You can start your own business not only in those areas that are aimed at producing products consumed directly by the population. Excellent profitability indicators are also shown by those niches that produce a product that is later used for the needs of other entrepreneurs. And a good confirmation of this is the release of foundation. If a wax production line is installed in the workshop and wholesale customers are found, all investments will quickly pay for themselves, and the enterprise will begin to generate high profits. Foundation is a sheet made from wax. Small hexagons are pressed onto it using a special method - the bottoms of the cells. This material is the basis for honeycombs.

Our business assessment:

Starting investments – from 800,000 rubles.

Market saturation is low.

The difficulty of starting a business is 5/10.

There are many private apiaries operating on the territory of Russia (especially in its southern regions). And every year they purchase the necessary raw materials (in particular, wax) necessary to produce tasty, high-quality honey. This is precisely the main prerequisite for launching a workshop in this niche. And in order to test the waters and understand whether this product will be in demand at all in a particular region, you can first open a home production of foundation. In this case, risks are minimized, since large capital investments are not required.

Experts agree that this line of business is especially profitable in those regions where at least several apiaries operate.

What it is

Under natural conditions, bees independently build honeycombs, in which honey is later stored and offspring are hatched. In hives this happens a little differently. Frames with foundation are placed inside and the bees draw honeycombs from it. This makes the task easier for the workers, prevents swarming, and ensures offspring and productivity. This is a thin wax sheet, on the surface of which shallow hexagonal cells are extruded.

Placing frames in hives makes many tasks easier for insects and significantly increases honey collection. Insects calmly accept such a substitute in the space of their hive and begin to actively build honeycombs from this material. The process occurs much faster than it would in nature. Therefore, this has a beneficial effect on the development of the family and nectar collection. This thin wax sheet has a number of positive functions:

- preserves the physical health of the worker bee;

- expands the nest;

- prevents swarming;

- increases productivity;

- improves brood.

This solution with foundation is directly responsible for the health of the colony and preserves the physical strength of the bee.

GOST, rules and parameters

To improve the quality of manufactured products, new indicators were introduced. Foundation is made using artificial and natural wax. To prevent it from being brittle and cloudy, you cannot use a lot of water. According to GOST, it is necessary to set a suitable humidity level.

The foundation must be sterilized to protect the bees from ascospherosis and foulbrood. Amendments have been made to the sheet dimensions. According to the new requirements, the sheet size is 410 by 400 millimeters in length.

Foundation is a sheet of wax that is used to equip a hive. Required to increase the health and fertility of the bee colony. The released base will free the insects from the need to build a home, and they will concentrate on collecting pollen (pollen) and nectar. Beekeepers are interested in how to make foundation with their own hands.

What is it for?

Making honeycombs is necessary for collecting nectar, breeding offspring, queens, and drones. For this, insects need nectar, propolis, and their own wax produced by the worker bee. Ready-made foundation makes the difficult task easier, allows you to significantly expand the nest, increase the brood, and free the worker bee. Makes it possible to obtain durable honeycombs with cells for honey and brood.

The sheets are attached to a frame and placed in the hive. If the family is weak, then 5-6 frames per hive, placed along the edges of the brood, are enough. Abrupt replacement is not recommended. It's better to do this gradually. If the family is strong, then seven frames are enough. Then they are installed in the center or alternating with brood.

After the frame with foundation is installed, you need to check its condition after a couple of days. Sometimes the insect begins to pull the honeycomb from one side. This leads to the sheets warping and breaking. If this happens, then simply turn the frame over.

Most often they are installed in hives in early spring, when dandelions begin to bloom and trees begin to bloom. At this time, the sheets are not deformed due to heat.

Important!

It is necessary to ensure that the bees do not pull on the drone combs. It is worth adhering to the installation time.

Throughout the season, gradually replace the filled frames with new foundation. Determining when this needs to be done is not difficult. The insects begin to sit tightly on top of the body; there is no room for the queen to sow.

What is it made from?

In nature, the worker bee independently produces wax using special glands. In the apiary it happens a little differently. The insect pulls honeycombs from the cells that are on the sheets. There are several types of such material.

Natural wax

The highest quality is considered natural, for the production of which natural wax is used. Any other impurities are excluded. Bees quickly react to such presence, so they are more active where it is natural. But this is not all the advantages. This natural material lasts a long time, can be used repeatedly, and is an environmentally friendly product.

Wax from used frames is collected, melted, and cleaned of impurities, debris, and waste. This is a ready-made pure material that can be used for further making foundation.

Artificial foundation

Usually artificial ones are made of plastic. There are advantages, but they are minor:

- durability;

- low cost;

- durability (impossible to damage);

- easier to store;

- can be used several times per season;

- absence of pathogenic bacteria, subject to regular processing.

But, along with this, the bee in the future will refuse to draw natural wax to build honeycombs. The use of plastic negatively affects the quality of the final product. And most importantly, this is a material that releases toxic harmful substances. They can cause the death of entire families. Moreover, there is no reliable data on how bees perceive artificial foundation. Self-respecting beekeepers will not put their families to the test. Such materials are more often used on an industrial scale.

Selection rules

Beekeepers have their own sources for purchasing the finished product. This is usually done in specialized stores. Not only the performance of insects, but sometimes the life of the entire family, as well as the amount of honey collected during the season depends on quality.

There are several standard rules on the basis of which the choice is made.

- High quality material. Takes into account the size of the honeycomb and its tensile strength.

- It is necessary to take into account that the honeycombs have the correct hexagonal shape, all cells are absolutely identical with standard dimensions from 5.3 to 5.45 mm. A large error is unacceptable.

- If you look through the plate into the light, it should be evenly translucent.

- The standard size is 410x260 and 410x190 for multi-body hives.

- The material should be free of inclusions, dirt, cracks and other visible defects.

But professional beekeepers recommend making foundation yourself.

Financial component

Currently, this hobby brings in about 10-15 thousand rubles. A few days before March 8, I completed orders totaling 3 thousand rubles. If we consider an 8-hour working day, then we can achieve an income of 35 thousand per month. Since this is a hobby, I don’t plan to increase the volume yet, because this will lead to a complete lack of free time, fatigue and, as a result, a decrease in the quality of the work performed.

I believe that to attract customers it is very important to maintain the quality of products at the highest level.

Manufacturing

Experienced beekeepers usually have their own equipment for making foundation. After each collection, the wax is collected for further processing. It is not profitable to constantly buy new foundation. You can purchase ready-made equipment and do your own manufacturing. There are only two ways:

- dipping method;

- casting wax slabs.

The poppy method of production is practically not used today. This does not make it possible to obtain high-quality wax. Special dipping boards, which are moistened with water, are dipped into molten wax several times. After hardening, carefully remove using warm water. The edges are then trimmed and adjusted to the desired size. It is troublesome and the quality of such material cannot be called high.

Casting wax slabs is the simplest and most progressive manufacturing method. Purified, free of debris and impurities, molten wax is cast in special molds. The result is a sheet of standard size, the thickness of which is 1.5 cm. These sheets are then passed through smooth rollers until the thickness reaches 3 mm. At the last stage it is passed through engraving rollers.

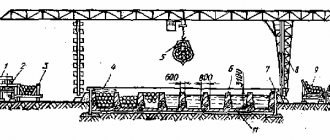

In manufacturing, belt machines are used in which the wax tape is rolled first on smooth and then on engraving rollers. Then, on an automatic line, the sheets are cut into specific sizes, which is already foundation. High quality, durable, clean, not dangerous to bees.

Basic equipment

To organize a small foundation manufacturing business, you will need several special machines. The minimum production set includes a wax sterilizer, a roller machine, and a belt-forming machine equipped with a rotating drum.

If you are planning a larger-scale production, then it is best to purchase an automated line. Such equipment for the production of foundation will allow you to significantly save on personnel, because only 2-3 people can operate the line.

Its cost will depend on the manufacturer, performance, modernity and additional parameters. The minimum price for a production line is 500 thousand rubles, but as the productivity of the equipment increases, its cost increases.

Foundation machine

Beekeepers use two methods for production, using:

- electric press;

- hand rollers.

The most popular rollers for manufacturing are manual ones. They have an engraved surface. By rolling sheets of warm wax through them, you get foundation of the required thickness. Before starting production, it is necessary to prepare a clean, high-quality material free of impurities, waste and traces of dirt.

DIY wax

The manufacturing process is simple, but requires attention. Experienced beekeepers have long mastered the process of producing foundation. Working with beeswax is not difficult. It is more important that it is a clean product, without foreign impurities, odors, dirt, dust. Some people add paraffin. This is not dangerous, but it is better not to practice it so as not to get a brittle result.

You can melt the wax at home. A professional beekeeper tells you how to do this.

Equipment and production

Several types of equipment are used to make foundation:

- hand rollers;

- electric and manual presses.

The rollers are a drum on which there are honeycomb-shaped granules. When the wax sheet is passed through the rollers, a clear imprint remains. The machine can operate from an electrical network or be manual.

This equipment is a bit like a home waffle iron, but instead of dough, it uses melted wax. It is poured onto one surface and pressed down with the top lid. After holding it for a while, remove the finished sheet of foundation with clear future honeycombs. Some beekeepers managed to independently make a production machine.

The welding is carried out with or without wire. In private apiaries, the wireless method is more often used.

DIY wax matrix

Making a manufacturing machine at home is quite simple. For this you will need:

- pure wax;

- molding silicone;

- two wooden plates;

- fasteners;

- sheet of prepared foundation.

It is necessary to place the finished foundation on a flat surface and completely fill it with silicone. To do this, squeeze the silicone onto the surface in lines and evenly so that the silicone forms a flat surface that completely fills all the fragments of the honeycomb. After the silicone has hardened, carefully detach it from and make a second fragment. This will leave two forms.

The finished forms must be attached to the boards. Connect the wooden fragments together with loops. Apply a second layer of silicone to the surface of both plates. Carefully smooth out and place the foundation between the planks. Secure with fasteners and place in the oven. Maintain at a temperature of 100 degrees. Let cool. Attach the handles. The matrix for making foundation is ready.

The matrix is used using the press method. Pour melted, clean wax onto the surface and press down carefully.

Wait until it cools down and remove the finished wax.

How much income can the business bring?

We found out that starting a homemade foundation production is not at all difficult. Compared to other areas of activity, there are few costs here, and the technology for producing finished products itself is no different in complexity. What income can a mini-workshop bring on average? First, all investments must be taken into account. They will amount to about 1,400,000 rubles. This includes the following expense items:

- Purchase of equipment – 700,000 rubles.

- Preparing the premises - 200,000 rubles.

- Preparation of the raw material base – 500,000 rubles.

- Registration of individual entrepreneur – 10,000 rubles.

If you buy a machine for producing foundation, even with a low productivity (50 kg/h), with well-established distribution channels you can have excellent profit for a mini-workshop. Let's calculate the income:

| Index | Magnitude |

| Productivity, kg/month. | 12000 |

| Cost, rub./kg | 310 |

| Variable costs (rent, salary, taxes, transport), rub./month. | 300000 |

| Average market price, rub./kg | 360 |

| Revenue, rub./month | 4320000 |

| Net profit, rub./month. | 300000 |

| Payback, months | 4,5 |

We have given approximate profitability indicators for a mini-workshop. Everything will depend on the sales of the finished product and the performance of the devices. For example, if you buy a press for the production of foundation with greater power, then your net profit will increase. But in this case, sales channels must be perfectly organized, otherwise the goods will remain in warehouses. You can increase net profit by reducing production costs. Of course, this must be done without compromising the quality of the finished product. If you agree on wholesale supplies of cheaper raw materials (natural wax) to your company, then production costs will be significantly reduced.