Business relevance

Despite the crisis, the pace of construction in our country continues to increase in both the private and public sectors. Along with them, the popularity of building materials is growing. It is known that almost no construction is carried out without bricks, among which Lego can be called in demand.

A business idea to open an enterprise for its production can lead to the construction of a successful and quickly profitable enterprise, giving high profits, since there are still few competitors in this niche. By properly planning your activities, you can find your niche in the construction market and increase production turnover.

Tragic repeat

History likes to repeat itself. Two years after the death of the founder of the company, a fire started at the plant! This hastened the decision to stop making toys made of wood. But the products began to be exported, in particular, to the USA. And in 1968, the first Legoland was launched in Billund - an entertainment city built from construction kits. Another director of the company was the grandson of the founder, Keld, and in 2004, management was entrusted to an outsider. However, to this day the majority of shares remain in the hands of the founder's family. Therefore, when asked which country, people again answer that it is Denmark.

Basic properties of the material

Lego brick is a high-quality facing material formed by hyper-pressing without firing. Outwardly, it is similar to a not little-known designer. This form makes the erected structures much stronger, and the masonry process simple and accessible to everyone. The peculiarity of using Lego bricks is their fixation thanks to a special adhesive mass (15 kg of such glue is enough for 1 m³ of brick). The use of standard mortars and cement is not allowed. The channels that are obtained through the holes of the materials can be used as highways for infrastructure nodes. Each brick has two holes protruding above the surface. During laying, the lower one is attached to the upper one. The result is a smooth surface that does not need to be plastered.

Making a brick machine yourself

First you need to decide on the specific type of machine: manual or electric. The first option is much easier to manufacture and requires less costs from the entrepreneur

It is important to note that the strength of such products is significantly lower than their more technologically advanced counterparts. According to experts, making an automatic machine yourself is not profitable for novice entrepreneurs

In this case, you will need to purchase electric drives and other units, the cost of which is quite high.

It should also be noted that homemade machines allow you to produce products that have a low safety margin. Such products cannot be used in the construction of load-bearing structural elements, due to the high risk of cracks in severe frosts. The reason for the appearance of cracks is the increased humidity of the manufactured bricks.

Suitable raw materials for Lego bricks are waste from crushing limestone rocks, volcanic dust or sand.

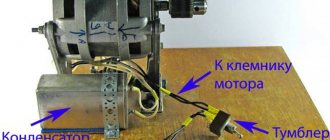

Necessary tools and components

To create a machine, you will need several sheets of steel, varying in thickness. Steel will be used to create the walls of the press. You will also need to purchase a channel and metal corners. In addition to all of the above, you will need thick-walled metal pipes to make the piston and handle.

To work with sheet steel, you will need a welding machine and a grinder. In addition, you will need to purchase several discs to work with different metals. The press is attached to the corners using bolts and nuts. This means you will also need a drill and special drill bits that can handle thick steel.

Step-by-step sequence of work

To make a press, you will need to make a cylinder from sheets of steel. The dimensions of this cylinder must correspond to the volumes of the products being manufactured. Next, you need to divide the channel into two sections one meter long. The press racks will be made from these pieces. It is necessary to install two metal rectangles between the upper parts of the rack to create a section. These rectangles are welded to the posts.

A channel is installed on top of the resulting structure. Its length should be seventy centimeters. The channel is welded with the ribs pointing upward. One of the parts of the channel must protrude beyond the structure itself. Supports are welded to this part. At the end of the welding work, a hole is cut out inside the cylinder.

For the manufacture of the bunker, pre-prepared metal sheets are used. The dimensions of the hopper outlet must be equal to the dimensions of the product. To attach the hopper to the protruding part of the structure, special legs made of metal strips are used. When attaching the legs, it should be taken into account that the form itself should easily slide along the ribs of the rail.

Rectangular metal sheets are used to make the piston. Two pipes must be passed through these sheets, which will be used as a handle to open and close the lid. Bolts are used to secure the handle to the main structure. The corners are used to make the base of the unit.

Lego brick is a simple and ingenious solution in construction

Technological nuances

A DIY Lego brick machine will be inferior in strength to those products that are made in a factory. In order to better understand all the features of this production, let's get acquainted with the technological process. To create raw materials, a mixture of clay, cement and sand is used. The mixed raw materials are poured into the bunker.

Next, a special dispenser selects part of the mixture necessary to create one product. This mixture enters the press matrix, where the brick itself is made. The manufactured bricks must be thoroughly dried under natural conditions. The drying time depends on the quality of the raw materials used. As practice shows, when choosing raw materials, the characteristics of existing equipment should be taken into account. Industrial equipment comes with a user manual, which lists all the basic requirements for the materials used.

Raw materials

To produce this material, environmentally friendly substances are used. All components are widely used and available. There is no exact recipe for preparing raw materials - the ratio of ingredients depends on the required density and quality. One of the mixture composition options:

- filler – screening of crushed limestone (up to 90%);

- binder – cement (7-15%);

- water (up to 5%);

- plasticizers;

- dyes.

Video - composition of light brick concrete mixture:

Characteristics of cinder block

Cinder block is widely used as a building brick due to the following qualities:

- low cost;

- fast construction times of buildings;

- high sound insulation;

- excellent thermal insulation;

- Possibility of manufacturing for your own use and for sale.

In order to achieve high strength of the resulting products when producing cinder block bricks, the following must be taken into account:

- sand quality – it is necessary to use coarse sand;

- Blast furnace slag is best suited;

- you need to use high quality cement - M400;

- equipment - for better compaction it is necessary to achieve vibration compaction.

Financial part

To calculate costs, we use approximate calculation data:

- personnel – 2 employees;

- working hours – 20 days a month for 8 hours;

- wage fund – 40 thousand rubles. per month;

- electricity for production – 1600 kW/hour;

- purchased equipment – 600,000 rubles.

Price for material and resources:

- cement M500 - 5 rubles/kg;

- screening – 0.6 rub./kg;

- electricity – 3.76 rubles.

The information provided in this article is only a brief introduction to the essence of the business. If you decide to move on to implementation, then you need to download a professional business plan for a brick factory with detailed calculations:

Profit calculation: In one shift you can produce 1,600 pieces of brick, in a month - 32,000 pieces. The cost of the finished product is approximately 12 rubles. Income with 100% sales of products will be 448,000 rubles.

To produce one Lego Creep, you need approximately 350 grams. cement (1.6 rub.), 3 kg. screenings (1.8 rubles), plasticizer and dye - 0.3 rubles, as well as 1.25 rubles. allocated for wages and 0.2 rub. for electricity. Other expenses (taxes, transport) – 0.75 rubles. The cost of one brick will be 6 rubles.

Net profit per month: (12 – 6) * 32,000 = 192,000 rubles.

Thus, the payback period of the project will be about four months.

Brick making technology

To understand the key intricacies of making bricks, pay attention to the key components of the machine. They include:

- dry mix hopper;

- dispenser;

- a chamber for the formation of bricks with a matrix that determines the future shape and size;

- electric motor (it is not available in manual models);

- oil pump and hydraulic press;

- the frame of the entire structure.

Design features may vary depending on the model and type of equipment, but the main components look exactly like this.

The production technology itself consists of using high pressure, which acts on the loaded mixture, while the filler is literally sintered with cement and water. This method is commonly called “cold welding”.

The production principle is as follows:

- The entire dry mixture is placed in the hopper and mixed thoroughly.

- Then the working mixture is transferred to a special container - a tray.

- After that, it falls on the matrix, and a press acts on it from above for several seconds.

- At the next stage, the platform with the brick moves up, and the press goes back.

- Now the worker can remove the finished product and transfer it to a tray for subsequent steaming or drying.

- The finished product must be placed in a separate room for several days, where strength will be gained. The exact drying time depends on the type of equipment.

Business registration

At the first stage of implementing the idea, it is enough to register your activities as an individual entrepreneur. This form requires a minimum package of documents:

- application in form P21001;

- receipt of payment of state duty (800 rubles);

- copy of the passport.

Then you should choose the form of taxation. The most profitable option in this case will be a simplified system (15% of profit or 6% of revenue). To start working immediately on the simplified tax system, at the time of registration, add to your package of documents an application for the transition to a simplified taxation system in form No. 26.2-1.

It will take 5 working days to complete all permitting documentation.

If you are planning large-scale production at the start, it is better to register as a limited liability company.

For boys and girls

Girls will certainly appreciate the LEGO Friends and LEGO Disney series. With such sets you can build houses for girlfriends and princesses, make friends with cute little animals, visit friends or throw a real ball. You can also try yourself as a veterinarian, doctor, seller or pastry chef. The game process is combined with construction, which is much more interesting and useful than a regular game of dolls.

Boys will be delighted with the LEGO Super Heroes and LEGO NINJAGO series. With the help of the designer, you can come up with unusual plots for games and organize real competitions for the winner's cup among ninjas.

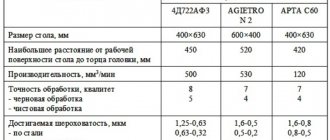

Equipment

To start working, it is enough to purchase a machine (hyperpress), an industrial mixer and other things - molds (matrices), pallets, shovels, etc. The cost of equipment for brick production depends on productivity:

- machines with low productivity up to 1000 pieces per shift (manual or low power) - 90-300 thousand rubles;

- middle class - about 2000 bricks per shift, price from 350 thousand rubles;

- industrial equipment or a mini plant make it possible to produce more than 750 pieces per hour, but the cost is high - from 2 million rubles.

The brick machine consists of the following parts:

- bunker for bulk materials;

- dispenser;

- matrix for forming Lego bricks;

- pump;

- press;

- bed;

- electric motor (not available in manual units).

Video - budget machine for light brick:

Advantages of Lego bricks

Lego brick as a business has a wide range of advantages:

- the popularity of this building material is associated with its design features - it looks like familiar toy bricks, has grooves and guides, making it possible to lay stones without developed skills and even without cement;

- as a consequence of the previous point, the dynamics of sales of Lego bricks is steadily growing;

- due to the novelty of production technology, there is now little competition in the market;

- general demand for bricks;

- stability of demand for products;

- great business prospects;

- no need for large financial investments to open production.

Lego bricks are made not from clay, but from a concrete mixture, thanks to this, not only are kilns not needed, but the raw materials will be much cheaper.

Thus, the production and sale of Lego bricks is an excellent opportunity for an entrepreneur to start a business that is not particularly difficult to implement and will definitely recoup all costs if done correctly.

At home

Making Lego bricks at home is beneficial in two cases - a lack of funds to purchase professional equipment or a desire to save on the purchase of building materials for your home.

In this case, you can purchase a manual machine for making bricks. Its cost varies within 40 thousand rubles. It does not consume electricity and can be transported in a regular car trailer. The scheme of its action is to prepare the mixture in a special matrix form. Manual mode is used. The machine has a loading hopper and a dosing unit. Small dimensions make it possible to work in a garage or small room and make bricks with your own hands. Video - Idea for a business in a garage. Making Lego bricks with your own hands:

What assortment to offer consumers?

Whatever manual press for Lego bricks you choose, it will be equipped with special dies. And it is these matrices that will determine what shape, what size and what type of finished products will be produced.

The matrix for Lego bricks will allow the entrepreneur to offer consumers a full range of manufactured blocks. By replacing molds on the machine, the following types of products can be obtained:

- Standard brick. This is the most popular type of all possible. And the sale of machines today is mainly carried out specifically for such bricks. Even if there is no extra money to purchase additional matrices, blocks of standard shape must be present in the assortment.

- Brick fitting. The dimensions of Lego bricks here are exactly the same, only they can be connected to each other by the side parts, and not just the top and bottom.

- Rail-shaped brick. Such blocks are laid like rails. Among professional builders, such Lego bricks are quite in demand. Therefore, if you want to enter a large market with your products, you must definitely acquire such matrices.

The price of the matrix is quite high - 25,000-50,000 rubles. But it is quite justified, taking into account the technology of their manufacture and the raw materials used (high-quality hardened steel 54-65 HRC)

And when ordering this “part” from a supplier, it is important to know what types of matrices there are:

- Simple. Such matrices are intended for making bricks individually. This is the simplest option, affordable for many.

- Combined. The dimensions of the matrix in this case are designed for the simultaneous production of 2-3 bricks

- Original. Such matrices are made to order according to individual measurements. It makes sense to purchase such “templates” only when there is a specific order for a specific brick. And there is absolutely no need to keep such matrices in reserve - a waste of money.

When deciding where to buy matrices for Lego bricks, it is worth considering that you need to choose them especially carefully. In order to last as long as possible, they must meet all quality standards. Otherwise, even a couple of technological cycles of the matrix will not last.

How to implement lego-kiprichi

The success of your sales depends on the quality of your advertising. This process also requires spending money, but the relationship here is directly proportional: the more money invested in the event, the more people will learn about your production.

You can promote your products in the following ways:

- use elements of outdoor advertising: notice boards, billboards, city lights, etc.;

- open your own online store;

- place advertisements and publications in construction newspapers and magazines;

- attend construction exhibitions and seminars.

This is the price of promoting your production and forming a customer base.

Features of masonry

Laying Lego bricks has its own specific nuances. The first row is fixed to the base using a cement-sand mixture, and all subsequent rows are laid with glue. For these purposes, adhesive intended for ceramic tiles is usually used.

When laid, it should have the consistency of fairly liquid sour cream. Consumption is 22-25 kg per 500 bricks. It is best to apply the mixture using a special glue gun.

Laying is carried out in the following order.

Laying the first row

The quality of the entire structure depends on the quality of laying the first row. To do this, the surface line and horizontal row are clearly controlled.

The first row is laid on the foundation, the surface of which is previously covered with insulation and waterproofing using cement mortar. Between the bricks at the ends, adhesion is ensured by a thin layer of glue.

All elements are joined so that the elements of the next row engage in the locking engagement, taking into account the displacement by half the brick. The compaction is ensured by a mallet.

Subsequent masonry

The glue is applied using a glue gun to the bottom of the brick with a zigzag roller 10-12 mm wide. First of all, the engagement pins are covered with glue.

Glue is also applied to the end of the element. Each layer is laid with binding, i.e. with an offset of exactly half a brick. The tenon is aligned with the groove and, with a little effort, is firmly driven into it.

Formation of openings

A Lego brick can itself become a floor beam, which eliminates the need to install a reinforced concrete element that distorts the masonry. The opening is made as follows:

- formwork is installed;

- one row of Lego bricks is laid, in which longitudinal channels are infiltrated and steel reinforcement is laid;

- 2 more rows of bricks are laid on glue;

- Concrete is poured into the holes.

We recommend: Which plaster is better - gypsum or cement? Which one to choose for leveling the walls?

After the solution hardens, a fairly strong overlap is formed.

Making an armored belt

To attach the roof to the wall, a reinforced belt is made from Lego bricks, which evenly redistributes the load.

To do this, the last row of the wall is laid out of brick with ready-made longitudinal grooves. They contain parallel steel reinforcement. Wooden plugs are inserted into the holes in the brick and a layer of concrete is poured around the entire perimeter of the structure.

We recommend reading: When is a monolithic belt used to strengthen walls?