Where it all began

The history of the steeloscope begins in the 1850-1860s, when German scientists dealt with the problem of detecting alkali metals using a spectroscope (a spectroscope is the simplest optical device for visually observing the spectrum of light supplied to the input of the device). The British were the first to use such a device in production. In 1923, they began using a spectroscope to sort scrap for smelting. Later, in 1931, the instrument was modified to quickly detect nickel, chromium and other metals in steels, and was equipped with a movable eyepiece for viewing any part of the visible spectrum. Such a device was called “Steeloscope” (from the words steel and observation).

The first steeloscope in the USSR was designed in 1933 at the Scientific Research Institute of Physics of Moscow State University. The first method for roughly determining the main alloying additives in steel (Ni, Cr, W, Mo, Co, Mn and V) was also written there. The simplicity and low cost of the device have become the guarantee of its widespread use in industry.

Have questions? - We answer!

This page is dedicated to interactive communication with our customers and partners. The answers will help you make a decision or reveal additional information about the equipment you are purchasing. This section is constantly being updated. To ask a specific question, please contact the appropriate department in the contacts section.

What is a steeloscope?

A steeloscope is a simple analyzer of metals and alloys, which has been used in industry for a very long time to determine the grade of an alloy or incoming control at an enterprise. Using a steeloscope, optical spectral analysis of many grades of alloy steels is carried out, as a qualitative one - i.e. on the presence of a chemical element in the alloy, and relatively quantitative or, as they are also expressed, semi-quantitative analysis - i.e. to determine the proportion of a chemical element.

How does a steeloscope work?

The sample being analyzed comes into contact with the steeloscope's electrode, resulting in a spark or arc. The emitted light passes through the optical system and is split into a spectrum. In the eyepiece, the laboratory technician observes spectral lines in the region of the spectrum accessible to human vision. Based on the guidelines for choosing the spectral range, the presence and intensity of spectral lines, the steeloscopist makes a decision about the presence of a chemical element in the alloy and its proportion.

What chemical elements can be analyzed using a steeloscope?

The steeloscope provides the opportunity for qualitative and semi-quantitative determination of the chemical elements Cr, W, Mn, Si, V, Mo, Ni, Co, Ti, Al, Nb, Zr, Cu, Zn, Fe, Pb, Sn, Be, Bi, Mg.

Is there any provision for certification of the steeloscope according to GOST?

In accordance with the current product range, for which the legislation of the Russian Federation provides for mandatory certification, put into effect by the resolution of the State Standard of Russia, the technical device “steeloscope” is not subject to mandatory certification and is not subject to mandatory declaration of conformity in the GOST System.

The steeloscope is not included in the list of products subject to mandatory certification, approved by Decree of the Government of the Russian Federation of December 1, 2009 No. 982, as amended by the Government of the Russian Federation of November 13, 2010 No. 906.

and is also not included in the Product Nomenclature for Declaration of Conformity of the Rostechregulirovaniye Agency.

Is there any provision for checking the styloscope?

According to clause 3 of Article 9 of the Federal Law of June 26, 2008 No. 102-FZ “On Ensuring the Uniformity of Measurements”, the technical device “steeloscope” is not classified as a measuring instrument due to the absence of a regulatory document adopted by the executive authority because according to clause 5 of the Order of the Ministry of Industry and Trade of the Russian Federation dated April 27, 2009 No. 323 “On approval of the procedure for classifying technical equipment as measuring instruments.”

The steeloscope technical device is not intended for making measurements, but is used to observe radiation spectra in accordance with the interpretation:

Steeloscope (from the English steel - steel and ... scope) - spectroscope for fast quality. chemical analysis composition of steels and alloys with visual observation of emission spectra.

Spectroscope (from spectrum and ...scope) is an optical device for visual observation of the radiation spectrum.

Large encyclopedic dictionary. Polytechnic: encyclopedia / ed. A.Yu.Ishlinsky. – M.: Great Russian Encyclopedia, 1998.

The steeloscope units that display values, such as an ammeter and a voltmeter, are subject to verification by the manufacturer of the corresponding device.

The spectral region selection drum is marked either in conventional units or in nanometers and is subject only to calibration.

What qualifications must a specialist have to be allowed to work independently?

What credentials/certificates should this specialist have?

The specialist must have the profession of a spectral analysis laboratory technician of at least 2nd category, and an electrical safety permit of at least 2nd group.

We are launching a NDT laboratory, what device should we buy for styloscopy?

Depends on the direction of work, if this is a laboratory format, start choosing with the SL-13 U steeloscope, if on-site analyzes are possible, or work in a workshop, pay attention to the lightweight device SLU-1 steeloscope.

I want to know the cost of equipment, is it not on the website?

Any of the steeloscopes can be equipped with a power source of your choice; all possible power sources are listed on the page describing the metal analyzer. Thus, various sets of equipment appear and it is easier for us to process your application by phone or via e-mail, since during the conversation a specialist will clarify the purpose of the device, the format and specifics of your work, and will be able to provide you with advice on technical characteristics or answer additional questions.

Tell us about the additional equipment, what does it provide?

First of all, the ability to digitize the displayed spectrum. The camera eyepiece allows you to use the steeloscope with any digital device with a USB port or analog input. Next, you will have the opportunity to record photographic recordings and save the analysis process. For example, you can record the process of analyzing a standard sample and then use it when studying an unfamiliar object or during incoming inspection.

The LCD display is an add-on to the camera eyepiece and is perfect for training centers and laboratory technician training.

Our old steeloscope has finally become unusable for work, is it possible to repair it?

The repair work scheme is as follows: in order to fully carry out repair work, we need to diagnose the device; this is more convenient, simpler and faster to do in our specialized center. You send the equipment to our address by any transport company. After receipt, within three working days, we provide a diagnostic sheet, which indicates all the necessary work and spare parts for repairs, as well as the timing of the work. If you are satisfied with the proposed work, we begin to carry it out; if not, we send the device back.

Principle of operation

Steeloscope refers to visual emission spectral analysis. In essence, it is the simplest spectrum analyzer. The purpose of this device is visual qualitative and, at best, semi-quantitative spectral analysis of metals and alloys in the visible region of the spectrum, the accuracy of which does not require serious requirements.

The operating principle of this device is as follows: a discharge (spark, arc or combined) is ignited between the sample under study and an electrode (usually copper). The operator visually observes the spectrum of this discharge using a spectroscope. By rotating the handle of the device, the operator scans the entire spectrum from the violet to the red region, paying special attention to those areas where the spectral lines of impurities should be located. Figure 1, Figure 2 and Figure 3 are an example of the spectrum observed by the operator in the eyepiece of the steeloscope (photos from the site vnii.ucoz.ru).

Rice. 1 |

Rice. 2 |

Rice. 3 |

Having found such an area using the steeloscope atlas, the operator identifies the spectral line of any impurity and then, visually comparing it by the brightness of the glow with adjacent lines of the base, draws conclusions regarding the concentration of a particular impurity, checking the table.

(Figure 4, Figure 5 and Figure 6 are examples of the spectrum in the table and the section of the spectrum used to determine the concentration, taken from a typical atlas of spectral lines for a steeloscope) Drawings from the atlas of spectral lines for a steeloscope

Rice. 4 Type of spectrum of iron. | Rice. 6 Spectral lines for the spectroscopic determination of nickel and copper in steels. |

Rice. 5 Type of spectrum of copper. |

Naturally, the operator can see the spectrum only at the moment when the discharge is lit. Finding the required part of the spectrum, identifying the line and assessing its brightness takes considerable time. And this procedure must be repeated for each impurity, sometimes many times. The device overheats after a few minutes and must be turned off to cool down, then turned on and continued evaluation. Naturally, the more experienced the steeloscopist, the more accurately and quickly he can estimate the amount of impurities in the sample under study.

Design and principle of operation of the SL-11 steeloscope.

Visual methods of atomic emission spectroscopy.

Visual methods are based on registration using the eye.

They can only be used to study spectra with wavelengths in the region 400 - 700 nm. In this region of the spectrum, a qualitative analysis is carried out by establishing the identity of the colors of the spectral analytical lines of the test and reference substances.

The average spectral sensitivity of the eye is maximum for yellow-green light with a wavelength of 550 nm. It is impossible to visually measure the intensity of a spectral line, but it is possible to establish with sufficient accuracy the equality of the line intensities of the test and reference substances, which allows for visual qualitative analysis.

Visual methods are divided into styloscopic and stylometric.

Styloscopic analysis is based on a visual comparison of the intensities of the spectral lines of the analyzed element (impurity) and nearby spectral lines of the main element of the sample.

For example, when analyzing steels, the intensities of the spectral lines of impurities and iron are usually compared. In this case, previously known styloscopic features are used, in which the equality of the intensity of the lines of a certain analytical pair corresponds to

a certain concentration of the element being analyzed.

Steeloscopes are used for express analysis if high accuracy is not required. 6-7 elements are determined in 2-3 minutes.

The sensitivity of the analysis is 0.01-0.1%. Both stationary and portable steeloscopes are used for analysis.

Stylometric analysis differs from styloscopic analysis in that the brighter line of the analytical pair is weakened using a special device (photometer) until the intensities of both lines are equal. In addition, stylometers allow the analytical line and the comparison line to be brought closer together in the field of view, which significantly increases the accuracy of measurements. are used for analysis .

The relative error of visual measurements is 1 – 3%. Their disadvantages are the limited visible spectrum, tediousness, and lack of objective documentation of the analysis.

Photographic and photoelectric registration and measurement of the intensity of spectral lines makes the analysis results more objective, i.e. independent of the individual characteristics of the analyst.

Calibration of the SL-11 steeloscope by wavelength.

The essence of analysis.

Qualitative spectral analysis on a steeloscope comes down to finding the characteristic lines of the desired elements in the field of view of the eyepiece. When a sample is burned, the spectra of many elements are excited, and when observing the spectra, it is necessary to be able to find the desired line among the lines of other elements that are similar in wavelength. This is done using a pre-built dispersion curve of the device, showing the relationship between the divisions of the drum scale and the wavelength of the spectral line. The most accurate calibration of the device can be carried out if you use the characteristic lines of several elements (lithium, sodium, zinc, copper...) located in the region of 400 - 700 nm.

Devices and materials.

1 steeloscope SL-11;

2 tables of spectral lines;

3 copper plate;

4 zinc plate.

Design and principle of operation of the SL-11 steeloscope.

The SL-11 steeloscope is designed for visual observation of the spectrum and express qualitative and quantitative analysis of metals and alloys.

Optical design.

The optical design of the device is shown in Figure 1. Light from the arc, using a three-lens system 1, 2 and 3, uniformly fills the slit 4; a reflective prism 5 directs light rays to the lens 10 (at the focus of which a slit is placed); the resulting parallel beam falls on dispersing prisms 11 and 12. The large leg of the prism 12 with a refractive angle of 31° is silvered, so the rays are reflected from it, pass in the opposite direction through the prisms on the lens and fall on the rectangular prism 9 and mirror 8, which direct them to the eyepiece 7.

A photometric wedge 6 is located in the focal plane of the eyepiece.

Figure 1 – Optical design of SL-11

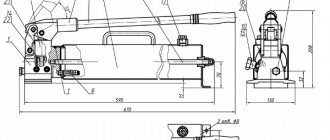

Device structure (Figure 2). An optical system with a table for electrodes is placed in the upper part of the device 1; a spectrum excitation generator is mounted in the lower part 2, allowing operation in the mode of an alternating current arc and low-voltage spark at currents of 2 and 4 A.

The arc and spark modes are turned on by turning knob 5 to position

“Arc” or “Spark” and toggle switch 3 and 4 The electrodes are placed on the table on the left. The lower electrode (counter electrode) is mounted on a throne inserted into the holder so that its upper end is on the optical axis of the device. The upper electrode 9 is installed above the lower one on the surface of the table 8.

The distance between the electrodes should not exceed 3 - 4 mm. The interelectrode distance and the position of the lower electrode are adjusted with handles 6 and 7. To evaluate the intensities of the compared lines during quantitative determinations of the analyzed elements, this device has a special device - a photometric wedge. By rotating the drum 11, placed on the top cover of the device opposite the eyepiece, a narrow wedge strip with a smoothly varying density (percentage of transmittance) is introduced into the field of view. The value of the wedge density is determined on the scale, observing simultaneously in the field of view of the eyepiece 12 or through the peephole 10 to the left of the eyepiece. Observations are carried out for no more than 5 minutes, followed by 5 minutes of rest for the device.

Figure 2 – Appearance of the SL-11 steeloscope

Visual methods of atomic emission spectroscopy.

Visual methods are based on registration using the eye.

They can only be used to study spectra with wavelengths in the region 400 - 700 nm. In this region of the spectrum, a qualitative analysis is carried out by establishing the identity of the colors of the spectral analytical lines of the test and reference substances.

The average spectral sensitivity of the eye is maximum for yellow-green light with a wavelength of 550 nm. It is impossible to visually measure the intensity of a spectral line, but it is possible to establish with sufficient accuracy the equality of the line intensities of the test and reference substances, which allows for visual qualitative analysis.

Visual methods are divided into styloscopic and stylometric.

Styloscopic analysis is based on a visual comparison of the intensities of the spectral lines of the analyzed element (impurity) and nearby spectral lines of the main element of the sample.

For example, when analyzing steels, the intensities of the spectral lines of impurities and iron are usually compared. In this case, previously known styloscopic features are used, in which the equality of the intensity of the lines of a certain analytical pair corresponds to

a certain concentration of the element being analyzed.

Steeloscopes are used for express analysis if high accuracy is not required. 6-7 elements are determined in 2-3 minutes.

The sensitivity of the analysis is 0.01-0.1%. Both stationary and portable steeloscopes are used for analysis.

Stylometric analysis differs from styloscopic analysis in that the brighter line of the analytical pair is weakened using a special device (photometer) until the intensities of both lines are equal. In addition, stylometers allow the analytical line and the comparison line to be brought closer together in the field of view, which significantly increases the accuracy of measurements. are used for analysis .

The relative error of visual measurements is 1 – 3%. Their disadvantages are the limited visible spectrum, tediousness, and lack of objective documentation of the analysis.

Photographic and photoelectric registration and measurement of the intensity of spectral lines makes the analysis results more objective, i.e. independent of the individual characteristics of the analyst.

Calibration of the SL-11 steeloscope by wavelength.

The essence of analysis.

Qualitative spectral analysis on a steeloscope comes down to finding the characteristic lines of the desired elements in the field of view of the eyepiece. When a sample is burned, the spectra of many elements are excited, and when observing the spectra, it is necessary to be able to find the desired line among the lines of other elements that are similar in wavelength. This is done using a pre-built dispersion curve of the device, showing the relationship between the divisions of the drum scale and the wavelength of the spectral line. The most accurate calibration of the device can be carried out if you use the characteristic lines of several elements (lithium, sodium, zinc, copper...) located in the region of 400 - 700 nm.

Devices and materials.

1 steeloscope SL-11;

2 tables of spectral lines;

3 copper plate;

4 zinc plate.

Design and principle of operation of the SL-11 steeloscope.

The SL-11 steeloscope is designed for visual observation of the spectrum and express qualitative and quantitative analysis of metals and alloys.

Optical design.

The optical design of the device is shown in Figure 1. Light from the arc, using a three-lens system 1, 2 and 3, uniformly fills the slit 4; a reflective prism 5 directs light rays to the lens 10 (at the focus of which a slit is placed); the resulting parallel beam falls on dispersing prisms 11 and 12. The large leg of the prism 12 with a refractive angle of 31° is silvered, so the rays are reflected from it, pass in the opposite direction through the prisms on the lens and fall on the rectangular prism 9 and mirror 8, which direct them to the eyepiece 7.

A photometric wedge 6 is located in the focal plane of the eyepiece.

Figure 1 – Optical design of SL-11

Device structure (Figure 2). An optical system with a table for electrodes is placed in the upper part of the device 1; a spectrum excitation generator is mounted in the lower part 2, allowing operation in the mode of an alternating current arc and low-voltage spark at currents of 2 and 4 A.

The arc and spark modes are turned on by turning knob 5 to position

“Arc” or “Spark” and toggle switch 3 and 4 The electrodes are placed on the table on the left. The lower electrode (counter electrode) is mounted on a throne inserted into the holder so that its upper end is on the optical axis of the device. The upper electrode 9 is installed above the lower one on the surface of the table 8.

The distance between the electrodes should not exceed 3 - 4 mm. The interelectrode distance and the position of the lower electrode are adjusted with handles 6 and 7. To evaluate the intensities of the compared lines during quantitative determinations of the analyzed elements, this device has a special device - a photometric wedge. By rotating the drum 11, placed on the top cover of the device opposite the eyepiece, a narrow wedge strip with a smoothly varying density (percentage of transmittance) is introduced into the field of view. The value of the wedge density is determined on the scale, observing simultaneously in the field of view of the eyepiece 12 or through the peephole 10 to the left of the eyepiece. Observations are carried out for no more than 5 minutes, followed by 5 minutes of rest for the device.

Figure 2 – Appearance of the SL-11 steeloscope

Advantages and disadvantages

Advantages of the steeloscope: price. Ease of manufacture and low cost of components add up to the low cost of the device.

Disadvantages: there are many of them, let’s try to list them:

- The source of the glow is extremely simple and cheap generators that do not ensure the stability of the discharge glow, depending on voltage fluctuations in the network. This negates attempts to equip the steeloscope with a video camera and software for deciphering spectra, which supposedly increase the accuracy of the device, but in fact only increases the cost: the ambiguity of the results is already built into the generator.

- The recording element is the operator's eye. Individual perception of information varies from person to person. Even for one person it can vary from day to day. Figuratively speaking, the results of the analysis can be influenced by what the operator drank and ate yesterday, or whether he slept well. The “human factor” affects the results of the analysis - this is unacceptable in modern production conditions.

- The steeloscope works exclusively in the visible region of the spectrum - that is, where the eye can see this spectrum. From approximately 400 nm to 700 nm. And not every person is able to discern light even at the boundaries of this area. In addition, the main spectral lines (the brightest and most stable) are in the range from 190 nm to 400 nm and below, so they are not available for recording with a steeloscope. This greatly reduces the possible detection limits.

- A good steeloscope operator remembers many fragments of the spectra of the metals being studied visually. Training a steeloscopist capable of producing satisfactory measurement results in a reasonable time takes months and sometimes years. Not to mention the fact that now in our country educational institutions no longer teach this profession.

- And finally, the steeloscope is not a measuring instrument, it is an evaluation analyzer. The measurement results on a steeloscope are not legitimate; they cannot be included in the finished product certificate or used in arbitration (legal disputes).