of 2 heating ovens. To heat the blooms, 3 methodical furnaces are installed.

Blooms heated to rolling temperature are delivered to the feed roller table 4 of the roughing group of mill stands, consisting of four working stands with horizontally located rolls. The nominal diameter of the first four working stands is 630 mm, the remaining five are 530 mm.

If necessary, the bloom is turned over in front of the roughing group by a turner. After rolling is completed in the roughing group of stands, the roll is supplied to trim the front end with scissors and is fed into subsequent working stands. All working stands are located in three parallel lines - the first line has five working stands, the second - three and the third - one.

The transfer of rolled material between the working stands is carried out by roller tables, and between parallel lines of stands - by a chain slapper 5. In each line of working stands, tilters are installed, allowing the rolled material to be turned at 45 or 90°.

On a large-section semi-continuous mill 500, I-beams and channels No. 10–20, angles No. 8–16, a circle with a diameter of 50 to 120 mm, a square with a cross-section from 50×50 to 100×100 mm, etc. are produced. Depending on the cross-sectional area, the finished product rolled products are obtained after a group of (roughing) working stands on the first, second or third line. All rolled products are cut with 6 circular saws into lengths from 6 to 24 m, and a stamp is applied to each strip. The rolled stock, cut into measured lengths, is transferred to refrigerators and, after cooling, is subjected to straightening on roller straightening machines and presses, cold cutting, and laying.

Rice. 6. Layout of large-section mill equipment

The average annual productivity of the mill is 1 million tons of finished steel.

Application of simple long products

Rolled steel products are used in all areas of human activity. Without it, many technological processes and productions are impossible. It is used to produce shafts, gears, axles, fasteners and other types of parts and mechanisms. It is used to make blanks for other metallurgical products and forgings.

Shaped products

This type includes long hollow metal elements. They are in demand in civil and industrial construction, as well as in almost all areas of industry and production. The cross section of the products has a solid non-convex geometric figure.

Assortment of shaped rolled products:

Corner profile. L-shaped steel profiles with equal or different sides. They are used in construction for the construction of various structures, as well as strengthening walls and ceilings. The material is also used in the engineering industry, in the construction of carriages and ships.

Steel channel. Rolled products with U-shaped profile. Its main side is longer than the sides. Used to create frames and structures, for covering roof purlins. It is often combined with concrete to create durable structures.

I-beam Beam profile with H-shape. Available in standard, wide-shelf and column versions. The edges of the shelves can be parallel or inclined. Characterized by high strength. I-beams can withstand very high vertical and horizontal loads. Carbon, low-alloy steels are used for manufacturing. It is used in the construction and installation of overhead tracks, shafts, bridges, balconies. The products bind and strengthen structures and are used as a basis for door and window openings.

Production of medium grade steel

A square billet with a cross-section from 150×150 to 200×200 mm and a length of up to 12 m is used as a source material in a medium-grade mill. After inspection and cleaning, the workpieces are loaded by crane onto receiving grids 1 (Fig. 7). To heat the workpieces, methodical heating furnaces 2 are installed. The workpieces heated to the rolling temperature are pushed one by one onto a roller conveyor and transported to the rolling mill. The rolling mill provides for the rolling of billets directly after NZS.

Rice. 7. Equipment layout plan for a continuous medium-section mill

In this case, the workpiece is heated in furnace 3 located in the rolling mill line, enlarged on butt welding machine 4, heated in sectional furnace 5 to 1250 °C and then follows the roller conveyor for rolling. Rolling mill 450 consists of roughing I, intermediate II and finishing III groups of working stands. The roughing group consists of six two-roll stands, two of which have vertical rolls.

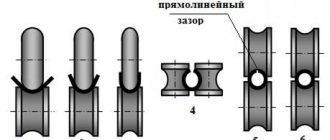

When rolling beams, channels and strips, a horizontal arrangement of rolls in combined working stands is used. On the rolls of the working stands, streams of box gauges of the rhombus-square, oval-square system and gauges for forming beams, channels, and angles are cut. The finished product is cut at a speed of 3–15 m/s using flying shears 7. The strip is wound into a roll weighing up to 3 tons by two alternately operating coilers 8 and transferred to a conveyor type conveyor 6 for cooling and tying.

Long products are cut with flying shears into lengths corresponding to the width of the refrigerator. After cooling, the rolled products are straightened, cut into lengths using scissors or circular saws (beams, channels), marked and sent for packaging.

The annual productivity of the mill is 1.4 million tons of finished steel.

Rolling of tool steel

Steel grades X12, X12M, as well as high-speed steel, belong to the ledeburite class. The ledeburite eutectic of this steel melts at low temperatures (about 1200°C), and in high-speed steel at temperatures above 1300°C. During rolling, the ledeburite eutectic is destroyed; in this case, ledeburite carbides behave like foreign inclusions, forming a line structure. For this reason, the heating temperature should not exceed 1140–1160 °C; the temperature at the end of rolling must not be lower than 850 °C.

Ingots of high-chromium tool steel are subjected to forging, although rolling is also possible. The billet for long products is deformed according to the same regime as high-speed steel.

High-chromium tool steels are prone to the formation of quench cracks, so they should be subjected to slow cooling after rolling and forging under the same conditions as high-speed steel.

HVG steel is used for the manufacture of measuring gauges and other precision instruments, since it has the property of little change in its dimensions after heat treatment. Long instruments are also made from it. This steel is sensitive to the stresses generated by heating, which must therefore be carried out quite slowly. This equally applies to the cooling rate, which must be slow to avoid the formation of cracks.

Due to the high carbon content, the heating temperature of this steel should be quite low: the steel is prone to the formation of carbide segregation and a carbide (cementite) network. To prevent the formation of a cementite network, the temperature at the end of rolling should be kept as low as possible with mandatory rapid cooling to 650 °C.

Production of small-grade steel

The small-section mill 250 uses a square billet with a cross-section of 80×80 mm and a length of 12 m as the source material. From the billet warehouse, the billets prepared for rolling are loaded by crane onto the receiving grids of the mill 250. From the loading grids, the billets are collided one by one onto a receiving roller table, which are transported to methodical furnace.

Billets heated to rolling temperature are pushed out of the furnace onto a roller table and fed into a continuous roughing group of stands. If necessary, the front end of the workpiece is trimmed on flying shears installed in front of the roughing group of the mill. The rolls are cut into strands of box gauges of the square-oval-circle, square-diamond system and gauges for rolling angle steel.

The mill uses an individual drive of the rolls of each working stand from a separate electric motor. The intermediate and finishing groups of the mill include working stands with vertical rolls, which eliminates the need for turning the rolls. On a small-section mill 250, round steel with a diameter of 10–30 mm, a square with a side of 8–27 mm, a strip with a thickness of 2–4 mm and a width of 12–70 mm, and angles up to 50×50 mm are rolled.

After rolling in the finishing group of stands, the finished steel is supplied to coilers or in the form of bars to a double-sided cooler. Four winders and flying shears are installed behind each finishing group of stands. Round steel with a diameter of up to 25 mm and strip steel are wound into coils, tied and transferred to a hook conveyor.

The rest of the rolled stock is cut into rods using flying shears and supplied to a double-sided refrigerator 125 mm long. After cooling, the rolled products are inspected, sorted, cut into lengths, packaged and sent to a warehouse.

The annual productivity of small-section mill 250 is 650 thousand tons.

Rolling of transformer and dynamic steel

Transformer and dynamic steel are made in the form of sheets with a thickness of 0.2 to 2.0 mm. Sheet widths are 700, 750 and 1000 mm, lengths are 1500 and 2000 mm. Dynamic steel is used for the manufacture of electric motors and generators, transformer steel is used for power and instrument transformers and radio equipment. This steel operates under alternating current magnetization reversal conditions and must have easy and good magnetizability, i.e., low coercivity (retention) force and good initial magnetic permeability. The properties of transformer steel depend on its carbon content, as well as on the structure of the steel.

The properties of steel are higher, the less carbon and impurities there are in it and the coarser its structure. These two features determine the technology of hot processing of transformer steel. The ductility of steel depends on the silicon content; it decreases as it increases. The average coefficient of longitudinal deformation when rolling ingots into 8×260 mm strip is 1.35. Rolling with such reductions is possible due to the heating of the ingots to high temperatures: for transformer steel up to 1300 °C, for dynamic steel up to 1280 °C. The duration of heating of ingots is 4.5-6 hours. Rolling of sheets from transformer and dynamo steel is carried out on two-roll mills on rolls made of bleached cast iron.

Rolling of sheets with a thickness of 0.35 and 0.5 mm is carried out in three heating stages.

When rolling sheets, transformer steel is heated to a temperature of 1240–1260°C, which is not used when rolling thin sheets of other steel, including dynamo steel. Such high heating has two goals: burning out carbon and obtaining a coarse-grained structure, which has a positive effect on the properties of steel.

The temperature at the end of rolling transformer steel sheets should be no lower than 800–900 °C. The higher the temperature at the end of rolling, the better the properties of this steel.

After rolling, transformer steel sheets are annealed at 800–900 °C. In this case, carbon is further removed from the steel, work hardening is reduced and the grain of the steel increases. All this improves its magnetic properties.

In recent years, transformer steel sheets have begun to be produced on continuous mills.

Cold-rolled transformer steel is also produced, which, as a result of special processing, is obtained with very high magnetic properties along the rolling direction. The best properties are obtained in grain-oriented steel, which has a certain orientation of the crystallographic axes.

When cold rolled, transformer steel has different plastic properties, which depend on the silicon content in it. With a high silicon content, transformer steel cannot be rolled at room temperature, since it is brittle.

Wire rod production

A square billet of 60×60 mm, 12 m long, is used as a source material on a wire mill 250. After inspection and cleaning, the billets are fed by crane to the loading grids of the rolling mill, from which one at a time they are supplied to the receiving roller table of the heating methodical furnace.

The loading and promotion of workpieces in the furnace is carried out using a pusher; The delivery of workpieces heated to 1180–1200 °C is ensured by an ejector. The distribution of workpieces among the gauges of the first roughing stand is carried out by a drum-type distribution device. After the workpiece distributor, shears are installed, with which, if necessary, the front end of the workpiece is cut off or the workpieces are cut into scrap in case of an accident at the mill. The 250 continuous wire mill consists of three groups of stands: roughing, intermediate, finishing.

The rolls of the first two stands of the roughing group have grooves of draw-out box gauges, which ensure good scale removal. On the rolls of the remaining stands of the roughing group, the gauges of the oval-square, rhombus-square system are made. On the rolls of the intermediate and finishing groups of stands, grooves of gauges of the oval-square system are cut.

An oval roll is inserted into the rolls of the last finishing working stand, which, after compression, takes the shape of a circle with a diameter of 6.5 to 10 mm.

The finished steel is supplied to the coilers at a speed of 12–30 m/s through water-cooled pipes.

Behind each finishing group of stands there are two coilers. The coils of wire rod are transferred by a plate conveyor to the dumping device and hung on the hooks of the hook conveyor. After cooling, the coils of wire rod are removed from the hook conveyor by a coil removal machine, tied in two places and delivered to the baling machine. On modern specialized wire mills, the rolling speed in the last working stands is ≥ 60 m/s.

The metal temperature after the last stand is 1000 °C.

In order to reduce scaling after rolling and obtain a fine-grained sorbitol structure, wire rolling mills are equipped with devices for accelerated cooling of the wire rod before coiling.

The annual productivity of the wire rolling mill is 700–800 thousand tons.

Rolling high speed steel

High-speed steel is cast into ingots weighing 100–1000 kg. Heating of high-speed steel ingots and workpieces, due to their low thermal conductivity, almost three times less than that of iron, and sensitivity to cracking, is carried out quite carefully, especially if the metal was not annealed before heating. The heating duration must be sufficient to ensure uniform and complete heating of the ingots and workpieces.

The ductility of high-speed steel increases with increasing temperature, which when heated should not exceed 1200–1230 °C. At higher temperatures, grain boundaries melt. The temperature at the end of rolling should not be lower than 900 °C.

At most plants, ingots of relatively small mass (200-400 kg) are rolled. As their mass increases, rolling becomes more difficult. The deformation of a high-speed steel workpiece from ingots weighing 200 kg is carried out according to a calibration, which consists of six box, twelve round and two square gauges. This combination of gauges, as well as the use of intermediate heating, makes it possible to obtain high-speed steel blanks without surface flaws.

Round gauges are rational when rolling low-plasticity steel, since their use reduces the risk of formation of flaws on the surface. At the same time, when rolling ingots in round calibers alone, the formation of internal cracks is possible, as during forging. The combination of box gauges with round gauges best solves the problem of obtaining a workpiece without any defects.

High-speed steel ingots are rolled in one or two preheats, the second after the eighth. Rolling is carried out at a speed of 1.0-1.5 m/s. At high rolling speeds, gripping is difficult, especially in the first calibers.

Rolling of sections (round, square, rectangular) of various sizes is carried out on medium-, small-section and wire mills. A workpiece with a cross-section of 80×80 or 50×50 mm weighing 60 kg is rolled. Due to a noticeable increase in deformation resistance and a decrease in the ductility of high-speed steel with decreasing temperature, rolling at all stages should be carried out at maximum temperature. The temperature at the end of rolling must not be lower than 900 °C. When rolling small sizes, a square billet of 40×40 mm, after cutting into pieces, is subjected to intermediate heating. In this regard, mills intended for rolling high-alloy steel are equipped with furnaces for heating semi-rolled products.

Rolling of a workpiece with a cross-section of 80×80 mm into a square with a side of 40 mm is carried out at a speed of no more than 3.0 m/s. As the cross-section decreases, the gripping conditions improve, which makes it possible to increase the rolling speed. The production of high-speed steel wire rod is carried out at a fairly high rotation speed of the rolls.

Cooling of high-speed steel after rolling is an important operation of the technological process: with rapid cooling, the steel is prone to the formation of quenching (cold) cracks. Therefore, it is subjected to slow cooling or isothermal annealing. Slow cooling of small grades and wire rods is carried out in thermostats, wells or furnaces.

Production of rails and beams

The rail and beam shops produce railway rails weighing up to 75 kg per meter of length, I-beams up to 400 mm high, channels, corner profiles up to 230×230 mm, sheet pile profiles and round bars with a diameter of 120–350 mm.

The blank for the rail-beam mill is bloom. The mass of the bloom is 2–4 tons. Blooms are heated in methodical furnaces.

Blooms for rolling rails are heated to 1180–1200 °C. Through the end window of the methodical furnace they are delivered to the supply roller conveyor of the crimping stand. In the crimping stand, five passes produce a workpiece with a rough rail shape.

In the next three-roll rolling stand, 3–4 passes further reduce the cross-sectional area and bring it closer to the shape of the rail. The four working stands of the rail-beam mill are arranged in a line (linear diagram). The last working stand is a two-roll stand, in which the rolled stock is given its final shape in one pass. From one bloom, two rails 25 m long are obtained. Depending on the weight of the meter length, the rails are rolled in 12–14 passes.

On the outfeed roller table, the rails are cut by circular saws into 25 m pieces.

On the surface of the finishing gauge strand, indentations are made (letters and numbers), which form a mark: manufacturer's brand (letter), steel grade, year and month of manufacture, rail type (P43, P50,... P75), designation of the type of heat treatment (I - isothermal exposure). In addition, after cutting, the heat number is extruded on a stamping machine.

Rails cut into pieces undergo slow cooling in wells or isothermal exposure at a temperature of 450–500 °C. Next in the production line, the rails are subjected to heat treatment. The hardness of the rail head should be within HB 320–380. In the rail finishing department, the rails are straightened in a cold state, the ends are milled, and holes are drilled. The final operation is high-frequency hardening of the rail ends.

The annual productivity of the rail-beam mill is ~ 1.5 million tons.

Rolling of steel and alloys with high ohmic resistance

For the manufacture of all kinds of heating devices, elements and furnaces, alloys with high ohmic resistance and heat resistance at 1000–1400 ° C are required.

According to the chemical composition, steel (alloys) of high ohmic resistance are divided into two groups: nichrome, containing 55-80% N1 and 15-25% Cr; chrome-aluminum containing up to 7% Al.

Chromium-aluminum alloys are much cheaper than nichrome, do not contain nickel and, at a certain content of chromium and aluminum, have higher ohmic resistance and heat resistance. The permissible operating temperature for steel grade 1Х25УА reaches 1350 °C. Chromium-aluminum steels tend to form a coarse-crystalline structure. Depending on the cooling conditions after casting, the steel structure can be very different - from pronounced transcrystalline to coarse-crystalline equilibrium; it can also be mixed.

Deformed steels are prone to excessive grain growth. Alloys 1Kh25YuA and 1Kh17YuA have very high brittleness in the cold state at almost all sizes.

Due to the low temperature at which recrystallization begins, chromium-aluminum alloys have a relatively low resistance to deformation. They tend to widen greatly. From ingots weighing 1 ton, a billet is obtained by both forging and rolling. In some cases, the workpiece has individual flaws, so they strive to obtain a round workpiece in order to be able to peel it to remove surface defects. The workpiece is rolled into wire rod according to the usual roll calibration for high-quality steel.

Special purpose mills

Special-purpose rolling mills produce railway wheels and tires, balls, rotating bodies of various shapes, gears, bent profiles, etc.

The production of wheels includes the following technological operations. Ten-twelve-sided ingots are cut into parts corresponding to the mass of the wheel and divided into separate blanks.

The separation of notched ingots is carried out on a hydraulic horizontal press with a force of 3 MN.

To produce wheels with a diameter of 950 and 1050 mm, the mass of the workpiece should be approximately 500 kg. Heating of billets to a temperature of 1200–1250 °C is carried out in continuous rotary furnaces.

Descaling is carried out using rotating chains and subsequent sedimentation on a hydraulic press. On the same press, the workpiece is calibrated by diameter, which is achieved by settling in the rings, and the central hole is pierced. The workpiece is moved using a floor-mounted rotating machine with a lifting capacity of 7.5 kN.

After the central hole is pierced, the workpiece is transferred to a hydraulic press with a force of 70 MN, on which the hub, disk and rim of the rough wheel are stamped.

Next, the wheel rolling mill rolls out the disk, rim and rolls out the wheel flange. The final operation is carried out on a hydraulic press with a force of 25 MN. During this operation, the wheel receives its final shape. This operation is combined with stitching two holes on the disk and branding.

Subsequently, the wheel is subjected to isothermal aging in well-type furnaces. The purpose of this operation is to eliminate the possibility of flake formation.

After cooling, the wheels are inspected, sorted and tested for hardness. Subsequently, the wheels are machined on metal-cutting machines, the rim and flange are hardened, the wheels are tempered in well furnaces, hardness testing and sorting are carried out. The annual productivity of the workshop with a wheel rolling mill is ~350 thousand wheels. High-performance technology for the production of balls of different diameters includes the following operations.

The initial cylindrical billet, heated to a temperature of 1000 °C, is fed into a two-roll rolling mill with screw gauges.

The workpiece is set along the axes of the rolls, rotating in one direction, and, rotating, moves translationally. The workpiece is cut with ridges of screw gauges, the cut parts are crimped and get the shape of a ball. The mill's productivity reaches 150 balls per minute. Round profiles of variable diameter along the length of the rod are rolled on a three-roll cross-helical rolling mill.

The axes of the rolls rotating in the same direction are rotated relative to the rolling axis by 3–6°. The billet heated to a temperature of 1000 °C is placed into rolls.

Rotating around its axis, the workpiece undergoes translational movement along the rolling axis. According to a given program, the rolls are brought closer to the workpiece axis or moved away from it. The approach and retraction of the rolls from the axis of the workpiece is carried out by a hydraulic pressure mechanism.

Cross-helical rolling is used to produce car axle shafts, blanks for bicycle bushings, etc. In principle, almost all bodies of rotation can be obtained. The precision of manufacturing parts is high, which allows minimizing waste of metal into chips during further machining.

Gears and gears are produced by hot rolling on a rolling mill with rolls, on the barrel of which teeth of the required profile and module are made. When rolling a workpiece heated to 1000°C, the teeth of the rolls are embedded in the body of the workpiece, forming cavities, and the displaced volume of metal fills the cavities in the rolls, forming tooth heads.

When producing gears and gears by rolling, great savings in metal are achieved during finishing machining.

Domestic industry has mastered production and produced rolling mills for thread rolling and the production of pipes with ribs on the outer surface.

Thin-walled bent profiles are widely used in mechanical engineering and construction. Thin-walled profiles with a complex cross-section are not economically feasible to produce by rolling from a solid billet, and in some cases it is impossible.

The production of thin-walled profiles is carried out on multi-stand roll forming mills.

Obtaining a profile of complex cross-section is achieved by gradual flexible sheet material in two-roll working stands. On the barrel of rolls, gauges are cut in which the sheet is sequentially bent until the finished profile is obtained. The exit speed of the profile from the last stand is up to 3 m/s. The thickness of the sheet material does not change during the profiling process.

The technological process includes the following operations. The strip roll is installed on the unwinder and, after bending the end, it is fed into the straightening machine. For the manufacture of profiles, a strip with a thickness of 0.5 to 20 mm is used. The next operation involves cutting the front end of the strip and welding it to the end of the strip of the previous roll. Thus, the process is carried out continuously.

Between the welding sections of the strip ends and the continuous roll forming mill, a loop strip storage is provided, from which the strip is supplied to forming during welding. A continuous roll forming mill consists of 20 or more working stands, in which the desired profile is formed due to gradual elastoplastic bending.

When changing the profile shape, the forming rolls are replaced. The profiles are cut into measured lengths by flying shears (saw) and are given their final shape in a straightening mill.

Before forming, a lubricant is applied to the strip in order to improve the quality of the profile surface; the finished profile is oiled before stacking for the purpose of preservation.

Rolling of chromium-nickel corrosion-resistant steel

Chromium-nickel corrosion-resistant steels have some features that in one form or another affect the technological process of their manufacture.

- Chromium-nickel corrosion-resistant steel has a reduced thermal conductivity, approximately 3-3.5 times less than that of carbon steel. Reduced thermal conductivity necessitates a longer heating time for this steel before rolling; steel is little sensitive to thermal stresses arising during heating, and therefore cracks do not form in it even at high heating rates.

- Steel 07Х18Н9Т has increased resistance to deformation, which increases as the chromium and nickel content increases. The deformation resistance of austenitic corrosion-resistant steel is approximately 1.5 to 2.0 times greater than the deformation resistance of carbon steel under comparable conditions. As the rolling temperature decreases, the relative difference between the deformation resistance of austenitic corrosion-resistant steel and carbon steel increases markedly. This is explained by the fact that the former is prone to hardening, starting from fairly high temperatures, because the recrystallization process at these temperatures occurs at a low rate.

- Austenitic steel is characterized by large broadening, which is 1.2–1.5 times greater than that of carbon steel under comparable conditions. This circumstance is of particular importance when rolling sections.

- Depending on the content of chromium, nickel and other elements, a ferrite phase is detected in the bulk of austenite of chromium-nickel corrosion-resistant steel grades. The two-phase structure to a certain extent affects the plastic properties of steel. Experience has shown that the two-phase structure of steel grades 07Х18Н9Т, Х23Н23 and Х23Н18 has relatively little effect on their plastic properties under the conditions of rolling sections, but greatly reduces the plastic properties of steel under the conditions of pipe production on piercing mills, where deformation conditions are more severe.

- The ductility of corrosion-resistant steel depends to a very large extent on the quality of the ingots. Practice shows that steel of the same grade, in particular the most widely used steel 1Х18Н9Т, has different plastic properties depending on the quality of the ingots (the method of their smelting and deoxidation, the purity of the charge materials used, etc.). The ductility of steel increases with increasing heating temperature. Thus, steel 07Х18Н9Т can be heated up to 1230 °C. To roll long profiles, it is customary to heat 07Х18Н9Т steel ingots to 1210–1220 °C.

Rolling of large mass ingots is carried out on blooming and slabs. Large ingots are placed hot in heating wells. Rolling is carried out at reduced reductions. The number of skips, compared to the deformation of ordinary steel, increases by 30-50%, which is mainly explained by the high resistance to deformation of this steel.

Slabs of corrosion-resistant steel are thoroughly cleaned on all four sides. Leaving defects on the side edges is unacceptable, since during rolling this leads to the formation of a torn edge on the strip. Successful rolling of such steel is possible if the required temperature range is observed. When rolling at relatively low temperatures, as already indicated, the deformation resistance of corrosion-resistant steel increases noticeably. This greatly complicates the deformation process and leads to a significant number of undercuts. The temperature at the end of rolling should be about 950–1000 °C. To ensure such a high temperature, the slabs are heated to 1240–1260 °C and their uniform heating is achieved.

To preserve the heat of the strip, it is advisable to roll with large reductions, cool the rolls less intensively, and use high rolling speeds.

During continuous rolling of corrosion-resistant steel, the state of the front end of the strip, which tends to bend upward the more, the lower the rolling temperature, has a very significant influence on the process. Bending the front end complicates deformation, leads to a large number of undercuts, and in some cases even to the binding of the rolls. Therefore, conditions must be created under which the bending of the front end of the strip would be insignificant.

Particularly high demands are placed on the surface of stainless steel sheets, therefore, at all stages of the technological process, certain conditions must be observed to ensure that the desired surface is obtained.

Hot rolled coils or sheets are pickled and then sent for cold rolling. Cold rolling is carried out on single-stand four-roll or three-stand continuous mills.

Technical and economic indicators of the operation of long rolling mills

Metal consumption

The rolling process is accompanied by metal losses in the form of scale, trimmings, chips formed during stripping, milling, drilling, etc.

Metal consumption for the production of finished products for a given rolling mill is estimated by the consumption coefficient. Let us determine the consumption coefficient when rolling blooms and slabs.

The trim from the head and tail parts of blooms and slabs reaches 17.5%, the loss of metal in the form of scale is 3%. Consequently, the mass of finished slabs is 20.5% less than the mass of ingots received for rolling and amounts to 79.5%; the consumption coefficient for the production of blooms (slabs) is 100:79.5=1.26.

Metal consumption coefficients in the production of long products are given below:

| Rolling mill type | Metal consumption coefficients |

| Rolling mill: rail-beam | 1,05–1,06 |

| Rolling mill: large sections | 1,1 |

| Rolling mill: medium grade | 1,075–1,087 |

| Rolling mill: small sections | 1,075 |

| Rolling mill: wire | 1,033–1,034 |

Electricity consumption

In long rolling mills, energy consumption depends on the degree of reduction in the cross-sectional area (draw) of the workpiece, the chemical composition of the steel, the design of the drive line and the working stand. Below are the average energy consumption values per 1 ton of rolled steel, MJ/t.

Average energy consumption per 1 ton of rolled steel, MJ/t:

| Rolling mill type | Electricity consumption per 1 ton of rolled steel, MJ/t |

| Rolling mill: rail-beam | 234 |

| Rolling mill: large sections | 108-198 |

| Rolling mill: medium grade | 126-162 |

| Rolling mill: small sections | 180 |

| Rolling mill: wire | 252 |

Heat consumption when heating billets on rail-beam, large- and medium-grade mills averages 210,000 MJ per 1 ton of billets. When heating billets in furnaces of small-section and wire mills, up to 1510 MJ is consumed per 1 ton of billets.

Roll consumption

During the rolling process, intensive wear of the roll surface occurs. To restore the shape of the calibers, the rolls are subjected to regrinding, during which a certain layer of the roll surface is removed and the diameter of the barrel is reduced. The permissible reduction in roll diameter is as follows: for blooming and slabs 12–16%, for section mills 8–10%.

After the permissible number of regrinds, the rolls are sent for remelting. The ratio of the mass of rolls used in a certain period of time to the mass of metal rolled over the same period is called specific roll consumption. For rail-beam and large-section mills, the specific consumption of rolls is about 2–3.5 kg/t, for small-section and wire mills 0.3–0.4 kg/t. Water consumption for cooling rolls and bearings with textolite liners on section mills is 600–700 m3/h.

Any questions? Contact us by phone from the page - Contacts

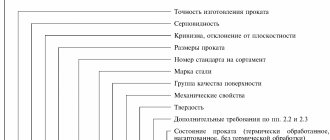

Assortment

The most common type of rolled products are long profiles. Section steel is divided into large-, medium- and small-grade. Accordingly, rolling mills are divided into large-, medium- and small-section. In table Figure 14 shows the assortment of section mill profiles.