Hello, Ivan Sergeevich.

Indeed, at first glance, both gearboxes are similar - connecting dimensions, there are 2 pressure gauges, and only the color of their housing differs. But this is only at first glance.

Oxygen is an explosive gas. When combined with oil vapor, it forms an explosive mixture. During production, many requirements are placed on oxygen reducers.

So, what is the difference between an oxygen reducer and a carbon dioxide reducer:

- The oxygen reducer is designed for higher inlet pressure (in the cylinder) than the carbon dioxide reducer. Oxygen is stored in compressed form in cylinders with a pressure of up to 200-225 atmospheres. For carbon dioxide, a cylinder of 100 atmospheres is sufficient, since it liquefies already at 70-80 atmospheres.

- The oxygen reducers are equipped with pressure gauges at the inlet of 25.0 MPa and at the outlet of 2.5 MPa.

- On the carbon dioxide reducer there is a pressure gauge at the inlet of 16.0 MPa and at the outlet at 1.0 MPa.

- In oxygen gearboxes, the presence of oil vapor inside the housing must be completely excluded. There are no such requirements for carbon dioxide gearboxes.

- The safety valves of the gearboxes are set to different pressures. Carbon dioxide is usually 9-10 atmospheres, oxygen is 16.5-18 atmospheres.

1ou › Blog › Technical gases for electric arc welding: cylinders, regulators

Are you steaming with a cylinder of carbon dioxide/argon/Ar+CO2 welding mixture for welding? dream of jet transfer, but are still looking for mixers and 10 liter cylinders? All the answers are here.

So, gas shielded electric arc welding knows three types of main gases that can be found in almost all major capital cities: - carbon dioxide (CO2); — argon (Ar); — welding mixture Ar+CO2 Everything else is either very specific or stupidly expensive (helium He).

The applicability of gases is well described on the Internet, but if it’s simpler, cook fences from chernukha => carbon dioxide. Cook in your garage: for TIG - argon, for semi-automatic - welding mixture.

What cylinders should I use? 5 liters? 10 liters? 40 liters? 50?

The question, as far as I understand, is really sick and there is no understanding of the situation with the cylinders. Let's first decide on the mass and volume of the cylinder. Every time, beginners and savvy people prefer to buy a 10 liter bottle and search the forums about the subsequent refilling of a 10 liter bottle. Advanced guys look for and buy 20 liter cylinders and in the same way ask “where to fill them?” The truth of life is that the sale of technical gases is aimed at the mass, industrial buyer and in the vast majority of cases this is a 40 liter cylinder. The structure of most gas stations is built specifically for 40 liter cylinders: they are promptly refilled and (or) exchanged. There is one exception to this rule - carbon dioxide from fire extinguishers used by firefighters. All EMERCOM (VDPO) refills are designed for small cylinders and carbon dioxide fire extinguishers.

Thus, if you want to work permanently with argon or welding mixture => your choice is definitely a 40 liter cylinder. If you want to be mobile and the availability of argon/welding mixture is not critical, then check with local firefighters whether it is possible to refill 10 liter carbon dioxide cylinders, and if the answer is yes, then buy 10 liters. with a flat bottom.

Into an oxygen carbon dioxide cylinder?

The question is: is it possible and safe to fill carbon dioxide into an oxygen cylinder?

at one time, I was also concerned about this issue, I inherited oxygen cylinders from my father-in-law (he was a gas welder in the past), the solution was at the carbon dioxide plant, they replaced them with carbon dioxide ones, there was some insignificant amount for re-certification, the old ones were there, I think it’s possible to repaint them, re-certify, and I think our people will start using fire extinguishers, and it’s normal

| ✅Special offer✅ - for all AL-KO and STIGA electric garden equipment, a 25-meter extension cord as a GIFT! Call one of the numbers and order a promotional kit, (093) 316-03-61. Don't miss your chance! |

Fire extinguishers are not at all cool. How long will the cylinder last?

and no carbon dioxide cylinders were issued. They were on oxygen. but a different color. Oxygen is filled under much higher pressure than U/C, so fill it up without fear. In our city I know places where cylinders are not refilled, but replaced. and no one really took any money even for re-certification. With gas cylinders, such as oxygen, acetylene, etc. everything is more serious there, of course.

What is the difference between an oxygen cylinder and a carbon dioxide cylinder? — Machine tools, welding, metalworking

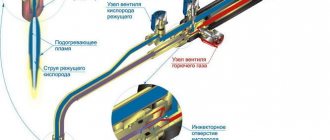

For normal gas welding, the main equipment of the welding station is equipped with devices that provide a decrease and subsequent stabilization of the pressure of carbon dioxide coming from the gas cylinder. In our case, such a device is a carbon dioxide reducer. We'll talk about choosing a good gearbox and its correct configuration.

Carbon dioxide cylinder

Good afternoon I have an oxygen cylinder, I want to fill it with carbon dioxide. It needs to be painted black. Question: is it possible to use a brush or a spray gun? What else needs to be applied. Yellow inscription CARBON ACID, yellow frame where is it branded?

But here they just change it.

LVN wrote: Good afternoon! I have an oxygen cylinder, I want to fill it with carbon dioxide. It needs to be painted black. Question: is it possible to use a brush or a spray gun? What else needs to be applied. Yellow inscription CARBON ACID, yellow frame where is it branded?

It should be taken into account that the “oxygen” and “carbon dioxide” are structurally different. The difference is in the valves; CO2 has a tube.

BelaZZ with what kind of “tube”?

You cannot arbitrarily choose the purpose of high-pressure cylinders; a carbon dioxide cylinder is really different.

a carbon dioxide cylinder is really different and the requirements for it are lower than for oxygen (argon, nitrogen). Sometimes the listed cylinders can be recertified as carbon dioxide.

BelaZZ wrote: The difference is in the valves, CO2 has a tube.

you are confusing it - with a tube it is for fire extinguishers, 40l carbon dioxide is the same as oxygen and the valve is the same except the cylinder is of a different color.

Warrax wrote: the carbon dioxide cylinder is really different.

Physically, 40L cylinders are the same and during certification they are checked for the same pressure. whether O2 or CO2, whether argon or helium, the latter has a different valve.

johnlc wrote: you are confusing it - with a straw it is for fire extinguishers, 40l carbon dioxide is the same as oxygen and the valve is the same, except the cylinder is of a different color.

DartWelder wrote: with what kind of “tube”?

Helium cylinders and their features

The main vessels for transporting and storing compressed gases are cylinders, the parameters of which, as well as the basic provisions for manufacturing and operation, are described in GOST 949-73. Cylinders with a working pressure of up to 200 kgf/cm2 are made of carbon or alloy steel (depending on the gas), and in addition to helium, they can be filled with a wide range of gaseous substances: nitrogen, oxygen, xenon, methane, chlorine and some others, a full list of which can be found read directly in GOST.

Externally, cylinders for compressed gases have practically no differences. These are cylindrical containers made of steel, manufactured (with rare exceptions) by cold rolling to eliminate welds and other stress raisers. For the same reason, the cylinders have a round bottom - to give them stability, a so-called shoe is welded at the bottom. Containers of a certain volume, for example, some ten-liter ones, do not have a shoe and for their operation it is necessary to use stands. At the top of the cylinder there is a neck on which a valve specific for each gas is installed.

“Mix” of gases for welding

In this case, the cylinder contains a mixture of argon and carbon dioxide in a ratio of 80 to 20%. They are presented in the form of gray containers. Often these cylinders are used for semi-automatic welding of non-ferrous and ferrous metals.

It is also worth clarifying that gas cylinders differ from each other and from the material of manufacture. There are steel cylinders and composite ones on sale today. It is important to understand that the strength, weight of the product, and, of course, its cost depend on the material.

Steel cylinders have the most affordable cost. However, they tend to rust quickly and should not be stored in direct sunlight. In addition, steel cylinders are quite heavy.

But composite cylinders are made of fiberglass and a plastic casing. The service life of such cylinders is noticeably longer compared to steel cylinders. In addition, gas in a composite cylinder will not explode. But the cost of such cylinders is quite high.

Why can't you fill other cylinders with helium?

At first glance, it may seem that all containers for compressed gases are identical and helium gas can be easily pumped, for example, into a carbon dioxide or oxygen cylinder, however, in practice this is not entirely true. There are a number of important factors that significantly distinguish helium cylinders from all others.

First of all, GOST 949-73 regulates the coloring and marking of helium cylinders. It is painted brown with the word “helium” written in white. However, such cylinders can be safely filled with other gases - helium is an inert gas and has high purity, its residual presence in the cylinder after bleeding will not greatly affect the purity of other gases, and there is no threat of explosion upon contact with other substances. At the same time, helium pumped into a cylinder from another gas without special purification will no longer have the proper purity, as a result of which it will be of little use for its intended use, and foreign odors from other gases may appear, which is unacceptable when decorating celebrations balloons.

Perhaps the most important difference between a helium balloon and others is the special valve. Valves such as KVB-53 and GSE are designed to maintain the operating pressure in the cylinder within 150-200 atm, blocking helium leakage from the container. Cylinders for other gases are equipped with other valves. Structurally, they are not designed to work with helium gas, and therefore leaks and losses are possible when working with balloons.

Source: tehgaz-dv.ru

Oxygen valves

Let's start with the valve VK-94-01 produced by TM BAMZ, as the most popular, as well as its modifications.

Valve VK-94-01 is a shut-off device and is designed for installation on a medium-volume cylinder. The valves can be used for compressed air, nitrogen and other non-aggressive gases. Oxygen valves are designed to operate in the temperature range from minus 50 to plus 60 C.

At the outlet, all VK-94 valves have an external thread G 3/4 V

For medium-volume cylinders, the valve VK-94-01 is designed, external thread at the inlet is W 27.8

For small volume cylinders the VK-94 valve is designed. 07. It has a W 19.2 thread at the inlet

For installation on the ramp manifold or in the gas network, VK-94 valves are designed. 03 with thread at the input G 1/2 V and VK-94 version. 10, it has a G 3/4 V thread at the input

There is also a new modification of the VK-94 valve. 20 with residual pressure valve

This valve is equipped with a residual pressure valve , which is installed in the outlet fitting and does not allow oxygen to be completely removed from the cylinder. The valve ensures the residual oxygen pressure in the cylinder within 0.5 atmospheres. This guarantees compliance with the requirements of clause 10.3.5 “Rules for the design and safe operation of pressure vessels PB 03-576-03” regarding the preservation of residual pressure in the cylinder.

The residual pressure in a conditionally empty cylinder is one of the necessary conditions that guarantees the purity of the gas in a filled cylinder. In the case of oxygen, this is also a guarantee of safe refilling; it means that the cylinder was not filled with foreign liquids and substances (for example, air, oil, water) at a time when it was not used for its intended purpose.

The valve can be used for compressed air, nitrogen, inert and other non-aggressive gases.

When filling the cylinder, an adapter (adapter) is used. The adapter is screwed onto the outlet fitting of the valve before filling the cylinder, and the residual pressure valve is forced to open. After this, the cylinder is filled through the adapter. At the end of filling, the cylinder valve is closed with the handwheel, the filling device and adapter are removed. The cylinder with the valve is transferred to operation.

The next valve is VK-1 produced by NZGA - Novogrudok Gas Equipment Plant, Rep. Belarus.

Valve VK-1 is a shut-off device and is designed for installation on a medium-volume cylinder. The valves are designed for oxygen, compressed air, nitrogen and other non-aggressive gases.

The valves are available in two versions - for medium and small volume cylinders. They differ in the thread at the inlet to the cylinder.

For medium volume cylinders there is a valve marked VK-1, external thread at the inlet W 27.8

For small-volume cylinders, a valve marked VK-2 is intended. It differs from VK-1 only in that it has a W 19.2 thread at the inlet

All valves have an external thread G 3/4 V at the outlet

The valve is made of brass, degreased, as indicated in the passport. Each valve is packaged in an individual bag.

The valve weighs 550 grams. Standard packaging 28 pcs.

In terms of technical characteristics, the VK-1 valve is a complete analogue of the VK-94-1 valve produced by BAMZ.

Oxygen valves have the highest operating pressure of 20 MPa. The body is made of brass.

As for the installation of these valves on carbon dioxide cylinders - yes, all modifications of the VK-94 and VK-1 valves are installed on carbon dioxide cylinders. From factories, cylinders are delivered to points of sale and gas stations with these valves. But in fact, (TM BAMZ) has long been producing special valves for carbon dioxide - VBU.