How to choose the right SG?

There is an opinion that semi-automatic MIG welding requires more current compared to the output power of the welding machine, but this is a misconception, since in this case it will be reflected in the weight of the torch itself and will affect maneuverability.

Therefore, emphasis should be placed on models with a lower current coefficient, lighter and more flexible, but at the same time perfectly coping with the assigned tasks. And there is an explanation for this. First of all, by the maximum current indicated in the product passport, the manufacturer usually means the permissible temperature, above which there is a risk of damage to the handle or cable-hose. Secondly, based on time statistics, it can be argued that operation at full power will be a cyclic process lasting no more than 10 minutes. Based on the above, it can be confirmed that this tool can be freely used at a lower current without compromising it and thereby provide some advantages during work, which affects their efficiency and economy.

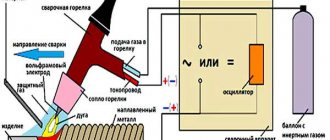

Burner for argon cooking

The main purpose of argon welding torches is to create a spark for welding. Such devices differ in power, cord length, type of cooling and control, methods of connection to the welding itself.

Criteria for a successful purchase of SG

Despite this, before purchasing a welding torch, it is recommended to determine the tasks for it, and then evaluate how feasible they are for a particular model. Only in this way can you make the right choice, which will subsequently affect productivity and profitability.

Welding torch

Quite often, buyers do not pay attention to the design of the product and consumables, and this is an important criterion when purchasing, since the quality of the weld, productivity and service life depend on them. In addition, in search of benefits, customers sometimes settle on little-known manufacturers who do not always provide a warranty card. Thus, failures and downtime cannot be ruled out. To avoid problems, it is more advisable to choose a model from a range of manufacturers with a good reputation, which guarantee flawless long-term operation and eliminate premature expenses for repairs. Moreover, the model does not have to be expensive. When assessing long-term investments in SG and its consumables, it is recommended to take into account the service life, costs of spare parts, the cost of downtime and maintenance, as well as the ease of replacing failed elements.

Torch for semi-automatic welding machine

The main difference between this burner and the manual version is the ability to cool it. Usually used in places that are rare and difficult to access.

The best tips for such torches are made from tungsten and copper. There are other options for insulating lugs: bronze, copper and graphite alloys.

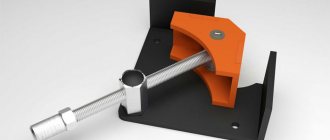

SG device and its parts

A welding torch for semi-automatic machines consists of a body with an insulating ring tightly adjacent to it, from which comes an electrode holder, a contact tip and a gas nozzle.

Consumables include the nozzle, diffuser and contact tip, which are responsible for the passage of the protective gas and the end point in the system where the wire exits and the arc is formed. Based on this, they require increased attention, as they are responsible for the quality of the weld and productivity. It is recommended to carry out regular checks and, if necessary, replace worn parts. Such inspections should be carried out several times a day. Particular attention should be paid to the inner hole at the contact tip, because it is responsible for good contact. In case of wear, mandatory replacement is required. It is equally important to clean the nozzle and diffuser from splashes, otherwise the normal supply of protective gas may be interrupted. The most complex component of the tool in question is the coil, which should be checked when changing the coil; to facilitate cleaning, it is better to use compressed air.

The operation scheme of the SG for a semi-automatic device is simple. The device supplies shielding gas and electrode wire to the combustion zone, where the worker, directing the tip to the required place and starting the welding process, manipulates it using a handle made of cast material with insulating properties.

Type of fuel

The materials used in burners are:

- Gas;

- Liquid fuel;

- Combined materials.

Intake of oxidizer

- With the use of air;

- With oxidizer supply.

Guide channels

The guide channel ensures smooth sliding of the wire, reduces the risk of tangling and bending of the wire.

Article: 071.320.550 Guide channel TEFLON 5.5m Yellow (1.2-1.6mm) OMS2030-05

Teflon guide channel is recommended for aluminum wire. Suitable for welding wire with diameter 1.2-1.6mm. Channel length 5.5 m. Compatible with MIG MP 36, MIG MP 400 and MIG MP 500 torches.

Price: RUR 1,807

Article: 071.320.450 TEFLON guide channel 4.5m Yellow (1.2-1.6mm) OMS2030-04

Teflon guide channel is recommended for aluminum wire. Suitable for welding wire with diameter 1.2-1.6mm. Channel length 4.5 m. Compatible with MIG MP 36, MIG MP 400 and MIG MP 500 torches.

Price: RUB 1,368

Article: 071.320.350 TEFLON guide channel 3.5m Yellow (1.2-1.6mm) OMS2030-03

Teflon guide channel is recommended for aluminum wire. Suitable for welding wire with diameter 1.2-1.6mm. Channel length 3.5 m. Compatible with MIG MP 36, MIG MP 400 and MIG MP 500 torches.

Price: RUR 1,181

Article: 071.220.550 TEFLON guide channel 5.5m Red (1.0-1.2mm) OMS2020-05

Teflon guide channel is recommended for aluminum wire. Suitable for welding wire with diameter 1.0-1.2mm. Channel length 5.5 m. Compatible with torches MIG MP 24, MASTER MIG MP 24 and MIG MP 25, MASTER MIG MP 25, MIG MP 26.

Price: RUB 1,793

Article: 071.220.450 TEFLON guide channel 4.5m Red (1.0-1.2mm) OMS2020-04

Teflon guide channel is recommended for aluminum wire. Suitable for welding wire with diameter 1.0-1.2mm. Channel length 4.5 m. Compatible with torches MIG MP 24, MASTER MIG MP 24 and MIG MP 25, MASTER MIG MP 25, MIG MP 26.

Price: RUB 1,428

Article: 171.220.350 TEFLON guide channel 3.5m Red (1.0-1.2mm) OMS2020-03

Teflon guide channel is recommended for aluminum wire. Suitable for welding wire with diameter 1.0-1.2mm. Channel length 3.5 m. Compatible with torches MIG MP 24, MASTER MIG MP 24 and MIG MP 25, MASTER MIG MP 25, MIG MP 26.

Price: RUR 1,182

Article: 071.120.550 Guide channel TEFLON 5.5m Blue (0.6-0.9mm) OMS2010-05

Teflon guide channel is recommended for aluminum wire. Suitable for welding wire with diameter 0.6-0.9mm. Channel length 5.5 m. Compatible with MIG MP 15 and MASTER MIG MP 15 torches.

Price: RUB 1,790

Article: 071.120.450 TEFLON guide channel 4.5m Blue (0.6-0.9mm) OMS2010-04

Teflon guide channel is recommended for aluminum wire. Suitable for welding wire with diameter 0.6-0.9mm. Channel length 4.5 m. Compatible with MIG MP 15 and MASTER MIG MP 15 torches.

Price: RUB 1,496

Article: 171.120.350 Guide channel TEFLON 3.5m Blue (0.6-0.9mm) OMS2010-03

Teflon guide channel is recommended for aluminum wire. Suitable for welding wire with diameter 0.6-0.9mm. Channel length 3.5 m. Compatible with MIG MP 15 and MASTER MIG MP 15 torches.

Price: RUR 1,176

Article: 171.300.550 Guide channel STEEL 5.5m Yellow (1.2-1.6mm) OMS1030-05

The guide channel is recommended for use with steel and stainless steel wires. Suitable for welding wire with diameter 1.2-1.6mm. Channel length 5.5 m. Compatible with MIG MP 36, MIG MP 400 and MIG MP 500 torches.

Price: 440 RUR

Article: 171.300.450 Guide channel STEEL 4.5m Yellow (1.2-1.6mm) OMS1030-04

The guide channel is recommended for use with steel and stainless steel wires. Suitable for welding wire with diameter 1.2-1.6mm. Channel length 4.5 m. Compatible with MIG MP 36, MIG MP 400 and MIG MP 500 torches.

Price: 357 RUR

Article: 171.300.350 Guide channel STEEL 3.5m Yellow (1.2-1.6mm) OMS1030-03

The guide channel is recommended for use with steel and stainless steel wires. Suitable for welding wire with diameter 1.2-1.6mm. Channel length 3.5 m. Compatible with MIG MP 36, MIG MP 400 and MIG MP 500 torches.

Price: 276 RUR

Article: 171.200.550 Guide channel STEEL 5.5m Red (1.0-1.2mm) OMS1020-05

The guide channel is recommended for use with steel and stainless steel wires. Suitable for welding wire with diameter 1.0-1.2mm. Channel length 5.5 m. Compatible with torches MIG MP 24, MASTER MIG MP 24 and MIG MP 25, MASTER MIG MP 25, MIG MP 26.

Price: 437 RUR

Article: 171.200.450 Guide channel STEEL 4.5m Red (1.0-1.2mm) OMS1020-04

The guide channel is recommended for use with steel and stainless steel wires. Suitable for welding wire with diameter 1.0-1.2mm. Channel length 4.5 m. Compatible with torches MIG MP 24, MASTER MIG MP 24 and MIG MP 25, MASTER MIG MP 25, MIG MP 26.

Price: 357 RUR

Article: 171.200.350 Guide channel STEEL 3.5m Red (1.0-1.2mm) OMS1020-03

The guide channel is recommended for use with steel and stainless steel wires. Suitable for welding wire with diameter 1.0-1.2mm. Channel length 3.5 m. Compatible with torches MIG MP 24, MASTER MIG MP 24 and MIG MP 25, MASTER MIG MP 25, MIG MP 26.

Price: 276 RUR

Article: 171.100.550 Guide channel STEEL 5.5m Blue (0.6-0.9mm) OMS1010-05

The guide channel is recommended for use with steel and stainless steel wires. Suitable for welding wire with diameter 0.6-0.9mm. Channel length 5.5 m. Compatible with MIG MP 15 and MASTER MIG MP 15 torches.

Price: 439 RUR

Article: 071.100.450 Guide channel STEEL 4.5m Blue (0.6-0.9mm) OMS1010-04

The guide channel is recommended for use with steel and stainless steel wires. Suitable for welding wire with diameter 0.6-0.9mm. Channel length 4.5 m. Compatible with MIG MP 15 and MASTER MIG MP 15 torches.

Price: 357 RUR

Article: 071.100.350 Guide channel STEEL 3.5m Blue (0.6-0.9mm) OMS1010-03

The guide channel is recommended for use with steel and stainless steel wires. Suitable for welding wire with diameter 0.6-0.9mm. Channel length 3.5 m. Compatible with MIG MP 15 and MASTER MIG MP 15 torches.

Price: 278 RUR